Professional Documents

Culture Documents

Automation of The Net Working Duration Technique For Analysis of Construction Delays and Work Changes

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Automation of The Net Working Duration Technique For Analysis of Construction Delays and Work Changes

Copyright:

Available Formats

IPASJ International Journal of Computer Science (IIJCS)

Web Site: http://www.ipasj.org/IIJCS/IIJCS.htm

Email: editoriijcs@ipasj.org

ISSN 2321-5992

A Publisher for Research Motivation ........

Volume 4, Issue 5, May 2016

Automation of the net working duration technique

for analysis of construction delays and work

changes

Mostafa G. Elwishahi1, Adel I. Eldosouky2 , Haytham M. Sanad3

1

Demonstrator, Faculty of Engineering Tanta University, Tanta, Egypt

Emeritus Professor of Construction Project Management, Faculty of Engineering Tanta University, Tanta, Egypt

3

Lecturer of Construction Project Management, Faculty of Engineering Tanta University, Tanta, Egypt

ABSTRACT

Delays and work changes is the most common problem in the construction industry. Many methods have been developed for

analysis of delays. In this research the net working duration based model is illustrated and automated with MS project using visual

basic for applications (VBA) programming language. The automated model can deal with real life project networks by reducing the

network into equivalent one with only paths affecting the analysis leading to less effort and cost for delay analysis. Viewpoints of

float ownership and concurrency of delays are major factors affecting the delay analysis results. A percentage method which deals

with multiple critical paths is used within the automated model instead of accounting for concurrency of delays. Also a suitable and

flexible concept of total float ownership is used with the automated model. Delay analysis using the automated model requires MS

project updated schedule, the baseline which represents project as-planned schedule, and liability of delays lying on the equivalent

network only. A hypothetical example is used to illustrate the model and a practical case study is used to compare the model results

with other methods. The automated model enables project participants to identify their responsibilities towards project delays and

work changes precisely.

Keywords:Construction management, Delay analysis, Concurrent delays, Automation.

1. INTRODUCTION

Delays happen in most construction projects, whether simple or complex. In construction, delay could be defined as the time

overrun either beyond the contract date or beyond the date that the parties agreed upon for delivery of a project [1].

Construction delays can be caused by owner (compensable delays) or contractor (non-excusable delays) or third party

(excusable), work changes can be made by the owner (increase / decrease of work) or contractor (acceleration / loss of

productivity). There are various methods for delay analysis. However, different analysis techniques provide different results

for the same circumstances depending on the time and resources available for the analysis and the availability of project

control documentation [2]. Also, delay analysis results can vary because of different viewpoints of total float ownership and

concurrency of delays.

The net working duration is one of the accepted delay analysis techniques. It is characterized by fair results, simple and

non-expensive analysis. This method was introduced by Antill and Woodhead [3]. In this method, the critical paths of the

as-built network is plotted and examined in turn to determine the net working duration for each path. The net working

duration of any path in the as-built network is calculated by deducting the delays and work changes lying on the path from

its total duration. The net working duration is the actual time in which all the activities along that path could have been

completed if there had been no delays affecting the path.

The primary critical path is an as-built critical path with the longest net working duration. The work could not have been

completed in less time than this, even if the delays had not occurred. Other parallel apparent critical paths with less net

working duration don't control the contract duration. The responsibility of each party for the contract delayed completion is

determined based on the inspection of the delays on primary critical path. Determination of the final primary critical path of

a project requires the completion of the project. Nevertheless, it is possible to perform the analysis at any stage through the

progress of the project by the examination of critical paths of the updated network to determine the net working duration of

each path in order to determine the primary critical path controlling the delay of the project. In this case, delay analysis

should be adjusted at the end of the project.

Volume 4 Issue 5 May 2016

Page 1

IPASJ International Journal of Computer Science (IIJCS)

A Publisher for Research Motivation ........

Volume 4, Issue 5, May 2016

Web Site: http://www.ipasj.org/IIJCS/IIJCS.htm

Email: editoriijcs@ipasj.org

ISSN 2321-5992

Jrad [4] introduced a net working duration based model for analyzing delays and work changes. This model improved the

original method and used the percentage method in case of multiple primary critical path instead of accounting for

concurrency of delays. It also has the ability to deal with a real life project network with thousands of paths, by eliminating

ineffective paths that would not be needed for the analysis, thus reducing the project network to equivalent one in order to

minimize the time and effort needed for the analysis. For many years, researchers developed different techniques for delay

analysis, but none of them reduced the project network into equivalent one.

In this paper, automation of the net working duration model with commercial scheduling software is considered to enable

project parties to identify their responsibilities towards project delays in an easy to use and effective way. Microsoft office

project is the most appropriate software to be used in the automation of the model using the visual basic for applications

(VBA) programming language. Minimization of users effort for data entry is considered through model automation.

2. FLOAT OWNERSHIP

Total float is defined as the amount of time by which the early finish date of any activity may be delayed without delaying

completion of the project. The delay analysis results can vary, depending on the different positions concerning float

ownership [5]. Available total float ownership viewpoints are reviewed in Al-Gahtani [6] and Tsai, Wang, and Chang [7].

A recent study investigating the opinions of Taiwanese and Chinese construction participants on float ownership through a

questionnaire showed that clearly defining float ownership in the contract is a preference of the majority of participants [8].

In the present research, it is assumed that total float of the as-planned schedule belongs to the contractor and can be used to

cover non-excusable delays. If the contractor did not consume the whole value of total float, the remaining total float can be

used to cover compensable delays. If any total float is left after covering non-excusable and compensable delays, this part of

total float can be used to cover excusable delays. This assumption of total float ownership of the as-planned network gives

suitable flexibility to the owner to order changes, keeps right of contractor to use the float and reduce the likelihood of the

contractor submitting unrealistic construction plans.

3. CONCURRENT DELAYS

Concurrency is one of the major challenges and is a controversial issue confronted by delay analysts. The main reason for

this situation is the different definitions of concurrency and the different methods of calculating entitlements for the

extension of time (EOT) and for calculating damages [9]. There are many definitions for concurrent delay. Five definitions

of concurrent delays are given by AACE [10]. Concurrent delays are customarily described as two or more delays that occur

at the same time, either of which would cause a delay but if either of them had not occurred, the project schedule would

have been delayed by the other [11]. There is different points of view concerning the timing condition of delays to be

considered concurrent. Some definitions considered only delays within the exact period of time to be concurrent. Other

definitions considered delays to be concurrent if they just fall on parallel critical paths. Others classified delays to have

concurrent effect if their effects in whole or in part are at the same time.

There are different points of view of apportionment of concurrent delays. A table showing different researchers viewpoints

of apportionment can be found in Nguyen [11]. Generally, when a compensable delay is concurrent with an inexcusable

delay, one of two scenarios is used: (1) Easy rule [12] or contributory negligence [13]; time extension is given. (2) Fair

rule [12] or comparative negligence [13]; apportionment of days and/or dollars. However, a recent trend advocates an

equitable apportionment when compensable and inexcusable concurrent delays occur. A party causing less impact of

concurrent delays should be permitted to recover damages from the other [11].

Accurate dealing and recognition of concurrent delays requires accurate recognition of delays and correct locating for them

on activities which is then required to be done on a daily basis. According to Arditi and Robinson [14], there is a difficulty

of how the day delay is located in activity duration especially in case of lost productivity delay. The net working duration

based model which is automated in this paper solves this issue by dealing with multiple critical paths using percentage

method instead of accounting for concurrency of delays.

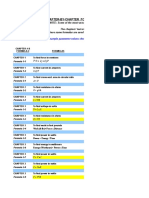

4. MODIFIED NET WORKING DURATION METHOD

According to Jrad [4] the net working duration technique gives incorrect results in case the net working duration of the

primary critical path is equal to or less than that of non-critical paths. This problem can be shown in the hypothetical

example shown in Fig 1, where parts a and b represent the as-planned and as-built schedules. According to the original net

working duration method, project delay analysis is based on primary critical path which is the path having longest net

working duration between as-built critical paths.

Volume 4 Issue 5 May 2016

Page 2

IPASJ International Journal of Computer Science (IIJCS)

Web Site: http://www.ipasj.org/IIJCS/IIJCS.htm

Email: editoriijcs@ipasj.org

ISSN 2321-5992

A Publisher for Research Motivation ........

Volume 4, Issue 5, May 2016

1

9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26

(C)

(B)

(L)

(D)

(E)

(A)

(M)

(F)

(H)

(G)

(U)

1

(K)

(I)

(S)

(P)

7

O

(V)

a- as-planned schedule

9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26

(C)

(B)

(L)

(D)

(E)

(A)

C

(F)

(P)

N

(K)

(I)

OW OW

(G)

(U)

(M)

(H)

O

(S)

O O O O O

(V)

b- as-built schedule

Paths with longest net working duration: ABCDK and AFGHK

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26

1st slack period

Slack path

2nd slack

O

(C)

period

(B)

L

(D)

N N

Redundant

E

O O O

M

Firm path

(A)

(K)

3rd slack period

C C C C C

(I)

Slack path

(F)

N N

OW OW

(H)

(G)

(U)

(P)

O

Redundant

C

O

O O O

Firm path

(S)

(V)

c- Slack periods, firm and slack paths of as-built schedule

O

(B)

9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26

Slack path

1st slack period

2nd slack

C C

(C)

period

(D)

N N O

(A)

Firm path

C C C

C

(F)

Legend :

non-critical

3rd slack period

Slack path

(H)

O O

(I)

OW OW

(G)

(P)

O

C

O O O

Firm path

(K)

(S)

critical O = compensable delay

C = Non-excusable delay N = Excusable delay

O W = Owner work change CW = Contractor work change

d- Representation of slack periods as delays on the equivalent network of example project

Figure 1Example project

Path A-F-P-S-K is the only as-built critical path of the project, thus it is the project primary critical path. It is clear that the

net working duration of primary critical path A-F-P-S-K (17 days) is less than the non-critical paths A-B-C-D-K (20 days)

and A-F-G-H-K (20 days). The analysis should be based on paths with the longest net working duration (both paths A-B-CD-K and A-F-G-H-K).

Paths A-B-C-D-K and A-F-G-H-K which shares the project delay responsibility have three slack periods; two days between

activities C and D, one day between activities D and K, and two days between activities H and K. Responsible party for each

slack period should be determined in order to determine project delay responsibility using these paths. The reason of each

slack period is a delay of a parallel path. The reason of the first slack period between activities C and D is the delay of

parallel firm path A-B-E-I which is caused by non-excusable delays. So, the first slack period is considered non-excusable

delay. By the same way, the reason of the second and third slack periods (between activities D and K and between activities

Volume 4 Issue 5 May 2016

Page 3

IPASJ International Journal of Computer Science (IIJCS)

A Publisher for Research Motivation ........

Volume 4, Issue 5, May 2016

Web Site: http://www.ipasj.org/IIJCS/IIJCS.htm

Email: editoriijcs@ipasj.org

ISSN 2321-5992

H and K) is the delay of parallel firm path A-F-P-S as shown in Fig 1.c.

The above discussion considered two types of paths for the analysis which are: (i) Slack paths; as-planned critical paths

turned to be non-critical in the as-built network where slack periods happen such as paths A-B-C-D-K and A-F-G-H-K in

Fig 1.c. (ii) Firm paths; paths of as-built schedule which are needed to determine the responsibility for slack periods. These

paths dont have any slack period and including as-built critical paths such as paths A-B-E-I and A-F-P-S in Fig 1.c.

The slack period is a time interval in the as-built schedule created between two sequential as-planned critical activities. The

value of each slack period is presented by a delay caused by delays on the parallel firm path.

Analysis of the modified net working duration method determines the responsibility of each party for the contract delayed

completion based on delays on the primary path(s) which are the path(s) with the longest net working duration of both firm

and slack paths. The method consist of three steps: (1) Equivalent network formation. (2) Slack period responsibility

calculations. (3) Percentage method calculations (dealing with multiple primary paths).

4.1 Equivalent Network for Modified Net Working Duration Analysis

Project network may contain thousands of paths, most of these paths are redundant and do not affect the analysis. Thus, Jrad

[4] proposed a technique to reduce the project network to an equivalent one based on the linear graph theory. The new

equivalent network contains only effective paths for the analysis, which are:

(1) As-planned critical paths. These paths are the primary paths of the project. Slack periods may (or may not) be found

between activities of these paths.

(2) Apparent critical paths whose durations are equal to as-built project duration. In this paper, the definition of these paths

is modified to be as-built firm paths: paths without slack periods which are needed to determine the responsibility for slack

periods. These paths include as-built critical paths.

Other paths are redundant and can be eliminated in order to obtain an equivalent network, which contains the effective

paths only. For the example project shown in Fig 1, as-planned critical paths are A-B-C-D-K and A-F-G-H-K, firm paths

are A-B-E-I and A-F-P-S. Activities L, M, U, and V dont belong to these paths, then they are eliminated, Fig 1.d shows the

as-built schedule after elimination of these activities.

The importance of using the equivalent network in the manual solution is to simplify the analysis. The main advantage for

the automated solution is reduction of users effort for data entry to the program. Data which is needed to form the

equivalent network is the as-planned schedule (MS project baseline) and the actual start and finish dates for each activity

(MS project updated schedule) without definition of the responsible parties for any activity that has increase of as-built

duration than as-planned duration. The responsibilities of delays are assigned to activities of the equivalent network only

after its formation. Responsible parties for delays on activities L, M, U, and V are not needed to be defined for the example

project in Fig 1.

4.2 Slack Period Responsibility Calculations

The paths of the equivalent network are firm and slack paths. Slack paths contain slack periods. It is required to determine

the responsibility of slack periods and represent them as delays. A slack period happens when the as-planned critical path

(slack path) is delayed by another firm path on the as-built schedule. Jrad [4] introduced the principles for calculating the

responsibilities of slack periods. These principles are based on assigning the responsibility for the slack period to the party

who delayed the firm path beyond delay of the parallel slack path. According to Jrad, the principles considered for

analyzing the slack period are:

1- The difference between values of each type of delays on a slack and parallel firm paths are:

R1 =O1 O2

(1)

R2 =C1 C2 (2)

R3 =N1 N2

(3)

Where, R1, R2, and R3 are the differences between compensable, non-excusable, excusable delays on firm and slack paths

respectively. C1, O1, and N1 are summation of non-excusable, compensable, and excusable delays on a firm path

respectively. Also C2, O2, and N2 are summation of non-excusable, compensable, and excusable delays on a slack path

respectively. It should be noted that delays of firm path C1, O1, and N1 are the values after the subtraction of the as-planned

total float (considering the assumptions of total float ownership) and they are the values of the firm path which has the least

as-planned total float among all firm paths (in case of many firm paths linked to a considered activity).

2- Responsibility of delays on a slack path is determined based on maximum value of R1, R2, and R3.

Note that work changes caused by the owner or contractor will be added to summation of compensable or non-excusable

delays on both firm and slack paths; (O1, C1, O2, and C2).

Applying these principles to the example project in Fig 1; () The first slack period; R1= 0 1 = -1, R2= (5 2) 0 = 3,

R3= 0 0 = 0; R2 is the highest value. Then, the first day of the first slack period is represented as non-excusable delay.

Delay differences for the second day; R1= 0 1 = -1, R2= (5 2) 1 = 2, R3= 0 0 = 0; R2 is the highest value. Then, the

Volume 4 Issue 5 May 2016

Page 4

IPASJ International Journal of Computer Science (IIJCS)

A Publisher for Research Motivation ........

Volume 4, Issue 5, May 2016

Web Site: http://www.ipasj.org/IIJCS/IIJCS.htm

Email: editoriijcs@ipasj.org

ISSN 2321-5992

second day of the first slack period is represented as non-excusable delay. () The second slack period; R1= (5 1) 2 = 2,

R2= (1 1) 0 = 0, R3= 2 2 = 0; R1 is the highest value. Then, the second slack period is represented as compensable

delay. It is noted that as-planned total float of firm path is 2 days which are used to reduce C1 to be zero instead of one day,

then the remaining one day of total float is used to reduce O1 to be 4 days instead of 5 days. In the same way the third slack

period is represented as compensable delays. Representation of slack periods as delays for the example project is shown in

Fig 1.d.

4.3 Percentage Method Calculations In Case Of Multiple Primary Paths

Jrad [4] suggested a new method to analyze delays and work changes on multiple primary critical paths instead of the

known concepts of concurrent delays. In this method, the percentage of summation of any type of delays lying on all

primary critical paths and summation of all types of delays lying on all primary critical paths is calculated. This percentage

represents the responsibility of the considered type of delays towards total project delay. The percentage for each type of

delays will be calculated using Eq 4. The responsibility of each party towards total project delay is determined using Eq 5.

D% =

(4)

D = D% * TD

(5)

Where, D% is the percentage of the considered type of delay towards total project delay. D is number of days with

responsibility assigned to the party with percentage D% of project delay and TD is total project delay.

Applying the percentage method to the example project; Owner percentage = 6/12, owner delay

= 6 * 6/12 = 3 days. Contractor percentage = 2/12, contractor delay = 6 * 2/12 = 1 days. Third party percentage = 4/12,

third party delay = 6 * 4/12 = 2 days.

It is obvious that the percentage method solved the issue of locating the days of delays along activity duration especially in

case of lost productivity by dealing with network paths instead of determining location of delay on the activity and then

investigating whether the delay is concurrent or not. Also the method considered each delay on all critical paths and gave

the party causing more delays on critical paths higher responsibility towards project delay instead of giving time extension

only or giving equal liability for parties causing a concurrent delay. The method is simple and easy to be used and can be

considered as a development of the fair rule because the method uses the apportionment of delays on critical paths.

5. AUTOMATION OF THE MODIFIED NET WORKING DURATION METHOD

The steps of the modified net working duration model are automated using three VBA macros added to MS project using its

embedded visual basic editor to enable its users to analyze project delays and work changes. The first macro is just an

extraction of data from MS project updated schedule and baseline. The second macro is the equivalent network formation

(the first step of the model). The third macro contains slack period responsibility calculations and analysis of delays with the

use of percentage method in case of multiple primary paths (the second and third steps of the model). Automation of the

model using these macros is illustrated besides its application on the example project shown in Fig 1.

The assumptions of the model are: (1) All logical relationships between activities are finish to start zero lag. (2) As-built

duration for each activity must contain all the delays and work changes for the activity to be used for as-built schedule

analysis in order to determine as-built critical activities. (3) Total float of the as-planned schedule is treated as discussed in

section 2.

5.1 The First Macro; Prepare Data for Analysis

MS project columns for Duration1 and Duration2 are used to store activities as-planned and as-built durations extracted

from MS project baseline and updated schedule. These two columns are renamed to be as-planned duration and as-built

duration, respectively.

The as-planned schedule of the example project of Fig 1.a is entered to MS project and then it is set as baseline. Activities

actual start and finish dates from Fig 1.b are used to update the project. Then the first macro is applied, columns of

extracted data are shown in Fig 2. Columns of as-planned and as-built durations are editable and can be used for data entry

for the program.

5.2 The Second Macro; Equivalent Network Formation

Steps for redundant path elimination are: (1) Perform network analysis using activities as-planned durations. (2) Mark asplanned critical activities and store activities as-planned total float. (3) Perform network analysis using activities as-built

durations. (4) Force marked activities to be critical on as-built network then re-analyze network and all firm paths will be

critical. (5) Inactivate any non-critical activity (activities which dont belong to either as-planned critical or as-built firm

paths). These steps are based on using the data which is stored in MS project columns of Duration 1 and Duration2.

Volume 4 Issue 5 May 2016

Page 5

IPASJ International Journal of Computer Science (IIJCS)

A Publisher for Research Motivation ........

Volume 4, Issue 5, May 2016

Web Site: http://www.ipasj.org/IIJCS/IIJCS.htm

Email: editoriijcs@ipasj.org

ISSN 2321-5992

Marking as-planned critical activities in step 2 is performed by giving a value of 1 in column Number11 for critical

activities instead of 0 for non-critical activities. Column Duration 3 is used to store activities as-planned total float. Forcing

marked activities to be critical in step 4 is performed using MS project by assignment of a (temporary) start on constrain to

each marked activity start date. As a result of adding constrains and re-scheduling the project, activities which belong to asplanned critical path(s) or as-built firm path(s) (including as-built critical path) are critical. Inactivation for activities in step

5 is an option by MS project to omit the activity from the analysis without losing its data. Flow chart for equivalent network

formation is given by Elwishahi [15].

Applying these steps on the example project; activities A, B, C, D, and K are determined as critical activities and then

marked [steps 1 and 2]. These activities are forced to be critical in their timings of as-built schedule. By re-scheduling the

project, activities of firm paths; E, I, F, P, and S are critical beside marked activities [steps 3 and 4]. Activities L, M, U, and

V are non-critical then inactivated [step5].

At the end of the second macro, five columns are added for purpose of entry of delays and work changes in MS project. The

five columns are number1, number2, number3, number4 and number5 which are renamed to be Owner work change,

Contractor work change and Owner (O), Contractor (C), and Neither (N) delays respectively. Delays responsibilities are

assigned to active activities only (equivalent network activities) in order to reduce the users effort for data entry. The

assigned delays using MS project added columns are viewed within the results of the application of the second macro on the

example project as shown in Fig 3.

Figure 2 Example project after application of the first macro (prepare data for analysis)

Figure 3Example project after application of the second macro and entry of activities delays responsibilities

Volume 4 Issue 5 May 2016

Page 6

IPASJ International Journal of Computer Science (IIJCS)

Web Site: http://www.ipasj.org/IIJCS/IIJCS.htm

Email: editoriijcs@ipasj.org

ISSN 2321-5992

A Publisher for Research Motivation ........

Volume 4, Issue 5, May 2016

5.3 The Third Macro; Slack Period Computations and Analysis of Delays

Slack period computations and delay analysis are network paths based analysis. Therefore, it is needed to represent the

equivalent network as a set of all possible paths. Thus the third macro contains the following steps: (1) Defining equivalent

network as paths (path matrix formation). (2) Slack period computations. (3) Analysis of delays.

5.3.1 Defining Equivalent Network as Paths (Path Matrix Formation)

The representation of the equivalent network paths is done using a zero one adjacency matrix which describes the

graphical structure of the network. The matrix has rows and columns, the rows represent network paths and the columns

represent activities (network nodes). If the activity (network node) belongs to the path (row), value 1 is given in the node

column, otherwise value 0 is given. The path matrix for the example project equivalent network which defines its four

paths; ABCDK, AFGHK, ABEIDK, and AFPSK is shown in table 1 where, the order of the activities which are the

columns of the path matrix describes the direction of logical relationships between network nodes. In order to arrange

activities in this order, a serial of sequential numbers from 1 to the number of equivalent network activities are used as new

IDs for activities which is called activities sequence IDs. These IDs are assigned to activities in increasing order

according to activities positions from the start to the end of the network which is defined using activities sequence step

numbers. These step numbers are logical relationships based order for the network and can be defined as the earliest logical

position in the network that an activity can occupy while maintaining its proper dependencies [16]. Fig 4 shows activities

sequence IDs and step numbers for the equivalent network of the example project.

Activity

Sequence ID

Path1

Path2

Path3

Path4

A

1

1

1

1

1

Step 1

Table 1: Path matrix of example project

B

F

C

E

G

P

I

H

2

3

4

5

6

7

8

9

1

0

1

0

0

0

0

0

0

1

0

0

1

0

0

1

1

0

0

1

0

0

1

0

0

1

0

0

0

1

0

0

Step 2

Step 3

Step 4

A

1

F

3

D

11

1

0

1

0

K

12

1

1

1

1

Step 5

C

4

B

2

S

10

0

0

0

1

Step 6

E

5

I

8

G

6

H

9

P

7

S

10

D

11

K

12

Legend:

Activity

Sequence ID

Figure 4 Activities sequence IDs and step numbers for example project equivalent network

Path matrix is represented by two dimensional array for visual basic language which is defined as:

1 if activity i belongs to path j

j = 1, 2, ., PN

P(j, i) =

i= 1, 2, ..,N

0 otherwise

(6)

Where, i is activity sequence ID, j is path number, N is number of activities in the network, and PN is number of paths of

the network.

It is noted that activities sequence ID is not activities original ID given and shown by MS project, but it is the ID used for

path matrix formation and any related calculations. Therefore, any data needed for rest of the analysis of each activity of the

equivalent network is stored as arrays of its sequence ID. The path matrix is defined using array P(j, i) through the

following steps; (1) Calculate activities step numbers in MS project column Number7. (2) Calculate activities sequence IDs

in MS project column of Number6. (3) Represent MS project data of each activity step number, number of successors,

logical relationships represented by identifying each successor of the activity, activity assigned delays, activity assigned

work changes, actual start, actual finish, and as-planned total float as VBA arrays of activitiy sequence ID. (4) Determine

number of paths of the equivalent network. (5) Identify the path matrix from the start to the end of the network using step

numbers and activities successors. Flow chart for path matrix generation is given by Elwishahi [15].

Volume 4 Issue 5 May 2016

Page 7

IPASJ International Journal of Computer Science (IIJCS)

A Publisher for Research Motivation ........

Volume 4, Issue 5, May 2016

Web Site: http://www.ipasj.org/IIJCS/IIJCS.htm

Email: editoriijcs@ipasj.org

ISSN 2321-5992

5.3.2 Slack Period Computations

.General steps for slack periods responsibility analysis are:

1. Determine as-planned critical paths, where slack periods may exist.

2. Check the existence of slack period on each as-planned critical path: (2.1) Consider each as-planned critical path on the

path matrix. Consider path cj. (2.2) Consider each two immediately succeeding activities a and b on path cj. It should be

noted that activity b is a predecessor to activity a. (2.3) If the difference between actual start of activity a and actual finish of

activity b is higher than zero, then a slack period is identified between b and a, and continue steps 3, 4, and 5 to determine

the responsible party. Otherwise, continue checking activities on path cj for existence of slack periods.

3. Study the firm paths connected to the considered slack period: (3.1) The firm paths for the considered slack period are

paths ending with activity a where predecessors of activity a on these paths are different from activity b. Store these firm

paths. (3.2) Determine the earliest activity connecting considered slack path cj and considered firm path jj; (activity II(jj)); it

may be first activity of the network. (3.3) Check that each firm path jj has no slack periods on it between activities a and

II(jj). (3.4) Determine as-planned total float of the considered firm path as the maximum total float of activities lying

between activities a and II(jj). (3.5) In case of multiple firm paths, determine the firm path having the least as-planned total

float; path fj. (3.6) Calculate summation of each type of delays and work changes on all activities of chosen firm path fj.

(3.7) Reduce summation of delays by total float of path fj according to float ownership rules mentioned in the assumptions

of the model. Get O1, Cl, and N1.

4. Calculate summation of each type of delays and work changes on all activities on the considered slack path cj. Get O2,

C2, and N2. This is because the studied part of the network to analyze the slack period is between activity II(fj) and activity

a where firm and slack paths are parallel.

5. Determine the responsibility for each day of the slack period: (5.1) Calculate the difference between each type of delays

on the firm and parallel slack path; R1, R2, and R3. (5.2) Determine the maximum value; M of R1, R2, and R3. The

responsibility for the considered day of slack period is determined based on the value M.

Where, C1, O1, and N1 are summation of non-excusable, compensable, and excusable delays on firm path. C2, O2, and N2

are summation of non-excusable, compensable, and excusable delays on a slack path. R1, R2, and R3 are the differences

between compensable, non-excusable, and excusable delays between firm and slack paths, respectively. Work changes

caused by the owner and contractor are added to relative summation of delays on firm and slack paths. Flow charts for

general and detailed steps for slack period responsibility analysis are given by Elwishahi [15].

5.3.3 Analysis of delays

The final step is to determine each party responsibility towards project delay using the net working duration method, by

determination of primary path(s) and accounting delays lying on these path(s) and using percentage method in case of

multiple primary paths.Primary path(s) is (are) the paths with the longest net working duration, delays on primary path(s)

determine the responsibility of each party towards delayed project completion. The net working duration of each path j;

WD(j) is determined by summing up its activities as-built durations after the subtraction of all delays and work changes

lying on them, and then the primary path(s) is (are) the path(s) with the longest networking duration. A zero-one array

pcp(j) is used to define whether the path j is primary or not. If the considered path is primary, then pcp(j) = 1 ,otherwise

pcp(j) = 0. Number of primary paths; NPP is calculated to determine whether the network has single or multiple primary

paths. In case of single primary path; NPP = 1, responsibilities towards project delay are found by summing up each type of

delays and work changes lying on this path. In case of multiple primary paths; NPP > 1, the analysis is continued using the

percentage method; responsibilities towards project delay are found using Eq 7 to. Eq 12.

CD` = SCD / (SCD + SND + SED) * (PAF PPF)

ND` = SND / (SCD + SND + SED) * (PAF PPF)

ED` = SED / (SCD + SND + SED) * (PAF PPF)

SCD =

* {DO(i) + WO(i) + SPO(j, i)}}

(7)

(8)

(9)

(10)

SND =

* {DC(i) + WC(i) + SPC(j, i)}}

(11)

SED =

* {DN(i) + SPN(j, i)}}

(12)

Where, CD`, ND`, and ED` are compensable, non-excusable, and excusable delays of the project, SCD, SND, and SED are

summations of compensable, non-excusable, and excusable delays on all primary paths. PAF and PPF are project actual and

as-planned finish dates. pcp(j) array which defines whether path j is primary pcp(j)=1 or not pcp(j)=0. DO(i), DC(i), and

DN(i) are compensable, non-excusable, and excusable delays of activity i. SPO(j, i), SPC(j, i), and SPN(j, i) are

Volume 4 Issue 5 May 2016

Page 8

IPASJ International Journal of Computer Science (IIJCS)

Web Site: http://www.ipasj.org/IIJCS/IIJCS.htm

Email: editoriijcs@ipasj.org

ISSN 2321-5992

A Publisher for Research Motivation ........

Volume 4, Issue 5, May 2016

compensable, non-excusable, and excusable slack periods on activity i of path j. WC, and WO are contractor, and owner

caused work changes. Respectively.

Flow chart of calculations of the responsibility of parties towards project delay and VBA codes for the three macros are

given by Elwishahi [15]. Applying the third macro to the example project, the results are given in message box which is

shown in Fig 5.

Figure5Example project delay analysis results

6. DELAY ANALYSIS TECHNIQUES COMPARISON - CASE STUDY

The case study used by Al-Gahtani and Mohan [17] for comparison between delay analysis techniques is solved by the

automated model to compare its results with other methods. As-planned CPM schedule of the case study is shown in Fig 6,

the as-built bar chart is shown in Fig 7. According to Al-Gahtani and Mohan [17], the case study has most types of delay

and acceleration events that might be faced on a real project. The results of applying the automated model to the case study

added to the results given by Al-Gahtani and Mohan [17] are shown in table 2.

0

0

start 0

0

0

Legend:

Early start

Early finish

Activity ID Original Duration

Late start

Late finish

0

A

0

7

7

7

7

B

7

17

10

17

17

C

17

30

13

30

0

D

0

10

10

10

10

E

10

22

12

22

22

F

22

30

8

30

0

G

5

8

8

13

8

H

13

16

8

21

16

I

21

25

9

30

30

J

30

38

8

38

0

K

7

9

9

16

9

L

16

17

8

24

17

M

24

23

6

30

23

N

30

31

8

38

9

O

19

16

7

26

16

P

26

20

4

30

38 38

Finish 0

38 38

Figure 6As-planned CPM schedule of the case study

1

9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48

(A)

(B)

(B)

2 Days contractor accleration

(D)

(C)

(E)

(E)

(J)

(G)

(H)

(J)

(K)

O = compensable delay

C = Non-excusable delay

N = Excusable delay

(F)

C

Legend:

2 Days owner

acceleration

(I)

(L)

(L)

(O)

(M)

(P)

75% increase of work

(3 days owner change order)

(N)

Figure 7As-built bar chart of the case study

Volume 4 Issue 5 May 2016

Page 9

IPASJ International Journal of Computer Science (IIJCS)

A Publisher for Research Motivation ........

Volume 4, Issue 5, May 2016

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Web Site: http://www.ipasj.org/IIJCS/IIJCS.htm

Email: editoriijcs@ipasj.org

ISSN 2321-5992

Table 2: Results of different delay analysis techniques of case study

Project Delays (Days)

Delay Analysis Technique

Notes

Compensable Non-excusable Excusable

Global Impact

12

18

8

As-Planned (Gross of Measure)

4

9

3

As-Planned (Unite of Measure)

4

8

3

As-Built

4

6

3

Impacted As-Planned

4

0

3

Time Impact

4

9

3

But For (Gross of Measure)

0

5

3

But For (Unite of Measure)

0

6

3

Isolated Delay Time (IDT)

6

9

Window/Snapshot

5

7

3

Window/But For

3

5

3

6 and 2 days owner and

TF Management (Easy-Rule)

2

3

3

contractor total float

TF Management (Fair-Rule)

3

4

3

consumption

Automated model (Modified

1

6

3

Net Working Duration)

The results of Table 2 shows that the automated model gives the most accurate and fair results, it gives exact identification

of the responsibility of 10 days delay which is the project total delay, besides its effort reduction caused by assignments of

delays only to activities of the equivalent network which is not available by other methods.

7. SUMMARY AND CONCLUSION

The net working duration based model has been reviewed and automated with MS project using its built-in VBA

programming language. The automated model gives fair and accurate analysis of delays. The model uses a suitable and

flexible concept of total float ownership and uses the percentage method which deals with multiple critical paths instead of

accounting for concurrency of delays. The model has the ability to deal with real life large project networks by reducing the

project network into an equivalent one with less number of activities. Formation of that equivalent network requires MS

project baseline and updated schedule which are mainly available data to start the analysis, and then liabilities for only the

delays lying on activities of the equivalent network are required which lead to less users effort.

Automation of the model with MS project is illustrated using an example project. A practical case study is used to compare

the results of the model with other delay analysis methods results. The automated model enables construction practitioners

to identify their responsibilities towards project delays in an easy and effective way and made the analysis of delays and

work changes easier and costless.

References

[1] S. A. Assaf, S. Al-Hejji,Causes of delay in large construction projects, International Journal of Project Management,

24(4), 357-349, 2006.

[2] W. Menesi, Construction Delay Analysis under Multiple Baseline Updates,MASc Thesis, University of Waterloo,

Canada, 2007.

[3] J. M. Antill, R. W. Woodhead, Critical path methods in construction practice, Wiley Interscience Publication,New

York, 1982.

[4] F. A. Jrad, Analysis of Delays and Work Changes in Construction Networks, PHD Dissertation, faculty of engineering

Tanta University, Egypt, 2004.

[5] D. Arditi, T.Pattanakitchamroon,Selecting a delay analysis method in resolving construction claims, International

Journal of Project Management, 24(2): 145-155, 2006.

[6] K. S. Al-Gahtani, A comprehensive construction delay analysis technique: Enhanced with a float ownership

concept,PHD Dissertation, State University of New York at Buffalo, USA, 2006.

[7] Tsai, Wang, Chang,Criticality index delay analysis method based on float allocation, Journal of the Chinese Institute

of Engineers, 10.1080/02533839.2015.1037350, 887-896, 2015.

[8] Wang, Fan, Tsai, Chang,A comparison of float ownership issues for construction projects between Taiwan and

China, Journal of Marine Science and Technology, Vol. 23, No. 1, pp. 69-77 DOI: 10.6119/JMST-014-0110-2, 2015.

Volume 4 Issue 5 May 2016

Page 10

IPASJ International Journal of Computer Science (IIJCS)

A Publisher for Research Motivation ........

Volume 4, Issue 5, May 2016

Web Site: http://www.ipasj.org/IIJCS/IIJCS.htm

Email: editoriijcs@ipasj.org

ISSN 2321-5992

[9] M. Abu-Osbeh, Integrated Forensic Delay Analysis Framework for Construction Projects Time and Cost Perspectives,

PhD thesis, Concordia University, Canada; 2011.

[10] American Association of Cost Engineers (AACE), AACE International recommended practice 29R-03: forensic

schedule analysis practice guide, Morgantown, WV, 2011.

[11] L. D. Nguyen, The Dynamics of Float, Logic, Resource Allocation, and Delay Timing in Forensic Schedule Analysis

and Construction Delay Claims, PHD Dissertation, University of California, Berkeley, USA, 2007.

[12] Z. M. Kraiem, J. E.Diekmann, J E,Concurrent delays in construction projects, Journal of Construction Engineering

and Management ASCE, 113(4), 591-602, 1987.

[13] F. J. Hughes, J. K. Ulwelling, True concurrent delays and a proposed rule of law for apportioning damages for delay

arising therefrom, Francis J. Hughes, 33p; 1992.

[14] D. Arditi, M. A. Robinson,Concurrent delays in construction litigation, Cost Engineering AACE, 37(7), 20-30, 1995.

[15] M. G. Elwishahi, Automation of the net-working duration technique for delay analysis with Microsoft project, MASc

Thesis, faculty of engineering Tanta University, Egypt, 2016.

[16] R. B. Harris, Precedence and arrow networking techniques for construction, John Willey and Sons, New York, 1978.

[17] K. S. Al-Gahtani, S. B. Mohan,Delay Analysis Techniques Comparison, Journal of Civil Engineering and

Architecture, ISSN 1934-7359, USA, Volume 5, No. 8 (Serial No. 45); 740-747, 2011.

Volume 4 Issue 5 May 2016

Page 11

You might also like

- THE TOPOLOGICAL INDICES AND PHYSICAL PROPERTIES OF n-HEPTANE ISOMERSDocument7 pagesTHE TOPOLOGICAL INDICES AND PHYSICAL PROPERTIES OF n-HEPTANE ISOMERSInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Detection of Malicious Web Contents Using Machine and Deep Learning ApproachesDocument6 pagesDetection of Malicious Web Contents Using Machine and Deep Learning ApproachesInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Detection of Malicious Web Contents Using Machine and Deep Learning ApproachesDocument6 pagesDetection of Malicious Web Contents Using Machine and Deep Learning ApproachesInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Experimental Investigations On K/s Values of Remazol Reactive Dyes Used For Dyeing of Cotton Fabric With Recycled WastewaterDocument7 pagesExperimental Investigations On K/s Values of Remazol Reactive Dyes Used For Dyeing of Cotton Fabric With Recycled WastewaterInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Study of Customer Experience and Uses of Uber Cab Services in MumbaiDocument12 pagesStudy of Customer Experience and Uses of Uber Cab Services in MumbaiInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Analysis of Product Reliability Using Failure Mode Effect Critical Analysis (FMECA) - Case StudyDocument6 pagesAnalysis of Product Reliability Using Failure Mode Effect Critical Analysis (FMECA) - Case StudyInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- An Importance and Advancement of QSAR Parameters in Modern Drug Design: A ReviewDocument9 pagesAn Importance and Advancement of QSAR Parameters in Modern Drug Design: A ReviewInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Experimental Investigations On K/s Values of Remazol Reactive Dyes Used For Dyeing of Cotton Fabric With Recycled WastewaterDocument7 pagesExperimental Investigations On K/s Values of Remazol Reactive Dyes Used For Dyeing of Cotton Fabric With Recycled WastewaterInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Customer Satisfaction A Pillar of Total Quality ManagementDocument9 pagesCustomer Satisfaction A Pillar of Total Quality ManagementInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Analysis of Product Reliability Using Failure Mode Effect Critical Analysis (FMECA) - Case StudyDocument6 pagesAnalysis of Product Reliability Using Failure Mode Effect Critical Analysis (FMECA) - Case StudyInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Customer Satisfaction A Pillar of Total Quality ManagementDocument9 pagesCustomer Satisfaction A Pillar of Total Quality ManagementInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- THE TOPOLOGICAL INDICES AND PHYSICAL PROPERTIES OF n-HEPTANE ISOMERSDocument7 pagesTHE TOPOLOGICAL INDICES AND PHYSICAL PROPERTIES OF n-HEPTANE ISOMERSInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Soil Stabilization of Road by Using Spent WashDocument7 pagesSoil Stabilization of Road by Using Spent WashInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Study of Customer Experience and Uses of Uber Cab Services in MumbaiDocument12 pagesStudy of Customer Experience and Uses of Uber Cab Services in MumbaiInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Design and Detection of Fruits and Vegetable Spoiled Detetction SystemDocument8 pagesDesign and Detection of Fruits and Vegetable Spoiled Detetction SystemInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- An Importance and Advancement of QSAR Parameters in Modern Drug Design: A ReviewDocument9 pagesAn Importance and Advancement of QSAR Parameters in Modern Drug Design: A ReviewInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- A Digital Record For Privacy and Security in Internet of ThingsDocument10 pagesA Digital Record For Privacy and Security in Internet of ThingsInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- The Mexican Innovation System: A System's Dynamics PerspectiveDocument12 pagesThe Mexican Innovation System: A System's Dynamics PerspectiveInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- The Impact of Effective Communication To Enhance Management SkillsDocument6 pagesThe Impact of Effective Communication To Enhance Management SkillsInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- A Comparative Analysis of Two Biggest Upi Paymentapps: Bhim and Google Pay (Tez)Document10 pagesA Comparative Analysis of Two Biggest Upi Paymentapps: Bhim and Google Pay (Tez)International Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- A Deep Learning Based Assistant For The Visually ImpairedDocument11 pagesA Deep Learning Based Assistant For The Visually ImpairedInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Staycation As A Marketing Tool For Survival Post Covid-19 in Five Star Hotels in Pune CityDocument10 pagesStaycation As A Marketing Tool For Survival Post Covid-19 in Five Star Hotels in Pune CityInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Secured Contactless Atm Transaction During Pandemics With Feasible Time Constraint and Pattern For OtpDocument12 pagesSecured Contactless Atm Transaction During Pandemics With Feasible Time Constraint and Pattern For OtpInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Performance of Short Transmission Line Using Mathematical MethodDocument8 pagesPerformance of Short Transmission Line Using Mathematical MethodInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Synthetic Datasets For Myocardial Infarction Based On Actual DatasetsDocument9 pagesSynthetic Datasets For Myocardial Infarction Based On Actual DatasetsInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Predicting The Effect of Fineparticulate Matter (PM2.5) On Anecosystemincludingclimate, Plants and Human Health Using MachinelearningmethodsDocument10 pagesPredicting The Effect of Fineparticulate Matter (PM2.5) On Anecosystemincludingclimate, Plants and Human Health Using MachinelearningmethodsInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Challenges Faced by Speciality Restaurants in Pune City To Retain Employees During and Post COVID-19Document10 pagesChallenges Faced by Speciality Restaurants in Pune City To Retain Employees During and Post COVID-19International Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Advanced Load Flow Study and Stability Analysis of A Real Time SystemDocument8 pagesAdvanced Load Flow Study and Stability Analysis of A Real Time SystemInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Impact of Covid-19 On Employment Opportunities For Fresh Graduates in Hospitality &tourism IndustryDocument8 pagesImpact of Covid-19 On Employment Opportunities For Fresh Graduates in Hospitality &tourism IndustryInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Anchoring of Inflation Expectations and Monetary Policy Transparency in IndiaDocument9 pagesAnchoring of Inflation Expectations and Monetary Policy Transparency in IndiaInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- XHB CommFuncDocument10 pagesXHB CommFuncPalatNo ratings yet

- CHEST Workout Structure and Training Log PREVIEWDocument3 pagesCHEST Workout Structure and Training Log PREVIEWgaurav singhNo ratings yet

- Letter To Local Residents From Sutton Council Re. Lidl Development To Replace Matalan Ref DM2019-02113 10 January 2020Document5 pagesLetter To Local Residents From Sutton Council Re. Lidl Development To Replace Matalan Ref DM2019-02113 10 January 2020etajohnNo ratings yet

- The Five Generations of Computers: AssignmentDocument10 pagesThe Five Generations of Computers: Assignmentjismon_kjNo ratings yet

- Transmission ImpairmentsDocument49 pagesTransmission ImpairmentsLaurentiuStanciuNo ratings yet

- A1.2.3 Method Statement 4a Redacted Version2Document98 pagesA1.2.3 Method Statement 4a Redacted Version2ChanelNo ratings yet

- 1893 Shadow RunDocument6 pages1893 Shadow RungibbamonNo ratings yet

- 3., 4., & 9. RBXC Catalogue Local 2015Document16 pages3., 4., & 9. RBXC Catalogue Local 2015Nilesh RanadeviNo ratings yet

- DTOcean - Optimal Design Tools For Ocean Energy ArraysDocument94 pagesDTOcean - Optimal Design Tools For Ocean Energy ArraysWilson NevesNo ratings yet

- Industry 4.0 FinaleDocument25 pagesIndustry 4.0 FinaleFrame UkirkacaNo ratings yet

- Waukesha Engine, Dresser, Inc. - Express Limited Warranty Covering Products Used in Continuous Duty ApplicationsDocument6 pagesWaukesha Engine, Dresser, Inc. - Express Limited Warranty Covering Products Used in Continuous Duty ApplicationsLUISA FERNANDA TORRES MANOSALVANo ratings yet

- Turkle Sherry What Does Simulation Want PDFDocument11 pagesTurkle Sherry What Does Simulation Want PDFmonterojuNo ratings yet

- Touch Screen TechnologyDocument18 pagesTouch Screen TechnologySmîlērNo ratings yet

- EOG Project2010Document34 pagesEOG Project2010Amey Kadam100% (2)

- Man Power PlanningDocument5 pagesMan Power PlanningKarthik AchinNo ratings yet

- Unban FormsDocument74 pagesUnban FormsNoob ab AbNo ratings yet

- MPTK Medium Pressure Pump Performance SpecsDocument2 pagesMPTK Medium Pressure Pump Performance SpecssaronandyNo ratings yet

- JEDI Slides Intro1 Chapter 02 Introduction To JavaDocument17 pagesJEDI Slides Intro1 Chapter 02 Introduction To JavaredbutterflyNo ratings yet

- Sitsyll PDFDocument57 pagesSitsyll PDFpreranaNo ratings yet

- Gypsum Ceiling PDFDocument1 pageGypsum Ceiling PDFAanchal Mishra100% (1)

- Updated After 11th BoS Course Curriculum - B.tech CSEDocument120 pagesUpdated After 11th BoS Course Curriculum - B.tech CSEAnonymous 9etQKwWNo ratings yet

- Introduction To Windows PDFDocument24 pagesIntroduction To Windows PDFRaymoon Twopass DaysNo ratings yet

- P8B WS Memory Qualified Vendors List (QVL)Document3 pagesP8B WS Memory Qualified Vendors List (QVL)bolpensmaierNo ratings yet

- TCON300Document722 pagesTCON300DGGNo ratings yet

- Prefabricated Structures ComponentsDocument16 pagesPrefabricated Structures ComponentsKrish KrishNo ratings yet

- Associating Numbers With Sets Having 51 Up To 100 Objects or ThingsDocument4 pagesAssociating Numbers With Sets Having 51 Up To 100 Objects or ThingssweetienasexypaNo ratings yet

- Smart Lighting Market Analysis and Forecast 2025 by Global Marketing InsightsDocument5 pagesSmart Lighting Market Analysis and Forecast 2025 by Global Marketing InsightsEko Hadi Susanto100% (1)

- Audio (Amplifier) - Electrical DiagnosticsDocument195 pagesAudio (Amplifier) - Electrical DiagnosticsRafael CherechesNo ratings yet

- حل جميع المعادلات الكهربائيةDocument60 pagesحل جميع المعادلات الكهربائيةGandhi HammoudNo ratings yet

- 7.qad-Dpr-11 ImteDocument4 pages7.qad-Dpr-11 ImteDhinakaranNo ratings yet