Professional Documents

Culture Documents

Fandrivesystem W Series

Uploaded by

ado_22Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fandrivesystem W Series

Uploaded by

ado_22Copyright:

Available Formats

W-SERIES ADVANCED HYDROSTATIC

FAN DRIVE SYSTEM

HYDRAULIC SYSTEMS DIVISION

Outstanding Hydraulic Products, Service and Expertise, Worldwide

Background

Hydrostatic Fan Drive Systems:

In a traditional fan drive the fan is linked to the engine through a belt drive or

mounted to the crank shaft. This means that the fan will run at a speed determined

by the engine and not determined by the required cooling power. In an electric

on/off installation it will either run at full speed when above the cut-in temperature limit or stall when below the cut-off temperature. These systems will cool

the engine in quite a wide temperature range, in some cases even more than

needed at the cost of fuel, noise, energy and emission.

Hydrostatic fan drive systems

basically consist of three main components:

Hydraulic pump Hydraulic motor (with fan) Cooling unit

In HALDEX Fan Drives the hydraulic pump and hydraulic motor are designed as a compact and cost efficient gear unit with

optional integrated control features.

The following sketch shows the schematic design of a hydrostatic fan drive system:

Heated water

10

Cooled water

14

3

7

12

8

4

Descriptions:

Fail safe

It has an integrated failsafe feature. If a

failure occurs in the electric system,

cables, sensors or control unit, the fan

speed is automatically adjusted to maximum cooling power and prevents the

engine from overheating and costly

engine damage. Times are gone with

engine breakdowns caused by a

defective fan belt.

avoids mechanical shock loads

compared to systems with simple on/

off coupling systems.

Temperature

Engine cooling temperature and hydraulic fluid temperature are presisely

controlled within a narrower temperature

range compared to other systems.

The fan speed is essential on the

machine for emission, noise and fuel

consumption.

Example:

This hydraulic fan drive system enables

design flexibility since units can be

located remote from the engine.

Additionally this means the radiator

airflow can be optimized with regard to

minimum noise emission.

A fan running at 1000 rpm and 2 kW

power input, will need 8 kW to run at

2000 rpm. So by making the fan independent from the engine speed the fan

will run only at required speed and

consequently consume just the power

needed.

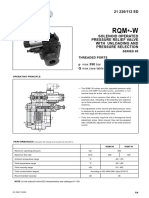

The proportional pressure relief valve

controls the torque of the fan and

generates the most precise speed

control.

Correct speed

Optional:

A smooth ramping up and down of fan

speed by a proportional pressure control

Electronic Control Unit is available

directly mounted to the solenoid valve.

Flexible

It has 3 input signals, 2 of them are

analogue, for cooling of e.g.. engine,

hydraulic circuit or transmission, 1 is a

digital signal e.g. for air-condition or

retarder. This Electronic Control Unit has

just the size of a matchbox. Connectors

of the outgoing cable can be provided

to suit customer wire harness demand.

Adjustment of electronics, solenoid and

sensors is factory preset.

Complete solution

Haldex Hydraulics supply complete

systems including hydraulic pump,

hydraulic motor with pressure control

and the Electronic Control Unit with

temperature sensors. Other features like

AC-valve, reversible fan direction,

pressure gauges etc. are optional. All

motors are equipped with a shaft seal

designed for high back pressure and

pressure spikes in the return line. This

eliminates the need for a case drain line

of uni-rotational motors in many

applications. Bi-rotational motors are

available as well. The system offers the

capability of being integrated into

existing hydraulic and electronic

systems of the machines.

11

13

6

5

Cooled oil

In the Haldex Hydraulics fan drive, the

fan speed is controlled independently

from engine speed and will only run to

supply the cooling power exactly as

required not less and not more and

independent of the engine speed.

Diesel motor

Power-take-off (PTO)

Hydraulic pump

Hydraulic motor

Hydraulic tank

Impeller

Prop. pressure relief valve

Electronic unit (ECU)

Plug for signal input

Digital signal (z. B. air conditioner or retarder)

Oil cooling unit (1-circuit design)

Water cooling unit (2-circuit design)

Temperature sensor cooling circuit 1

Temperature sensor cooling circuit 2

Heated oil

The Haldex design

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

Haldex Fan Drive Systems

Pumps

Motors

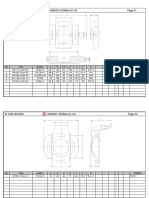

W-series pump W600, W900, W1500

Displacement range 3 50 cc/rev

Pressure range p1 up to 276 bar

Optional valve features:

- Priority flow control

- LS priority flow control

- Relief valve

W-series motors WM600, WM900, WM1500

Displacement range 3 50 cc/rev

Pressure range p1 up to 276 bar

Uni- or birotational

Outboard bearing optional

Optional valve features:

- Anticavitation check valve

- Relief valve

- 2-speed selection valve

- Thermal valve

- Prop-pressure relief valve

- Reversible rotation valve

- Electronic control unit & temperature sensor

For more details please see individual product brochures or contact your local Haldex Hydraulics representative.

HALDEX W-SERIES FAN DRIVE GB-03-03

HALDEX W-SERIES FAN DRIVE GB-03-03

HALDEX W-SERIES FAN DRIVE GB-03-03

PRODUCT RANGE

www.haldex.com

HE Powerpacks

12/24/48 VDC 0.3 4.5 kW and

0.75 3 kW AC modular power

packs

Pressure Switches

5 - 350 bar, connecting/

disconnecting

HE Box Powerpacks

12/24/48 VDC modular

powerpacks in weatherproof

boxes

W100 Hydraulic pumps

0,5 - 2,0 cc 227 bar

Haldex Hydraulics AB

Industrigatan 6

Box 511

SE-195 25 ARLANDASTAD

Sweden

Tel:

+468 591 288 50

Fax:

+46-8 591 288 60

info.hydraulics.eu@haldex.com

Haldex Hydraulics Corp.

2222 15th Street

ROCKFORD, IL 61104

USA

Tel:

+1-815 398 4400

Fax:

+1-815 398 5977

info.hydraulics.us@haldex.com

Haldex Hydraulics AB

Ringvgen 3

SE-280 40 SK. FAGERHULT

Sweden

Tel:

+46-433 32400

Fax:

+46-433 30546

info.hydraulics.eu@haldex.com

Haldex Hydraulics Corp.

214 James Farm Road

Statesville, NC 28625

USA

Tel:

+1-704 873 2587

Fax:

+1-704 838 7989

info.hydraulics.us@haldex.com

Haldex Hydraulics GmbH

Seligenweg 12

Postfach 1507

DE-95014 HOF

Germany

Tel:

+49-9281 895-0

Fax:

+49-9281 87133

info.hydraulics.eu@haldex.com

Haldex is an innovator

in vehicle technology

and supplies proprietary systems and

components for trucks, cars and

industrial vehicles worldwide. Haldex is

listed on the Stockholm Stock Exchange

and has yearly sales exceeding 6,5 billion Swedish Krona with 4.000

employees (www.haldex.com).

W300 Hydraulic pumps

0.8 5.7 cc 230 bar

W600 Hydraulic pumps

3 12 cc 276 bar

WM600 Hydraulic motors

3 12 cc 276 bar

W900 Hydraulic pumps

5 31 cc/section 276 bar

WM900 Hydraulic motors

5 - 31 cc/section 276 bar

WQ900 The quiet pump

5 - 23 cc/section 230 bar

W1500 Hydraulic pumps

19 - 50 cc/section 276 bar

WM1500 Hydraulic motors

19 - 50 cc/section 276 bar

G25 Hydraulic pumps

21.3 63 cc/section 250 bar

GPA Internal Gear pumps

1.7 63 cc/section 100 bar

GC Hydraulic pumps

1.06 11.65 cc/section 275 bar

II-Stage Hydraulic pumps

4.2 22.8 cc/section 275 bar

Rotary Flow Dividers

3.8 13.3 cc/section 300 bar

G20/G30 (LS) Hydraulic pumps

23 161 cc/section 275 bar

Transmission pumps

Fuel pumps

You might also like

- New Holland CR6.80, CR6.90, CR7.90, CR8.90, CR9.90 Tier 4B (Final) Combine Service Repair Manual NADocument31 pagesNew Holland CR6.80, CR6.90, CR7.90, CR8.90, CR9.90 Tier 4B (Final) Combine Service Repair Manual NAggjjjjotonesNo ratings yet

- Folder A4 Agrícola 2022Document2 pagesFolder A4 Agrícola 2022Mairson DiasNo ratings yet

- 4020 Main Pump PDFDocument2 pages4020 Main Pump PDFPreett Rajin MenabungNo ratings yet

- Handok Hydraulic - Co: Flow Rate ControlDocument1 pageHandok Hydraulic - Co: Flow Rate Controlanon_485665212No ratings yet

- Gea6500w1 Gea6000w1 DWF 770W DWF820WDocument53 pagesGea6500w1 Gea6000w1 DWF 770W DWF820WKarim Fernandez CampusanoNo ratings yet

- 98-05110 r1 FP Rogator 854 InstallDocument18 pages98-05110 r1 FP Rogator 854 InstallJulio CRNo ratings yet

- Volvo Control ValveDocument9 pagesVolvo Control ValveAnas OmarNo ratings yet

- 16 - Kit de Servicos e Componentes de PecasDocument66 pages16 - Kit de Servicos e Componentes de PecasMary BetcelNo ratings yet

- Komptech CribusDocument12 pagesKomptech CribusbaleizaobzNo ratings yet

- Relief Cartridge ValvesDocument16 pagesRelief Cartridge Valvesvivek_11111987No ratings yet

- General, Steering ComponentsDocument60 pagesGeneral, Steering ComponentsIndra H BasriNo ratings yet

- Plano Hidráulico 994H PDFDocument29 pagesPlano Hidráulico 994H PDFluis angel ruiz gomezNo ratings yet

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document13 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768julio cesarNo ratings yet

- Spare Parts Catalogue: Series 2000Document96 pagesSpare Parts Catalogue: Series 2000pascukintaNo ratings yet

- 11068682Document48 pages11068682manjappahNo ratings yet

- Battery Service EquipmentDocument11 pagesBattery Service EquipmentMary CastilloNo ratings yet

- Portable Data Recorder HMG 4000: Operating ManualDocument124 pagesPortable Data Recorder HMG 4000: Operating Manualphankhoa83-1No ratings yet

- Vickers PVB MVB Piston PumpDocument29 pagesVickers PVB MVB Piston Pumppablo cofreNo ratings yet

- Test Procedure (Margin Pressure and Load Sensing Pressure)Document10 pagesTest Procedure (Margin Pressure and Load Sensing Pressure)Halil KaraNo ratings yet

- Pump description and operationDocument4 pagesPump description and operationNaing Min HtunNo ratings yet

- DX80R Travel Device GM10Document12 pagesDX80R Travel Device GM10ZawminhtunNo ratings yet

- Universo de Reposio MobilDocument36 pagesUniverso de Reposio MobilAdrian MartinNo ratings yet

- Senr3981-04 - Fluid Power Graphic SymbolsDocument21 pagesSenr3981-04 - Fluid Power Graphic SymbolsRolandoJeffersonVivesCarreñoNo ratings yet

- 470GLC (1FF) Catálogo de Peças - PC11288PDocument604 pages470GLC (1FF) Catálogo de Peças - PC11288PKaio DavyNo ratings yet

- AR-200 Operating Manual Revision 1Document133 pagesAR-200 Operating Manual Revision 1Paola de LeonNo ratings yet

- 45 Series G Frame 74cc and 90cc Parts Manual (520L0582 REV AA Dec 2007)Document56 pages45 Series G Frame 74cc and 90cc Parts Manual (520L0582 REV AA Dec 2007)Sasko Dimitrov100% (2)

- Tractor Hydraulics in Line with TrendsDocument10 pagesTractor Hydraulics in Line with TrendsNelson PaicoNo ratings yet

- Brochure R 9350 English 2013-04 - 11723-0 PDFDocument22 pagesBrochure R 9350 English 2013-04 - 11723-0 PDFJulhefry Maroan Situngkir100% (1)

- Radial Piston Motor (Multi-Stroke) MCR10: RE 15207/07.10 1/16 Replaces: 02.98Document16 pagesRadial Piston Motor (Multi-Stroke) MCR10: RE 15207/07.10 1/16 Replaces: 02.98juanchis650No ratings yet

- Volvo HydbasicDocument127 pagesVolvo Hydbasicabduallah muhammadNo ratings yet

- HydraulicsDocument253 pagesHydraulicsvelavansuNo ratings yet

- EC480D - Servo Pump, DescriptionDocument4 pagesEC480D - Servo Pump, DescriptionPreett Rajin MenabungNo ratings yet

- 8120-8520 SerieDocument1 page8120-8520 Serieinfo7879No ratings yet

- Rexroth DFR InformationDocument2 pagesRexroth DFR InformationLucas AndradeNo ratings yet

- Cat1 2008 EN PDFDocument779 pagesCat1 2008 EN PDFWedar KaribetNo ratings yet

- Cam Rocker Handok Hydraulic - Co Page 01Document6 pagesCam Rocker Handok Hydraulic - Co Page 01Chin Hui Chan100% (1)

- Rexroth Pump AV8ODocument24 pagesRexroth Pump AV8OvanhoackdNo ratings yet

- Catalogo UnitecDocument2 pagesCatalogo UnitecGiovani FariasNo ratings yet

- Om S300LC VDocument236 pagesOm S300LC Vnaim khchimi100% (1)

- Zx210w Workshop ManuelDocument702 pagesZx210w Workshop Manuelguven gurolNo ratings yet

- TDV 100 DIRECTIONAL PROPORTIONAL CONTROL VALVEDocument6 pagesTDV 100 DIRECTIONAL PROPORTIONAL CONTROL VALVE林育豪No ratings yet

- 036 Excavator en Mobile2003Document14 pages036 Excavator en Mobile2003Star SealNo ratings yet

- Desmontaje Mando Final D155AX-6Document3 pagesDesmontaje Mando Final D155AX-6claudioNo ratings yet

- Manitou Electric Scissor Lift Operation ManualDocument82 pagesManitou Electric Scissor Lift Operation ManualViacheslav BurmistrNo ratings yet

- PC210LC-11 Sen06695-01 SpecificationsDocument16 pagesPC210LC-11 Sen06695-01 SpecificationsdatphuongNo ratings yet

- Bucher Motor ComparisonDocument8 pagesBucher Motor ComparisononurousNo ratings yet

- TMG Under XCMGDocument28 pagesTMG Under XCMGМаксим СтратилаNo ratings yet

- Hagglunds CADocument84 pagesHagglunds CAVINAY VISHWAKARMANo ratings yet

- Technical specifications and dimensions of BOMAG single drum rollersDocument4 pagesTechnical specifications and dimensions of BOMAG single drum rollersJeffreyNo ratings yet

- Section E Hydraulics Technical Data TablesDocument22 pagesSection E Hydraulics Technical Data TablesАлександр НовиковNo ratings yet

- Control StructDocument835 pagesControl Structenergymaster0% (1)

- Link Belt X4 Long Front FamilyDocument12 pagesLink Belt X4 Long Front FamilyYew LimNo ratings yet

- 015.2 - 6060 - Terminals and ConnectorsDocument11 pages015.2 - 6060 - Terminals and ConnectorsJorby CuadrosNo ratings yet

- Hydraulic System: Main Menu Click The Volvo-Logo in The Lower Right Corner To Return To This MenuDocument42 pagesHydraulic System: Main Menu Click The Volvo-Logo in The Lower Right Corner To Return To This MenuCarlos Alberto BaptistaNo ratings yet

- HC Series TrainingDocument461 pagesHC Series TrainingKrum KashavarovNo ratings yet

- DM30 II Instruction Manual (English) 005 035033Document520 pagesDM30 II Instruction Manual (English) 005 035033icatandhika77No ratings yet

- p1 PD XL Service Lte 00062 3 C 0707 075 100 140Document42 pagesp1 PD XL Service Lte 00062 3 C 0707 075 100 140Bernardo Orozco LariosNo ratings yet

- Char-Lynn: Power SteeringDocument13 pagesChar-Lynn: Power SteeringJohn Cadenillas Rumay100% (1)

- Instalatii de ClimatizareDocument19 pagesInstalatii de ClimatizareAdi MusatNo ratings yet

- Clint Cha k726p 36012p Brochure 0325 enDocument2 pagesClint Cha k726p 36012p Brochure 0325 enDorin100% (1)

- 3660 IngDocument2 pages3660 Ingado_22No ratings yet

- DuplomatikDocument4 pagesDuplomatikado_22No ratings yet

- TTDCD en 00 CircuitDocument11 pagesTTDCD en 00 Circuitado_22100% (10)

- PW160-7K S 0411Document890 pagesPW160-7K S 0411ado_22100% (2)

- Cylcoup CA Eng 0841Document12 pagesCylcoup CA Eng 0841ado_22No ratings yet

- Komatsu Wa150Document289 pagesKomatsu Wa150mnowaq82% (11)

- TroubleshootingDocument440 pagesTroubleshootingado_2298% (47)

- Pt6and8 Bu Eng 1372Document2 pagesPt6and8 Bu Eng 1372ado_22No ratings yet

- Operation & Maintenance Manual for PC290LC-7K & PC290NLC-7K Hydraulic ExcavatorsDocument321 pagesOperation & Maintenance Manual for PC290LC-7K & PC290NLC-7K Hydraulic Excavatorsado_22100% (1)

- WB93R-5 M Weam006000 WB93R-5Document284 pagesWB93R-5 M Weam006000 WB93R-5ado_2280% (5)

- D85ex-15 M Eeam022804 D85ex PX-15 0509Document240 pagesD85ex-15 M Eeam022804 D85ex PX-15 0509Carlos Israel Gomez100% (4)

- WH609-716 SDocument516 pagesWH609-716 Sado_22100% (1)

- Case Hydraulics Excavators 1188 Shop ManualDocument318 pagesCase Hydraulics Excavators 1188 Shop ManualВалерийБылинин94% (33)

- Top Performance under Pressure: SEMPERIT Hydraulic and Pressure Washer HosesDocument24 pagesTop Performance under Pressure: SEMPERIT Hydraulic and Pressure Washer Hosesado_22No ratings yet

- Salami Catalog Group2Document35 pagesSalami Catalog Group2ado_22No ratings yet

- ReadMe EnglishDocument1 pageReadMe Englishado_22No ratings yet

- Salami Catalog Group3 Zupcaste PumpeDocument32 pagesSalami Catalog Group3 Zupcaste Pumpeado_22No ratings yet

- K3V112 Parts DrawingDocument4 pagesK3V112 Parts Drawingado_22No ratings yet

- RE 10 436 Direct Controlled Vane PumpDocument8 pagesRE 10 436 Direct Controlled Vane Pumpado_22No ratings yet

- CLRG 326e GBDocument4 pagesCLRG 326e GBado_22No ratings yet

- Zupcastepumpe PZGDocument4 pagesZupcastepumpe PZGado_22No ratings yet

- Rocket PropulsionDocument41 pagesRocket PropulsionV DhinakaranNo ratings yet

- Marsh FunnelDocument2 pagesMarsh Funnel123shripadNo ratings yet

- Chapter 14 Modern SpectrosDocument24 pagesChapter 14 Modern SpectrosChicken ChickenNo ratings yet

- Lab 6 SpectrophotometerDocument11 pagesLab 6 SpectrophotometerChing Wai YongNo ratings yet

- 1981 - Leeper - Wet Cooling Tower - Rule of Thumb Design and SimulationDocument32 pages1981 - Leeper - Wet Cooling Tower - Rule of Thumb Design and SimulationGuilherme Venturi RonchiNo ratings yet

- WISDM-dataset-description 2Document5 pagesWISDM-dataset-description 2yuliasihkripsianditaNo ratings yet

- Optimum Penstocks For Low Head Microhydro Schemes - Alexander, Giddens - 2008Document13 pagesOptimum Penstocks For Low Head Microhydro Schemes - Alexander, Giddens - 2008cbarajNo ratings yet

- Alpton Construction Structural Basis of DesignDocument53 pagesAlpton Construction Structural Basis of DesignChristian ReyesNo ratings yet

- Solving The Simandoux EquationDocument15 pagesSolving The Simandoux Equationjose_rarmenta100% (1)

- Calculating Energy: Complete These Questions in Your Exercise Books, With Full ESTAU Working OutDocument2 pagesCalculating Energy: Complete These Questions in Your Exercise Books, With Full ESTAU Working Outruby lillyNo ratings yet

- Physics: Investigatory ProjectDocument10 pagesPhysics: Investigatory ProjectSourav SethuNo ratings yet

- S P I C e J e T Q U e S T I o N SDocument43 pagesS P I C e J e T Q U e S T I o N SDharavGosaliaNo ratings yet

- Quatitative Microscopy Cog PDFDocument6 pagesQuatitative Microscopy Cog PDFNiyati GuptaNo ratings yet

- ChemDocument2 pagesChemBaliuag Guia100% (4)

- Francis Bacon, Logic of SensationDocument2 pagesFrancis Bacon, Logic of SensationShrankhla NaryaNo ratings yet

- 2oo3plus - A New Design of Electro-Hydraulic Safety Controls For Critical ApplicationsDocument6 pages2oo3plus - A New Design of Electro-Hydraulic Safety Controls For Critical Applicationsultrasonic81No ratings yet

- T3-Revision-Internal-ResistanceDocument22 pagesT3-Revision-Internal-Resistancejordan2gardnerNo ratings yet

- Lab Report 5Document6 pagesLab Report 5Sarwar Hosen SimonNo ratings yet

- Stiffness of Cable-Based Parallel Manipulators With Application To Stability AnalysisDocument8 pagesStiffness of Cable-Based Parallel Manipulators With Application To Stability AnalysisNhật MinhNo ratings yet

- Basic Simulation LabDocument69 pagesBasic Simulation LabkamalahasanmNo ratings yet

- Bosch L Jetronic Injection Technical Instructions PDFDocument40 pagesBosch L Jetronic Injection Technical Instructions PDFjorge Angel LopeNo ratings yet

- Design of Masonry StructuresDocument10 pagesDesign of Masonry StructuresmuhammedNo ratings yet

- IS 516 (Part-2) Sec-1 - 2018Document16 pagesIS 516 (Part-2) Sec-1 - 2018Sai Pavan100% (9)

- 1117 1 M-Ary Signals PART 1Document11 pages1117 1 M-Ary Signals PART 1PARKSANGWOOKNo ratings yet

- D V V U: T A.II.i.4. M P BS 1178Document4 pagesD V V U: T A.II.i.4. M P BS 1178ShubhamRanjanNo ratings yet

- Linear DC Machine PDFDocument21 pagesLinear DC Machine PDFAbdul Aziz0% (1)

- Chemical Engineering Magazine Abril 2009 PDFDocument108 pagesChemical Engineering Magazine Abril 2009 PDFFélix Vargas Santillán100% (1)

- ME 555 Stress Analysis Unit 4Document57 pagesME 555 Stress Analysis Unit 4TheoNo ratings yet

- Hvs-313. Maximum Demand ControllerDocument3 pagesHvs-313. Maximum Demand ControllerHari BabuNo ratings yet

- Motion 1Document3 pagesMotion 1Fenil ShahNo ratings yet