Professional Documents

Culture Documents

Sistema de Inyeccion Mono-Jetronic

Uploaded by

Diego De La FuenteOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sistema de Inyeccion Mono-Jetronic

Uploaded by

Diego De La FuenteCopyright:

Available Formats

4D1

Chapter 4 Part D:

Fuel and exhaust systems Mono Jetronic fuel injection

The following information is a revision of, or supplementary to, that contained in Part B of this Chapter

Contents

Air cleaner element - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Air inlet duct and manifold - removal and refitting . . . . . . . . . . . . . . 3

Air inlet pre-heater - testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Fuel injector - testing, removal and refitting . . . . . . . . . . . . . . . . . . . 7

Fuel pump - testing, removal and refitting . . . . . . . . . . . . . . . . . . . . . 10

General information and precautions . . . . . . . . . . . . . . . . . . . . . . . .

Idle speed and mixture (CO content) - testing . . . . . . . . . . . . . . . . .

Idle switch control valve - testing . . . . . . . . . . . . . . . . . . . . . . . . . . .

Injector unit housing - removal and refitting . . . . . . . . . . . . . . . . . . .

Throttle damper - adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

5

6

8

9

Degrees of difficulty

Easy, suitable for

novice with little

experience

Fairly easy, suitable

for beginner with

some experience

Fairly difficult,

suitable for competent

DIY mechanic

Difficult, suitable for

experienced DIY

mechanic

Specifications

Injection system

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Idle speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CO content % . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Holding pressure (system off for 5 minutes) . . . . . . . . . . . . . . . . . . . . . .

Injector resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mono Jetronic, central injection system

1.8 litre (code RP) engine

0.8 to 1.2 bar

750 to 950 rpm (not adjustable)

0.2 to 1.2

0.5 bar

1.2 to 1.6 ohm

Torque wrench settings

Nm

10

5

6

13

25

10

Air inlet manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Injector holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Throttle valve positioner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inlet manifold-to-injector unit flange . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inlet manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inlet manifold pre-heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1081 VW Golf & Jetta

lbf ft

7

3.7

4.4

9

18

7

Very difficult,

suitable for expert DIY

or professional

4D

4D2 Fuel and exhaust systems - Mono Jetronic fuel injection

1 General information and

precautions

General information

The Mono-Jetronic central fuel injection

system is fitted to the 1.8 litre (code RP)

engine. It is a simplified method of fuel

injection (see illustrations).

Fuel is injected into the inlet manifold by a

single solenoid valve (fuel injector) mounted

centrally in the top of the injector unit housing.

The length of time for which the injector

remains open determines the quantity of fuel

reaching the cylinders for combustion. The

electrical signals which determine the fuel

injector opening duration are calculated by

the Electronic Control Unit (ECU) from

information supplied by its network of

sensors. Fuel pressure is regulated

mechanically.

The signals fed to the ECU include the

following:

a) The engine coolant temperature

b) The engine speed and crankshaft position

- from the distributor

c) The position of the throttle valve plate from the throttle position sensor

d) The oxygen content in the exhaust gases

- via a sensor (Lambda probe) in the

exhaust manifold

Using the information gathered from the

various sensors, the ECU sends out signals to

control the system actuators as required.

The ECU also has a diagnostic function

which can be used in conjunction with special

VW test equipment for fault diagnosis. With

the exception of basic checks to ensure that

all relevant wiring and hoses are in good

condition and securely connected, fault

diagnosis should be entrusted to a VW dealer.

Basic testing can be carried out on the

system components covered in the following

text. More detailed testing can be carried out

by using specialised equipment but this must

be entrusted to a VW dealer.

Precautions

Refer to Sections 1 and 2 in Part B of this

Chapter.

2 Air cleaner element - renewal

Refer to Chapter 1, Section 32

3 Air inlet duct and manifold removal and refitting

1 Undo the retaining clips and release the

duct from the manifold and air cleaner.

2 To remove the manifold from the top of the

injector unit housing, detach the hoses from

the temperature sensor unit on the manifold

whilst noting their fitted positions.

3 Undo the retaining bolt and lift the manifold,

together with its gasket, from the top face of

the injector unit.

4 Refit in the reverse order of removal.

4 Air inlet pre-heater - testing

1.0a Mono-Jetronic system component location

1 Electronic Control unit (ECU)

2 Connector (throttle valve positioner and

idle switch)

3 Throttle damper

4 Connector (injector and air intake

temperature sender)

5 Throttle valve positioner and idle switch

6 Intake air pre-heater temperature regulator

7 Injector and air temperature sender

8 Fuel pressure regulator

9 Inlet manifold pre-heater

10 Injection timing vacuum control valve

11 Injector

12 Throttle valve potentiometer

13 Water separator (throttle valve

potentiometer)

14 Self diagnosis fault warning lamp

15 Lambda probe connector

16 Activated charcoal filter solenoid valve

17 Activated charcoal filter solenoid valve

18 Injector series resistor

19 Thermoswitch for manifold pre-heater

20 Coolant temperature sender

21 Self diagnosis plug

1081 VW Golf & Jetta

1 With the engine cold, detach and remove

the upper section of the air cleaner followed

by the filter element.

2 Check the air flap valve in the base of the

lower section of the air cleaner for freedom of

movement. Ensure that when closed, it shuts

off the warm air passage.

3 Whilst running the engine at idle speed,

check that the flap closes off the cold air

passage.

4 To check that the temperature regulator is

operating correctly, disconnect the two hoses

from it (see illustration), connect them

together and then note if the warm air

passage remains closed off. If this is the case,

the vacuum unit is defective. Where the flap

valve closes off the cold air passage, the

temperature regulator is at fault and in need of

replacement.

5 The position of the flap valve when the

engine is running is dependent on the

temperature of the regulator. When the

temperature is below 35C, the temperature

regulator should be open and the cold air

Fuel and exhaust systems - Mono Jetronic fuel injection 4D3

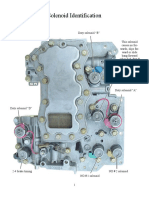

6.1 Injector, ECU and associated

components

1

2

3

4

1.0b Mono-Jetronic system inlet manifold and associated components

1

2

3

4

5

6

7

8

9

Warm air deflector

Nut

Flange

Bolt

Bracket

Lambda probe

Bolt

Inlet manifold

O-ring

10

11

12

13

14

15

16

17

Gasket

Cap

CO measuring pipe

Spacer

Coolant hose connection

Vacuum connection

O-ring

Thermoswitch (red) for

manifold pre-heater from

8/1988

passage closed off. At temperatures above

45C, the regulator should be closed and the

warm air passage sealed off.

4.4 Air intake components in air cleaner

housing

1

2

3

4

Warm air nozzle

Cold air nozzle

Temperature regulator

Vacuum unit

18 Coolant temperature

sender (blue)

19 Retainer spring

20 Thermoswitch (red) for

manifold pre-heater up

to 7/1988

21 Coolant sender unit

22 Inlet manifold pre-heater

23 Screw

24 Connector

5 Idle speed and mixture (CO

content) - testing

1 The prerequisites for this test are that the

ignition timing must be correct and the engine

must be at its normal operating temperature.

During the test, all electrical circuits including

the engine cooling fan and, where applicable,

the air conditioning, must be switched off.

2 The ignition must be switched off before the

test meter is attached to check engine speed.

An exhaust gas analyser must be used to

check the CO content from the exhaust.

3 The idle speed and mixture are not

adjustable on this system and if they are not

as specified, all that can be done is to inspect

the various fuel system and associated

vacuum electrical connections to ensure that

they are in good condition and securely

connected. If found to be in good condition, it

will be necessary to have the system checked

out by a VW dealer using specialised testing

equipment to identify and rectify the fault.

1081 VW Golf & Jetta

5

6

7

8

Series resistor

Vacuum hose

Fixing screw

Temperature

regulator

Poppet valve

O-ring

Injector unit

Connector

9 Electronic Control

Unit (ECU)

10 Spacer

11 Flap vent

12 Idle switch control

valve

13 Vacuum pipe

14 Fuel return pipe

15 Fuel feed pipe

6 Idle switch control valve testing

This device is attached to the throttle

position sensor (see illustration) and its

function is to control the ignition timing vacuum

advance. If defective, it can cause problems

with the idle speed and/or the overrun cut-off.

A simple test can be made by switching on

the ignition, then opening and closing the

throttle valve. Listen to hear if the control

valve clicks twice. If this is proved to be in

order, start the engine, allow it to idle and then

momentarily detach the wiring connector from

the control valve and reconnect it. The idle

speed should momentarily increase and then

drop back to normal. If not, the control valve

is faulty and should be renewed.

7 Fuel injector - testing,

removal and refitting

Testing

1 Run the engine up to its normal operating

temperature, then detach and remove the air

inlet duct from the top of the injector unit.

4D

4D4 Fuel and exhaust systems - Mono Jetronic fuel injection

8.3 Injector unit lower body and associated components

7.5 Injector unit and upper body components

1

2

3

4

5

6

7

Screw

Injector holder

Protector cap

O-ring

Injector

Stud

Injector upper body

8

9

10

11

12

13

Gasket

Screw

Pressure regulator

Fuel pipe adapter

Seal ring

Connector

2 With the engine running at idle speed, look

into the top of the injector unit and check the

fuel spray pattern which should be visible on

the throttle valve.

3 Increase the engine speed to 3000 rpm

then snap shut the throttle and check that the

fuel spray from the injector is momentarily

interrupted. Turn the ignition off and then

check that no more than two drops of fuel per

minute leak from the injector. This indicates

that the overrun cut-off is functioning in a

satisfactory manner.

Removal

4 Remove the inlet duct and manifold.

5 Undo the retaining screw and lift clear the

injector holder and O-ring seal from the top of

the injector. Note its orientation, then grip and

pull the injector from its location in the

housing. Remove the O-ring seals (see

illustration).

1

2

3

4

5

6

7

8

9

10

Throttle valve stop screw

O-ring

Plug

Screw

Retainer

Connector

Connector

Throttle valve potentiometer

Injector lower body

Water separator

Refitting

6 Refit in the reverse order of removal. The

O-ring seals must be renewed and lightly

lubricated prior to fitting.

8 Injector unit housing removal and refitting

11 Screw

12 Throttle valve positioner

13 Throttle damper adjuster

screw

14 Throttle damper

15 Bracket

16 Protector grommet (for idle

switch)

17 Idle switch

18 Screw

4 Disconnect the accelerator cable from the

throttle lever at the injector unit.

5 Undo the retaining screws and withdraw

the injector unit housing from the inlet

manifold. Remove the gasket and if damaged

or in doubtful condition, renew it when

refitting the injector unit.

Refitting

6 Refit in the reverse order of removal. Ensure

that the mating faces of the housing and fuel

lines are clean before reconnecting.

Removal

1 Remove the air inlet duct and manifold.

2 Detach the fuel feed and return lines from

their connections on the side of the injector

unit. Allow for fuel spillage as they are

detached and plug the hoses to prevent

further leakage and the ingress of dirt.

3 Disconnect the wiring plugs from their

connections on the injector unit (see

illustration).

1081 VW Golf & Jetta

9 Throttle damper - adjustment

When the throttle valve is in the closed

position, the throttle damper plunger should

be pressed into the damper a minimum

Fuel and exhaust systems - Mono Jetronic fuel injection 4D5

distance of 4.0 mm by the operating lever

(see illustration).

If adjustment is required, loosen off the

adjuster locknut then rotate the damper screw

to the point where the lever is just in contact

with the plunger. Now turn the damper four

and a half turns towards the lever, then

retighten the locknut.

10 Fuel pump - testing , removal

and refitting

From mid 1989, certain models fitted with

the Mono Jetronic system were fitted with a

single fuel pump in the fuel tank rather than

the previous arrangement of one in the tank

and a secondary pump outside the tank. The

pump can be tested in the same manner as

that for the in-tank dual pump referred to in

Part F of this Chapter, Section 12.

The fuel pump can be removed in a similar

manner to that described for the fuel gauge

sender unit in Part A of this Chapter, Section 8.

9.1 Throttle damper assembly

1 Throttle lever

2 Plunger

3 Damper

4 Locknut

4D

1081 VW Golf & Jetta

4D6

Notes

1081 VW Golf & Jetta

You might also like

- DIGIFANT FUEL INJECTIONDocument6 pagesDIGIFANT FUEL INJECTIONembokoNo ratings yet

- Passat b3 Vr6 ClimatronicDocument3 pagesPassat b3 Vr6 Climatronicvasseto50% (2)

- Manual Trans Overhaul - Type 02A Article TextDocument20 pagesManual Trans Overhaul - Type 02A Article TextHakim Ben Abdeljelil100% (1)

- Carburador Pierburg Solex 2e3Document7 pagesCarburador Pierburg Solex 2e3Benito SantosNo ratings yet

- Libro Motores VW Volkswagen Datos HaynesDocument127 pagesLibro Motores VW Volkswagen Datos HaynesCésar Santos100% (1)

- 1.8 L 20V Engine: ServiceDocument27 pages1.8 L 20V Engine: ServiceHenkNo ratings yet

- BOSCH Fuel Supply System MEV 17.4 Technical DescriptionDocument4 pagesBOSCH Fuel Supply System MEV 17.4 Technical DescriptionRui MendesNo ratings yet

- 106 Torque Settings PDFDocument5 pages106 Torque Settings PDFRicardo MatosNo ratings yet

- Diagrama de Caja de Fusibles Ford f150 Año 1992Document3 pagesDiagrama de Caja de Fusibles Ford f150 Año 1992Oscar Gutiérrez100% (2)

- Motronic 1.5 Engine Management CodesDocument9 pagesMotronic 1.5 Engine Management CodesMiloš KrnetićNo ratings yet

- VW Golf 3 Vento PDFDocument180 pagesVW Golf 3 Vento PDFDawronNo ratings yet

- Ford Escort Rear Disc Brake Conversion - 001Document8 pagesFord Escort Rear Disc Brake Conversion - 001910pcsupport100% (1)

- Manual Webbers 40IDF70Document2 pagesManual Webbers 40IDF70Luis Manuel Cadavieco AlarcónNo ratings yet

- 01N Getriebe Passat ServiceDocument8 pages01N Getriebe Passat ServiceHany Elsehrawy100% (1)

- Digifant Engine Management SystemDocument5 pagesDigifant Engine Management SystemSantz TechNo ratings yet

- Mirror Power Repair GuideDocument5 pagesMirror Power Repair GuidepitoNo ratings yet

- Secondary Air System ComponentsDocument24 pagesSecondary Air System ComponentsNPNo ratings yet

- Jetta SE 2.5L 2013Document119 pagesJetta SE 2.5L 2013Jenny Mora Leon100% (1)

- Fuel Pump Flow RatesDocument6 pagesFuel Pump Flow Rateshenry0% (1)

- Xantia II - Body Computer (CPH) DiagnosisDocument40 pagesXantia II - Body Computer (CPH) DiagnosisArturHeise100% (1)

- Body Electrical SystemDocument59 pagesBody Electrical SystemLeonardo Gómez Berniga100% (1)

- Familia 33 BQ 50Document76 pagesFamilia 33 BQ 50FlakoO0No ratings yet

- Drive Technology Connection DiagramsDocument30 pagesDrive Technology Connection DiagramsSimon Tolomeo100% (1)

- Install Cruise Control T4Document9 pagesInstall Cruise Control T4daveyp2001100% (1)

- Alfa Romeo 164 - V6 Turbo 1996Document41 pagesAlfa Romeo 164 - V6 Turbo 1996tecnoincNo ratings yet

- Installation Manual for MP48 Dual Fuel SystemDocument26 pagesInstallation Manual for MP48 Dual Fuel SystemEduRoi100% (1)

- Idle, Slow Running and Progression: 8 Theidle SpeedissetbyanadjusttDocument13 pagesIdle, Slow Running and Progression: 8 Theidle Speedissetbyanadjustt14carlos14100% (1)

- Peugeot 205, 309, 405 - Engine Xu9Jaz, Xu9j4K, Xu9j4Lz (1988Document2 pagesPeugeot 205, 309, 405 - Engine Xu9Jaz, Xu9j4K, Xu9j4Lz (1988Alejandro Antonio Arriagada LabléeNo ratings yet

- WAPU Overhaul BZBDocument8 pagesWAPU Overhaul BZBNedim ErkocevicNo ratings yet

- Z18XE SCHDocument3 pagesZ18XE SCHJan WolnyNo ratings yet

- Weber Carburator 44 IDF 71 PartsDocument2 pagesWeber Carburator 44 IDF 71 PartsRanieri AlmeidaNo ratings yet

- Seat Leon (Data Lines) 2005-2011Document4 pagesSeat Leon (Data Lines) 2005-2011Chino PlagaNo ratings yet

- Vw-Wi RL V.en-GB.k00589623.wi 40508771.xml XSL 3 PDFDocument2 pagesVw-Wi RL V.en-GB.k00589623.wi 40508771.xml XSL 3 PDFgilbertogato100% (1)

- 2007 Toyota Prius 1.5L MFI HEV DOHC 4cyl - Repair Guides - Components & Systems - Idle Air Control ValveDocument11 pages2007 Toyota Prius 1.5L MFI HEV DOHC 4cyl - Repair Guides - Components & Systems - Idle Air Control ValvePrivate LaneNo ratings yet

- AC Auto Repair DocumentDocument2 pagesAC Auto Repair DocumentWayne WattsNo ratings yet

- 08 Holley Catalog Pages - 90Document1 page08 Holley Catalog Pages - 90João Lucas ZaionsNo ratings yet

- Sprinter Turbo Vacuum Valve Circuito Valvula Control Turbo SprinterDocument1 pageSprinter Turbo Vacuum Valve Circuito Valvula Control Turbo SprinterFacu BertoldoNo ratings yet

- Engine Temperature Control Actuator - N493-, CHECKING: General DescriptionDocument3 pagesEngine Temperature Control Actuator - N493-, CHECKING: General Descriptionbyungchul kimNo ratings yet

- Fiat SST 2Document4 pagesFiat SST 2Sajin Raj100% (1)

- RelaysDocument3 pagesRelaysSanja Pušara100% (1)

- Weber ManualDocument18 pagesWeber Manualjme.91No ratings yet

- VW Golf 5 - Electro-Mechanical Steering Gear, Servicing (Generation II)Document49 pagesVW Golf 5 - Electro-Mechanical Steering Gear, Servicing (Generation II)NPNo ratings yet

- FT450 FT550 Ft550lite FT600Document158 pagesFT450 FT550 Ft550lite FT600juan c GimenoNo ratings yet

- Ducato Databook SpecificationsDocument1 pageDucato Databook Specificationsearl34No ratings yet

- Golf MK 3Document79 pagesGolf MK 3banemojsin100% (1)

- Current Flow Diagram Seats Heating VW Golf 5Document5 pagesCurrent Flow Diagram Seats Heating VW Golf 5Marius NeaguNo ratings yet

- Daewoo Matiz 2000-2013 Clutch PDFDocument14 pagesDaewoo Matiz 2000-2013 Clutch PDFsheoNo ratings yet

- Lambda Sensor LSU 49 Datasheet 51 en 2779147659pdf PDFDocument4 pagesLambda Sensor LSU 49 Datasheet 51 en 2779147659pdf PDFRogério MorenoNo ratings yet

- Volkswagen Fox 2003-2010 Motor BNM Manual Reparacion EspañolDocument128 pagesVolkswagen Fox 2003-2010 Motor BNM Manual Reparacion EspañolAndres Jauregui Garcia100% (2)

- Audi TT MKI 1.8T & VW Mkiv 1.8T: Timing Belt InstallationDocument20 pagesAudi TT MKI 1.8T & VW Mkiv 1.8T: Timing Belt InstallationBoth JánosNo ratings yet

- ALH 1.9D 121 PinsDocument5 pagesALH 1.9D 121 PinsEdward MainaNo ratings yet

- Digifant MP 4.0Document30 pagesDigifant MP 4.0victorvicvicNo ratings yet

- 4 Ataxle PDFDocument22 pages4 Ataxle PDFAnonymous XTkln6H100% (1)

- l7x EngineDocument110 pagesl7x Engine69 DeLiR100% (1)

- Electric System For Opel AmperaDocument24 pagesElectric System For Opel AmperaLuca TrottaNo ratings yet

- VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004From EverandVW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004Rating: 3 out of 5 stars3/5 (1)

- Hybrid Electric Vehicles: Principles and Applications with Practical PerspectivesFrom EverandHybrid Electric Vehicles: Principles and Applications with Practical PerspectivesNo ratings yet

- Digijet Fuel Injection Testing and Adjustment GuideDocument6 pagesDigijet Fuel Injection Testing and Adjustment GuideValentina Mains D'orNo ratings yet

- Chapter 4 Part C:: Fuel and Exhaust Systems - K-Jetronic Fuel Injection - 16 Valve EnginesDocument6 pagesChapter 4 Part C:: Fuel and Exhaust Systems - K-Jetronic Fuel Injection - 16 Valve EnginesmohhizbarNo ratings yet

- Auxiliary Organs PDFDocument108 pagesAuxiliary Organs PDFAny SantacroceNo ratings yet

- Tomb - Raider InfoDocument1 pageTomb - Raider InfoDiego De La FuenteNo ratings yet

- 50MackHolley PDFDocument14 pages50MackHolley PDFDiego De La FuenteNo ratings yet

- Acryl PDFDocument1 pageAcryl PDFDiego De La FuenteNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- LISTA DE PRECIOS EN PESOS ARGENTINOS DE MAQUETAS ACADEMY ABRIL 2009Document110 pagesLISTA DE PRECIOS EN PESOS ARGENTINOS DE MAQUETAS ACADEMY ABRIL 2009Diego De La FuenteNo ratings yet

- ManulDocument32 pagesManulDiego De La FuenteNo ratings yet

- Leaflet SolidoDocument14 pagesLeaflet SolidoDiego De La Fuente100% (1)

- Ttype G22Document6 pagesTtype G22Diego De La FuenteNo ratings yet

- Jaguar XJ Daimler CatalogueDocument105 pagesJaguar XJ Daimler CatalogueGonzalo Rodríguez JoverNo ratings yet

- ZBrush Documentation Guide PDFDocument693 pagesZBrush Documentation Guide PDFDiego De La Fuente100% (1)

- Effective November 2007: 5% Off Online OrdersDocument192 pagesEffective November 2007: 5% Off Online OrdersDiego De La FuenteNo ratings yet

- Honda Civic Service Manual 96-98Document1,416 pagesHonda Civic Service Manual 96-98mosesass83% (18)

- Nissan Kicks PDFDocument1 pageNissan Kicks PDFDiego De La FuenteNo ratings yet

- Alfa Romeo 156 Manual de TallerDocument32 pagesAlfa Romeo 156 Manual de TallerMiguel Francisco Gomez Silva0% (1)

- Ttype G22Document6 pagesTtype G22Diego De La FuenteNo ratings yet

- 34 46 PDFDocument144 pages34 46 PDFDiego De La FuenteNo ratings yet

- Link-Volkswagen Gol PDFDocument11 pagesLink-Volkswagen Gol PDFDiego De La FuenteNo ratings yet

- Nuevo Documento de TextoDocument1 pageNuevo Documento de TextoDiego De La FuenteNo ratings yet

- Link Volkswagen GolDocument11 pagesLink Volkswagen GolDiego De La Fuente0% (1)

- Link-Volkswagen Gol PDFDocument11 pagesLink-Volkswagen Gol PDFDiego De La FuenteNo ratings yet

- Digijet Fuel Injection Testing and Adjustment GuideDocument6 pagesDigijet Fuel Injection Testing and Adjustment GuideValentina Mains D'orNo ratings yet

- Nuevo Documento de TextoDocument1 pageNuevo Documento de TextoDiego De La FuenteNo ratings yet

- Casting Numbers ChevyDocument29 pagesCasting Numbers ChevyDiego De La Fuente100% (2)

- Fiat Marea 97-98 Alarma GEMINI Pin Out y CablesDocument2 pagesFiat Marea 97-98 Alarma GEMINI Pin Out y Cableskelo22No ratings yet

- Nuevo Documento de TextoDocument1 pageNuevo Documento de TextoDiego De La FuenteNo ratings yet

- VW Passat, Polo, Vento - Engine RP, Aam, Abs, Adz, Aau, AavDocument2 pagesVW Passat, Polo, Vento - Engine RP, Aam, Abs, Adz, Aau, AavDiego De La FuenteNo ratings yet

- s3 GearboxDocument2 pagess3 GearboxDiego De La FuenteNo ratings yet

- Aim Methodology Activities and DocumentsDocument7 pagesAim Methodology Activities and DocumentsKiran NambariNo ratings yet

- Student Marks AnalysisDocument24 pagesStudent Marks AnalysisjayNo ratings yet

- Dot Net 2008 Syllabus IntroductionDocument3 pagesDot Net 2008 Syllabus Introductionsanga_sravanthiNo ratings yet

- MOS Patching Best PracticesDocument74 pagesMOS Patching Best PracticesmghomriNo ratings yet

- Black Box Testing m10L24Document6 pagesBlack Box Testing m10L24evilanubhavNo ratings yet

- W B S (WBS) : ORK Reakdown TructureDocument9 pagesW B S (WBS) : ORK Reakdown TructureSantiago Caro CifuetesNo ratings yet

- 12 Spring Ioc Basics OverviewDocument11 pages12 Spring Ioc Basics OverviewRohit SolankiNo ratings yet

- Waterfall vs Agile - Which Project Methodology is Best? (38Document14 pagesWaterfall vs Agile - Which Project Methodology is Best? (38Ana CasuNo ratings yet

- Control ProjectDocument12 pagesControl Projectالمؤسس عثمان بن ارطغرلNo ratings yet

- Software Testing - Session 6 Recap and Exploratory Testing TechniquesDocument24 pagesSoftware Testing - Session 6 Recap and Exploratory Testing TechniquesAndrei UrsacNo ratings yet

- Engine Control FundamentalsDocument29 pagesEngine Control FundamentalsVikrant SharmaNo ratings yet

- PLC Types and Programming MethodsDocument2 pagesPLC Types and Programming MethodsLoveRahul100% (1)

- Software Test Plan For A Mobile ApplicationDocument7 pagesSoftware Test Plan For A Mobile ApplicationKrishna Duvvuri67% (3)

- Piston Engine Troubleshooting IndexDocument11 pagesPiston Engine Troubleshooting IndexjpontiNo ratings yet

- Integrating Security SolutionsDocument3 pagesIntegrating Security SolutionskalkumarmNo ratings yet

- SE Assignment 2015Document6 pagesSE Assignment 2015Faizaan AhmedNo ratings yet

- Ford Motor Company Group Diagnostic Trouble CodesDocument5 pagesFord Motor Company Group Diagnostic Trouble Codeslester100% (40)

- Standard engine scope sheetDocument1 pageStandard engine scope sheetAseem Vivek MasihNo ratings yet

- Ovation Intelligence Framework en 5560782Document3 pagesOvation Intelligence Framework en 5560782NeverNo ratings yet

- CS504 Quiz-3 by Vu Topper RMDocument32 pagesCS504 Quiz-3 by Vu Topper RMLALA100% (1)

- Fault Code 1718 Engine Misfire For Multiple Cylinders - Condition ExistsDocument6 pagesFault Code 1718 Engine Misfire For Multiple Cylinders - Condition ExistsAhmedmahNo ratings yet

- Student Project Synopses CollectionDocument3 pagesStudent Project Synopses CollectionAshwani Kumar SharmaNo ratings yet

- Viewpoints For Requirements Elicitation: A Practical ApproachDocument8 pagesViewpoints For Requirements Elicitation: A Practical ApproachPhạm Phú TàiNo ratings yet

- Biometric Authentication: A Case Study in SecurityDocument8 pagesBiometric Authentication: A Case Study in SecurityDami YusuphNo ratings yet

- AUTOSAR SWS EthernetStateManagerDocument56 pagesAUTOSAR SWS EthernetStateManagerStefan RuscanuNo ratings yet

- Plcopen: Iec 61131-3: A Standard Programming ResourceDocument4 pagesPlcopen: Iec 61131-3: A Standard Programming ResourceChaitanya KumarNo ratings yet

- Admin Guide SAP Advanced Track TraceDocument64 pagesAdmin Guide SAP Advanced Track TraceYagna NarayanaNo ratings yet

- Unit-4 ASEDocument13 pagesUnit-4 ASEdeepikaNo ratings yet

- PLC Lab #4 Event SequencingDocument15 pagesPLC Lab #4 Event SequencingIan SpacekNo ratings yet

- Lab 3Document18 pagesLab 3Phú ĐoànNo ratings yet

![VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004](https://imgv2-2-f.scribdassets.com/img/word_document/282876773/149x198/5fb74bd6e1/1675169638?v=1)