Professional Documents

Culture Documents

1002 Geotechnical Modelling

Uploaded by

LukeCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1002 Geotechnical Modelling

Uploaded by

LukeCopyright:

Available Formats

CUSTOMER SUPPORT NOTE

Geotechnical modelling methods for short

term, long term and full consolidation

behaviour

Note Number:

CSN/LUSAS/1002

This support note is issued as a guideline only.

Finite Element Analysis Ltd. 2005

Finite Element Analysis Ltd 2005

CSN/LUSAS/1002

Table of Contents

1.

INTRODUCTION

2.

DESCRIPTION

2.1

Effective stress

2.2

Initial stresses

2.3

Material model

2.4

Long-term, drained solutions

2.5

Short-term, undrained solutions

2.6

Full consolidation modelling

3.

EXAMPLES

3.1

Long-term drained analysis

3.2

Short-term undrained analysis (total stress method)

3.3

Short-term undrained analysis (effective stress method)

3.4

Consolidation analysis

3.5

Consolidation analysis of an excavation

4.

REFERENCES

CSN/LUSAS/1002

1. Introduction

When carrying out a full non-linear, geotechnical analysis using LUSAS where the

actual ground itself is discretised into finite elements (i.e. Winkler Springs are not

used), it is important to establish whether short term, long term or full consolidation

behaviour is required. This will initially depend on the type of soil present in the

model and more specifically, the permeability of the material. The permeability will

control how quickly excess pore pressures set up in the soil due to

excavation/construction will come to equilibrium.

Sandy or gravelly soils with relatively high permeabilities will enable excess pore

pressures to dissipate almost immediately and so a drained or long-term analysis

will be necessary. Soils with a large clay content and therefore a low permeability

however will mean that excess pore pressures dissipate much more slowly, often

taking many years to reach equilibrium. In this case it is important to establish

whether it is the short term behaviour which is required (immediately postconstruction) or the long-term behaviour (once full dissipation of excess pore

pressures has taken place). This will often be dependent on the type of analysis in

question and which condition is the more critical in terms of stability. Cuttings and

excavations will be more stable in the short term when negative excess pore pressures

are present while embankments and foundation type problems will be more stable in

the long term once excess pore pressures have been completely dissipated.

LUSAS also has the capability to model the full consolidation sequence using TwoPhase plane strain elements and so the excess pore pressure dissipation with time can

be reproduced simulating the change from short term to long term behaviour. This

type of model may be necessary when the engineer requires the length of time taken

to establish equilibrium conditions.

This support note will describe how each of these types of analysis should be

undertaken using the LUSAS finite element software.

2. Description

2.1 Effective stress

The deformability and strength of soil depends on the effective stress present, NOT

the total stress. The effective stress is the difference between the applied external

total loading stress, and the pore water pressure, u. Therefore when considering the

type of analysis required for low permeability soil types such as clay, consideration

should be given to the magnitude of effective stresses present within the soil both in

the short term and long term conditions.

Excavation of a low permeability soil will give rise to a reduction in pore pressure as

well as total stress and therefore the changes in effective stresses will be minimal. As

dissipation of excess pore pressures subsequently takes place over time, pore water

pressures within the soil will increase and therefore the effective stress will decrease,

leading to a reduction in soil strength. In this case it can be seen that the long-term

condition is the more critical as the effective stresses within the soil will be at their

lowest values.

Page 1

CSN/LUSAS/1002

Finite Element Analysis Ltd 2005

Construction, on the other hand will give rise to positive excess pore pressures within

the soil and subsequent dissipation will lead to an increase in effective stress and

strength making the short term condition the more critical. A long term analysis may

also be necessary in this case however if the final long-term displacements of the

structure are required.

2.2 Initial stresses

The initial, in situ stresses existing in the ground should be entered in the very first

loadcase. Variations can be used to represent a varying stress profile with depth. It is

important that stresses in all three (X, Y and Z) directions are included for plane strain

as well as 3-dimensional analyses. Stress profiles should be entered such that the

vertical stress profile balances the gravity load acting from the acceleration due to

gravity and the material density. There should be minimal displacements produced in

the in situ loadcase.

When carrying out a short-term or consolidation analysis with two-phase elements the

initial pore pressure profile within the ground is ignored and therefore generated

pressures are always excess pore pressures, i.e. pressures above or below the initial

pressure profile. Full consolidation will once more give rise to zero pore pressures

indicating that all excess pore pressures have dissipated.

2.3 Material model

All geotechnical analyses should make use of a non-linear material model to represent

the behaviour of soil as only very small strains are necessary in order to overcome the

yield stress and induce plasticity. In general an elastic, perfectly-plastic soil model

is recommended such as the Mohr-Coulomb failure criteria (Model 65). A more

advanced soil model known as Cam clay is due for implementation into the LUSAS

software in Version 14.

The Mohr-Coulomb material model can be used for both short term and long term

analyses using effective stress as well as total stress soil parameters.

2.4 Long-term, drained solutions

When carrying out drained, long-term solutions, effective stress soil strength and

stiffness parameters must be used with the Mohr-Coulomb material model,

comprising:

1.

2.

3.

4.

5.

Youngs modulus, E

Poissons ratio,

Cohesion, c

Angle of friction,

Angle of dilation,

Analyses of this type do not consider any generation of excess pore pressures.

2.5 Short-term, undrained solutions

Short term solutions can be carried out as either a total stress analysis using undrained

strength and stiffness parameters or as an effective stress analysis using drained

Page 2

CSN/LUSAS/1002

Finite Element Analysis Ltd 2005

parameters together with two-phase finite elements. The latter method will predict

the magnitude of excess pore pressures that are induced within the soil due to the

construction sequences involved. At present only plane strain problems can be

analysed with two-phase elements. Additional material properties are required for

two phase elements, namely the bulk modulus of water, the unit weight of water, and

the porosity and permeability of the soil continuum.

2.5.1 Total stress analyses

Short-term total stress analyses will require the following undrained, strength and

stiffness material parameters to be used with the Mohr-Coulomb material:

1.

2.

3.

4.

5.

Youngs modulus, Eu

Poissons ratio, u = 0.5

Undrained shear strength, Cu

Angle of friction, u = 0

Angle of dilation, u = 0

Although a value of 0.5 is required for Poissons ratio to simulate the fact that no

volume changes are permitted for undrained, total stress solutions, it is not possible;

to enter a value of exactly 0.5 as this will give rise to an infinite bulk modulus. For

this reason a value of 0.495 is often used. The angle of friction must always be zero

hence analyses of this type are often referred to as phi = 0 analyses.

Although excess pore pressures will be generated in the short-term condition, they are

not calculated in analyses of this type.

2.5.2 Effective stress analyses

Short-term effective stress analyses with two-phase finite elements will require the

following drained strength and stiffness material parameters together with additional

parameters describing the soil/fluid interaction:

1. Youngs modulus, E

2. Poissons ratio,

3. Cohesion, c

4. Angle of friction,

5. Angle of dilation,

6. Bulk modulus of solid particles, Ks

7. Bulk modulus of fluid phase, Kw

8. Porosity, n

9. Unit weight of fluid phase, w

10. Permeability, (kx, ky, kz)

The equivalent bulk modulus, Ke of the soil particle/fluid material is derived

internally from the supplied values of Ks and Kw by the following relationship:

1

n (1 n)

=

+

Ke Kw

Ks

As the bulk modulus of the solid particles, Ks is usually much higher than the bulk

modulus of the fluid phase, Kw then:

Page 3

CSN/LUSAS/1002

Finite Element Analysis Ltd 2005

n

1

Ke K w

This type of analysis will predict the generation of excess pore pressures within the

soil.

2.6 Full consolidation modelling

The same effective stress input soil parameters used for undrained solutions with

excess pore pressure predictions are used for consolidation type problems where the

dissipation of these pore pressures are also considered. The Time domain option

must be switched on in the nonlinear control dialog and set to Consolidation. The

Initial Time Step and Total Response Time must also be set depending on the units of

time being used. The analysis will then be carried out as a coupled time-marching

solution.

3. Examples

The following examples use two linear, elastic materials to represent a standard silty

clay soil upon which an embankment is constructed. The soils should ideally be

modelled using a non-linear material; elastic properties have been used in the

examples in order to speed up the analysis times.

3.1 Long-term drained analysis

[LUSAS model: embankment_drained.mdl]

This example uses drained, effective stress parameters to model the long term

settlement of the embankment. Standard plane strain elements have been used

throughout and a maximum displacement of 141mm is produced directly beneath the

centre of the embankment as shown in Figure 1.

LOAD CASE

Increment 2

RESULTS FILE =

DISPLACEMENT

CONTOURS OF DY

-0.14099

-0.132178

-0.123366

-0.114554

-0.140978

-0.105742

-0.0969306

-0.0881187

-0.0793068

-0.0704949

-0.0616831

-0.0528712

-0.0440593

-0.0352475

-0.0264356

-0.0176237

-8.81187E-3

Max 0.0000E+00 at Node 182

Min -0.1410 at Node 570

Figure 1. Vertical displacements for long-term drained solution

Page 4

CSN/LUSAS/1002

Finite Element Analysis Ltd 2005

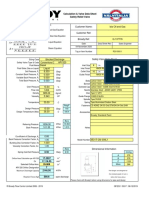

3.2 Short-term undrained analysis (total stress method)

[LUSAS model: embankment_undrained_total.mdl]

This example uses undrained, total stress parameters to model the short term

settlement of the embankment. Standard plane strain elements have been used

throughout and a maximum displacement of 37mm is produced directly beneath the

centre of the embankment as shown in Figure 2.

LOAD CASE

Increment 2

RESULTS FILE =

DISPLACEMENT

CONTOURS OF DY

-0.0349595

-0.0305896

-0.0262196

-0.0218497

-0.0367739

-0.0174798

-0.0131098

-8.73988E-3

-4.36994E-3

0

4.36994E-3

8.73988E-3

0.0131098

0.0174798

0.0218497

0.0262196

0.0305896

Max 0.3284E-01 at Node 351

Min -0.3708E-01 at Node 160

Figure 2. Vertical displacements for short-term undrained solution (total stress)

3.3 Short-term undrained analysis (effective stress method)

[LUSAS model: embankment_undrained_effective.mdl]

This example uses drained, effective stress parameters together with two phase

material properties to model the short-term solution. Two phase plane strain elements

have been used for the loaded soil while standard plane strain elements have been

used for the embankment. A maximum displacement of 40mm is produced directly

beneath the centre of the embankment as shown in Figure 3. This result is very

similar to the undrained total stress analysis as expected. As two-phase plane strain

elements have been used contours of the excess pore pressures generated in the soil

due to the placement of the embankment are also calculated as shown in Figure 4.

Page 5

CSN/LUSAS/1002

Finite Element Analysis Ltd 2005

LOAD CASE

Increment 2

RESULTS FILE =

DISPLACEMENT

CONTOURS OF DY

-0.03585

-0.0313688

-0.0268875

-0.0400846

-0.0224063

-0.017925

-0.0134438

-8.96251E-3

-4.48126E-3

0

4.48126E-3

8.96251E-3

0.0134438

0.017925

0.0224063

0.0268875

0.0313688

Max 0.3160E-01 at Node 342

Min -0.4010E-01 at Node 635

Figure 3. Vertical displacements for short-term undrained solution (effective stress)

LOAD CASE

Increment 2

RESULTS FILE =

DISPLACEMENT

CONTOURS OF PRES

0

13.3333

26.6667

40

53.3333

66.6667

80

93.3333

106.667

120

133.333

146.667

160

173.333

186.667

200

Max 272.5 at Node 22

Min -54.98 at Node 343

Figure 4: Excess pore pressures for short-term undrained solution (effective stress)

3.4 Consolidation analysis

[LUSAS model: embankment_consolidation.mdl]

This example uses drained, effective stress parameters together with two phase

material properties to model the complete time-history solution from the short-term to

the long-term in a consolidation analysis. Two phase plane strain elements have been

used for the loaded soil while standard plane strain elements have been used for the

embankment. Drainage is permitted from the top surface beneath the embankment

only. At time T=0 the solution can be compared to the two undrained solutions above

and at time T= with the drained solution. Figure 5 shows that the maximum

Page 6

CSN/LUSAS/1002

Finite Element Analysis Ltd 2005

displacement beneath the embankment at T=0 is 38mm (again in agreement with the

two undrained solutions) and Figure 6 shows the excess pore pressures generated

which again are in agreement with the undrained effective stress solution. Figure 7

shows the maximum displacement beneath the embankment at T= which is in

excellent agreement with the long-term drained solution.

LOAD CASE

Time Step 2 Time = 0.200000E-03

RESULTS FILE =

RESPONSE T IME = 0.2000E-03

DISPLACEMENT

CONTOURS OF DY

-0.0355072

-0.0310688

-0.0374897

-0.0266304

-0.022192

-0.0177536

-0.0133152

-8.87681E-3

-4.4384E-3

0

4.4384E-3

8.87681E-3

0.0133152

0.0177536

0.022192

0.0266304

0.0310688

Max 0.3351E-01 at Node 342

Min -0.3750E-01 at Node 635

Figure 5: Vertical displacements for consolidation solution at T=0

LOAD CASE

Time Step 2 Time = 0.200000E-03

RESULTS FILE =

RESPONSE T IME = 0.2000E-03

DISPLACEMENT

CONTOURS OF PRES

0

13.3333

26.6667

40

53.3333

66.6667

80

93.3333

106.667

120

133.333

146.667

160

173.333

186.667

200

Max 276.4 at Node 107

Min -55.98 at Node 343

Figure 6: Excess pore pressures for consolidation solution at T=0

Page 7

CSN/LUSAS/1002

Finite Element Analysis Ltd 2005

LOAD CASE

21

Time Step 21 Time = 0.500000E+09

RESULTS FILE =

RESPONSE T IME = 0.5000E+09

DISPLACEMENT

CONTOURS OF DY

-0.140876

-0.132071

-0.123266

-0.140864

-0.114462

-0.105657

-0.0968522

-0.0880474

-0.0792427

-0.070438

-0.0616332

-0.0528285

-0.0440237

-0.035219

-0.0264142

-0.0176095

-8.80474E-3

Max 0.0000E+00 at Node 182

Min -0.1409 at Node 635

Figure 7: Vertical displacements for consolidation solution at T=

3.5 Consolidation analysis of an excavation

[LUSAS model: excavation_consolidation.mdl]

A similar consolidation example has been created for excavation rather than

construction. In this case an excavation is carried out in the same soil deposit as the

construction examples above. In this case negative excess pore pressures are

produced giving rise to suction and water is drawn in from the outside world. This

has been permitted at the top boundary of the model only and the excavated region is

assumed to be kept clear of free standing water. An excess pore pressure profile on a

deformed mesh at time T=0 is shown in Figure 8 and vertical displacement contours

at time T= are shown in Figure 9.

Page 8

CSN/LUSAS/1002

Finite Element Analysis Ltd 2005

LOAD CASE

Time Step 2 Time = 0.200000E-03

RESULT S FILE =

RESPONSE TIME = 0.2000E-03

DISPLACEMENT

CONT OURS OF PRES

-259.882

-242.557

-225.231

-207.906

-190.58

-173.255

-155.929

-138.604

-121.278

-103.953

-86.6274

-69.3019

-51.9764

-34.651

-17.3255

0

Max 2.493 at Node 502

Min -274.7 at Node 503

Figure 8: Excess pore pressures for consolidation solution at T=0

LOAD CASE

21

Time Step 21 Time = 0.500000E+09

RESULT S FILE =

RESPONSE TIME = 0.5000E+09

DISPLACEMENT

CONT OURS OF DY

0

0.0133276

0.0266551

0.0399827

0.0533103

0.0666379

0.0799654

0.093293

0.106621

0.119948

0.133276

0.146603

0.159931

0.173258

0.186586

0.199914

Max 0.2132 at Node 123

Min 0.0000E+00 at Node 182

Figure 9: Vertical displacements for consolidation solution at T=

4. References

SIMONS, N.E. and MENZIES, B.K. (1977). A short course in foundation

engineering. Butterworth & Co (Publishers) Ltd.

Page 9

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- (GEOSS) - Guidelines On Good Practices For Pile Load TestDocument10 pages(GEOSS) - Guidelines On Good Practices For Pile Load TestPeter KyawNo ratings yet

- Basic Design of AHU (General)Document64 pagesBasic Design of AHU (General)Dimyati Es100% (5)

- Revised Summative Test Based On TOS Science 3 2021Document6 pagesRevised Summative Test Based On TOS Science 3 2021Henry Kahal Orio Jr.100% (1)

- ASM - Tensile TestingDocument283 pagesASM - Tensile TestingSanthosh Nair83% (6)

- S9-CnS Waterproofing ConcreteDocument2 pagesS9-CnS Waterproofing ConcreteLukeNo ratings yet

- Section 6 - Piling: C&S Particular Specifications PilingDocument13 pagesSection 6 - Piling: C&S Particular Specifications PilingLukeNo ratings yet

- Python SyntaxDocument1 pagePython SyntaxLukeNo ratings yet

- S18-CnS Splice Sleeve PDFDocument2 pagesS18-CnS Splice Sleeve PDFLukeNo ratings yet

- S23-CnS Rapid Load TestDocument2 pagesS23-CnS Rapid Load TestLukeNo ratings yet

- S21-CnS Roads and DrainsDocument39 pagesS21-CnS Roads and DrainsLukeNo ratings yet

- Circular Administrative Instruction For FSC and Maa SubmissionsDocument9 pagesCircular Administrative Instruction For FSC and Maa SubmissionsLukeNo ratings yet

- Eco-Sanctuary Precast Drawings Production Report Summary Drawings Completion TrackerDocument3 pagesEco-Sanctuary Precast Drawings Production Report Summary Drawings Completion TrackerLukeNo ratings yet

- Building Vibration Check To NBC 2005 - No Tie BeamDocument12 pagesBuilding Vibration Check To NBC 2005 - No Tie BeamLukeNo ratings yet

- TAir-ST02-V.01 (03may16)Document5 pagesTAir-ST02-V.01 (03may16)LukeNo ratings yet

- 2005-ST50 - PL01 - 20200518Document1 page2005-ST50 - PL01 - 20200518LukeNo ratings yet

- URA Conserved ReservationDocument11 pagesURA Conserved ReservationLukeNo ratings yet

- Lam Hong Wire Rope & Chain Sling CapacityDocument2 pagesLam Hong Wire Rope & Chain Sling CapacityLukeNo ratings yet

- 2020-01-29 Structural Study M&E DfMA For IsaacDocument1 page2020-01-29 Structural Study M&E DfMA For IsaacLukeNo ratings yet

- 1) Skis PresentationDocument37 pages1) Skis PresentationLukeNo ratings yet

- Hilti 2018 Financial-Report PDFDocument104 pagesHilti 2018 Financial-Report PDFLukeNo ratings yet

- REDiBOX STD Permanent Recess Former 0218Document1 pageREDiBOX STD Permanent Recess Former 0218LukeNo ratings yet

- Memo 56c Tss 41 Rekommended Reinforcement Pattern PDFDocument4 pagesMemo 56c Tss 41 Rekommended Reinforcement Pattern PDFLukeNo ratings yet

- Precast Landing Slab - Connection TSSDocument8 pagesPrecast Landing Slab - Connection TSSNor Asni AzizanNo ratings yet

- Memo 56c Tss 41 Rekommended Reinforcement Pattern PDFDocument4 pagesMemo 56c Tss 41 Rekommended Reinforcement Pattern PDFLukeNo ratings yet

- Technical Specification PS 300 and PS 1000Document6 pagesTechnical Specification PS 300 and PS 1000LukeNo ratings yet

- Design of Coupling BeamsDocument20 pagesDesign of Coupling BeamsLuke100% (1)

- c2-10 Site InvestigationDocument26 pagesc2-10 Site InvestigationLukeNo ratings yet

- Seismic Design With Eurocode 8Document110 pagesSeismic Design With Eurocode 8Luke100% (1)

- Sizing CalcDocument1 pageSizing CalcHilary AbaratuNo ratings yet

- ME 601 - Stress Analysis Assignment 1 - Review of Strength of Materials Due Date: 27/07/2015, at The Beginning of The ClassDocument6 pagesME 601 - Stress Analysis Assignment 1 - Review of Strength of Materials Due Date: 27/07/2015, at The Beginning of The Classfatty acidNo ratings yet

- Theory Questions Asked in Mid Sem and CVMU QP - 07072023Document26 pagesTheory Questions Asked in Mid Sem and CVMU QP - 07072023a9157272235No ratings yet

- Topic 3 - Flexible Pavement Stress AnalysisDocument22 pagesTopic 3 - Flexible Pavement Stress AnalysisWelly Pradipta bin Maryulis100% (1)

- Self-Assessment Exercise 1Document3 pagesSelf-Assessment Exercise 1Deniz YiğitNo ratings yet

- Pile Analysis in Accordance With EN 1997-1:2004 Incorporating Corrigendum Dated February 2009 and The Recommended ValuesDocument4 pagesPile Analysis in Accordance With EN 1997-1:2004 Incorporating Corrigendum Dated February 2009 and The Recommended ValuesRuemu Godwin InikoriNo ratings yet

- Legend Miscellaneous Equipments Vessels / Tanks Type of Valves / FittingsDocument1 pageLegend Miscellaneous Equipments Vessels / Tanks Type of Valves / FittingsUdayNo ratings yet

- Steel Concrete Composite Structures Design Data Hand BookDocument33 pagesSteel Concrete Composite Structures Design Data Hand BookManikanta Sharma100% (1)

- VRF v6 Service VC Pro Engineering Data BookDocument192 pagesVRF v6 Service VC Pro Engineering Data BookMarcia FranciscoNo ratings yet

- 2009 06 CIA Achieving Durability in Design Crack ControlDocument17 pages2009 06 CIA Achieving Durability in Design Crack Controlcaojin259No ratings yet

- Pascal WSDocument4 pagesPascal WSMochamad Yoga Windu DharmawanNo ratings yet

- Permeability AssignmentDocument2 pagesPermeability AssignmentJejomar MotolNo ratings yet

- Shear Force and Bending MomentDocument3 pagesShear Force and Bending MomentDej AdmasuNo ratings yet

- IntroductionDocument37 pagesIntroductionsomsubhraNo ratings yet

- Property Modifiers PDFDocument1 pageProperty Modifiers PDFraj vaddiNo ratings yet

- Fundamentals of Chemical Engineering Thermodynamics, SI EditionDocument1 pageFundamentals of Chemical Engineering Thermodynamics, SI EditionNoman MaqsoodNo ratings yet

- MMS50CDocument6 pagesMMS50CClaudio SaNo ratings yet

- Indicator DigrameDocument17 pagesIndicator DigrameRa jaTNo ratings yet

- Manual Ast 24uw4sdbtg10 1Document96 pagesManual Ast 24uw4sdbtg10 1pacoNo ratings yet

- Heat Transfer ActivityDocument4 pagesHeat Transfer ActivityMark Angelo UyNo ratings yet

- Thermo BookDocument145 pagesThermo BookShahla GondalNo ratings yet

- Budget of Work For Advanced PhysicsDocument25 pagesBudget of Work For Advanced PhysicsCiv NortubNo ratings yet

- Fluid Machinery: Textbook: Fluid Mechanics and Hydraulic Machines by Sukumar Pati M. G. HillsDocument23 pagesFluid Machinery: Textbook: Fluid Mechanics and Hydraulic Machines by Sukumar Pati M. G. Hillsminesh.manu6531No ratings yet

- Test 3: Atterberg Limits: Solid State Semi-Solid State Plastic State Liquid StateDocument9 pagesTest 3: Atterberg Limits: Solid State Semi-Solid State Plastic State Liquid Statehabib agezeNo ratings yet

- Heat T CH 2-1Document67 pagesHeat T CH 2-1Fira tubeNo ratings yet

- Aerodynamics of Airfoil & WingsDocument38 pagesAerodynamics of Airfoil & WingsaerochirishNo ratings yet

- Design of Dams and Bridges 1Document44 pagesDesign of Dams and Bridges 1Muralikrishna Baduru100% (1)