Professional Documents

Culture Documents

ICS Components

Uploaded by

Nageswara Rao NanduriOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ICS Components

Uploaded by

Nageswara Rao NanduriCopyright:

Available Formats

Components

Wall Panels

Maximum width 4'-0" (120 cm). Maximum height 16'-0" (480

cm). Panel thicknesses are 3" (7.6cm), 4 1/2" (11.4 cm), and 6

1/2" (16.3 cm). ICS wall panels are built around present

construction normal standards. The most common panel is 4'-0"

(120 cm) x 8'-0" (240 cm) x 4 1/2" (11.3 cm). Structural

components are embedded into each panel providing extra

strength and ease of erection. The R-value is approximately R-7

per inch of thickness. Locking devices are embedded at specific

intervals providing you with a simple, easy method of securing

the panels together. Consequently, field labor is significantly

reduced.

Door and window openings can be pre-engineered into the

panels and foamed-in-place, reducing air infiltration and thermal

breeches.

ICS-SIPs reduce construction site waste and material theft.

90 Corner Panels

The ICS Corner Panel is a one-piece unit. Each leg of the

corner has a maximum of 2'-4 1/2" (72 cm) outside dimension

and a maximum height of 12'-0" (360 cm). Panel thicknesses

are 3" (7.6cm), 4 1/2" (11.4 cm), and 6 1/2" (16.3 cm). The

structural capabilities far exceed any traditional building method

or other joining methods using two insulated panels butted

together to form a corner. The stability of this one-piece

construction provides additional strength and eliminates panel

racking during erection. Locking devices are embedded at

specific intervals providing you with a simple, labor-saving, easy

method of securing the panels together. The insulation is

injected polyurethane foam injected at a density of 2.5 pounds

per cubic foot giving you an insulating factor of approximately R7 per inch of thickness. In a 4 1/2" (11.4 cm) Corner Panel from

ICS you have an insulation value of R-28. The insulation value

of the 6 1/2" (16.3 cm) panel is R-42.

135 Corner Panels

The ICS Angle Panel is a one-piece unit. This unique panel

allows you to enhance your building architecture while providing

structural and insulating capabilities far higher than traditional

building methods or other joining methods using insulated

panels to form an angle. Locking devices are embedded at

specific intervals providing you with a simple, labor-saving, easy

method of securing the panels together. The insulation is highR-value polyurethane foam injected at a density of 2.5 pounds

per square inch giving an insulating value of R-7 per inch of

thickness. The 4 1/2" (11.3 cm) thick Angle Panel from ICS

provides an R-value of 28. The 6 1/2" (16.3 cm) thick panel

provides R-42.

Roof Panels and Floor Panels

ICS Roof Panels can be manufactured in two thicknesses,

depending on your insulating requirements:

4 1/2"(11.3 cm) = R28+

6 1/2" (16.3 cm) = R42+

Maximum panel length is 16'-0" (480 cm).

Maximum panel width is 4'-0" (120 cm).

The insulation is high-R-value polyurethane foam injected at a

density of 2.5 pounds per cubic foot.

Insulated Cladding Panels

ICS Insulated Cladding Panels are designed to add insulation to

an existing structure over existing walls and roofs, and can be

manufactured in nearly any thickness, depending on your

insulating requirements. They have a substrate, such as OSB,

on one side only. The substrate serves as a nail-base for

various shingle or siding applications.

R-7 per inch of thickness

Maximum panel length is 16'-0" (480 cm).

Maximum panel width is 4'-0" (120 cm).

The insulation is high-R-value polyurethane foam injected at a

density of 2.5 pounds per cubic foot.

Cam-Locks

Concentric steel cam-locking devices are embedded into each

panel. These eliminate cutting and nailing panels together.

They provide a positive panel seat helping in alignment when

joining the panels. The engineered panel fastener offers

strength and economy. They save significant field labor

compared to spline connection methods.

You might also like

- Planned by Asta Powerproject: 1 Design Stages 255d 28/07/14 07/08/15Document1 pagePlanned by Asta Powerproject: 1 Design Stages 255d 28/07/14 07/08/15Manoj KumarNo ratings yet

- Baison 1Document24 pagesBaison 1mohanty_anantakumar6332No ratings yet

- Branz Advisory Trower PartitionsDocument6 pagesBranz Advisory Trower PartitionsMatt Stubbins100% (1)

- Sound Curtains: Specializing in Acoustics, Noise & Vibration ControlDocument6 pagesSound Curtains: Specializing in Acoustics, Noise & Vibration ControlNguyễn LinhNo ratings yet

- Enoise Control Sound Curtains Brochure PDFDocument6 pagesEnoise Control Sound Curtains Brochure PDFNguyễn LinhNo ratings yet

- Seminar On: By-Monika SmritiDocument26 pagesSeminar On: By-Monika SmritiJaishree BaidNo ratings yet

- Seminar On: By-Monika SmritiDocument26 pagesSeminar On: By-Monika SmritiKompal SinhaNo ratings yet

- Requirements of A Good PartitionDocument11 pagesRequirements of A Good PartitionShraddha Bahirat100% (1)

- Exterior Wall Finishes BCDocument42 pagesExterior Wall Finishes BCPreene Dias officialNo ratings yet

- Cerramientos Livianos - Usg - Sheetrock Brand Ultralight PanelsDocument3 pagesCerramientos Livianos - Usg - Sheetrock Brand Ultralight PanelsALBEX CELISNo ratings yet

- AP - 325 - Buiilding Material Science-V: Assignment No: 3Document11 pagesAP - 325 - Buiilding Material Science-V: Assignment No: 3Tannu SharmaNo ratings yet

- BISON PANEL Product GuideDocument24 pagesBISON PANEL Product Guideg_periwal_pune9635No ratings yet

- Interior Wall FinishesDocument16 pagesInterior Wall FinishesPriyesh Dubey100% (1)

- Hiraga Onkens English PDFDocument6 pagesHiraga Onkens English PDFbeepx1No ratings yet

- 2010 Product Presentation For 3d PanelDocument44 pages2010 Product Presentation For 3d PanelsageschnookNo ratings yet

- Acoustic Building Materials CatalogsDocument12 pagesAcoustic Building Materials CatalogsOsam HassenNo ratings yet

- Low Cost Acoustic MaterialsDocument11 pagesLow Cost Acoustic Materialsarpanaroy1100% (2)

- APA Rated Sheathing & Structural 1 Sheathing-LP OSBDocument5 pagesAPA Rated Sheathing & Structural 1 Sheathing-LP OSBhoojzteNo ratings yet

- Acoustic Materials and Their Different TypesDocument8 pagesAcoustic Materials and Their Different TypesMimi EDCNo ratings yet

- Polymax Accoustic Design GuideDocument11 pagesPolymax Accoustic Design GuidempwasaNo ratings yet

- PARTITION WALL - Room Divider: What Is Parttion WallDocument5 pagesPARTITION WALL - Room Divider: What Is Parttion WallShraddha BahiratNo ratings yet

- Bank BOQ 2Document14 pagesBank BOQ 2ovaishashmiNo ratings yet

- 1 37753 BR Egger-Holzbau enDocument28 pages1 37753 BR Egger-Holzbau enstefan hergheligiuNo ratings yet

- Kinetics Noise Control: Design Series 90Document2 pagesKinetics Noise Control: Design Series 90onspsnonsNo ratings yet

- Acoustic Panels PDFDocument10 pagesAcoustic Panels PDFAkanksha GuptaNo ratings yet

- Stucco-Facade MaterialDocument53 pagesStucco-Facade MaterialHarsh AryaNo ratings yet

- Bison Panel Board: PartitionsDocument2 pagesBison Panel Board: PartitionsaaryasaiNo ratings yet

- Material and Construction CA1Document20 pagesMaterial and Construction CA1Amit DharaNo ratings yet

- Interior Wall FinishesDocument16 pagesInterior Wall FinishesPriyesh DubeyNo ratings yet

- Drveni Zidovi PDFDocument35 pagesDrveni Zidovi PDFMartinJankovićNo ratings yet

- Nonstructural Partition WallsDocument13 pagesNonstructural Partition WallsDeemaNo ratings yet

- Flexible Resin Mouldings For Curved Applications: Interior or Exterior ApplicationsDocument2 pagesFlexible Resin Mouldings For Curved Applications: Interior or Exterior ApplicationsjewellyaNo ratings yet

- Durable and Versatile, Ultra-Thin, Prestressed Precast Panels - at A Fraction of The WeightDocument12 pagesDurable and Versatile, Ultra-Thin, Prestressed Precast Panels - at A Fraction of The WeightAfzal100% (1)

- Alternative Wall Technologies-Sandwitch PanelsDocument14 pagesAlternative Wall Technologies-Sandwitch PanelsDiya MakanurNo ratings yet

- Acoustic Wall System: Application NotesDocument2 pagesAcoustic Wall System: Application NotesYaniNo ratings yet

- "The Home" 1.0 Executive SummaryDocument3 pages"The Home" 1.0 Executive SummarydeepaletchumiNo ratings yet

- TN28B Brick Veneer Steel Stud WallsDocument15 pagesTN28B Brick Veneer Steel Stud WallsKen SuNo ratings yet

- Design No. L521: June 11, 2021Document19 pagesDesign No. L521: June 11, 2021Issam El ChamiNo ratings yet

- Material Portofolio: Design of Audi Acoustic FlooringDocument12 pagesMaterial Portofolio: Design of Audi Acoustic FlooringthunneNo ratings yet

- MCT Sem 4 PanellingDocument22 pagesMCT Sem 4 PanellingKhushi ChauhanNo ratings yet

- Data Sheet For Al 800 AltairDocument4 pagesData Sheet For Al 800 Altairirfan vpNo ratings yet

- EnerSIP Construction ManualDocument53 pagesEnerSIP Construction ManualIvan Klyuchka100% (2)

- انشاء مباني ٢ 3Document9 pagesانشاء مباني ٢ 3ach.aseelalwakerNo ratings yet

- Parition WorksDocument46 pagesParition WorkslavekushNo ratings yet

- Keywords: Structural Insulated Panels, Thermal Insulation, Sandwich PanelDocument19 pagesKeywords: Structural Insulated Panels, Thermal Insulation, Sandwich PanelAlSt BondNo ratings yet

- Acoustical Materials 2Document25 pagesAcoustical Materials 2Pratik RajNo ratings yet

- Raised Heel TrussesDocument8 pagesRaised Heel TrussesPatrice AudetNo ratings yet

- GT Exhaust SystemDocument5 pagesGT Exhaust SystemKarthy GanesanNo ratings yet

- DOKA FormworkDocument7 pagesDOKA Formworkhenok hailemichaelNo ratings yet

- DOKA FormworkDocument7 pagesDOKA Formworkhenok hailemichaelNo ratings yet

- Boism PanelDocument24 pagesBoism PanelhipreyashNo ratings yet

- Acoustic Treatments Acoustic Treatments: Understanding Noise Transmission Between UnitsDocument4 pagesAcoustic Treatments Acoustic Treatments: Understanding Noise Transmission Between UnitsAnonymous LKUkoWqjoNo ratings yet

- Ceiling Support System and CeilingsDocument24 pagesCeiling Support System and CeilingsRoland CepedaNo ratings yet

- Timber m2Document47 pagesTimber m2Ankur SharmaNo ratings yet

- Acoustical Treatment RESIDENCEDocument20 pagesAcoustical Treatment RESIDENCEritikaritikaNo ratings yet

- Acoustical Material Submitted By: Rewa Marathe Pallavi ChitnisDocument57 pagesAcoustical Material Submitted By: Rewa Marathe Pallavi ChitnisritikaritikaNo ratings yet

- Types of Materials: - Sound Absorbers - Sound Diffusers - Noise Barriers - Sound ReflectorsDocument11 pagesTypes of Materials: - Sound Absorbers - Sound Diffusers - Noise Barriers - Sound ReflectorsrahsanjiNo ratings yet

- False Ceiling: Types and Methods of ConstructionDocument26 pagesFalse Ceiling: Types and Methods of Constructionswarna ravi100% (1)

- Family Handyman Big Book of ProjectsFrom EverandFamily Handyman Big Book of ProjectsFamily HandymanNo ratings yet

- PropertiesandapplicationsoffoamedconcreteareviewDocument17 pagesPropertiesandapplicationsoffoamedconcreteareviewEJ KooNo ratings yet

- Redi Balcony DrainDocument1 pageRedi Balcony DrainMazen KNo ratings yet

- Chilled Beam SystemsDocument3 pagesChilled Beam SystemsIppiNo ratings yet

- KNAUF MP75 Product LiteratureDocument4 pagesKNAUF MP75 Product Literatureindoryo shinNo ratings yet

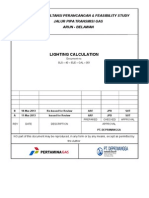

- Lighting CalculationDocument13 pagesLighting Calculationmringkel100% (1)

- Daniel Tian Li: Concrete Column Design Based On ACI 318-05Document3 pagesDaniel Tian Li: Concrete Column Design Based On ACI 318-05Mirko Aliaga100% (1)

- KDS142001 File 20180730Document49 pagesKDS142001 File 20180730최광민No ratings yet

- Dopet: Section 1 GeneralDocument15 pagesDopet: Section 1 GeneralSai Ram NadimuthuNo ratings yet

- English BondDocument7 pagesEnglish BondJEN YEE LONGNo ratings yet

- Topics Seminar Topics For Civil Engineering StudentsDocument6 pagesTopics Seminar Topics For Civil Engineering StudentsawasarevinayakNo ratings yet

- LacDocument6 pagesLacJason McCaffreyNo ratings yet

- Icc Evaluation Placa TygDocument3 pagesIcc Evaluation Placa TygOscar LeonNo ratings yet

- Mahindra Luminare PDFDocument18 pagesMahindra Luminare PDFJyoti DhingraNo ratings yet

- Posi-Strut™ Truss Systems Manual: June 2008Document39 pagesPosi-Strut™ Truss Systems Manual: June 2008Như NguyễnNo ratings yet

- Detailed Cost Estimates: Preliminaries/ General RequirementsDocument5 pagesDetailed Cost Estimates: Preliminaries/ General RequirementsEmileandro Perito QuindiaganNo ratings yet

- Class-1-HVAC GLOSSARYDocument7 pagesClass-1-HVAC GLOSSARYAmrit BaniyaNo ratings yet

- Sanitary Materials From BoilerDocument60 pagesSanitary Materials From BoilerILIA SHEKELASHVILINo ratings yet

- The Difference Between Nfpa 54 and MS930Document7 pagesThe Difference Between Nfpa 54 and MS930Daniel ShahNo ratings yet

- Top 100 Concrete Technology Interview Questions and AnswersDocument49 pagesTop 100 Concrete Technology Interview Questions and Answers210140106013.zaheeransariNo ratings yet

- Gantt ChartDocument10 pagesGantt ChartAyesha KholaNo ratings yet

- p2 - 221841 - MAINTENANCE ACMVDocument36 pagesp2 - 221841 - MAINTENANCE ACMVVin BdsNo ratings yet

- Simulation of Masonry Wall Using Concrete Damage Plasticity ModelDocument4 pagesSimulation of Masonry Wall Using Concrete Damage Plasticity Modelحيدر الهنداويNo ratings yet

- DBH Timber TreatmentDocument9 pagesDBH Timber TreatmentSam LeungNo ratings yet

- Bill of Materials: Item Description EarthworksDocument3 pagesBill of Materials: Item Description EarthworksjoemarNo ratings yet

- Build 160 38 Design Right Weatherboards Above Brick VeneerDocument3 pagesBuild 160 38 Design Right Weatherboards Above Brick VeneerKesavan DhuraiNo ratings yet

- Unicem BrochureDocument20 pagesUnicem BrochureVengatesh HariNo ratings yet

- On Bubble Deck SlabDocument16 pagesOn Bubble Deck SlabChalla RamanamurtyNo ratings yet

- Nikhil Comforts Interiors' ProfileDocument28 pagesNikhil Comforts Interiors' Profilenikhil_comfortsNo ratings yet