Professional Documents

Culture Documents

Solseal - Pile Cap Sealer Datasheet

Uploaded by

TrCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Solseal - Pile Cap Sealer Datasheet

Uploaded by

TrCopyright:

Available Formats

Datasheet

SOLSEAL

Liquid Applied Systems

Last Issue Date: 30.01.12

SOLSEAL Pile Cap Sealer

Basements / retaining walls

Technical Data

Concrete slabs (floor/roof/balcony)

Hydrostatic Pressure

>12 bars @28 days

Colour

Cement Grey

Water retaining structures

Bulk Density

1.25 (approx)

Swimming pools

Setting Time

60 mins

Pack Size

25kg Pail

Construction joints

Sewage treatment plants

Description

Solseal Pile Cap Sealer is a surface applied system which waterproofs and protects concrete in depth, it consists of ordinary

Portland cement, specially treated quartz sand and a compound of active chemicals.

When Solseal Pile Cap Sealer is applied to a concrete surface the active chemicals combine with the free lime and moisture

present in the capillary track, to form insoluble crystalline complexes. These crystals block the capillaries and minor

shrinkage cracks in the concrete to prevent any further water ingress (even under pressure). However, the layer will still allow

the passage of water vapour through the structure (i.e. the concrete will still be able to breathe).

In addition to waterproofing the structure, Solseal Pile Cap Sealer protects concrete against seawater, wastewater,

aggressive ground water and certain chemical solutions. Solseal Pile Cap Sealer is suitable for the treatment of water

storage tanks, reservoirs, water towers etcSolseal Pile Cap Sealer is not a decorative material.

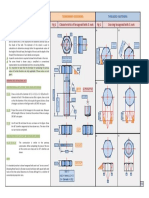

Solseal Pile

Cap Sealer

1.5kg/M 2

Insoluble

crystalline growth

Water

Water

Water

150mm

Installation

Self Adhesive Overseal

Solseal Pile Cap Sealer

1.5kg/M 2

All concrete to be treated with Solseal Pile

Cap Sealer must be clean and have an

open capillary system. Remove laitance,

dirt, grease etc by means of high pressure

water jetting, wet sandblasting or wire

brushing.

Faulty concrete in the form of cracks,

honeycombing, etc must be chased out,

coated with Solseal Pile Cap Sealer and filled

flush with Solco Fillet Seal.

Surfaces must be carefully pre watered prior

to the Solseal Pile Cap Sealer application.

The concrete surface must be damp but not

wet.

Gas Membrane

Pile Cap

Blinding

Pile

Concrete Blinding

SOLCO

The use of the Solseal Pile Cap Sealer, suitably sealed and linked to the Solco sheet membranes, ensures protection

to the pile cap and eliminates the sheet membrane through the pile cap and floor slab construction detail, thus

eliminating the slip plane through this detail.

Technical Support: 0808 168 6927

www.solco.co.uk

enquiries@solco.co.uk

Datasheet

Application

Solseal Pile Cap Sealer is mechanically mixed with clean water to a consistency of thick oil paint. Approximate mixing ratio

is 2 parts water to 5.0 parts of powder (by volume). Mix only as much as can be used within 20 minutes and stir mixture

frequently. If the mixture starts to set do not add more water, simply re-stir to restore workability

Slurry consistency.

Apply Solseal Pile Cap Sealer in one or two coats according to specification by masonry brush or appropriate power spray

equipment. When two coats are specified apply the second coat whilst the first coat is still green.

Dry powder consistency (for horizontal surfaces only).

The specified amount of Solseal Pile Cap Sealer is distributed in powder form through a sieve and towelled into the freshly

placed concrete once this has reached initial set.

Post treatment.

Once the Solseal Pile Cap Sealer treatment has reached initial set it should be moist cured with a fine fog spray of water 2-3

times per day for three days. In hot or windy conditions it should be moist cured more frequently. During the curing period the

Solseal Pile Cap Sealer treatment must be protected from rainfall, frost or puddling of water.

NOTE: Do not apply Solseal Pile Cap Sealer at temperatures below +5oC.

Solseal Pile Cap Sealer cannot be used as an additive to concrete.

Coverage

Concrete surfaces to be backfilled.

One coat of Solseal Pile Cap Sealer at 0.75kg/m2 followed by one coat at 1kg/m2. Brush or spray applied.

Water retaining structures, internal concrete wall surfaces.

Two coats of Solseal Pile Cap Sealer each at 0.75kg/m2. Brush or spray applied.

Concrete slabs.

Solseal Pile Cap Sealer at 1.00kg/m2 applied in one slurry coat to hardened concrete or dry sprinkled and trowel applied to

fresh concrete when this has reached initial set.

Construction Joints.

Solseal Pile Cap Sealer at 1.5kg/m2 applied in slurry or dry powder consistency immediately prior to placing the next lift/bay of

concrete.

Building concrete.

Solseal Pile Cap Sealer at 1.2kg/m2 applied in slurry or dry powder consistency immediately prior to placing the overlay

concrete slab.

NBS Clause

J10 130 Proprietary Crystallization Active Mortar

Storage

When stored in a dry place in unopened, undamaged original packaging, shelf life is 12 months.

Health And Safety

SOLCO

Solseal Pile Cap Sealer contains cement and is Irritating to eyes and skin. Solseal Pile Cap Sealer may cause sensitisation by

skin contact. Keep out of reach of children. Avoid contact with skin and eyes. In case of contact with eyes, rinse immediately

with plenty of water and seek medical advice. Wear suitable gloves.

For full information consult the relevant Material Safety Data Sheet.

Solco, Unit 2, Stadium Indstrial Estate, Cradock Road, Luton, LU4 0JF

You might also like

- Masterseal 501Document5 pagesMasterseal 501Haresh BhavnaniNo ratings yet

- TDS - Masterseal 501-502Document3 pagesTDS - Masterseal 501-502Venkata RaoNo ratings yet

- CMCI Floor Coat Seals, Cures & Dustproofs ConcreteDocument2 pagesCMCI Floor Coat Seals, Cures & Dustproofs Concretepravi3434No ratings yet

- Floorshield 811 Vapour Barrier: DescriptionDocument4 pagesFloorshield 811 Vapour Barrier: Descriptionsri projectssNo ratings yet

- A Discussion On Curing and Sealing: By: Hank HaugeDocument11 pagesA Discussion On Curing and Sealing: By: Hank HaugeErMelvinDiasNo ratings yet

- MasterSeal - 501 502 v1Document2 pagesMasterSeal - 501 502 v1Sivaram KottaliNo ratings yet

- MasterSeal 501 TDSDocument3 pagesMasterSeal 501 TDSYegetafikerNo ratings yet

- Aqua Cure VoxDocument2 pagesAqua Cure Voxpravi3434No ratings yet

- Project Details - Anand ShrivastavDocument12 pagesProject Details - Anand ShrivastavAnand ShrivastavNo ratings yet

- Application of Zycosil Soil On PavementsDocument3 pagesApplication of Zycosil Soil On PavementsEinstein JeboneNo ratings yet

- CMCI REZ-SEAL Concrete Curing Sealer & DustprooferDocument2 pagesCMCI REZ-SEAL Concrete Curing Sealer & Dustprooferpravi3434No ratings yet

- Aqua Stop+TDS+25kg+TubDocument4 pagesAqua Stop+TDS+25kg+Tubshess1No ratings yet

- EucosealDocument1 pageEucosealpravi3434No ratings yet

- Tiling of Balconies (SODAMCO)Document2 pagesTiling of Balconies (SODAMCO)Emre DalgicNo ratings yet

- How To Stack Concrete Paving Moulds For The Best CuringDocument3 pagesHow To Stack Concrete Paving Moulds For The Best Curing7vortex9No ratings yet

- Sikatop Seal 107, Mortar Water ProofingDocument2 pagesSikatop Seal 107, Mortar Water ProofingZulfian St IanNo ratings yet

- Seal FlexDocument2 pagesSeal Flexpravi3434No ratings yet

- Amber & Company: A Reliable Company of WaterproofingDocument20 pagesAmber & Company: A Reliable Company of WaterproofingRaj PatilNo ratings yet

- SILRES® PROVIDES PERFECT WATER REPELLENCY FOR HEAVY CLAY PRODUCTSDocument22 pagesSILRES® PROVIDES PERFECT WATER REPELLENCY FOR HEAVY CLAY PRODUCTSiysernaNo ratings yet

- MS - Sikalastic-1 KMY For Swimming PoolDocument6 pagesMS - Sikalastic-1 KMY For Swimming PoolXuân Nam NguyễnNo ratings yet

- LeafSeal-WP 503 EN - Rev 0221Document5 pagesLeafSeal-WP 503 EN - Rev 0221Le Tuan VietNo ratings yet

- Addmix 310: SpecificationDocument3 pagesAddmix 310: SpecificationAnkita Baban GavadeNo ratings yet

- TDS - Emaco S68 PlusDocument3 pagesTDS - Emaco S68 PlusVenkata RaoNo ratings yet

- Masterseal 501: Surface Applied Capillary Waterproofing System For Concrete and MasonryDocument4 pagesMasterseal 501: Surface Applied Capillary Waterproofing System For Concrete and MasonryFrancois-No ratings yet

- Masterseal 501 Tds 1Document3 pagesMasterseal 501 Tds 1Mohand EliassNo ratings yet

- Masterseal 501 TdsDocument3 pagesMasterseal 501 TdsMohand EliassNo ratings yet

- Durability of Reinforced Concrete Wharves in Norwegian HarborsDocument7 pagesDurability of Reinforced Concrete Wharves in Norwegian HarborsAngelina CruzNo ratings yet

- Water ProofingDocument5 pagesWater ProofingMalith De SilvaNo ratings yet

- Sikalastic 560 Pds enDocument8 pagesSikalastic 560 Pds enJason AndersonNo ratings yet

- Sika Latex: High Performance Water Resistant Bonding Agent and Mortar ImproverDocument3 pagesSika Latex: High Performance Water Resistant Bonding Agent and Mortar ImproverBunhav Lim100% (1)

- CL CDocument4 pagesCL CSagar MandaleekaNo ratings yet

- Tamseal 20Document2 pagesTamseal 20pravi3434No ratings yet

- MASTERSEAL - 501-502 - v5Document2 pagesMASTERSEAL - 501-502 - v5Parth GondaliaNo ratings yet

- Epoxy Methdology 29.10.2023Document7 pagesEpoxy Methdology 29.10.2023Herani DawitNo ratings yet

- Float CoatDocument2 pagesFloat CoatAnkush SharmaNo ratings yet

- IS-216 Queens Boiler Pit Leak RepairDocument8 pagesIS-216 Queens Boiler Pit Leak RepairShamsherHussainNo ratings yet

- Cebex 100 Non-Shrink Grout AdmixtureDocument19 pagesCebex 100 Non-Shrink Grout AdmixturePutu Roby Adhitya Sapanca100% (1)

- Voltex Ds Shotcrete: Product ManualDocument25 pagesVoltex Ds Shotcrete: Product ManualbogdanobiNo ratings yet

- Basf Masterseal 550 Waterproof Wall CoatingDocument3 pagesBasf Masterseal 550 Waterproof Wall Coatingmeja.gamerNo ratings yet

- Water Repellents For Concrete Masonry WallsDocument8 pagesWater Repellents For Concrete Masonry WallsvictorNo ratings yet

- Masterseal 550 TdsDocument3 pagesMasterseal 550 TdsMohammed EssamNo ratings yet

- Sikalastic®-560 GCC Eco-friendly Liquid Roof WaterproofingDocument7 pagesSikalastic®-560 GCC Eco-friendly Liquid Roof WaterproofingDarwin SagiNo ratings yet

- Maxseal Flex EngDocument4 pagesMaxseal Flex EngMohit Rakesh GuptajiNo ratings yet

- Glenium 27Document3 pagesGlenium 27Ct TanNo ratings yet

- MasterSeal - 501 502 v1Document2 pagesMasterSeal - 501 502 v1Jaga NathNo ratings yet

- SikaTop-Seal 107 PDFDocument4 pagesSikaTop-Seal 107 PDFSed BeelzeNo ratings yet

- Sikatop®-107 Seal KH: Product Data SheetDocument4 pagesSikatop®-107 Seal KH: Product Data SheetReab SimanthNo ratings yet

- Cebex 100Document2 pagesCebex 100Riyan Aditya NugrohoNo ratings yet

- Failures in Brick MasonryDocument39 pagesFailures in Brick MasonryRoshan Sanjeev K75% (4)

- Hydrophobic Protecton of FRC Boards With Silicon-Based Materials - IIBCC 2010 PDFDocument13 pagesHydrophobic Protecton of FRC Boards With Silicon-Based Materials - IIBCC 2010 PDFdmonroy0335No ratings yet

- Quicseal 119: AquapoxyDocument4 pagesQuicseal 119: AquapoxyRenaldo BunaidiNo ratings yet

- Waterproofing in ToiletDocument11 pagesWaterproofing in ToiletchaityaNo ratings yet

- Sealants StepsDocument3 pagesSealants StepsBilal el JelalyNo ratings yet

- Repairing ConcreteDocument10 pagesRepairing ConcreteWan HabibNo ratings yet

- Concrete Top SupremeDocument2 pagesConcrete Top Supremepravi3434No ratings yet

- Fresco Painting - Modern Methods and Techniques for Painting in Fresco and SeccoFrom EverandFresco Painting - Modern Methods and Techniques for Painting in Fresco and SeccoNo ratings yet

- Your Home Inspected: An Addendum for Residential Home Inspection ReportsFrom EverandYour Home Inspected: An Addendum for Residential Home Inspection ReportsNo ratings yet

- Popular Mechanics: How to Fix Anything: Essential Home Repairs Anyone Can DoFrom EverandPopular Mechanics: How to Fix Anything: Essential Home Repairs Anyone Can DoRating: 4 out of 5 stars4/5 (2)

- Waterproof Pile Cap SealerDocument4 pagesWaterproof Pile Cap SealerTr100% (1)

- CRL01Document17 pagesCRL01cdestudosNo ratings yet

- 4 3shiratoDocument14 pages4 3shiratoTommy PhanNo ratings yet

- Pile Cap Design Guide - Part 1Document25 pagesPile Cap Design Guide - Part 1Zafar100% (2)

- Shear EnhancedDocument8 pagesShear Enhancedunitedfc9612No ratings yet

- Who Would You Turn To in A Crisis?: First Aid Training With A Name You Can TrustDocument9 pagesWho Would You Turn To in A Crisis?: First Aid Training With A Name You Can TrustTrNo ratings yet

- Assigment 1 Osha UthmDocument10 pagesAssigment 1 Osha UthmInahMisumi100% (1)

- Soil Permeability LectureDocument34 pagesSoil Permeability LectureSheikh AnikNo ratings yet

- Bridge JointsDocument3 pagesBridge JointsJs TanNo ratings yet

- INB301 Assignment Team 6008Document36 pagesINB301 Assignment Team 6008Ajwad HuqNo ratings yet

- Tabela Completa Especificacao de TubulacaoDocument251 pagesTabela Completa Especificacao de TubulacaoAlessandre OliveiraNo ratings yet

- SB Part Bill - 3 (GR Floor) of Protik Fine Ceramics Factory BuildingDocument10 pagesSB Part Bill - 3 (GR Floor) of Protik Fine Ceramics Factory BuildingShafiul AlamNo ratings yet

- Wind Load CalculationDocument3 pagesWind Load CalculationGajera HarshadNo ratings yet

- Method Statement For Application of Waterproofing MembraneDocument5 pagesMethod Statement For Application of Waterproofing MembraneAnjo MolinaNo ratings yet

- PERI UP Rosett For The Use On The Constr. Jobsite.Document28 pagesPERI UP Rosett For The Use On The Constr. Jobsite.YUSAK ABDILLAHNo ratings yet

- Ventilator ValveDocument2 pagesVentilator ValveThiyagarajan Rajendran100% (1)

- Concrete Elements: Bridge Inspection Procedure ManualDocument80 pagesConcrete Elements: Bridge Inspection Procedure ManualHTC1111No ratings yet

- MD Module 1 StressDocument5 pagesMD Module 1 StressCllyan Reyes100% (1)

- Machine Drawing: Hexagonal Bolts & NutsDocument1 pageMachine Drawing: Hexagonal Bolts & Nutsyesbee100% (1)

- Planning and Site Investigation Guidelines for Tunnelling ProjectsDocument6 pagesPlanning and Site Investigation Guidelines for Tunnelling ProjectsJean DalyNo ratings yet

- HIT Rebar Fatigue enDocument7 pagesHIT Rebar Fatigue enWalter CastilloNo ratings yet

- Student Housing Unit in A Oor Area Without Corridors: ArticleDocument8 pagesStudent Housing Unit in A Oor Area Without Corridors: ArticleShólànké Ezekiel ShówúnmiNo ratings yet

- Pour CardDocument2 pagesPour Cardsuchendra singhNo ratings yet

- Anaconda Brand Type SHD-GC Power, Shielded Round Portable w/Ground-Check, EPR/CPEDocument1 pageAnaconda Brand Type SHD-GC Power, Shielded Round Portable w/Ground-Check, EPR/CPECarlos JavierNo ratings yet

- Introduction To TrackDocument81 pagesIntroduction To TrackiritmspceNo ratings yet

- R-Value of Building Materials: Material R/ Inch R/ Thick-Ness Insulation Materials Material R/ Inch R/ Thick - NessDocument2 pagesR-Value of Building Materials: Material R/ Inch R/ Thick-Ness Insulation Materials Material R/ Inch R/ Thick - NessThangalaxmi ArunjunaivelNo ratings yet

- 3 Wolter ProfileDocument34 pages3 Wolter ProfiletejasNo ratings yet

- Super Asia Mds Limited Service Centre, LahoreDocument40 pagesSuper Asia Mds Limited Service Centre, Lahoresohailakhtar5No ratings yet

- Hardware Auto & MachineryDocument86 pagesHardware Auto & MachineryHenry ChanNo ratings yet

- Portals - 0 - Checklist For Internal Plumbing WorkDocument2 pagesPortals - 0 - Checklist For Internal Plumbing Workrahul kumarNo ratings yet

- 5geb20c2 PB 31107 016Document6 pages5geb20c2 PB 31107 016lei songNo ratings yet

- BS StandardsDocument13 pagesBS StandardsShyam Prasad K S100% (3)

- Hafsa - Bensghir French PrimeveraDocument3 pagesHafsa - Bensghir French Primeverahz135874No ratings yet

- BBC011OD001GL01Document141 pagesBBC011OD001GL01Marko PavlicevicNo ratings yet

- List Updated 14 Augustus 2019Document1,032 pagesList Updated 14 Augustus 2019muhammad fuad hasanNo ratings yet

- Water Hammer Tutorials Attempt The Tutorials and Check Your Answers Against The Solutions GivenDocument3 pagesWater Hammer Tutorials Attempt The Tutorials and Check Your Answers Against The Solutions GivenNickson KomsNo ratings yet