Professional Documents

Culture Documents

US20060108767 - Patent 1

Uploaded by

Abhijit RoyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

US20060108767 - Patent 1

Uploaded by

Abhijit RoyCopyright:

Available Formats

US 20060108767Al

(19) United States

(12) Patent Application Publication (10) Pub. N0.: US 2006/0108767 A1

Susko

(54)

(43) Pub. Date:

POWER PEDAL FOR A BICYCLE

(57)

May 25, 2006

ABSTRACT

(76) Inventor: Rudolf Susko, Vancouver (CA)

A novel drive mechanism for a bicycle, featuring a scissor

Correspondence Address:

assembly de?ned by plurality of arms pivotally intercon

RUDOLF SUSKO

nected in an expandable sequence. The scissor assembly is

1110-1500 HOWE STREET

attached pivotally to a frame on both sides and via a rigid

VANCOUVER, BC V6Z 2N1 (CA)

slot attached pivotally to pedal cranks Whereby permitting

cranks oscillating motion. The cranks reciprocal oscillating

motion is transferred by the assembly into a linear pulling

(21) Appl' NO:

.

10/993955

(22) Flled'

force connected to a drive Wheel axle, equipped With a

NOV 22 2004

Publication Classi?cation

freewheeling reel, by a ?exible ligament spiraled in the reel.

The e?iciency of assemblys poWer transfer kinetics lessens

required human force, in addition, the speed is substantially

(51)

Int, Cl,

362M 5/00

362M 1/00

(52)

increased because the cranks motion is con?ned to the most

(200601)

(200601)

US. Cl. ............................................................ .. 280/253

1D

efficient frontal segment of the 360-degree orbit Whereby

eliminating back-upward segment of the circular motion

Pedals

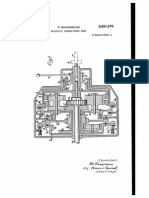

Patent Application Publication May 25, 2006 Sheet 1 0f 2

FIG.1

US 2006/0108767 A1

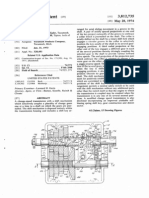

Patent Application Publication May 25, 2006 Sheet 2 0f 2

FIG.2

FIG.3

US 2006/0108767 A1

May 25, 2006

US 2006/0108767 A1

POWER PEDAL FOR A BICYCLE

BACKGROUND OF THE INVENTION

[0007] It is another object of the present invention to

improve substantially the speed of a vehicle/bicycle. The

pedal sloW motion is transmitted by the scissor-type units

into a rapid pulling force enabling a substantial improve

[0001] This invention relates to a poWer-transmitting

device for a vehicle. More speci?cally, the present invention

ment in the speedilimited on the conventional circular

relates to a neW drive mechanism for transferring power

from the pedals to the rear Wheel of a bicycle.

force.

[0002] The use of bicycle drive mechanisms is Well knoWn

in the prior art. Bicycle drive mechanisms devised and

utilized are knoWn to consist of familiar, expected and

obvious structural con?gurations. The prior art is croWded

With numerous designs Which have been developed for the

eliminate cumbersome back-upWard retracting portion of

circular motion pedals and permitting only effective front

motion pedals by achievable maximum rpm of the human

[0008]

Still another object of the present invention is to

doWnWard segment of the pedal lever rotation of less than

360-degree.

ful?llment of countless objectives and requirements.

[0009] The pedal assembly is suitably siZed and adapted

[0003] Known prior art bicycle drive mechanisms include

the rider position. It features simplicity, inexpensive design,

U.S. Pat. NO. 4,564,206; U.S. Pat. NO. 6,749,211; U.S. Pat.

NO. 6,764,089; U.S. Pat. NO. 6,779,807; and U.S. Pat. NO.

tenance burden.

for the use on existing bicycle-type frames Without changing

eliminates unnecessary moving parts and thus lessens main

6,783,139;

[0004]

The objective of a conventional bicycle pedal con

BRIEF DESCRIPTION OF THE DRAWINGS

?guration is to exert a pulling force to the endless chain by

circular motion of the pedal lever. Pedals Work on lever

principle Wherein the net lever arm is the difference betWeen

embodiment, is described With reference to the draWings in

Which:

the pedal length and the radius of the driving sprocket.

Improving this ratio for circular motion pedals is limited by

the human leg anatomy. Circular motion of the pedal is

applied on a bicycle.

further restricted by the number of revolution per minute

that human can perform. The prior art is predominantly

in a retracted position.

concerned in improving the easiness of ride using less

human poWer, enhancing the speed and improving cumber

some complexity and maintenance. While these devices

[0010] The invention, as exempli?ed by a preferred

[0011]

[0012]

FIG. 1 is a side vieW illustrating the poWer pedal

FIG. 2 is a side vieW illustrating the poWer pedal

[0013] FIG. 3 is a side vieW illustrating the poWer pedal

in a depressed position.

ful?ll their respective, particular objectives and require

ments, the aforementioned patents do not disclose features

claimed by the present invention. In these respects, the drive

DESCRIPTION OF THE PREFERRED

EMBODIMENTS

mechanism according to the present invention substantially

departs from the conventional concepts and designs of the

prior art, and in so doing provide an apparatus primarily

FIG. 1, one embodiment of the poWer pedal is illustrated on

developed for a novel poWer transfer from the pedals to the

rear Wheel of a bicycle.

SUMMARY OF THE INVENTION

[0005] The present invention comprises of a novel pedal

mechanism de?ned by a scissor-type assembly. A pedal

lever, being integral With the scissor-type assembly, is

[0014]

Referring noW to the draWings and in particular to

a bicycle. The omission of the detail de?nition and descrip

tion of the bicycle does not preclude from the understanding

of preferred embodiments. HoWever, for the purpose of the

present invention embodiments, a cycle-type vehicle

includes at least tWo Wheels from Which one is a driven

Wheel 1 With an axle 2 and a frame 3. The frame 3

alternatively has supports or struts commonly provided on

bicycles, or other desired structural members, etc.

nected scissor-type units desired expansion and contraction.

[0015] The preferred embodiments of the present inven

tion include tWo scissor-type pedal assembly 4 positioned in

TWo points of pivoted attachment to the frame include a

?xed shaft, positioned on the frame in frontal relation to the

a mirror image on both sides of the frame, although the

illustrations refer mostly to one. The pedal assembly 4 is

poWered Wheel axle, and a slot disposed longitudinally from

the shaft permitting slidable attachment. It further comprises

pivotally mounted on a stationary shaft 8 on both sides of the

frame 3, more or less in the vicinity Where the conventional

a novel Wheel driver de?ned by a freeWheel reel coaxially

engaged on the rear Wheel axle. A linkage, for example a

pedals are mounted. Pedal assembly units are de?ned by

pivotally interconnected ?at rods in a scissor-like fashion

being made preferably from a metal or metal alloy material.

pivoted on the frame in a con?guration enabling intercon

draW cable attached to the poWer pedal assembly, is spiraled

in a single plane on the reel. Whereby the pedal assembly

draW force causes Wheel rotation by unWinding cable spiral

from the reel. Pedal levers are arranged and con?ned to the

most ef?cient front-doWnWard segment of the 360-degree

orbit and are reciprocally retracted to the upWard position by

retraction means including a pulley. The present invention

does not preclude the use of a Wheel hub transmission.

[0006] It is an object of the present invention to alleviate

the human force requirements on the foot pedal by ef?cient

transfer of the pedal lever force for poWering the Wheel.

The siZe of assembly arms can be variable from unit to unit

and arms are suitably siZed for the engagement range

betWeen the shaft 8 and the Wheel axle 2. For example, if the

above-mentioned distance is 25 inches and each arm length

is four inches then only six interconnected full units Would

suf?ce and a linkage 6 de?ned herein by a draW cable

accounts for the difference, as shoWn in FIG. 2, for fully

retracted pedal position.

[0016] The leverage of the pedal is given by the position

of the fulcrum being integral With a pivot 12 Where the ?rst

May 25, 2006

US 2006/0108767 A1

unit arm 10, de?ned by a pedal lever, is interconnected With

he second arm 11. The leverage of the pedal lever 10, for

example of 4:1, indicates that the human force on the foot

pedal 14 is four times lesser than the force provided by the

shaft 8 and the second arm pivot 13 on the draW cable 6. The

second arm 11 is longer then the pedal lever 10 segment

from the pivot 12 to the shaft 8. This arrangement makes the

pivot 12 eccentrically positioned and its location determines

the moving range of the pedal lever 10 from the upper

retracted position as shoWn in FIG. 2 to fully depressed

position as seen in FIG. 3. The front-doWnWard segment of

the 360-degree potential orbit around the shaft 8 is recog

poWered Wheel in a predictable direction and causes inverse

rotation of freeWheel reel 5 on the other side and thus

reciprocal upWard retraction of respective pedal levers 10.

[0021] The actual length of cable 6 is determined by the

distance from the last unit of fully depressed pedal lever 10,

as illustrated in FIG. 3, on one side to fully retracted pedal

in FIG. 2 on the other side and the required siZe of the spirals

15 diameter. This can easily be established by those skilled

in the equipment-manufacturing ?eld. Cable 6 is preferably

made from a steel rope covered With plastic layer similar to

a commonly used cable in pulley-type exercise equipment.

niZed to be the most ef?cient range. Pedal lever 10, con

[0022] HoWever, it should be appreciated that the present

structed similar to the conventional bicycle pedal levers, is

rotatably mounted on the stationary shaft 8 and includes

conventional foot pedals 14 rotatably mounted thereon.

invention is expressly not limited to these embodiments. For

instance, the retraction can be accomplished, in absence of

the pulley 7, by a coil spring engaged on the reel 5 on both

[0017] A slot 9 is rigidly Welded at the bottom of the

stationary shaft 8 enabling perpendicular slidable move

ments of the second arm pivot 13 engaged in the slot 9. Its

sides enabling independent pedal 10 movements and retrac

tion. Furthermore the freeWheel reel 5 can have a different

con?guration including an arrangement for various spiral 15

length is determined by the siZe of engaging arms. Applied

siZes and thus de?ning a transmission.

force on pedal 14 moves the pivot 13 aWay from the shaft 8

[0023] The invention is capable of other embodiments and

of being practiced and carried out in various Ways. Also, it

is to be understood that the phraseology and terminology

employed herein are for the purpose of description and

should not be regarded as limiting. As such, those skilled in

the art Will appreciate that the conception, upon Which this

in the con?nement of the slot 9, Whereby the pedal assembly

4 scissor units are rapidly closing horiZontally and draWing

cable 6 as illustrated in FIG. 3. Alternatively, the slot 9 can

be disposed from the stationary shaft 8 horizontally toWards

the Wheel axle 2. In this con?guration, the pivot 12 is

integral With the shaft 8 and the middle pivot of the second

unit is engaged slidably in the horiZontally disposed slot 9.

[0018] A rotating driver 5, herein de?ned by a freeWheel

reel having capability of moving in one direction, is rotat

ably engaged on the Wheel axle 2 on both sides of the Wheel

1 and drives the Wheel 1 one direction similar to the

conventional sprocket system. The reel 5 is made preferably

from a light, strong material like aluminum or other metal

alloy or plastic. Width of the reel 5 is relatively narroW and

dependent on the thickness of the cable 6 in order to ?t only

couple of single plane spirals 15 on the reel 5 hub.

[0019] The conventional circular motion pedals are dis

posed on each side in opposite direction. The manual poWer

on the pedal is exerted on a front-doWnWard portion of the

cycle and the pedals are retracted by the back-upWard

motion. The present invention pedal levers 10 are both

disposed in frontal direction for a front-doWnWard reciprocal

operation and front-upWard reciprocal retraction. This

arrangement eliminates the laborious back-upWard retrac

tion of the full cycle classic pedals.

[0020] Retraction means 7, as shoWn in FIG. 1, in the

present embodiment is a pulley secured on the frame 3

enabling a reciprocal retraction of the pedal lever 10 on both

sides of the frame by being engaged With cable 6 departing

from each reel 5. Cable 6 is secured on the reel 5 hub and

forms a double spiral con?guration each oriented in opposite

direction so that one end exits the reel 5 at the top for

adjustable connection to the pedal assembly 4 and the other

end exits the reel 5 at the bottom for engaging the pulley 7

as seen in FIG. 1. This arrangement provides an inverse

rotation of respective freeWheel reels 5 from each side of the

Wheel. Depressed pedal lever 10 on one side rotates the

disclosure is based, may readily be utiliZed as a basis for the

designing of other structures, methods and systems for

carrying out the several purposes of the present invention. It

is important, therefore, that the claims be regarded as

including such equivalent constructions insofar as they do

not depart from the spirit and scope of the present invention.

What is claimed is:

1-10. (canceled)

11. A drive mechanism for a bicycle having partially

rotating pedal cranks, comprising:

a rigid slot being disposed longitudinally from a frame for

slidable engagement;

a scissor assembly de?ned by plurality of arms pivotally

interconnected in expandable sequence being attached

pivotally to the frame and slidably to the rigid slot and

via the slot being connected to the pedal cranks per

mitting the cranks rotating partially, Whereby transfer

ring the pedal cranks force into the linear pulling force;

and

a ?exible ligament connecting the scissor assembly to a

driven Wheel axle arranged for causing rotary motion of

the Wheel.

12. The drive mechanism of claim 11, being positioned on

both side of the frame in mirror image includes a pulley

mounted on the frame and engaged by the ?exible ligament

extending from the Wheel axle from each side of the frame

and thus causing reciprocal cranks movement.

13. The drive mechanism of claim 11, Wherein the Wheel

axle includes a freeWheeling reel and the ligament being

spiraled in the reel.

You might also like

- United States: (12) Patent Application Publication (10) Pub. No.: US 2015/0051052 A1Document8 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2015/0051052 A1Adarsh Avaneesh KamillaNo ratings yet

- United States Patent: Gow (10) Patent N0.: (45) Date of PatentDocument5 pagesUnited States Patent: Gow (10) Patent N0.: (45) Date of PatentAdam SalehNo ratings yet

- European Patent Specification: Optimizing Guidance of Railway VehiclesDocument7 pagesEuropean Patent Specification: Optimizing Guidance of Railway VehiclesAlejandro Copete MorilloNo ratings yet

- Variable Speed Transmission for VehiclesDocument10 pagesVariable Speed Transmission for VehiclesFernandoNo ratings yet

- US2631476Document17 pagesUS2631476Stefan IlicNo ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2011/0192672 A1Document14 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2011/0192672 A1Sahaya GrinspanNo ratings yet

- Other Mechanisms: Looking For GATE Preparation Material? Join & Get Here Now!Document7 pagesOther Mechanisms: Looking For GATE Preparation Material? Join & Get Here Now!Akash SoniNo ratings yet

- EP09166154NWA1Document10 pagesEP09166154NWA1maes.daan1No ratings yet

- United States Patent (19) : Cruise Et Al. (11) Patent NumberDocument8 pagesUnited States Patent (19) : Cruise Et Al. (11) Patent NumberOmkar SharmaNo ratings yet

- Project ZDocument31 pagesProject ZADITYANo ratings yet

- Friction Mechanism for ClockDocument3 pagesFriction Mechanism for ClockjoycebaylonNo ratings yet

- Chain Less BicycleDocument20 pagesChain Less BicycleSankalp HiremathNo ratings yet

- US20120024613A1Document12 pagesUS20120024613A1Praveen DNo ratings yet

- Universal JointDocument17 pagesUniversal Jointakmalzuhri96No ratings yet

- July 9, 1968 T M. A. Cardoso 3,391,746: Helicopter Control System Filed May 15, 1967 3 Sheets-Sheet 1Document7 pagesJuly 9, 1968 T M. A. Cardoso 3,391,746: Helicopter Control System Filed May 15, 1967 3 Sheets-Sheet 1rte678No ratings yet

- Analysis of Piston-Crank System Balancing in V-VR Engines: Sławomir WierzbickiDocument8 pagesAnalysis of Piston-Crank System Balancing in V-VR Engines: Sławomir WierzbickiNourTarekHassenNo ratings yet

- Chapter 8. Other MechanismsDocument8 pagesChapter 8. Other MechanismsAshish SinglaNo ratings yet

- Design and Fabrication of Shaft Driven BicycleDocument46 pagesDesign and Fabrication of Shaft Driven BicycleNishanth Krishnan80% (10)

- Chain Less BicycleDocument46 pagesChain Less BicycleShubham PatilNo ratings yet

- Fabrication of A Bicycle Without A ChainDocument6 pagesFabrication of A Bicycle Without A ChainFranklin Delano JuniorNo ratings yet

- Reduce film shift timeDocument4 pagesReduce film shift timeFred JohnsonNo ratings yet

- Differential Gear System Mini Project - ReportDocument40 pagesDifferential Gear System Mini Project - ReportSalman Saifuddin84% (25)

- Electric Hub MotorDocument6 pagesElectric Hub Motorirctcsbt6bimblikipilNo ratings yet

- July 26, 1966 R. Mowatt-Larssen Etal 3,262,402 IDocument13 pagesJuly 26, 1966 R. Mowatt-Larssen Etal 3,262,402 IKrozeNo ratings yet

- Chapter No 2 Methodology: Antireverse DifferentialDocument32 pagesChapter No 2 Methodology: Antireverse DifferentialDEEPAK CNo ratings yet

- Four-Speed Transmission Shift MechanismDocument18 pagesFour-Speed Transmission Shift MechanismJoão Paulo Canto RibeiroNo ratings yet

- Monorail - US4996928Document8 pagesMonorail - US4996928Rob ZelNo ratings yet

- Camera Slider PatentDocument19 pagesCamera Slider PatentjaimepajarolocoNo ratings yet

- Mechanical ActuatorsDocument39 pagesMechanical ActuatorsKashif UsmanNo ratings yet

- Design of A Two-Stage Cycloidal Gear Reducer WithDocument14 pagesDesign of A Two-Stage Cycloidal Gear Reducer WithAlejandro ChavezNo ratings yet

- Article 0001 Ravigneaux Planetary TransmissionDocument9 pagesArticle 0001 Ravigneaux Planetary Transmissionthisisjinesh100% (1)

- Design & Fabrication of Shaft Drive Bicycle: Project Members: Abishek PDocument18 pagesDesign & Fabrication of Shaft Drive Bicycle: Project Members: Abishek Pameer kannanNo ratings yet

- How To Apply Example Patent Application enDocument8 pagesHow To Apply Example Patent Application endawit alemzewdNo ratings yet

- Mass College ProjectDocument68 pagesMass College ProjectGLOBAL INFO-TECH KUMBAKONAMNo ratings yet

- Experiment No. 5 Objective: Four Bar Mechanism (Fig 5.1)Document6 pagesExperiment No. 5 Objective: Four Bar Mechanism (Fig 5.1)Waqas IbrahimNo ratings yet

- Hutchinson Mfg. Co. v. Mayrath, 192 F.2d 110, 10th Cir. (1951)Document6 pagesHutchinson Mfg. Co. v. Mayrath, 192 F.2d 110, 10th Cir. (1951)Scribd Government Docs100% (1)

- Boite Seamless XtracDocument13 pagesBoite Seamless Xtracdudule01No ratings yet

- United States Patent (19) : Brown (45) Date of PatentDocument9 pagesUnited States Patent (19) : Brown (45) Date of Patentapsint12No ratings yet

- Hubless WheelDocument34 pagesHubless WheelAbhinavTiwariNo ratings yet

- TransmissionDocument26 pagesTransmissionVik PatelNo ratings yet

- Tripod Joint and Drive ShaftDocument10 pagesTripod Joint and Drive ShaftArnob DasNo ratings yet

- Chapter 6 CuDDocument20 pagesChapter 6 CuDMukesh BohraNo ratings yet

- Damping device for limiting trailer yaw motionsDocument12 pagesDamping device for limiting trailer yaw motionsErkanAksoyluNo ratings yet

- Pour Principles of Mechanics. Belt, Chain, Rope, Foot Treadle andDocument5 pagesPour Principles of Mechanics. Belt, Chain, Rope, Foot Treadle andPrasanna GopalrathinamNo ratings yet

- Mechanical principles and drivesDocument5 pagesMechanical principles and drivesRobinson GarciaNo ratings yet

- R.M. Van Druten, P.G. Van Tilborg, P.C.J.N. Rosielle, M.J.W. SchoutenDocument6 pagesR.M. Van Druten, P.G. Van Tilborg, P.C.J.N. Rosielle, M.J.W. SchoutenAjay ChandranNo ratings yet

- Project ReportDocument5 pagesProject ReportAshley Sam100% (1)

- Two-Axis Motion Mechanism with Reduced BacklashDocument10 pagesTwo-Axis Motion Mechanism with Reduced BacklashNile_JockeyNo ratings yet

- United States Patent: Blahnik (45) Date of Patent: Jun. 13, 2006Document16 pagesUnited States Patent: Blahnik (45) Date of Patent: Jun. 13, 2006Ipolos KawnNo ratings yet

- Puneet Chaudhary 302Document20 pagesPuneet Chaudhary 302puneet_chaudhary07No ratings yet

- United States Patent (19) : Miiller (45) Date of PatentDocument8 pagesUnited States Patent (19) : Miiller (45) Date of PatentRodrigoPomaNo ratings yet

- Sliding Gate Movement System with Low Torque Wheel EngagementDocument8 pagesSliding Gate Movement System with Low Torque Wheel EngagementRohit BirajdarNo ratings yet

- Electric Rear Wheel Steering ActuatorDocument10 pagesElectric Rear Wheel Steering ActuatorPCezzzNo ratings yet

- Shaft Driven BicycleDocument1 pageShaft Driven BicyclesalmanNo ratings yet

- Padal Oprated HacksawDocument27 pagesPadal Oprated Hacksawvkumar_345287No ratings yet

- Resilient Pilot Bushing for Transmission Input ShaftDocument5 pagesResilient Pilot Bushing for Transmission Input ShaftMarc GlebNo ratings yet

- High Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsFrom EverandHigh Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsNo ratings yet

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- 507 Mechanical Movements: Mechanisms and DevicesFrom Everand507 Mechanical Movements: Mechanisms and DevicesRating: 4 out of 5 stars4/5 (28)

- Abhijit GYTIDocument6 pagesAbhijit GYTIAbhijit RoyNo ratings yet

- The Cow of The Barricades and Other Stories - Raja Rao As A Short Story WriterDocument7 pagesThe Cow of The Barricades and Other Stories - Raja Rao As A Short Story WriterAbhijit Roy100% (1)

- Electrowetting Park ThesisDocument65 pagesElectrowetting Park ThesisAbhijit RoyNo ratings yet

- Only As Good As Their TelescopesDocument3 pagesOnly As Good As Their TelescopesAbhijit RoyNo ratings yet

- Curriculum VitaeDocument3 pagesCurriculum VitaeAbhijit RoyNo ratings yet

- Lecture 1, PHYSICAL LAWDocument5 pagesLecture 1, PHYSICAL LAWAbhijit RoyNo ratings yet

- How To Use Matrix in Matlab?: Example 1Document2 pagesHow To Use Matrix in Matlab?: Example 1Abhijit RoyNo ratings yet

- Chain LessDocument7 pagesChain LessMoHit KuMarNo ratings yet

- Differential EquationDocument75 pagesDifferential EquationAbhijit RoyNo ratings yet

- Demo PicDocument1 pageDemo PicAbhijit RoyNo ratings yet

- Short StorisDocument26 pagesShort StorisAbhijit RoyNo ratings yet

- US20070228687A1 VVIDocument12 pagesUS20070228687A1 VVIAbhijit RoyNo ratings yet

- Nanotech and Biomimicry: Nature's Inspiration for InnovationDocument27 pagesNanotech and Biomimicry: Nature's Inspiration for InnovationAbhijit RoyNo ratings yet

- Prakhar Hospital Private LimitedDocument1 pagePrakhar Hospital Private LimitedAbhijit RoyNo ratings yet

- Engineering DiagramDocument1 pageEngineering DiagramAbhijit RoyNo ratings yet

- Nanotech and Biomimicry: Nature's Inspiration for InnovationDocument27 pagesNanotech and Biomimicry: Nature's Inspiration for InnovationAbhijit RoyNo ratings yet

- Lens FabricationDocument1 pageLens FabricationAbhijit RoyNo ratings yet

- BiosensorDocument8 pagesBiosensorAbhijit RoyNo ratings yet

- Stock RegisterDocument1 pageStock RegisterAbhijit RoyNo ratings yet

- Engineering DiagramDocument1 pageEngineering DiagramAbhijit RoyNo ratings yet

- A Comprehensive ReportDocument24 pagesA Comprehensive ReportAbhijit RoyNo ratings yet

- Chapter 3Document98 pagesChapter 3Abhijit RoyNo ratings yet

- OptochemoptochemDocument1 pageOptochemoptochemAbhijit RoyNo ratings yet

- Pixel Values and Focal Lengths for Microscope SamplesDocument1 pagePixel Values and Focal Lengths for Microscope SamplesAbhijit RoyNo ratings yet

- ConfocalDocument6 pagesConfocalAbhijit RoyNo ratings yet

- Lens DataDocument67 pagesLens DataAbhijit RoyNo ratings yet

- Molecular Imprinting TechnologyDocument1 pageMolecular Imprinting TechnologyAbhijit RoyNo ratings yet

- Lists of ItemsDocument1 pageLists of ItemsAbhijit RoyNo ratings yet

- BioDocument21 pagesBioAbhijit RoyNo ratings yet

- Dunningstown Road ProposalDocument15 pagesDunningstown Road Proposaleoin01No ratings yet

- Pavement Design Flexible PavementDocument86 pagesPavement Design Flexible PavementAK47100% (2)

- Diverging Tracks - American Vs English Rail Travel PDFDocument306 pagesDiverging Tracks - American Vs English Rail Travel PDFDhan VincentNo ratings yet

- Alitalia v. IACDocument7 pagesAlitalia v. IACmisterdodiNo ratings yet

- Schematic - IR2104 Synchronous Buck Conv - 2023!03!11Document1 pageSchematic - IR2104 Synchronous Buck Conv - 2023!03!11RamKumarNo ratings yet

- Advantages and DisadvantagesDocument2 pagesAdvantages and DisadvantagesRica PalinsadNo ratings yet

- T-01-03 (Pasca) - ATT III - Operate Fuel, Lubrication, Ballast and OtherDocument4 pagesT-01-03 (Pasca) - ATT III - Operate Fuel, Lubrication, Ballast and Otheryudi jdxNo ratings yet

- 054 Compania Maritima v. Insurance Company of North AmericaDocument2 pages054 Compania Maritima v. Insurance Company of North AmericaAlfonso Vargas100% (1)

- Import A Car To Zambia Q&A - Duty, Levies & Shipping (Updated For 2018) PDFDocument13 pagesImport A Car To Zambia Q&A - Duty, Levies & Shipping (Updated For 2018) PDFHUMPHREY KAYUNYINo ratings yet

- Operating in Satellite-Based Augmentation System (SBAS) AirspaceDocument8 pagesOperating in Satellite-Based Augmentation System (SBAS) Airspacemiguel12y5No ratings yet

- Vehicle Body Engg-1Document247 pagesVehicle Body Engg-1Aman HanspalNo ratings yet

- Unit 2 Higher TestDocument2 pagesUnit 2 Higher TestBatica ManicNo ratings yet

- Construction FieldworkDocument18 pagesConstruction FieldworkRizalyn Oraye67% (3)

- All SCMDocument23 pagesAll SCMthkim8No ratings yet

- (2010, Biana) A Semi-Integral Composite Bridge of High SkewDocument10 pages(2010, Biana) A Semi-Integral Composite Bridge of High SkewAnderson UrreaNo ratings yet

- The Search For Marvin Gardens PDFDocument7 pagesThe Search For Marvin Gardens PDFAnonymous 45z6m4eE7pNo ratings yet

- Delivery of 910 Sennheiser HD 206 HeadphonesDocument6 pagesDelivery of 910 Sennheiser HD 206 HeadphonesVimal GeorgeNo ratings yet

- 18) 6 Annex e General MattersDocument4 pages18) 6 Annex e General MattersRomawi StevyandiNo ratings yet

- Sailing Directions - Pub182bkDocument279 pagesSailing Directions - Pub182bkSvenNo ratings yet

- Power Window System OverviewDocument2 pagesPower Window System OverviewMaxi SardiNo ratings yet

- UrbanDocument24 pagesUrbanWahyunal YuriswanNo ratings yet

- Note!: Rear Shock Absorber For YAMAHA N-MAXDocument4 pagesNote!: Rear Shock Absorber For YAMAHA N-MAXAdityaArnas0% (1)

- Metro Board of Directors Agenda, March 2019Document13 pagesMetro Board of Directors Agenda, March 2019Metro Los AngelesNo ratings yet

- Honda Accord SRS - 10086206-2280Document6 pagesHonda Accord SRS - 10086206-2280tong SaetungNo ratings yet

- Truck-Mounted Cranes HB350R Lifts Heavy LoadsDocument4 pagesTruck-Mounted Cranes HB350R Lifts Heavy LoadsRodrigo LealNo ratings yet

- Lithium BatteriesDocument3 pagesLithium BatteriesKarzan Wria100% (1)

- Product MTUDocument107 pagesProduct MTUKaiser IqbalNo ratings yet

- BL 4WD EST & TOD GuideDocument106 pagesBL 4WD EST & TOD Guidealeksejik1_604843622100% (5)

- 1a3gx200e1 - Ag200f Ag200 - 2003 - 3GXG 3GXHDocument56 pages1a3gx200e1 - Ag200f Ag200 - 2003 - 3GXG 3GXHCelso Flores TovarNo ratings yet

- Good Building Practices Guideline PDFDocument262 pagesGood Building Practices Guideline PDFPatrice Audet100% (1)