Professional Documents

Culture Documents

Painting Method Statment

Uploaded by

Khaled Gamal50%(2)50% found this document useful (2 votes)

188 views5 pagespainting method statement

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentpainting method statement

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

50%(2)50% found this document useful (2 votes)

188 views5 pagesPainting Method Statment

Uploaded by

Khaled Gamalpainting method statement

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 5

NEGEMCO FOR ENGINEERING & CONTRACTING

METHOD STATEMENT

TITLE

Revision

NEG-015-MS-BP

Method Statement for Blasting &

Painting

00

Method Statement

For Blasting & Painting

Name

Signature

Date

Rev.

Prepared By

Iyas Alkhatib

10.JAN.2015

00

Reviewed &

Approved By

Arabi Soudi

10.JAN.2015

00

NEGEMCO FOR ENGINEERING & CONTRACTING

METHOD STATEMENT

TITLE

Revision

NEG-015-MS-BP

Method Statement for Blasting &

Painting

00

CONTENTS

1.0

General

2.0 Scope of project

3.0 Documentation provided by APC

4.0 Description of the activities to be cared out on site

4.1 Supply & erection of external scaffoldings

4.2 Preparation of equipment for handling

4.3 Preparation of boiler to start re-tubing

4.4 Pulling & Expanding of water tubes

4.5 Reinstallation of insulation

4.6 Reinstallation of refractory

4.7 Replace the boiler inlet duct expansion joint

4.8 NDE Execution

4.9 Prepare & execution of the hydraulic test

4.10 Prepare assisting & restoration for chemical cleaning

4.11 Mechanical cleaning inside the boiler & flue gas side

4.12 Painting

5.0 Documentations and activities

5.1 Preliminary documentations

5.2 Documents during work execution

5.3 Final Documents

6.0 Activities, Erection tools / machineries & Equipment

7.0 List of Annexes

7.1 Drawings of boiler No. 1

7.2 Welding Procedures Specifications (WPS)

7.3 Extension of Non-Destructive testing (NDT)

2

NEGEMCO FOR ENGINEERING & CONTRACTING

METHOD STATEMENT

TITLE

Revision

NEG-015-MS-BP

Method Statement for Blasting &

Painting

00

1.0 Scope of work

This method statement provides information concerning the

materials, tools, manpower and method of application

protective coatings of steel products to ensure compliance

with the requirements of the contract documents and

technical specifications.

2.0 Pre-work activities

2.1 Delivery, Handling & Storage

All delivered materials clearly labeled with identification of

manufacturer & brand name, and located in a safe area

following the approved manufacturers recommendations for

special delivery, storage and handling of materials.

2.2 Tools check

NEGEMCO FOR ENGINEERING & CONTRACTING

METHOD STATEMENT

TITLE

Revision

NEG-015-MS-BP

Method Statement for Blasting &

Painting

00

Before commencement, ensure that all paints, blasting and

personnel protective equipments are run tidily and comply

with safety requirements.

3.0

Process description

3.1 Surface preparation & cleaning

All surface contaminations such as dust, oil, grease etc.

shall be removed by appropriate method before

commencement in blasting the metal surface. Workshop blast

cleaning shall be carried out to get SA 2 1/2 .

3.2 Check climatic condition

Before applying any paint coat, humidity, air temperature, substrate surface

temperature & dew point must be checked to verify that it comply with the

technical specifications and the manufacturer recommendations for applying

the paints.

3.3 Paint process

All paints mixed with the appropriate thinner as per the manufacturer data

sheet, then starting applying the system's paint using airless spray machine.

Painters shall wait for the recommended time by the manufacturer data sheet

before applying the next coat.

4.0 Inspection and testing

Painting inspector is responsible to check all the blasting and painting

activities including:

Checking the blast cleaning process.

Checking surface roughness before applying the first coat.

Checking the climatic conditions before commencement of painting

each protective coat.

Checking wet film thickness (WFT) during painting process.

Checking dry film thickness (DFT) after painting process.

Visual inspecting the final coats.

NEGEMCO FOR ENGINEERING & CONTRACTING

METHOD STATEMENT

TITLE

Revision

NEG-015-MS-BP

Method Statement for Blasting &

Painting

00

Painting inspector is responsible to issue a painting report include:

Substrate rust grade.

Surface cleaning grade.

Surface roughness after blasting.

Humidity.

Substrate surface temperature.

Air temperature.

Dew point.

DFT readings.

You might also like

- Painting Procedure GlobalDocument15 pagesPainting Procedure GlobalUbed KudachiNo ratings yet

- Clean Pipes with Cardboard Bursting and Air BlowingDocument3 pagesClean Pipes with Cardboard Bursting and Air BlowingParthiban Karuna100% (1)

- Pneumatic Test ProcedureDocument3 pagesPneumatic Test Procedurevijay padale50% (2)

- National Water Supply Building Works Method StatementDocument16 pagesNational Water Supply Building Works Method StatementPROJECT MANAGERNo ratings yet

- MOS of BackfillingDocument2 pagesMOS of BackfillingPoru ManNo ratings yet

- ITP For Mild Steel Pipe WorksDocument4 pagesITP For Mild Steel Pipe WorksKumar AbhishekNo ratings yet

- QIP of Boiler For ErectionDocument6 pagesQIP of Boiler For ErectionUmair Awan100% (2)

- Fire Hose Rack & Reel Testing ProcedureDocument2 pagesFire Hose Rack & Reel Testing ProcedureDong VanraNo ratings yet

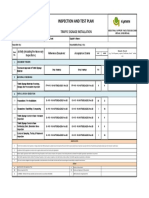

- Traffic Signage Installation ITPDocument1 pageTraffic Signage Installation ITPmoytabura96No ratings yet

- Method Statement For Fabrication and Installation For ReferenceDocument7 pagesMethod Statement For Fabrication and Installation For ReferenceMano RanjithNo ratings yet

- Method Statement: Emergency Contact DetailsDocument9 pagesMethod Statement: Emergency Contact DetailsShazwaniNo ratings yet

- MS For Survey and Setting OutDocument4 pagesMS For Survey and Setting OutShan THALANo ratings yet

- Efficient Framing and Sheeting ErectionDocument6 pagesEfficient Framing and Sheeting Erectionjoseph chewNo ratings yet

- QATAR Pin Braze pdfr1Document14 pagesQATAR Pin Braze pdfr1Karunanithi NagarajanNo ratings yet

- Method Statement For Hydraulic JackingDocument22 pagesMethod Statement For Hydraulic Jackinghwen.hh100% (1)

- Hydrotest Foreman Job DescriptionDocument2 pagesHydrotest Foreman Job DescriptionRosyad Broe CaporegimeNo ratings yet

- Pipeline Repair Products: Repair Patch, Melt Stick, Epoxy Primer and Mastic FillerDocument2 pagesPipeline Repair Products: Repair Patch, Melt Stick, Epoxy Primer and Mastic FillerCherif GhalebNo ratings yet

- 03 Strength Assessment of Recycled Aggregate Concrete by Ultrasonic Pulse Velocity Test PDFDocument5 pages03 Strength Assessment of Recycled Aggregate Concrete by Ultrasonic Pulse Velocity Test PDFYati R. TankNo ratings yet

- CR 10 (2) D Safety Harness Inspector TEMPLATEDocument1 pageCR 10 (2) D Safety Harness Inspector TEMPLATELiam Du Piesanie0% (1)

- Samsung engineering construction work method statementDocument7 pagesSamsung engineering construction work method statementgururaj100% (1)

- MS For Fabrication of Above-Ground Storage TankDocument8 pagesMS For Fabrication of Above-Ground Storage Tankdadz mingiNo ratings yet

- PT-03 JSA Dismantling of Slip Form (22-05-09)Document10 pagesPT-03 JSA Dismantling of Slip Form (22-05-09)M Waqas HabibNo ratings yet

- Method Statement For LPG DismantlingDocument8 pagesMethod Statement For LPG DismantlingHusain abidiNo ratings yet

- Method Statement For Foundation InstallationDocument5 pagesMethod Statement For Foundation InstallationFrancis GonzalesNo ratings yet

- Method Statement For Installation Anchor BoltsDocument7 pagesMethod Statement For Installation Anchor BoltsSyed AtherNo ratings yet

- Mezzanine Installation InstructionDocument19 pagesMezzanine Installation InstructionfaustomariottNo ratings yet

- 8 JSA Holyday TestDocument3 pages8 JSA Holyday TestYosua SitumorangNo ratings yet

- G42-LSP-CSC-S-MST-003 Bliding WorksDocument9 pagesG42-LSP-CSC-S-MST-003 Bliding WorksDan SarmientoNo ratings yet

- Method Statement - PilingDocument16 pagesMethod Statement - Pilinguebdennis100% (1)

- (Painting Works) : Inspection and Test PlanDocument2 pages(Painting Works) : Inspection and Test Planrize1159No ratings yet

- Material Handling SOPDocument1 pageMaterial Handling SOPRajesh Sharma100% (1)

- Method of Statement For: Hot WorksDocument9 pagesMethod of Statement For: Hot WorksHussam WaleedNo ratings yet

- Cold Cutting Guideline ChecklistDocument2 pagesCold Cutting Guideline Checklisttahatekri100% (1)

- Safe Work Method For Hydro TestDocument1 pageSafe Work Method For Hydro TestEswar RaoNo ratings yet

- Excavation Safety ProceduresDocument7 pagesExcavation Safety ProceduresHasanuddin HAMIDNo ratings yet

- Blinding and De-Blinding SWSDocument11 pagesBlinding and De-Blinding SWSThái Đạo Phạm Lê100% (1)

- JHA (RO Pump)Document4 pagesJHA (RO Pump)Mohamed Faisal KhanNo ratings yet

- (PDF) 5 - TANK ITP - INSPECTION & TEST PLAN FOR TANKS - Docx - CompressDocument5 pages(PDF) 5 - TANK ITP - INSPECTION & TEST PLAN FOR TANKS - Docx - CompressAnonymous xyZH2OaUVNo ratings yet

- Zee-Method Statement For Construction Steel Platform ErectionDocument8 pagesZee-Method Statement For Construction Steel Platform Erectionzeeshansheikh7No ratings yet

- Work Procedure For Touch Up Painting (Restoration)Document9 pagesWork Procedure For Touch Up Painting (Restoration)ResearcherNo ratings yet

- Blasting Painting Procedure For Structural Steel Rev 00Document17 pagesBlasting Painting Procedure For Structural Steel Rev 00Praful N KNo ratings yet

- Method Statement FOR Painting Works: Revision RecordDocument16 pagesMethod Statement FOR Painting Works: Revision RecordrajatNo ratings yet

- JSA23 Hydro Static Pressure Testing Various Pipe AuxiliariesDocument5 pagesJSA23 Hydro Static Pressure Testing Various Pipe AuxiliariesslmLSU100% (3)

- Method Statement For For Cable Tray and Conduit Installation With Risk AssesmentDocument9 pagesMethod Statement For For Cable Tray and Conduit Installation With Risk Assesmentobasiigwe8499No ratings yet

- Samet Daily Scaffold Safety Inspection ReportDocument1 pageSamet Daily Scaffold Safety Inspection Reportyohanes aprinusNo ratings yet

- BLASTING AND PAINTING PROCEDUREDocument9 pagesBLASTING AND PAINTING PROCEDUREAhmad FadlullahNo ratings yet

- Fire Stop Installation MethodDocument22 pagesFire Stop Installation MethodWahid HusainNo ratings yet

- Industrial Rope Access ChecklistDocument12 pagesIndustrial Rope Access ChecklistPaulNo ratings yet

- Inspection of Testing LaboratoryDocument4 pagesInspection of Testing Laboratorycristina23No ratings yet

- Method Statement For Fabrication and Erection of Piping: Krueng Geukueh, North Aceh, IndonesiaDocument10 pagesMethod Statement For Fabrication and Erection of Piping: Krueng Geukueh, North Aceh, IndonesiaFendik NewbieNo ratings yet

- Ms For Foundation Excavation and Casting.Document6 pagesMs For Foundation Excavation and Casting.botchNo ratings yet

- Hose Testing Doors WindowsDocument6 pagesHose Testing Doors WindowsRavi ValiyaNo ratings yet

- JSA Building WorksDocument9 pagesJSA Building WorksMon Trang Nguyễn100% (1)

- Work Method Statement FOR HSS PQTDocument6 pagesWork Method Statement FOR HSS PQTenels77No ratings yet

- Method Statement Fo Reinforcement Works BlogDocument8 pagesMethod Statement Fo Reinforcement Works BlogMohasin Khan100% (1)

- DSR 2013Document472 pagesDSR 2013Anjaneyulu BodhanapuNo ratings yet

- CAT Group Painting Works QA ProcedureDocument7 pagesCAT Group Painting Works QA ProcedurekbldamNo ratings yet

- Work Method ProceduresDocument37 pagesWork Method ProceduresAnonymous K0fqIO100% (2)

- Painting ProcedureDocument8 pagesPainting ProcedureSunday Paul50% (2)

- QC - 06 Surface Preparation & Painting 2Document6 pagesQC - 06 Surface Preparation & Painting 2mahendraNo ratings yet

- Geomet 321Document2 pagesGeomet 321Garden005No ratings yet

- Negemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Document3 pagesNegemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Khaled GamalNo ratings yet

- One of The Followings Internal UserDocument2 pagesOne of The Followings Internal UserKhaled GamalNo ratings yet

- Account Name Amount: Amount Amount Revenue Description - نايبل اDocument2 pagesAccount Name Amount: Amount Amount Revenue Description - نايبل اKhaled GamalNo ratings yet

- Steel Structure For Tareq - Ain Ghazal Link (BRT) Phase 1 - ProjectDocument15 pagesSteel Structure For Tareq - Ain Ghazal Link (BRT) Phase 1 - ProjectKhaled GamalNo ratings yet

- TUV Hakc CE CWB ABS Rina DB DNV-GL TL TSE: Gas Metal Arc (MAG) Welding Wire Non Alloyed SteelsDocument4 pagesTUV Hakc CE CWB ABS Rina DB DNV-GL TL TSE: Gas Metal Arc (MAG) Welding Wire Non Alloyed SteelsKhaled GamalNo ratings yet

- Work Order / Time Sheet: Client Name: Location: DateDocument1 pageWork Order / Time Sheet: Client Name: Location: DateKhaled GamalNo ratings yet

- AISC - Pub - No - 303 - 16 - Code - of - Standard (Calculation of Weights)Document2 pagesAISC - Pub - No - 303 - 16 - Code - of - Standard (Calculation of Weights)Khaled GamalNo ratings yet

- HLP Painting Inspection ReportDocument10 pagesHLP Painting Inspection ReportKhaled GamalNo ratings yet

- Servisni Manual King 3a5422en-DDocument42 pagesServisni Manual King 3a5422en-DKhaled GamalNo ratings yet

- TDS - Chemflake Classic - English (Uk) - Issued.25.10.2013Document5 pagesTDS - Chemflake Classic - English (Uk) - Issued.25.10.2013Khaled GamalNo ratings yet

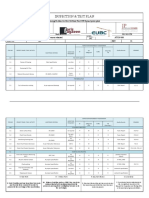

- Inspection and Test Plan: JS19-010 Haddadin Engineering Co. AISC & AWS D1.1 2015Document3 pagesInspection and Test Plan: JS19-010 Haddadin Engineering Co. AISC & AWS D1.1 2015Khaled GamalNo ratings yet

- TDS - Chemflake Classic - English (Uk) - Issued.25.10.2013Document5 pagesTDS - Chemflake Classic - English (Uk) - Issued.25.10.2013Khaled GamalNo ratings yet

- SW 702si: TSE TUV CEDocument2 pagesSW 702si: TSE TUV CEKhaled GamalNo ratings yet

- Standards Approvals & Certificates: Rmrs Ce DNV-GL LR Classnk Tuv BV Abs Rina TL DBDocument2 pagesStandards Approvals & Certificates: Rmrs Ce DNV-GL LR Classnk Tuv BV Abs Rina TL DBKhaled GamalNo ratings yet

- Standards Approvals & Certificates: TL Tuv CWB Abs Hakc Classnk Rina DB Ce BV DNV-GL LR Tse GostDocument3 pagesStandards Approvals & Certificates: TL Tuv CWB Abs Hakc Classnk Rina DB Ce BV DNV-GL LR Tse GostKhaled GamalNo ratings yet

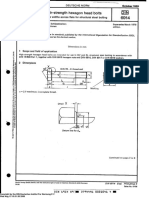

- DIN 6914-1989, High Strenght Hexagon Head BoltsDocument6 pagesDIN 6914-1989, High Strenght Hexagon Head BoltsKhaled GamalNo ratings yet

- Inspection and Test Plan: JS19-010 Haddadin Engineering Co. AISC & AWS D1.1 2015Document3 pagesInspection and Test Plan: JS19-010 Haddadin Engineering Co. AISC & AWS D1.1 2015Khaled GamalNo ratings yet

- DIN 6915-1989, High Strenght Hexagon Head NutsDocument3 pagesDIN 6915-1989, High Strenght Hexagon Head NutsAhmad AshshiddieqyNo ratings yet

- ITP Inspection and Test Plan for Aqaba Screening Project Steel FabricationDocument3 pagesITP Inspection and Test Plan for Aqaba Screening Project Steel FabricationKhaled GamalNo ratings yet

- Negemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Document3 pagesNegemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Khaled GamalNo ratings yet

- Insulated Roof & Wall Panels Ks103 SSF Data Sheet: Microlambri Superlambri SmoothlambriDocument5 pagesInsulated Roof & Wall Panels Ks103 SSF Data Sheet: Microlambri Superlambri SmoothlambriKhaled GamalNo ratings yet

- Non-Conformity Report: Date NCR No.: Sheet: 1/1 Client: Project: Job No: ItemDocument2 pagesNon-Conformity Report: Date NCR No.: Sheet: 1/1 Client: Project: Job No: ItemKhaled GamalNo ratings yet

- Inspection & Test PlanDocument2 pagesInspection & Test PlanKhaled GamalNo ratings yet

- (EW-492) - Flux Cored Arc Welding-Hobart Institute of Welding Technology (Yasser Tawfik)Document106 pages(EW-492) - Flux Cored Arc Welding-Hobart Institute of Welding Technology (Yasser Tawfik)Khaled Gamal100% (1)

- (EW-472) - Shielded Metal Arc Welding-Hobart Institute of Welding Technology (Yasser Tawfik)Document86 pages(EW-472) - Shielded Metal Arc Welding-Hobart Institute of Welding Technology (Yasser Tawfik)Khaled Gamal67% (3)

- API-653-Mar 2016Document7 pagesAPI-653-Mar 2016Khaled Gamal100% (3)

- Weldspec ASME PQRDocument2 pagesWeldspec ASME PQRSunil KumarNo ratings yet

- Section 078100 - Applied FireproofingDocument13 pagesSection 078100 - Applied FireproofingWENDING HUNo ratings yet

- Coating System Standard Ps 28.02: SSPC: The Society For Protective CoatingsDocument6 pagesCoating System Standard Ps 28.02: SSPC: The Society For Protective CoatingsUrbanizacion XochitlanNo ratings yet

- Tender DSRDocument110 pagesTender DSRRakesh ParaliyaNo ratings yet

- Astm d2486Document4 pagesAstm d2486mtnguyenns100% (1)

- Art and Artisans: Production Process, Medium, Technique, CurationDocument12 pagesArt and Artisans: Production Process, Medium, Technique, CurationAngel CastilloNo ratings yet

- D770 - 11 Standard Specification For Isopropyl Alcohol PDFDocument2 pagesD770 - 11 Standard Specification For Isopropyl Alcohol PDFJacques Blueq100% (1)

- CNH - 86628044 - K - MP - 06 - e - Mat0103 (Verniciatura)Document8 pagesCNH - 86628044 - K - MP - 06 - e - Mat0103 (Verniciatura)LucaNo ratings yet

- ANNUAL PROCUREMENT PLAN TITLEDocument95 pagesANNUAL PROCUREMENT PLAN TITLEMisty HughesNo ratings yet

- 2 STR-100KVDocument22 pages2 STR-100KVraj_stuff006No ratings yet

- Materials Used at HomeDocument3 pagesMaterials Used at HomejoannenazarenoNo ratings yet

- MOCK ALE Set 3A - Day 1 Part 2 Answer KeyDocument31 pagesMOCK ALE Set 3A - Day 1 Part 2 Answer KeyROQUENo ratings yet

- Sumo For Panel Technical Data Sheet Rev 1 010122Document6 pagesSumo For Panel Technical Data Sheet Rev 1 010122Nam Hoàng HảiNo ratings yet

- Hempaline Defend 630 AI (Cure 24) v3Document3 pagesHempaline Defend 630 AI (Cure 24) v3Mohamed NouzerNo ratings yet

- Butyl TitanateDocument22 pagesButyl TitanatesidneidecarvalhoNo ratings yet

- Application Guide: Selection of Type EnclosuresDocument20 pagesApplication Guide: Selection of Type EnclosuresAdam BehielsNo ratings yet

- Normas Editadas Netamentes NacionalesDocument245 pagesNormas Editadas Netamentes NacionalesJosé EstorchNo ratings yet

- Cage by Design RetileDocument24 pagesCage by Design RetileShanethebigkid PritchardNo ratings yet

- Plas Con GuideDocument30 pagesPlas Con GuideAlayou TeferaNo ratings yet

- FRP Vs Traditional MaterialsDocument4 pagesFRP Vs Traditional MaterialsPankaj MalviyaNo ratings yet

- Ecc SF 80Document1 pageEcc SF 80longyiequipmentNo ratings yet

- Flaking, Blistering & Cracking: Common Paint Defects CausesDocument13 pagesFlaking, Blistering & Cracking: Common Paint Defects CausesMcDevonNo ratings yet

- Niir Alkyd Resins Technology HandbookDocument2 pagesNiir Alkyd Resins Technology HandbookSanket Panchal67% (3)

- Tempera Grassa:RecipeDocument5 pagesTempera Grassa:RecipeAnonymous Y2qwEuA100% (1)

- Management FinalDocument13 pagesManagement FinalAdil Javed KhanNo ratings yet

- Sikafloor 144Document8 pagesSikafloor 144Jessica CaldwellNo ratings yet

- Product Catalogue 2018Document19 pagesProduct Catalogue 2018Anonymous EPSHB9tXZNo ratings yet

- BOYSEN Product Presentation 2023 v1.1Document75 pagesBOYSEN Product Presentation 2023 v1.1Andrew MarasiganNo ratings yet

- D 1700-00 Simafix Sealer WBDocument1 pageD 1700-00 Simafix Sealer WBNanda Hendra PratamaNo ratings yet

- Rembrandt Aquarel 0519 Eng LowresDocument36 pagesRembrandt Aquarel 0519 Eng LowresJose ValenzuelaNo ratings yet

- Amtex Re-2Document2 pagesAmtex Re-2CHIRE SARAYASI MANUELNo ratings yet