Professional Documents

Culture Documents

T60man f2

Uploaded by

ashish_2187Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

T60man f2

Uploaded by

ashish_2187Copyright:

Available Formats

5.

2 PRODUCT SETUP

5 SETTINGS

5.2.7 USER-PROGRAMMABLE FAULT REPORT

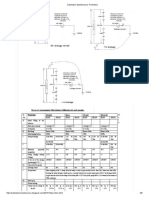

PATH: SETTINGS ! PRODUCT SETUP !" USER-PROGRAMMABLE FAULT REPORT ! USER-PROGRAMMABLE FAULT REPORT 1(2)

FAULT REPORT 1

FUNCTION: Disabled

Range: Disabled, Enabled

PRE-FAULT 1 TRIGGER:

Off

Range: FlexLogic operand

MESSAGE

FAULT 1 TRIGGER:

Off

Range: FlexLogic operand

MESSAGE

FAULT REPORT 1 #1:

Off

Range: Off, any actual value analog parameter

MESSAGE

FAULT REPORT 1 #2:

Off

Range: Off, any actual value analog parameter

MESSAGE

# USER-PROGRAMMABLE

# FAULT REPORT 1

%

MESSAGE

FAULT REPORT 1 #32:

Off

Range: Off, any actual value analog parameter

When enabled, this function monitors the pre-fault trigger. The pre-fault data are stored in the memory for prospective creation of the fault report on the rising edge of the pre-fault trigger. The element waits for the fault trigger as long as the prefault trigger is asserted, but not shorter than 1 second. When the fault trigger occurs, the fault data is stored and the complete report is created. If the fault trigger does not occur within 1 second after the pre-fault trigger drops out, the element

resets and no record is created.

The user programmable record contains the following information: the user-programmed relay name, detailed firmware

revision (3.4x, for example) and relay model (T60), the date and time of trigger, the name of pre-fault trigger (specific FlexLogic operand), the name of fault trigger (specific FlexLogic operand), the active setting group at pre-fault trigger, the

active setting group at fault trigger, pre-fault values of all programmed analog channels (one cycle before pre-fault trigger),

and fault values of all programmed analog channels (at the fault trigger).

Each fault report is stored as a file to a maximum capacity of ten files. An eleventh trigger overwrites the oldest file. The

enerVista UR Setup software is required to view all captured data.

The relay includes two user-programmable fault reports to enable capture of two types of trips (for example, trip from thermal protection with the report configured to include temperatures, and short-circuit trip with the report configured to include

voltages and currents). Both reports feed the same report file queue.

The last record is available as individual data items via communications protocols.

PRE-FAULT 1 TRIGGER: Specifies the FlexLogic operand to capture the pre-fault data. The rising edge of this

operand stores one cycle-old data for subsequent reporting. The element waits for the fault trigger to actually create a

record as long as the operand selected as PRE-FAULT TRIGGER is On. If the operand remains Off for 1 second, the

element resets and no record is created.

FAULT 1 TRIGGER: Specifies the FlexLogic operand to capture the fault data. The rising edge of this operand

stores the data as fault data and results in a new report. The trigger (not the pre-fault trigger) controls the date and time

of the report.

FAULT REPORT 1 #1 to #32: These settings specify an actual value such as voltage or current magnitude, true RMS,

phase angle, frequency, temperature, etc., to be stored should the report be created. Up to 32 channels can be configured. Two reports are configurable to cope with variety of trip conditions and items of interest.

5-18

T60 Transformer Management Relay

GE Multilin

You might also like

- 2TJM bROUCHDocument6 pages2TJM bROUCHSangram PatilNo ratings yet

- Test Siemens 7UT61 Relay Differential ProtectionDocument4 pagesTest Siemens 7UT61 Relay Differential ProtectionNassar Abdulrahiman100% (2)

- BeyondKneePoint AH 20190418 WebDocument25 pagesBeyondKneePoint AH 20190418 Webs_waqarNo ratings yet

- Test 7utDocument1 pageTest 7utashish_2187No ratings yet

- MVAJ053Document38 pagesMVAJ053Yusof BasriNo ratings yet

- Electrical System Minimum Clearances Safety StandardsDocument1 pageElectrical System Minimum Clearances Safety Standardsashish_2187No ratings yet

- Cont ProtDocument44 pagesCont Protashish_2187No ratings yet

- Substation Maintenance - ProtectionDocument1 pageSubstation Maintenance - Protectionashish_2187No ratings yet

- Test 7ut 2Document1 pageTest 7ut 2ashish_2187No ratings yet

- Testing Procedure PTDocument13 pagesTesting Procedure PTashish_2187No ratings yet

- Protection Application Guide Chap 7-pg 98-111 PDFDocument14 pagesProtection Application Guide Chap 7-pg 98-111 PDFDarrylpnzNo ratings yet

- Protection Relay Application Guide Chap. 5-pg 46-77 PDFDocument32 pagesProtection Relay Application Guide Chap. 5-pg 46-77 PDFDarrylpnzNo ratings yet

- Substation Maintenance - ProtectionDocument1 pageSubstation Maintenance - Protectionashish_2187No ratings yet

- Bill of ExchangeDocument8 pagesBill of Exchangeashish_2187No ratings yet

- Cont ProtDocument44 pagesCont Protashish_2187No ratings yet

- TDRDocument18 pagesTDRashish_2187No ratings yet

- Ground Fault ProtectionDocument1 pageGround Fault Protectionashish_2187No ratings yet

- Is 14697Document50 pagesIs 14697lalit123india0% (1)

- CDG and CDD RelaysDocument6 pagesCDG and CDD Relaysashish_2187No ratings yet

- B. External Protection Provided To Transformer at Site:-: Electrical Project Installation Training ProgrammeDocument1 pageB. External Protection Provided To Transformer at Site:-: Electrical Project Installation Training Programmeashish_2187No ratings yet

- Induction Disc (Phase Angle Comparator) Relay - : Electrical Project Installation Training ProgrammeDocument1 pageInduction Disc (Phase Angle Comparator) Relay - : Electrical Project Installation Training Programmeashish_2187No ratings yet

- MSC-II/ conventional power Trf specsDocument1 pageMSC-II/ conventional power Trf specsAshish PatilNo ratings yet

- Relay NumberingDocument2 pagesRelay Numberingashish_2187No ratings yet

- Inductance Capacitance Impedance Reactive Power Power FactorDocument1 pageInductance Capacitance Impedance Reactive Power Power Factorashish_2187No ratings yet

- Safet Working ClearanceDocument1 pageSafet Working Clearanceashish_2187No ratings yet

- Safet Working ClearanceDocument1 pageSafet Working Clearanceashish_2187No ratings yet

- Relay NumberingDocument2 pagesRelay Numberingashish_2187No ratings yet

- 220 KV Tower Concrete Volumes & Reinforcement QuantitiesDocument1 page220 KV Tower Concrete Volumes & Reinforcement Quantitiesashish_2187No ratings yet

- Foundation 220 KV DCDocument1 pageFoundation 220 KV DCashish_2187No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 7-Speed Direct Shift Gearbox (DSG - 0AM) - Ross-Tech WikiDocument3 pages7-Speed Direct Shift Gearbox (DSG - 0AM) - Ross-Tech WikiRadu SopteaNo ratings yet

- Group Policies For Linux, Unix and Mac OS X ComputersDocument16 pagesGroup Policies For Linux, Unix and Mac OS X ComputersLikewise SoftwareNo ratings yet

- NEW - Mikrotik - WIKI - Ebook 1 - Basics - Firewall - EthernetDocument114 pagesNEW - Mikrotik - WIKI - Ebook 1 - Basics - Firewall - Ethernethabalforever100% (1)

- OracleDocument1,236 pagesOracleel_especialista1y2No ratings yet

- Efi Arazi School of Computer ScienceDocument9 pagesEfi Arazi School of Computer Scienceshashwatasawa100% (2)

- Mach3 V3.x VB Macro ProgrammingDocument141 pagesMach3 V3.x VB Macro ProgrammingAlyssa LamontagneNo ratings yet

- SIPI - Week 6 Group Discussion (SOLUTION)Document2 pagesSIPI - Week 6 Group Discussion (SOLUTION)Luthfia_Sarasvati100% (1)

- Vise, Is Used To Clamp Metal Instead of Wood. It Is Used To Hold MetalDocument6 pagesVise, Is Used To Clamp Metal Instead of Wood. It Is Used To Hold MetalElgen EquipadoNo ratings yet

- Introduction OptiPerformerDocument2 pagesIntroduction OptiPerformerLaura_Martinez22No ratings yet

- FaultfindingDocument3 pagesFaultfindingdeveshdashora123100% (2)

- Panasonic 2012 PDP Troubleshooting Guide ST50 ST Series (TM)Document39 pagesPanasonic 2012 PDP Troubleshooting Guide ST50 ST Series (TM)Henrique PauloNo ratings yet

- BASIC CBLM8 Use Information Creatively and CriticallyDocument28 pagesBASIC CBLM8 Use Information Creatively and CriticallyChristian Dela CruzNo ratings yet

- Service SchematicDocument3 pagesService SchematicskaNo ratings yet

- TS1351 249 R SheetDocument4 pagesTS1351 249 R SheetdigitaltextNo ratings yet

- History of DbmsDocument9 pagesHistory of Dbmsanusrini23No ratings yet

- September 2010 ISAM 7302 and 7330 AP1 EN DS PDFDocument4 pagesSeptember 2010 ISAM 7302 and 7330 AP1 EN DS PDFNopphadol JirayuwanonNo ratings yet

- Seminar Report On 3D PrintingDocument20 pagesSeminar Report On 3D PrintingArchitbhardwaj13No ratings yet

- Information Storage and Management StudentGuide v3 2015 PDFDocument713 pagesInformation Storage and Management StudentGuide v3 2015 PDFDavid GiriNo ratings yet

- ASUS 1101HA Schematic Diagram. Rev 1.2Document50 pagesASUS 1101HA Schematic Diagram. Rev 1.2Utube MaNo ratings yet

- Abs HondaDocument22 pagesAbs HondaJuan Sánchez LópezNo ratings yet

- PLC & SCADA Based Condition Monitoring of Three Phase Induction MotorDocument7 pagesPLC & SCADA Based Condition Monitoring of Three Phase Induction MotorBui Hong PhongNo ratings yet

- Ar900ii RT (1kva-10kva) PDFDocument1 pageAr900ii RT (1kva-10kva) PDFHa NguyenNo ratings yet

- Fujitsu M12 Server Installation AssessmentDocument26 pagesFujitsu M12 Server Installation AssessmentAl MamunNo ratings yet

- User Guide: DIN Mount 4 Channel 4 20ma / 0 10VDC Analog Fiber Optic Link SystemDocument8 pagesUser Guide: DIN Mount 4 Channel 4 20ma / 0 10VDC Analog Fiber Optic Link SystemAbdullah IbrahimNo ratings yet

- NetAct Plan Editor 4.9-4 CNDocument4 pagesNetAct Plan Editor 4.9-4 CNAshraf JarjeesNo ratings yet

- Wistron DW50 Winery15 - 48.4et05.0sa 09289-Sa PDFDocument88 pagesWistron DW50 Winery15 - 48.4et05.0sa 09289-Sa PDFWillian AngeloNo ratings yet

- Hi 5100601 CMEN5Document463 pagesHi 5100601 CMEN5Aravindhan50% (2)

- LV1 2010 06Document174 pagesLV1 2010 06Francisco PochatNo ratings yet

- NAS Tutorial - Oplocks and NASes - SmallNetBuilderDocument1 pageNAS Tutorial - Oplocks and NASes - SmallNetBuilderAnonymous DQqy1dHXBNo ratings yet

- SGDO-FSU Troubleshooting ProcedureDocument2 pagesSGDO-FSU Troubleshooting ProcedurePeter SnellNo ratings yet