Professional Documents

Culture Documents

Common Problems of Concreting and How To Avoid Them - A Civil Engineer

Uploaded by

aankur guptaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Common Problems of Concreting and How To Avoid Them - A Civil Engineer

Uploaded by

aankur guptaCopyright:

Available Formats

Commonproblemsofconcretingandhowtoavoidthem

LitonBiswas

ConcreteTechnology,Construction,HowtoGuide

Nocomments

For producing high quality concrete you should take control of problems which are commonly

occurred during concreting. These problems mainly happen for improper mixing, placing and

handling. Some problems also happen due to weather effect and other reasons. These problems

have major impact on strength and duration of concrete First you should know about the

common problems of concreting. The common problems are:

Segregation

Bleeding

Shrinkage cracking

Dusting

Laitance

Scaling,etc.

Segregation:Segregation is the tendency of separating concrete particles in fresh concrete.

Due to segregation honey comb, scaling, laitance, porous layers and bond failure at

construction joint etc. can happen in concrete. To avoid segregation following actions can be

taken

Properly following concrete mixdesign

Mixing concrete ingredients properly

Maintaining watercement ratio

Not dropping concrete from too high during placing

Avoid over vibrating of concrete

Bleeding:when concrete begin to set the mixing water come out from the concrete and evaporates. If evaporation

rate of water is not sufficient then water stay on the concrete surface. This the conc bleeding. Normal Bleeding is a

part of concrete hardening process. But excess bleeding is harmful to concrete. It reduces the bond between

reinforcement & concrete and also concrete particles with cement paste. As a result, it reduce the strength and

durability of hardened concrete.Bleeding can be avoided using following technique:

Maintaining proper watercement ratio

Using water reducing admixture with concrete mix

Using well graded fine aggregates.

Plastic Shrinkage cracking:If the evaporation rate of mixing water of concrete is higher than

the bleed water of concrete then this cracking occurs in concrete surface. It happen due to hot

weather. To avoid this concreting problem see "Impacts of hot weather on concreting and

protective actions".

Dusting:If the concrete surface bond is weak with subsequent layer then the surface dusts

under traffic. The following measures can be taken to avoid this problem:

Keep the watercement ratio under reasonable level

Use dust free aggregates

Ensure proper hydration of concrete

Avoid concrete finishing work with bleed water. etc

Laitance: laitance is the bad effect of concrete bleeding and segregation. Due to bleeding & segregation a thin

layer of cementsand particles appears on the concrete surface that is the laitance. It's also harmful to concrete as it

weaken the bond of subsequent layers of concrete. The following measures can be taken to prevent the occurrence of

concrete laitance:

Remove the clay, dust, silt and other organic materials from concrete aggregate before mixing.

Don't apply water on fresh concrete during finishing work.

Maintain proper water cement ratio.

Using well graded fine aggregates.

Using water reducing admixture with concrete mix.

Scaling:Scaling is the appearing of concrete aggregate on surface due to flaking or peeling

away mortar from concrete surface. Same protective actions for laitance and dusting can be

taken to protect concrete scaling.

Therearealsosomeotherproblemshappenduringconcretingwork.Butthesearemajor

concretingproblemtoavoid.

You might also like

- Shipping Label 64853408 1904177046501 PDFDocument1 pageShipping Label 64853408 1904177046501 PDFaankur guptaNo ratings yet

- Shipping Label 64856712 1904177051736 PDFDocument1 pageShipping Label 64856712 1904177051736 PDFaankur guptaNo ratings yet

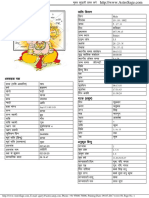

- Shiprocket manifest tracking barcodeDocument1 pageShiprocket manifest tracking barcodeaankur guptaNo ratings yet

- Shipment details for asta kada orderDocument1 pageShipment details for asta kada orderaankur guptaNo ratings yet

- Invoice 2Document1 pageInvoice 2aankur guptaNo ratings yet

- VedicReport19 10 202016 15 27Document56 pagesVedicReport19 10 202016 15 27aankur guptaNo ratings yet

- Shiprocket Manifest: To Be Filled by Delhivery Surface Standard Logistics ExecutiveDocument1 pageShiprocket Manifest: To Be Filled by Delhivery Surface Standard Logistics Executiveaankur guptaNo ratings yet

- Manifest 0089Document1 pageManifest 0089aankur guptaNo ratings yet

- Step by Step Process of Mosaic Flooring - A Civil EngineerDocument1 pageStep by Step Process of Mosaic Flooring - A Civil Engineeraankur guptaNo ratings yet

- कर्रिएर कम्पनीDocument1 pageकर्रिएर कम्पनीaankur guptaNo ratings yet

- Manifest 0088Document1 pageManifest 0088aankur guptaNo ratings yet

- Hindi PDFDocument47 pagesHindi PDFaankur guptaNo ratings yet

- HGJKKK JKHFJ Hsuf PDFDocument1 pageHGJKKK JKHFJ Hsuf PDFaankur guptaNo ratings yet

- कर्रिएर कम्पनीDocument1 pageकर्रिएर कम्पनीaankur guptaNo ratings yet

- Hello Hy Bye Here Is The Sane BDHC HhdgteDocument1 pageHello Hy Bye Here Is The Sane BDHC Hhdgteaankur guptaNo ratings yet

- How To Plaster On Surface - A Civil EngineerDocument2 pagesHow To Plaster On Surface - A Civil Engineeraankur guptaNo ratings yet

- Batch TransferDocument2 pagesBatch Transferaankur guptaNo ratings yet

- Road Pocket Book 1.2.11 For Engineers N 4Document79 pagesRoad Pocket Book 1.2.11 For Engineers N 4krishshellyNo ratings yet

- How To Make Concrete Cube For Compression Test - A Civil EngineerDocument3 pagesHow To Make Concrete Cube For Compression Test - A Civil Engineeraankur guptaNo ratings yet

- Plain Cement Concrete (PCC) - How To Produce and Construct - A Civil EngineerDocument3 pagesPlain Cement Concrete (PCC) - How To Produce and Construct - A Civil Engineeraankur guptaNo ratings yet

- Placement of Main Reinforcement (Bar) of Footing - A Civil EngineerDocument1 pagePlacement of Main Reinforcement (Bar) of Footing - A Civil Engineeraankur guptaNo ratings yet

- How To Make Cylinder Specimen of Concrete For Compression Test - A Civil EngineerDocument2 pagesHow To Make Cylinder Specimen of Concrete For Compression Test - A Civil Engineeraankur guptaNo ratings yet

- Placement of Main Reinforcement (Bar) of Footing - A Civil EngineerDocument1 pagePlacement of Main Reinforcement (Bar) of Footing - A Civil Engineeraankur guptaNo ratings yet

- How To Plaster On Surface - A Civil Engineer 1Document2 pagesHow To Plaster On Surface - A Civil Engineer 1aankur guptaNo ratings yet

- How to Make the RCC Bottom Slab of an Underground Water TankDocument2 pagesHow to Make the RCC Bottom Slab of an Underground Water Tankaankur guptaNo ratings yet

- How To Make Cylinder Specimen of Concrete For Compression Test - A Civil EngineerDocument2 pagesHow To Make Cylinder Specimen of Concrete For Compression Test - A Civil Engineeraankur guptaNo ratings yet

- How To Locate Pile On Plot and Protect Them From Missing - A Civil Engineer PDFDocument3 pagesHow To Locate Pile On Plot and Protect Them From Missing - A Civil Engineer PDFaankur guptaNo ratings yet

- How To Calculate Materials For Different-Ratio Concrete - A Civil EngineerDocument2 pagesHow To Calculate Materials For Different-Ratio Concrete - A Civil Engineeraankur guptaNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- East Ring Road (STC)Document3 pagesEast Ring Road (STC)mohamed ayadNo ratings yet

- PROJECT MANAGEMENT (Rowhouse)Document78 pagesPROJECT MANAGEMENT (Rowhouse)Marke Paraguya100% (1)

- 02 IBS Konsep Rekabentuk IBS Sistem KerangkaDocument65 pages02 IBS Konsep Rekabentuk IBS Sistem KerangkaFarhanNo ratings yet

- Precast Concrete Design and Construction RequirementsDocument5 pagesPrecast Concrete Design and Construction RequirementsNino Celso Astillero100% (2)

- Are Cracks in Concrete Slab NormalDocument3 pagesAre Cracks in Concrete Slab Normalmohannad eliassNo ratings yet

- Hardened ConcreteDocument33 pagesHardened Concretechicku_iwayNo ratings yet

- Question Bank For Basic Civil EngineeringDocument4 pagesQuestion Bank For Basic Civil EngineeringSenthil Kumar0% (1)

- General FormulaDocument53 pagesGeneral FormulaTsegawbezto97% (32)

- Gantt Chart and Cashflow Sistona VellarimoDocument5 pagesGantt Chart and Cashflow Sistona VellarimoKirby LabadanNo ratings yet

- Avante Typical Detail List Drawing Number Rev. Sheet NODocument16 pagesAvante Typical Detail List Drawing Number Rev. Sheet NOkjdaraNo ratings yet

- TECHNICAL NOTE 007 Structural Steel Sub-Grades JR, J0 and J2 Does It MatterDocument1 pageTECHNICAL NOTE 007 Structural Steel Sub-Grades JR, J0 and J2 Does It MatterOM PRAKASH PALNo ratings yet

- Information Bulletin 3 Building Def Rev3Document1 pageInformation Bulletin 3 Building Def Rev3Alan TanNo ratings yet

- Building Cladding - Types, Uses and Application MethodsDocument7 pagesBuilding Cladding - Types, Uses and Application MethodsAnqa ParvezNo ratings yet

- CH 15 - Precast Concrete FramingDocument5 pagesCH 15 - Precast Concrete FramingRon Julienne Rebugio100% (1)

- Structural Calculation ReportDocument22 pagesStructural Calculation ReportPhillip Frencillo100% (1)

- Guide To Standards-Building and ConstructionDocument37 pagesGuide To Standards-Building and ConstructionDenise2512No ratings yet

- Pile FoundationDocument13 pagesPile FoundationmelvinNo ratings yet

- Quantity & BOQ of PWDDocument11 pagesQuantity & BOQ of PWDMuhammad HamzaNo ratings yet

- 0091-IS-2911 Part 3-1Document31 pages0091-IS-2911 Part 3-1Hikmat AyerNo ratings yet

- Astm E1557 09 (2020)Document45 pagesAstm E1557 09 (2020)Patrick LitteeNo ratings yet

- BCM Partitioncase StudyDocument9 pagesBCM Partitioncase StudyB 02 Kavya DcruzNo ratings yet

- BEAMDESIGN XLSMDocument4 pagesBEAMDESIGN XLSMSaurabh PednekarNo ratings yet

- Cost Overrun in The Case of Nib International Bank Headquarters Building ProjectDocument11 pagesCost Overrun in The Case of Nib International Bank Headquarters Building ProjectEsayas Getachew100% (1)

- Earthwork and Concrete EstimatesDocument204 pagesEarthwork and Concrete EstimatesDhanjit Hazarika33% (3)

- Luxury Appartments BOQ PDF Rev.1Document38 pagesLuxury Appartments BOQ PDF Rev.1Nazir Ahmed Mahar0% (1)

- Es2008 54190Document6 pagesEs2008 54190Selvaraji MuthuNo ratings yet

- LS GILADocument12 pagesLS GILAfyqaeNo ratings yet

- Section 4: HVAC Systems & Indoor Air Quality: 4.1 OverviewDocument6 pagesSection 4: HVAC Systems & Indoor Air Quality: 4.1 OverviewMarschall Nuñez GrandisonNo ratings yet

- A000 TRAB 1 - MergedDocument7 pagesA000 TRAB 1 - MergedRodrigo Ibañez GreilbergerNo ratings yet

- The Concrete Panels HomesDocument8 pagesThe Concrete Panels Homeschancer2No ratings yet