Professional Documents

Culture Documents

Liquefaction Hazard Assessment of Ramgarh Tal Pariyojna

Uploaded by

GJESROriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Liquefaction Hazard Assessment of Ramgarh Tal Pariyojna

Uploaded by

GJESRCopyright:

Available Formats

www.globaljournal.

asia

GJESR RESEARCH PAPER VOL. 1 [ISSUE 10] NOVEMBER, 2014

ISSN:- 2349283X

LIQUEFACTION HAZARD ASSESSMENT OF RAMGARH

TAL PARIYOJNA

1Abhishek

Kumar Tiwari

Department of Civil Engineering,

Madan Mohan Malviya University of

Technology, Gorakhpur, India

Email: abhicivilengg07@gmail.com

2Dr.S.M

Ali Jawaid

Department of Civil Engineering,

Madan Mohan Malviya University of

Technology, Gorakhpur, India

Email: smaj@rediffmail.com

ABSTRACT: Determination of liquefaction potential due to earthquake is complex geotechnical problem.

Many factors including soil parameters and seismic characteristics influence this phenomenon. The

devastating damage of liquefaction induced ground failures in the Alaska 1964 and Niigata 1964

earthquakes serve as a clear reminder of such events. Liquefaction is one of the ground failures in

potential earth science hazard. Since Gorakhpur falls in the area with high seismic probability, there is

need for the assessment of liquefaction potential, so the study area is Ramgarh Tal Pariyojna to

recognize the conditions that exist in a soil deposit before an earthquake in order to identify liquefaction.

Results of an extensive analysis for determination of liquefaction hazard analysis of Ramgarh Tal

Pariyojna of Gorakhpur city at different locations is addressed here. The simplified procedure suggested

by seed & Idriss (1971) on the basis of field performance data is used for determination of liquefaction

potential and also to present a liquefaction hazard map using SPT data collected from the various sites at

different locations of Ramgarh Tal Pariyojna. From the analysis it is observed that the areas with river

channel deposit are the most hazardous area for liquefaction. From the study it is also concluded that if

acceleration level is increased then more area will be affected due to liquefaction. In this study we

concluded that if earthquake more than or equal to 6.5 ritcher scale occurs in Gorakhpur region, it will be

extensively damaged due to liquefaction. The percentage of silt and poorly graded sand is high in the area

under Ramgarh Tal Pariyojna indicating that there is a great chance of soil liquefaction. Here

liquefaction potential analysis is done to determine the factor of safety at different depth. The structure

constructed should be liquefaction resistant i.e., designing the foundation elements to resist the effects of

liquefaction if at all it is necessary to construct the structure on liquefiable soil because of favourable

location, space restriction and other reasons.

Keywords: Liquefaction, microzonation, standard penetration test, Seismic Hazard

1. INTRODUCTION

Gorakhpur lies between Latitude 26 13 N and

2729N and long.8305E and 8356E.the

district occupies the north-eastern corner of the

state along with the state of Deoria, & comprises

a large stretch of country lying to the north of

river Ghaghra, the deep stream of which forms

its boundary with district Azamgarh. In the

earthquake zonal map of India the district lies in

zone IV liable to moderate damage by

earthquakes. Although no major earthquake

occurred close to it, the tract being not far from

the

Great

Himalayan

Boundary

fault,

experiences the effects of moderate to great

earthquake occurring there. The seismic

intensity may not exceed VIII on the Modified

Mercalli 1931. As India experiencing lots of

seismic threats and Liquefaction is one of the

major types for ground failure. Liquefaction is a

soil behaviour phenomenon in which a

saturated soil losses a substantial amount of

strength due to high excess pore-water pressure

generated by and accumulated during strong

earthquake ground shaking. Large numbers of

liquefaction studies were conducted in all the

earthquake prone areas of the world. After the

2001 Bhuj earthquake, attracted the great

attention of liquefaction studies.

Soil liquefaction has been a major cause of

damage to soil structure, lifelines and building

foundation. Zoning for liquefaction, therefore,

has been an important goal for seismic hazard

mitigation.

Gorakhpur region is potentially prone to

damaging earthquakes, as it is located in an

active seismic zone IV. Because of the haphazard

urbanization and increasing population in the

Gorakhpur region now, it has become very

essential to carry out studies on different

aspects of the earthquake hazard leading to long

term earthquake vulnerability reduction

Virtu and Foi..

17

GJESR RESEARCH PAPER VOL. 1 [ISSUE 10] NOVEMBER, 2014

program. This situation has created the

necessity for carrying out a detailed seismic

hazard assessment of the city and an awareness

building measures to the people of Gorakhpur

regarding the earthquake safety.

So seeing the fact the study area is RAMGARH

TAL PARIYOJNA, Gorakhpur, Ramgarh Tal, and

a natural lake, which is situated to the southeast

of Gorakhpur in Uttar Pradesh and covers an

area of about 723 hectare. The catchment area

around the lake is approximately 1632 acres,

out of which, 1235 acres land is under

Gorakhpur Development authority (GDA).

Liquefaction is one of the main effects of an

earthquake that is responsible to structural

failure and damage to roads, pipelines and

infrastructures. In Gorakhpur region in spite of

weak subsurface condition, many tall buildings

have been built and the number is constantly

rising. Most of these buildings (Except

commercial, governmental and organizational

buildings) have been constructed without

adequate research on the subsurface sediment

conditions and hence may run a high risk that

they are not properly designed to withstand the

particular accelerations at the site. Looking at

this situation, the study on subsurface geology is

very important, as it helps for the study of

seismic hazard and hence for the earthquake

vulnerability reduction program. For the study

of subsurface geology, the generation of a

geological database is important which can be

done by the collection of borehole data. One

other potential source of useful information for

subsurface

information,

geophysical

measurements, are completely lacking for

Gorakhpur region. The work is done to analyse

the liquefaction potential of Ramgarh Tal

Pariyojna in Gorakhpur city using SPT data

collected from the various sites of Pariyojna by

simplified procedure of Seed & Idriss (1982).

The geological, geotechnical, and seismological

details of an area have to be studied which

forms important parameters and information to

analyse Liquefaction potential of this region.

The main objectives of this work is to1. Estimate the liquefaction resistance of soils

using SPT data.

2. Estimate the maximum or equivalent cyclic

shear stress likely to be induced in a soil deposit

during an earthquake;

ISSN:- 2349283X

3. Estimate the liquefaction potential.

4. Prepare liquefaction hazard zonation map.

LIQUEFACTION AND ITS MECHANISM

Soil liquefaction has been a major cause of

damage to soil structure, lifelines and building

foundation. Zoning for liquefaction, therefore,

has been an important goal for seismic hazard

mitigation. Soil liquefaction occurs in loose,

saturated cohesionless soil units (sands and

silts) and sensitive clays when a sudden loss of

strength and loss of stiffness is experienced,

sometimes resulting in large, permanent

displacements of the ground. Even thin lenses of

loose saturated silts and sands may cause an

overlying sloping soil mass to slide laterally

along the liquefied layer during earthquakes.

Liquefaction beneath and in the vicinity of a

waste containment unit can result in localized

bearing capacity failures, lateral spreading, and

excessive settlement that can have severe

consequences upon the integrity of waste

containment systems. Liquefaction-associated

lateral spreading and flow failures can also

affect the global stability of a waste containment

facility.

There is need to understand the mechanism of

soil liquefaction, where it occurs and why it

occurs so often during earthquake. Liquefaction

of soil is a process by which sediments below

the water table lose their shear strength and

behave more as viscous liquid than as a solid.

The water in the soil voids exerts pressure upon

the soil particles. If the pressure is low enough,

the soil stays stable. However, once the water

pressure exceeds a certain level, it forces the soil

particles to move relative to each other, thus

causing the strength of the soil to decrease and

failure of the soil. So when the earthquake

occurs the shear waves passes through

saturated soil layers and causes the granular soil

structure to deform and weak part of soil begins

to collapse.

Then collapse soil starts filling the lower layer

and forces the pore water pressure in this to

increase layer. If increased water pressure

cannot be released, it will continue to build up

and after a certain limit effective stress of the

soil becomes zero .If situation aroused then the

soil layer losses its shear strength and it cannot

certain the total weight of the soil layer above,

Virtu and Foi..

18

GJESR RESEARCH PAPER VOL. 1 [ISSUE 10] NOVEMBER, 2014

ISSN:- 2349283X

thus the upper layer soils are ready to move

down and behaves as a viscous liquid, if then it

is said to be soil liquefaction occurred.

produces unacceptably large permanent

deformation during earthquake shaking, which

is also known as lateral spreading. It can occur

on very gently sloping ground or on virtually flat

ground adjacent to bodies of water.

Flow liquefaction occurs much less frequently

than cyclic mobility but its effects are usually far

more severe. Besides these two types, Ground

oscillation, loss of bearing strength and sand

boils are common phenomena of Liquefaction.

Fig-1. Mechanism of Liquefaction (courtesy:

http://www.cee.ehime-u.ac.jp)

Geology of Gorakhpur

The district of Gorakhpur lies between Lat.

2613N and 2729N and Long. 8305E and

8356E. The district occupies the north-eastern

corner of the state along with the district of

Deoria, and comprises a large stretch of country

lying to the north of the river Rapti, the deep

stream of which forms its southern boundary

with the Azamgarh district. On the west, the

boundary marches along Basti and on the east

adjoins Deoria and the Chhoti Gandak Nadi and

further south the Jharna Nala forms the dividing

line. To the north lies Nepal. Gorakhpur has also

a lake Ramgarh Tal Lake, which is 18 km bigger.

It is bigger than Dal Lake of Kashmir which is of

15.5 km Ramgarh Tal. It's vast and provides

home to various types of fishes. Geography it is

located on the bank of river Rapti and Rohani, a

Ganges tributary originating in Nepal that

sometimes causes severe floods. The Rapti is

interconnected through many other small rivers

following meandering courses across the

Gangetic

Plain.

The

district

presents

characteristics distinct from natural features of

the western districts of Uttar Pradesh. This

difference is due primarily to the relative

proximity of the Himalayas, the outermost

foothills of which are only a few kilometres from

the northern borders. The peak of Dhaulagiri,

some 8,230 meters above sea-level, is visible

under favourable climatic conditions as far

south as Gorakhpur itself. The district geology is

primarily river born alluvium. Few mineral

products are mined in Gorakhpur, with the most

common

being

a

nodular

limestone

conglomerate known as kankar, brick, and

saltpetre. The last occurs principally in the south

and south-east and is manufactured in a crude

state in considerable quantities most of it being

exported to markets of Bihar. In the Bans gaon

Liquefaction occurs in saturated soils, in which

the space between individual particles is

completely filled with water. Its effects are most

commonly observed in low-lying areas near

bodies of water such as rivers, lakes, bays, and

oceans (ABAG's Report, "Real dirt on

Liquefaction, 2001).

Liquefaction occurs in Cohesionless sand

deposited in alluvial environment. Areas of high

liquefaction potentials are alluvial floodplains,

deltaic deposits, estuaries deposit, colluvial and

aeolian deposit, artificial fill etc. Areas of

medium liquefaction potentials are alluvial fans,

channel deposits, and beaches. Areas of coarse

deposits and rock debris do not undergo

liquefaction. The susceptibility to liquefaction

depends on the density of the sand and intensity

of ground motion (amplitude and duration).

According to Kramer (1996), two types of

liquefaction exist.

Flow Liquefaction:

It occurs when the shear stress required for

static equilibrium of a soil mass (The static

shear stress) is greater than the shear strength

of the soil in its liquefied state. When

liquefaction occurs in such case the strength of

the soil decreases and the ability of soil deposit

to support for the structure is reduced.

Flow liquefaction failures are characterized by

the sudden nature of their origin, the speed with

which they develop and the large distance cover

over which the liquefied materials often move.

Cyclic mobility:

It occurs when the static shear stress is less than

the shear strength of the liquefied soil. It

Virtu and Foi..

19

GJESR RESEARCH PAPER VOL. 1 [ISSUE 10] NOVEMBER, 2014

tehsil kankar is most abundant and quarries are

seen at many places. It is also extracted from

some places in Mahrajganj tehsil. Lime is

obtained by burning kankar. Brick clay is

abundant everywhere and bricks are made all

over the district. The soil in the district is light

sandy or dense clay of yellowish brown colour.

The sand found in the rivers is medium to coarse

grained, greyish white to brownish in colour and

is suitable for construction. The high seismic

activity occurred in Nepal, the Gorakhpur lies in

the border of Nepal. This impasses a very high

risk of an earthquake disaster in Gorakhpur

resulting into great damage. To determine the

potential hazard due to an earthquake

ISSN:- 2349283X

appropriate

site

characterization

and

determination of the soil properties are

essential in order to suitably design a structure.

Ramgarh Tal, a natural lake, is situated to the

southeast of Gorakhpur in Uttar Pradesh and

covers an area of about 723 ha. The catchment

area around the lake is approximately 1632

acres, out of which, 1235 acres land is under

Gorakhpur Development authority (GDA).As we

know that Gorakhpur is under seismic zone the

need of liquefaction analysis requires the

characterization of soil profile. So my work is to

analyse the liquefaction potential of an area and

the liquefaction potential map.

Fig-2. Map of Ramgarh Tal Pariyojna

GENERATION OF SUBSURFACE DATA AND

DATA ACQUISITION

Collection and organisation of the data

The effective management of borehole data is

crucial for many applications in the geosciences;

among which is earthquake microzonation

(Houlding, 1994). Collection and organization of

data-extensive borehole data is collected from

various locations of Ramgarh Tal pariyojna and

seventeen borehole data were collected at

different sites shown in fig 3.1 for liquefaction

zonation. The collected geotechnical data is in

different formats depending upon the source of

organization and the particular project. Data is

then synthesized and was brought to common

platform needed for the geotechnical

characterization and liquefaction study. The

data is given in appendix.

Data acquisition

Data acquisition is one of the most difficult parts

of a research work. It is time consuming and

more personal relations are required, in order to

contact people in institutions that might have

relevant data.

Data management

All the data managed in a same platform so as to

easily accessible. Data used to analyse

liquefaction potential of a soil, Microsoft Excel

2000 and Microsoft Access were used to store

the borehole data. Initially the data were

entered in the Excel sheets. After the data

acquisition was completed, all the boreholes

were grouped according to their types and

source as shown in the tables given in appendix.

The deep bore holes are used to study the

geological evaluation of the site. Three tables are

Virtu and Foi..

20

GJESR RESEARCH PAPER VOL. 1 [ISSUE 10] NOVEMBER, 2014

generated - One containing attributes such as:

Borehole_id, location, depth range, geological

information, Soil type, thickness of the layers,

SPT N, corrected N-value and SPT curve. The

second and third type of tables includes the

geotechnical information with the following

attributes: Borehole-id, Location, Depth range,

particle size distribution, consistency limit, soil

classification, Moisture content, Bulk Density,

Unit weight, and, shear characteristics.

ISSN:- 2349283X

Table: 02. SUMMARY OF MECHANICAL

GRADING AND CONSISTANCY LIMIT

Site: Proposed GDA Staff Quarter Building,

Siddhartha Enclave, Gorakhpur

Bore Hole No-01

APPENDIX-1

Table: 01.BORELOG CHART AND SPT CURVE

Site: Proposed GDA Staff Quarter Building,

Siddhartha Enclave, Gorakhpur

Bore Hole No-01

Table: 03. SUMMARY OF LABORATORY

RESULTS

Site: Proposed GDA Staff Quarter Building,

Siddhartha Enclave, Gorakhpur

Bore Hole No-01

Fig-3. Map of Ramgarh Tal pariyojna representing Location of Bore Holes

Virtu and Foi..

21

GJESR RESEARCH PAPER VOL. 1 [ISSUE 10] NOVEMBER, 2014

LITREATURE REVIEW

A liquefaction analysis should, at a minimum,

address the following:

Developing a detailed understanding of site

conditions, the soil stratigraphy, material

properties and their variability, and the

areal extent of potential critical layers.

Developing

simplified

cross-sections

amenable to analysis. SPT procedures are

widely used in practice to characterize the

soil (field data are easier to obtain on loose

cohesion less soils than trying to obtain and

test undisturbed samples). The data needs

to be corrected as necessary, for example,

using the normalized SPT blow count

[(N1)60] or the normalized CPT. The total

vertical stress (vo) and effective vertical

stress (vo') in each stratum also need to be

evaluated. This should take into account the

changes in overburden stress across the

lateral extent of each critical layer, and the

temporal high phreatic and piezometric

surfaces,

Calculation of the force required to liquefy

the critical zones, based on the

characteristics of the critical zone(s) (e.g.,

fines content, normalized standardized blow

count, overburden stresses, level of

saturation),

Calculation of the design earthquakes effect

on each potentially liquefiable layer should

be performed using the site-specific in situ

soil data and an understanding of the

earthquake magnitude potential for the

facility, and

Computing the factor of safety against

liquefaction

for

each

liquefaction

susceptible critical

Field Methods

The use of insitu testing is the dominant

approach in common engineering practice for

quantitative

assessment

of

liquefaction

potential. Calculation of two variables is

required for evaluation of liquefaction

resistance of soils (Seed et al, 2001; Youd et al,

2001).They is as follows

1. The seismic demand on a soil layer

expressed in terms of CSR and

2. The capacity of the soil to resist liquefaction

expressed in terms of CRR.

ISSN:- 2349283X

The models proposed by Seed & Idriss methods

are extensively used for predicting liquefaction

potential using field data.

Seed & Idriss method

After the disastrous earthquakes in Alaska and

in Niigata, Japan in 1964, Professors Seed and

Idriss (1971), developed and published a

methodology termed the simplified procedure

for evaluating liquefaction resistance of soils.

Seed and Idriss (1971) developed and published

the basic simplified procedure. That

procedure has been modified and improved

periodically since that time, primarily through

landmark papers by Seed (1979), Seed and

Idriss (1982), and Seed et al. (1985). In 1985,

Whitman (1985) convened a workshop on

behalf of the National Research Council (NRC),

USA in which 36 experts and observers

thoroughly reviewed the state-of-knowledge

and the state-of-the-art for assessing

liquefaction hazard. That workshop produced a

report (NRC 1985) that has become a widely

used standard and reference for liquefaction

hazard assessment. Liquefaction is defined as

the transformation of a granular material from a

solid to a liquefied state as a consequence of

increased pore-water pressure and reduced

effective stress (Marcuson 1978). Increased

pore-water pressure is induced by the tendency

of granular materials to compact when

subjected to cyclic shear deformations. The

change of state occurs most readily in loose to

moderately dense granular soils with poor

drainage, such as silty sands or sands and

gravels capped by or containing seams of

impermeable sediment. As liquefaction occurs,

the soil stratum softens, allowing large cyclic

deformations to occur. In loose materials, the

softening is also accompanied by a loss of shear

strength that may lead to large shear

deformations or even flow failure under

moderate to high shear stresses, such as beneath

a foundation or sloping ground. In moderately

dense to dense materials, liquefaction leads to

transient softening and increased cyclic shear

strains, but a tendency to dilate during shear

inhibits major strength loss and large ground

deformations. A condition of cyclic mobility or

cyclic liquefaction may develop following

liquefaction of moderately dense granular

Virtu and Foi..

22

GJESR RESEARCH PAPER VOL. 1 [ISSUE 10] NOVEMBER, 2014

materials. Beneath gently sloping to flat ground,

liquefaction may lead to ground oscillation or

lateral spread as a consequence of either flow

deformation or cyclic mobility. Loose soils also

compact

during

liquefaction

and

reconsolidation, leading to ground settlement.

Sand boils may also erupt as excess pore water

pressures dissipate.

CYCLIC STRESS RATIO (CSR) AND

CYCLICRESISTANCE RATIO (CRR)

Calculation, or estimation, of two variables is

required for evaluation of liquefaction

resistance of soils: (1) the seismic demand on a

soil layer, expressed in terms of CSR; and (2) the

capacity of the soil to resist liquefaction,

expressed in terms of CRR.

EVALUATION OF CSR

Seed and Idriss (1971) formulated the following

equation for calculation of the cyclic stress ratio:

ISSN:- 2349283X

Blake (1996) approximated the mean curve

plotted in Fig. 2.6 by the following equation:

(3)

Where z= depth beneath ground surface in

meters. Eq. (3) yields essentially the same

values for rd as (2), but is easier to program and

may be used in routine engineering practice.

CSR = (av /vo) = 0.65(amax /g) (vo /'vo)rd (1)

Where amax = peak horizontal acceleration at the

ground surface generated by the earthquake; g =

acceleration of gravity; vo and 'vo are total and

effective

vertical

overburden

stresses,

respectively; and rd= stress reduction

coefficient. For routine practice and noncritical

projects, the following equations may be used to

estimate average values of rd (Liao and Whitman

1986b):

rd= 1.0 -0.00765z for z 9.15 m

(2a)

rd= 1.174 -0.0267z for 9.15 m <z 23 m

(2b)

Where z= depth below ground surface in meters.

Some investigators have suggested additional

equations for estimating rd at greater depths

(Robertson and Wride 1998), but evaluation of

liquefaction at these greater depths is beyond

the depths where the simplified procedure is

verified and where routine applications should

be applied. Mean values of rd calculated from (2)

are plotted in Fig. 4, along with the mean and

range of values proposed by Seed and Idriss

(1971). With past practice, rd values determined

from (2) are suitable for use in routine

engineering practice. Factor rd calculated from

(2) are the mean of a wide range of possible rd,

and that the range of rd increases with depth

(Golesorkhi 1989).For ease of computation,

FIG-4. rd versus Depth Curves Developed by

Seed and Idriss(1971) with Added MeanValue Lines Plotted from Eq. (2)

EVALUATION OF LIQUEFACTION RESISTANCE

(CRR)

A plausible method for evaluating CRR is to

retrieve and test undisturbed soil specimens in

the laboratory. Unfortunately, in situ stress

states generally cannot be reestablished in the

laboratory, and specimens of granular soils

retrieved with typical drilling and sampling

techniques are too disturbed to yield meaningful

results. Only through specialized sampling

techniques, such as ground freezing, can

sufficiently undisturbed specimens be obtained.

Criteria for evaluation of liquefaction

resistance based on the SPT

Criteria for evaluation of liquefaction resistance

based on the SPT have been rather robust over

the years. Those criteria are largely embodied in

the CSR versus (N1)60 plots reproduced in Fig. 5,

(N1)60 is the SPT blow count normalized to an

overburden pressure of approximately 100 kPa

(1 ton/sqft) and a hammer energy ratio or

hammer efficiency of 60%. Fig. 2.7 is a graph of

Virtu and Foi..

23

GJESR RESEARCH PAPER VOL. 1 [ISSUE 10] NOVEMBER, 2014

calculated CSR and corresponding (N1)60 data

from sites where liquefaction effects were or

were not observed following past earthquakes

with magnitudes of approximately 7.5. CRR

curves on this graph were conservatively

positioned to separate regions with data

indicative of liquefaction from regions with data

indicative of nonliquefaction. Curves were

developed for granular soils with the fines

contents of 5% or less, 15%, and 35% as shown

on the plot. The CRR curve for fines

contents<5% is the basic penetration criterion

for the simplified procedure and is referred to

hereafter as the SPT clean sand base curve.

The CRR curves in Fig. 2 are valid only for

magnitude 7.5 earthquakes. Scaling factors to

adjust CRR curves to other magnitudes are

addressed in a later section of this report.

ISSN:- 2349283X

Rauch (1998), approximated the clean-sand

base curve plotted in Fig.5, by the following

equation:

(4)

This equation is valid for (N1)60< 30. For

(N1)6030, clean granular soils are too dense to

liquefy and are classed as nonliquefiable. This

equation may be used in spreadsheets and other

analytical techniques to approximate the cleansand base curve for routine engineering

calculations.

FIG-5. SPT Clean-Sand Base Curve for Magnitude 7.5 Earthquakes with Data from Liquefaction

Case Histories (Modified from Seed et al. 1985)

Influence of Fines Content

In the original development, Seed et al. (1985)

noted an apparent increase of CRR with increased

fines content. Whether this increase is caused by

an increase of liquefaction resistance or a

decrease of penetration resistance is not clear.

Based on the empirical data available, Seed et al.

developed CRR curves for various fines contents

reproduced in Fig. 5.

The following equations were developed by Seed

and Idriss (1971) with the assistance of R. B. Seed

for correction of (N1)60 to an equivalent clean

sand value, (N1)60cs:

(N1)60cs= + (N1)60

(5)

= 0 for FC 5%

(6a)

= exp [1.76 2 (190/FC)] for 5% < FC < 35%

(6b)

= 5.0 for FC 35%

(6c)

= 1.0 for FC 5%

(7a)

1.5 = [0.99 1 (FC /1,000)] for 5% < FC < 35%

(7b)

= 1.2 for FC 35%

(7c)

Virtu and Foi..

24

GJESR RESEARCH PAPER VOL. 1 [ISSUE 10] NOVEMBER, 2014

ISSN:- 2349283X

Where and = coefficients determined from the

following relationships:

These equations may be used for routine

liquefaction resistance calculations. A backcalculated curve for a fines content of 35% is

essentially congruent with the 35% curve plotted

in Fig. 5. The back-calculated curve for fines

contents of 15%plots to the right of the original

15% curve.

Other Corrections

Several factors in addition to fines content and

grain characteristics influence SPT results, as

noted in. Eq. (8) incorporates these corrections

(N1)60 = Nm CN CE CB CR CS

(8)

Where:Nm= measured standard penetration resistance;

CN=factor to normalize Nm to a common reference

effective overburden stress;

CE= correction for hammer energy ratio (ER);

CB= correction factor for borehole diameter;

CR= correction factor for rod length; and

CS= correction for samplers with or without liners.

Because SPT N-values increase with increasing

effective overburden stress, an overburden stress

correction factor is applied (Seed and Idriss

1982). This factor is commonly calculated from

the following equation (Liao and Whitman

1986a):

CN= (P /'VO)

(9)

Where:CN normalizes Nm to an effective overburden

pressure of 'vo approximately 100 kPa (1 atm) Pa.

CN should not exceed a value of 1.7

The effective overburden pressure 'vo applied in

equation (8) should be the overburden pressure

at the time of drilling and testing. Although a

higher ground-water level might be used for

conservatism in the liquefaction resistance

calculations, the CN factor must be based on the

stresses present at the time of the testing.

FIG-6. CN Curves for Various Sands Based on

Field and Laboratory Test Data along with

Suggested CN Curve Determined from Eqs. (9)

and (10) (Modified from Castro 1995)

Skempton (1986) suggested and Robertson and

Wride (1998) updated correction factors for rod

lengths <10 m, borehole diameters outside the

recommended interval (65125mm), and

sampling tubes without liners. Range for these

correction factors is listed in Table 2.3 For

liquefaction resistance calculations and rod

lengths <3 m, a CR of 0.75 should be applied as

was done by Seed et al. (1985) in formulating the

simplified procedure.

STANDARD PENETRATION TEST (SPT)

The standard penetration test (SPT) is an

empirical dynamic penetration test developed in

USA in the 1920s and was usually carried out in

50 to 100 mm diameter wash borings. The test is

most commonly used in situ test especially for

cohesionless soils, which cannot be easily

sampled. The test is extremely used for

determining the relative density, bearing capacity

and the angle of shearing resistance of the

cohesionless soil. The test is performed using a

split barrel sample tube of 50 mm external

diameter, 35 mm internal diameter and about 65

mm in length as specified in BS 1377.

In this process, a hammer of 63.5 kg weight with a

free fall height of 750 mm is used to drive the

sampler. Initially the sampler is driven 150 mm

into the sand to seat the sampler and by-pass any

disturbed sand at the bottom of the borehole. The

number of blows required to drive the sampler a

further 300 mm is then recorded. This number is

Virtu and Foi..

25

GJESR RESEARCH PAPER VOL. 1 [ISSUE 10] NOVEMBER, 2014

called the Standard penetration resistance (N)

value. If 50 blows are reached before a

penetration of 30 cm no further blows should be

recorded. If the test is to be carried out in gravelly

soils, the driving shoe is replaced by the 600 cone.

SPT test is very specific tool for the liquefaction

hazard analysis. It also has the unique feature of

supplying samples for soil classification purpose.

Usually SPT is conducted at every 1 m depth or at

the change of stratum.

The N-values are extensively used in determining

the bearing capacity and predicting the settlement

of cohesionless soil and are described by a

number of authors (Meyerhof, 1956; Terzaghi and

Peck, 1967). It has wide application in

determining the liquefaction susceptibility of a

place.

There are a number of factors involved in the SPT,

which can affect the blow count, mainly related to

poor testing practice. The standard penetration

number is corrected for dilatancy effect and

overburden effect (Craig, 1986)

(i) Dilatancy correction

Silty fine sands and fine sands below the water

table develop pore pressure, which is not easily

dissipated. The pore pressure affects the

resistance of the soil and hence the penetration

number (N). Terzaghi and peck (1967)

recommend the following correction in the case of

silty fine sands when the observed value of N

exceeds 15.

1

N'= 15 + (N -15)

2

ISSN:- 2349283X

hammer being referred to as the rod energy ratio,

which varies between 45% and 78% for the

operating procedures used in several countries. It

has been recommended that a standard rod

energy ratio of 60% should be adopted and that

all measured N values should be normalized by

simple proportion of energy ratios, to this

standard: the normalized values are denoted

(N1)60.

Standard penetration resistance depends not only

on relative density but also on the effective

stresses at the depth of measurements. Effective

stresses can be represented to a first

approximation by effective overburden pressure.

This dependence was first demonstrated in the

laboratory by Gibbs and Holtz and was later

confirmed in the field. Sand at the same relative

density would thus give different value of

standard penetration resistance at different

depths. Several proposals have been made for the

correction of measured N values. The corrected

value (N1) is related to the measured value (N) by

the factor CN, where

N1 = CN N

(11)

CN = Correction factor and can be obtained from

the graph prepared by Liao and Whitman, (1986).

Also

CN=

(12)

SPT correction factor, CN

(10) (Craig, 1988)

Where:N Corrected SPT value

N Observed SPT value.

If NR 15,

Nc =NR

(ii)Overburden Pressure

Skempton summarized the evidence regarding

the influence of test procedure on the value of

standard penetration resistance (Craig, 1986).

Measured N value should be corrected to allow for

the different methods of releasing the hammer,

the type of anvil and the total length of boring

rods. Only the energy delivered to the sampler is

applied in penetrating the sand, the ratio of the

delivered energy to the free fall energy of the

Fig -7: SPT overburden correction factor after

Liao and Whiteman (1986)

Virtu and Foi..

26

GJESR RESEARCH PAPER VOL. 1 [ISSUE 10] NOVEMBER, 2014

ISSN:- 2349283X

(N1)60 is the standard penetration resistance

normalized to a rod energy ratio of 60% and an

effective overburden pressure of 100 kN/m2.

MAGNITUDE SCALING FACTORS (MSFs)

The clean-sand base or CRR curves in Fig. 5, only

to magnitude 7.5 earthquakes. To adjust the

clean-sand curves to magnitudes smaller or larger

than 7.5, Seed and Idriss (1982) introduced

correction factors termed magnitude scaling

factors (MSFs). These factors are used to scale

the CRR base curves upward or downward on

CRR versus (N1)60, qc1N, or Vs1 plots.

Conversely, magnitude weighting factors, which

are the inverse of magnitude scaling factors, may

be applied to correct CSR for magnitude. Either

correcting CRR via magnitude scaling factors, or

correcting CSR via magnitude weighting factors,

leads to the same final result.

To illustrate the influence of magnitude scaling

factors on calculated hazard, the equation for

factor of safety (FS) against liquefaction is written

in terms of CRR, CSR, and MSF as follows:

FS = (CRR7.5/CSR) MSF

(13)

Where CSR = calculated cyclic stress ratio

generated by the earthquake shaking; and CRR7.5

= cyclic resistance ratio for magnitude 7.5

earthquakes. CRR7.5 is determined from Fig. 2 7

for SPT data, MSF= Magnitude Scaling Factor.

In 2001 Youd and Idriss recommend the

following equation for obtaining MSF

MSF=102.24/Mw2.56,

Where,

Mw=

Magnitude of earthquake

When the design ground motion is conservative,

earthquake-related

permanent

ground

deformation is generally small if FS 1.

Liquefaction Hazard Assessment /Liquefaction

potential Analysis

If potential exists for liquefaction at a facility,

additional subsurface investigation may be

necessary. Once all testing is complete, a factor of

safety against liquefaction is then calculated for

each critical layer that may liquefy.

Fig-8, Flow chart for Liquefaction Hazard

Assessment

As mentioned that our first aim is to analyse

liquefaction potential of soil and to prepare

liquefaction susceptibility map of Ramgarh Tal

pariyojna using borehole data. Liquefaction

phenomena have been recorded in many parts of

the world, where ground shaking is frequent and

soils consist of loose fine sand where the water

table is shallow. Liquefaction of saturated loose

sands and silty sands induce flow slides,

differential settlement, and subsidence, leading

damage to buildings and infrastructure and

eventually to loss of life.

Determination of liquefaction potential due to

earthquake is complex geotechnical problem.

Many factors including soil parameters and

seismic

characteristics

influence

this

phenomenon To assess the liquefaction hazard in

an area, it is important to examine the

geotechnical characteristics like grain size

distribution, percentage of silt, water table ,water

table depth,D50 value and SPT N value. The

percentage of silt and poorly graded sand is high

in the area under Ramgarh Tal Pariyojna

indicating that there is a great chance of soil

liquefaction. Here liquefaction potential analysis

is done to determine the factor of safety at

different depth. The liquefaction potential of

Ramgarh Tal Pariyojna in Gorakhpur city using

SPT data collected from the various sites of

pariyojna is estimated by simplified procedure of

Seed & Idriss (1982).

The methodology used to estimate the

liquefaction potential is given as example for one

borehole Excel spread sheet used to calculate the

Virtu and Foi..

27

GJESR RESEARCH PAPER VOL. 1 [ISSUE 10] NOVEMBER, 2014

Factor of Safety with depth and enclosed in tables

ISSN:- 2349283X

shown below.

Table: 04. LIQUIFACTION ASSESSMENT OF PROPOSED GDA STAFF QUARTER BUILDING,

SIDDHARTHA ENCLAVE, GORAKHPUR

(BORE HOLE-1)

RESULTS AND ITS DISCUSSIONS

Result of liquefaction is shown with depth for of

each site of bore holes and graph shows factor of

safety vs. depth.

Factor of Safety (FS)

0

0 .2

0 .4

0 .6

0 .8

1 .2

1 .4

1 .6

Depth (m)

Bore hole Number 1 (BH1)

The analysis of SPT results at Bore hole number

1(BH1) shows that the strata between depths

13.65-15.05 m are Non-Liquefiable, and the strata

between 1.65-12.5 m are liable to liquefy under

earthquake shaking corresponding to peak

horizontal ground acceleration of 0.33g.

10

12

14

16

Depth vs Factor of Safety

Fig-9. Depth vs. Factor of Safety (Bore Hole-1)

Virtu and Foi..

28

GJESR RESEARCH PAPER VOL. 1 [ISSUE 10] NOVEMBER, 2014

ISSN:- 2349283X

Factor of Safety

0

0.5

1.5

2.5

depthbh1 vs. FS bh1

2

depthbh2 vs. FS bh2

depthbh3 vs. FS bh3

depthbh4 vs. FS bh4

depthbh5 vs. FS bh5

depthbh6 vs. FS bh6

Depth (m)

depthbh7 vs. FS bh7

depthbh8 vs. FS bh8

depthbh9 vs. FS bh9

depthbh10 vs. FS bh10

depthbh10 vs. FS bh11

depthbh12 vs. FS bh12

10

depthbh13 vs. FS bh13

depthbh14 vs. FS bh14

depthbh15 vs. FS bh15

12

depthbh17 vs. FS bh17

14

16

Depth vs Factor of Safety

Fig-10. Depth vs Factor of safety of all borehole

Fig-11- Depth wise liquefaction of each bore hole

Virtu and Foi..

29

GJESR RESEARCH PAPER VOL. 1 [ISSUE 10] NOVEMBER, 2014

ISSN:- 2349283X

Fig-12. - Liquefaction Hazard map of Ramgarh Tal Pariyojna

CONCLUSION

Based on the study for assessment of liquefaction

potential for Ramgarh Tal Pariyojna, it is

concluded that soil of study area is susceptible to

liquefaction extra care should be taken against

liquefaction during construction upon this type of

soil. The Study area being a reclaimed area has a

top layer of loose fine sand followed by soft to

medium or loose sandy silt or clayey silt is also

susceptible to liquefaction.

In this study we concluded that if earthquake

more than or equal to 6.5 ritcher scale occurs in

Gorakhpur region, it will be extensively damaged

due to liquefaction.

In the fig 19, we have bore hole position

wise combined data of all the studied

boreholes and depth wise zone of

liquefaction, and zone of no liquefaction.

Observation of combined graph shows

liquefaction potential for each borehole

and depth upto which soil may liquefy

during an earthquake, for the design of

any structure in the considered area, if

liquefaction is to be considered then an

average depth of 6m can be taken for the

analysis

purposes.

An

average

Virtu and Foi..

liquefaction is observed upto the depth

6m.

In fig 18. combined graph is drawn

between factor of safety and depth of

borehole in which all soils below factor of

safety -1 is susceptible to liquefaction and

should be considered for mitigation

before building a structure on it.

The percentage of silt and poorly graded

sand is high in the area under Ramgarh

Tal Pariyojna indicating that there is a

great chance of soil liquefaction. Here

liquefaction potential analysis is done to

determine the factor of safety at different

depth.

Construction on liquefaction susceptible

soils is to be avoided. It is required to

characterize the soil at a particular

building site according to the various

criterias available to determine the

liquefaction potential of the soil in a site.

The structure constructed should be

liquefaction resistant i.e., designing the

foundation elements to resist the effects

of liquefaction if at all it is necessary to

construct the structure on liquefiable soil

30

GJESR RESEARCH PAPER VOL. 1 [ISSUE 10] NOVEMBER, 2014

because of favourable location, space

restriction and other reasons.

This involves mitigation of the

liquefaction hazards by improving the

strength,

density

and

drainage

characteristics of the soil. This can be

done using variety of soil improvement

techniques.

REFERENCES

1.

ABAG (2001). Bay area Liquefaction Hazard

The

REAL

Dirt

on

Liquefaction.

(http://www.abag.ca.gov/bayarea/eqmaps/li

quefac/liquefac.html,)

2. ABAG (2001). Collection and analysis of

Liquefaction data from the Northridge and

Loma Prieta Earthquakes Appendix C

3. Andrus, R. D. and Stokoe, K. H.( 1997)

Liquefaction Resistance of Roils from Shear

Wave Velocity. In Proceedings of NCEER

Workshop on Evaluation of Liquefaction

Resistance of Soils, , pp. 89128..

4. Craig, R.F. (1986). Soil Mechanics (4th

edition). Van Nostrand Reinhold co.ltd. (UK).

5. IS: 1893-2002, Criteria for Earthquake

Resistant Design of Structures.

6. Iwasaki, T., Tokida, K., Tatsuoka, F., Watanabe,

S.,Yasuda, and Sato, H. (1982), Microzonation

for soil Liquefaction Potential Using

Simplified Methods. In Proceedings of Third

International Conference on Microzonation,

Seattle, , vol. 3,pp. 13101330.

7. Youd T. L and I. M. Idriss, Editors, (1997).

National Centre for Earthquake Engineering

Research (NCEER), Proceedings of the NCEER

Workshop on Evaluation of Liquefaction

Resistance of Soils,., Technical Report NCEER97-022

8. Rao, K. S. (2003), Seismic Microzonation of

Delhi region. In Proceedings of 12th Asian

Regional Conference, Singapore, , vol. 1, pp.

327330.

9. Rao, K. S. (2001) and Mohanty, W. K.,

Microzonation of Delhi region: An approach.

J. Indian Build. Congr., 8, 102114.

10. Rao, K. S. (2001), Liquefaction Studies for

seismic Microzonation of Delhi region. In

Indian Geotechnical Conference, vol. 2, pp.

4451.

ISSN:- 2349283X

11. Rao, K. S., Stability and rehabilitation aspects

of earth dams damaged during the Bhuj

earthquake, India. Proc. Forensic Geotech.

Engg., 2003, 1, 151158.

12. Seed, H. B. and Idriss, I. M., (1971) Simplified

Procedure for Evaluating Soil Liquefaction

Potential. J. Soil Mech. Found. Div., , 97, 1249

1273.

13. Seed, H. B., (1979) Soil Liquefaction and

Cyclic Mobility Evaluation for Level Ground

During Earthquakes. J. Geotech. Eng. Div., ,

105, 210255.

14. Seed, H.B., and Idriss, I.M., and Arango, I.

(1983). Evaluation of liquefaction potential

Using Field Performance data. ASCE Journal of

Geotechnical Engineering,

109(3),

458482.

15. Seed, H.B. (1997),Soil Liquefaction and Cyclic

Mobility Evaluation Level Ground During

Earthquake, J. of Geotech Engrg Div, ASCE,

22(3), pp. 298-307.

16. Seed H.B., Tokimatsu, K., L.F. and Chung, R.M.

(1985). The Influence of SPT Procedures in

soil Liquefaction Resistance Evaluations, J. of

Geotech Engrg Div, ASCE,

111(20),

pp.

1425-1445.

17. Whitman, R.V., 1971. Resistance of Soil to

Liquefaction and Settlement. Soils Found 11

(4), 5968.

18. Youd, T. L. and Perkins, D. M, (2004) Mapping

Liquefaction

Induced

Ground

Failure

Potential. J. Geotech. Eng. Div. ASCE, 1978,

104, 433446. DST Report, Geo-Scientific

Studies in and around Delhi, , p. 74.

19. Youd, T.L. and Idriss, (2001).Liquefaction

Resistance of Soils: Summary Report from

1996 NCEER and 1998 NCEER/NSF

Workshop on Evaluation of Liquefaction

Resistance of Soils, J. of Geotech& Geo- env.,

ASCE 127(4) pp.297

20. Youd, T. L., 1991. Mapping of Earthquake

Induced Liquefaction for Seismic Zonation.

Proc. Fourth Int. Int. Conf. Seismic Zonation 1,

pp. 111-147

21. Youd, T.L.,(1984a).Recurrence of Liquefaction

at the same site, Proceedings, 8th World

Conference on Earthquake Engineering, Vol.

3, pp. 2313-238.

Virtu and Foi..

31

GJESR RESEARCH PAPER VOL. 1 [ISSUE 10] NOVEMBER, 2014

Youd, T. L., and Perkins, D.M. (1978). Mapping

Liquefaction-Induced

GroundFailure Potential,

ISSN:- 2349283X

Proc. ASCE Civil Eng., v.104, n0. GT4, p. 433-446.

Virtu and Foi..

32

You might also like

- ES-153-SCC-Design - Panel + Geostrap - Backfill-Sandy Soil - 01Document314 pagesES-153-SCC-Design - Panel + Geostrap - Backfill-Sandy Soil - 01Er navneet jassiNo ratings yet

- L1 - Introduction-Rock MechanicsDocument42 pagesL1 - Introduction-Rock Mechanicsroxcox2160% (1)

- Ground Freezing 1980: Selected Papers from the Second International Symposium on Ground Freezing, Trondheim, Norway, 24-26 June 1980From EverandGround Freezing 1980: Selected Papers from the Second International Symposium on Ground Freezing, Trondheim, Norway, 24-26 June 1980No ratings yet

- Complete WorkDocument51 pagesComplete WorkOdell Arome Darian100% (3)

- Celebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985From EverandCelebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985No ratings yet

- Vibroreplacement PDFDocument9 pagesVibroreplacement PDFthadikkaranNo ratings yet

- International Society for Rock Mechanics: List of Members 1980From EverandInternational Society for Rock Mechanics: List of Members 1980Rating: 3.5 out of 5 stars3.5/5 (2)

- Soil Nailing PDFDocument14 pagesSoil Nailing PDFRonald De GuzmanNo ratings yet

- Pinhole Erosion Test For Identification of Dispersive ClaysDocument28 pagesPinhole Erosion Test For Identification of Dispersive ClaysAndyra Jaiz Baddu100% (1)

- Semi-Empirical Procedures For Evaluating Liquefaction Potential, Idriss & Boulanger, 2004Document26 pagesSemi-Empirical Procedures For Evaluating Liquefaction Potential, Idriss & Boulanger, 2004hugojameswoodNo ratings yet

- Design of Piles Under Cyclic Loading: SOLCYP RecommendationsFrom EverandDesign of Piles Under Cyclic Loading: SOLCYP RecommendationsAlain PuechNo ratings yet

- Drainage Systems AssignmentDocument19 pagesDrainage Systems AssignmentKayseri PersaudNo ratings yet

- A Comprehensive Database of Tests on Axially Loaded Piles Driven in SandFrom EverandA Comprehensive Database of Tests on Axially Loaded Piles Driven in SandNo ratings yet

- Chapter 5 - Part III - Ground ImprovementDocument42 pagesChapter 5 - Part III - Ground Improvementsam19961No ratings yet

- Analysis of Stone Column in Soft Soil by Finite Elements MethodsDocument15 pagesAnalysis of Stone Column in Soft Soil by Finite Elements MethodsSeif EddineNo ratings yet

- Uplift Capacity of Piles in Two Layered SoilDocument7 pagesUplift Capacity of Piles in Two Layered SoilIAEME PublicationNo ratings yet

- Challenges Associated With Expansive Soils and Remedial MeasuresDocument13 pagesChallenges Associated With Expansive Soils and Remedial MeasuresSaurav BhattacharjeeNo ratings yet

- Shallow and Deep Foundations DR PDFDocument8 pagesShallow and Deep Foundations DR PDFLleiLleiNo ratings yet

- Well Foundation - RVNLDocument9 pagesWell Foundation - RVNLVenkateswarlu DanduNo ratings yet

- On Estimating Slope Stability Reduction Due To Rain Infiltration MoundingDocument36 pagesOn Estimating Slope Stability Reduction Due To Rain Infiltration MoundingSuvadeep DalalNo ratings yet

- PVD Design PDFDocument17 pagesPVD Design PDFAndreas Brian V PNo ratings yet

- New Piles Installation SystemsDocument38 pagesNew Piles Installation SystemsAnand JadoenathmisierNo ratings yet

- Dowel Calculation For Ramp DDocument2 pagesDowel Calculation For Ramp DaselabambarandageNo ratings yet

- Invert Heave in Operation TunnelDocument9 pagesInvert Heave in Operation TunnelKen LiewNo ratings yet

- Characterisation of Soil ESCI 16-2-2012Document102 pagesCharacterisation of Soil ESCI 16-2-2012Divya Tadepalli100% (1)

- Diaphragm Walls Construction and DesignDocument18 pagesDiaphragm Walls Construction and DesignShirley Munoz100% (1)

- Lateral Earth Pressure in Expansive Clay SoilsDocument14 pagesLateral Earth Pressure in Expansive Clay SoilsSamad Arabi100% (1)

- Tunneling in Himalaya'sDocument9 pagesTunneling in Himalaya'sAjay SinghNo ratings yet

- Earth Pressure TheoryDocument20 pagesEarth Pressure TheoryMohan ManickamNo ratings yet

- Failure of An Embankment Treated With Vacuum Preloading MethodDocument4 pagesFailure of An Embankment Treated With Vacuum Preloading MethodtangkokhongNo ratings yet

- Wk9 Bearing Capacity From Field TestsDocument35 pagesWk9 Bearing Capacity From Field TestsAli Saeed100% (2)

- Keynote D.V. KarandikarDocument47 pagesKeynote D.V. KarandikarlingamkumarNo ratings yet

- Case Studies in GGeotech Engineering Constructionseotech Engineering Constructions - B.R.srinivasa MurthyDocument34 pagesCase Studies in GGeotech Engineering Constructionseotech Engineering Constructions - B.R.srinivasa MurthyTHULASI MNo ratings yet

- Bearing Capacity Improvement of Soil Using Bamboo MicropilesDocument14 pagesBearing Capacity Improvement of Soil Using Bamboo MicropilesIsrael AdegboyegaNo ratings yet

- 13-HPCL Vizag Soil Report-VOL.VDocument28 pages13-HPCL Vizag Soil Report-VOL.VDhananjay KumarNo ratings yet

- Foundations On Soft Soils For Khulna MedicalDocument6 pagesFoundations On Soft Soils For Khulna MedicalJahid Jahidul Islam KhanNo ratings yet

- Numerical Analysis of Deep ExcavationsDocument7 pagesNumerical Analysis of Deep ExcavationsChinnaswamy GounderNo ratings yet

- Use of Geogrids in Railroad ApplicationsDocument12 pagesUse of Geogrids in Railroad Applicationsthadikkaran100% (1)

- IND - Indian Railways Erosion Control and DrainageDocument61 pagesIND - Indian Railways Erosion Control and DrainagesubbaraoNo ratings yet

- Assessment of Soil Nailing Performance by Using Finite Element and Finite Difference MethodsDocument14 pagesAssessment of Soil Nailing Performance by Using Finite Element and Finite Difference MethodsHT BinhNo ratings yet

- 2D Numerical Simulations of Soil Nail WallsDocument12 pages2D Numerical Simulations of Soil Nail WallsShahab KhaledNo ratings yet

- The Seepage Control of The Tunnel Excavated in High-Pressure Water Condition Using Multiple Times Grouting Method PDFDocument17 pagesThe Seepage Control of The Tunnel Excavated in High-Pressure Water Condition Using Multiple Times Grouting Method PDFMarsheal FisongaNo ratings yet

- Bearing Capacity of Closed and Open Ended Piles Installed in Loose Sand PDFDocument22 pagesBearing Capacity of Closed and Open Ended Piles Installed in Loose Sand PDFAnonymous 8KOUFYqNo ratings yet

- Consolidation of Soil For Foundation by Using Sand DrainsDocument7 pagesConsolidation of Soil For Foundation by Using Sand DrainsAulia Nurul AnnisaNo ratings yet

- Geotechnical Investigations of Mumbai-Pune ExpresswayDocument17 pagesGeotechnical Investigations of Mumbai-Pune Expresswayblackberry7100gNo ratings yet

- Stabilization of Black Cotton Soil by Using Fly AshDocument52 pagesStabilization of Black Cotton Soil by Using Fly AshManohar ManuNo ratings yet

- PVD Case Study by Soham FoundationsDocument5 pagesPVD Case Study by Soham FoundationsJack DoverNo ratings yet

- Rock-Socketed Large Diameter Bored Pile and Geophysical Survey in Cavernous Karst AreaDocument8 pagesRock-Socketed Large Diameter Bored Pile and Geophysical Survey in Cavernous Karst AreaHilary YNo ratings yet

- Plate Load Test Is.1888.1982Document16 pagesPlate Load Test Is.1888.1982cmthebossNo ratings yet

- Vertical DrainDocument15 pagesVertical DrainSyahbani EkaNo ratings yet

- Terrabind Product DetailsDocument6 pagesTerrabind Product DetailschakrapanithotaNo ratings yet

- Soil Nailed Retaining WallDocument4 pagesSoil Nailed Retaining WallB Divya jyothiNo ratings yet

- Types of Earth Retaining Systems For Deep ExcavationsDocument16 pagesTypes of Earth Retaining Systems For Deep ExcavationsRajesh KhadkaNo ratings yet

- PDF Power Grid On Well FoundationDocument150 pagesPDF Power Grid On Well FoundationLiton ShilNo ratings yet

- Design and Calculation Process of Friction PilesDocument63 pagesDesign and Calculation Process of Friction PilesDoughnut Chilli PiNo ratings yet

- Morth 3200Document9 pagesMorth 3200RameshNo ratings yet

- StabilizationSolidification and Micro-Structural Analysis of Pond Ash Using Lime 05Document4 pagesStabilizationSolidification and Micro-Structural Analysis of Pond Ash Using Lime 05GJESR0% (1)

- Soil Modification Using Shredded Scrap TiresDocument4 pagesSoil Modification Using Shredded Scrap TiresIJBSTRNo ratings yet

- Review On Polymer Nanocomposites by Using Various Resins and Nanoclays and Their Applications 06 JuneDocument8 pagesReview On Polymer Nanocomposites by Using Various Resins and Nanoclays and Their Applications 06 JuneGJESRNo ratings yet

- Studying The Behaviour of Lap Splices in RCC BEAMS 09 JulyDocument4 pagesStudying The Behaviour of Lap Splices in RCC BEAMS 09 JulyGJESRNo ratings yet

- 02 July 2013Document4 pages02 July 2013IJBSTRNo ratings yet

- Utilization of Sugarcane Bagasse Ash (SCBA) As Pozzolanic Material in Concrete A Review 09 AugDocument3 pagesUtilization of Sugarcane Bagasse Ash (SCBA) As Pozzolanic Material in Concrete A Review 09 AugGJESRNo ratings yet

- Single Phase Supply Fed Three Phase Induction Motor Using SVPWM Inverter 04 JuneDocument4 pagesSingle Phase Supply Fed Three Phase Induction Motor Using SVPWM Inverter 04 JuneGJESRNo ratings yet

- Stabilization of Incinerated Hospital Waste Using Different Type of Binders A Review 03 AugDocument4 pagesStabilization of Incinerated Hospital Waste Using Different Type of Binders A Review 03 AugGJESRNo ratings yet

- Experimental Modeling of Shear Behavior of Reinforced Concrete Pile Caps 01 AugDocument9 pagesExperimental Modeling of Shear Behavior of Reinforced Concrete Pile Caps 01 AugfannypramisNo ratings yet

- Speed Control of Doubly-Fed Induction Generator Using PI-Controller 06 AugDocument5 pagesSpeed Control of Doubly-Fed Induction Generator Using PI-Controller 06 AugGJESRNo ratings yet

- 07 July 2013Document5 pages07 July 2013IJBSTRNo ratings yet

- 04 July 2013Document7 pages04 July 2013IJBSTRNo ratings yet

- Sewage Smells Like A Power Source For Developing 03 MayDocument2 pagesSewage Smells Like A Power Source For Developing 03 MayGJESRNo ratings yet

- A Comprehensive Analysis of Space Vector Pulse Width Modulation For 3-Phase Voltage Source Inverter (VSI) 01 JuneDocument7 pagesA Comprehensive Analysis of Space Vector Pulse Width Modulation For 3-Phase Voltage Source Inverter (VSI) 01 JuneGJESR100% (1)

- Second Generation Feedstock Biodiesel From Jatropha 01 MayDocument5 pagesSecond Generation Feedstock Biodiesel From Jatropha 01 MayGJESRNo ratings yet

- Paper Mill Sludge Utilization in Ground Improvement 15 AugDocument4 pagesPaper Mill Sludge Utilization in Ground Improvement 15 AugGJESRNo ratings yet

- Rabies Vaccine Production From Different Viral Infected Cell Line and Vaccine Production 04 FebDocument6 pagesRabies Vaccine Production From Different Viral Infected Cell Line and Vaccine Production 04 FebGJESRNo ratings yet

- Improving The Behavior of Reinforced Concrete Beam With Varying Lap Splices Length 04 AugDocument4 pagesImproving The Behavior of Reinforced Concrete Beam With Varying Lap Splices Length 04 AugGJESRNo ratings yet

- Performance Estimate of Gateway Discovery Techniques in MANET Internet Connectivity 03 JulyDocument4 pagesPerformance Estimate of Gateway Discovery Techniques in MANET Internet Connectivity 03 JulyGJESRNo ratings yet

- Parametric Optimization of Wire EDM by Using Fuzzy Logic 08 AugDocument5 pagesParametric Optimization of Wire EDM by Using Fuzzy Logic 08 AugGJESRNo ratings yet

- Induce Pluripotent Stem Cell Methods, Development and Advancesn 02 FebDocument11 pagesInduce Pluripotent Stem Cell Methods, Development and Advancesn 02 FebGJESRNo ratings yet

- Noise Pollution An Overview 13 AugDocument4 pagesNoise Pollution An Overview 13 AugGJESRNo ratings yet

- Environmental Impact of Paper Industry 05 JuneDocument5 pagesEnvironmental Impact of Paper Industry 05 JuneGJESRNo ratings yet

- Control Strategies For Water Level Control of Two Tank System 11 AugDocument7 pagesControl Strategies For Water Level Control of Two Tank System 11 AugGJESRNo ratings yet

- 10 Aug 2013Document9 pages10 Aug 2013IJBSTRNo ratings yet

- Comparison of Traffic Noise Prediction Using FHWA and ERTC Models in Gorakhpur City 16 AugDocument7 pagesComparison of Traffic Noise Prediction Using FHWA and ERTC Models in Gorakhpur City 16 AugGJESRNo ratings yet

- Design Optimization of The Formation of Boss or Ridge and Passivation of Electrolyte Flow in ECM Process Using CFD Simulation 05 JulyDocument8 pagesDesign Optimization of The Formation of Boss or Ridge and Passivation of Electrolyte Flow in ECM Process Using CFD Simulation 05 JulyGJESRNo ratings yet

- Comparison of Core and Cube Compressive Strength of Hardened Concrete 02 JuneDocument6 pagesComparison of Core and Cube Compressive Strength of Hardened Concrete 02 JuneGJESRNo ratings yet

- CrcwikiDocument8 pagesCrcwikiPratik MahajanNo ratings yet

- Wheelchair Lift Executive SummaryDocument5 pagesWheelchair Lift Executive SummaryIsabelle HanafiahNo ratings yet

- DocumentationDocument131 pagesDocumentationm_adnane_dz3184No ratings yet

- Compare Models - RitchieSpecsDocument4 pagesCompare Models - RitchieSpecsMochammad JihadNo ratings yet

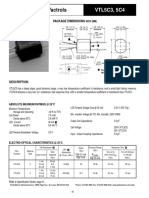

- Low Cost Axial Vactrols: VTL5C3, 5C4Document2 pagesLow Cost Axial Vactrols: VTL5C3, 5C4sillyNo ratings yet

- Bridge Inspection ManualDocument539 pagesBridge Inspection ManualماقوريNo ratings yet

- Power SteeringDocument31 pagesPower SteeringpeskeirasNo ratings yet

- Changes and Implications On Contractors & Sub-ContractorsDocument2 pagesChanges and Implications On Contractors & Sub-ContractorsFrd Ohsem Hafr0% (1)

- Hydrulic Hose and FittingDocument66 pagesHydrulic Hose and FittingMamdouhAlhanafyNo ratings yet

- Saskatchewan Drivers HandbookDocument175 pagesSaskatchewan Drivers HandbookdrivershandbooksNo ratings yet

- Air Compressor Anatomy 101Document20 pagesAir Compressor Anatomy 101Rahul ChandrawarNo ratings yet

- Wolkite University Clearance SystemDocument16 pagesWolkite University Clearance SystemZa Yâ Yâ80% (10)

- Free Spanning Analysis of Offshore PipelinesDocument14 pagesFree Spanning Analysis of Offshore PipelinesMaringan JuliverNo ratings yet

- Bulk CollectDocument5 pagesBulk CollectAbhishekNo ratings yet

- PALRUF 100 Technical Guide (En)Document6 pagesPALRUF 100 Technical Guide (En)mohammed nafethNo ratings yet

- SSH Client LogDocument82 pagesSSH Client LogintorefNo ratings yet

- Interconnecting Cisco Networking Devices Part 1 (100-101) : Exam DescriptionDocument5 pagesInterconnecting Cisco Networking Devices Part 1 (100-101) : Exam DescriptionDaniel DelT̶̽͌͛ͭ̍̔҉̖̯̥̪͈a̛̘̙̠̯̲͝No ratings yet

- 600 / 1000v Stranded Copper Conductors PVC Insulated With Steel Wire Amour and PVC Sheathed Overall. (BS 6346: 1997)Document8 pages600 / 1000v Stranded Copper Conductors PVC Insulated With Steel Wire Amour and PVC Sheathed Overall. (BS 6346: 1997)Himdad TahirNo ratings yet

- Catalogo MQ HDG SsDocument56 pagesCatalogo MQ HDG SsMiguel CamargoNo ratings yet

- Features: Self Reset Auxiliary Flag Relay - Two ElementDocument3 pagesFeatures: Self Reset Auxiliary Flag Relay - Two ElementbledmikifrNo ratings yet

- How To Build Your Own Solid State OscilloscopeDocument100 pagesHow To Build Your Own Solid State OscilloscopemariopilarNo ratings yet

- Octagonal Blender PDFDocument4 pagesOctagonal Blender PDFMohsinShaikhNo ratings yet

- Move Core Application: Fully Integrated 2D and 3D Model Building and AnalysisDocument2 pagesMove Core Application: Fully Integrated 2D and 3D Model Building and AnalysisAlfredo Iguaran AmayaNo ratings yet

- Formula Notes For Cracking Fluid Mechanics For Gate by Jain SirDocument27 pagesFormula Notes For Cracking Fluid Mechanics For Gate by Jain SirSachin Saini93% (27)

- Freno Motor ISMDocument6 pagesFreno Motor ISMFabiiam Kiimtero100% (2)

- General Description: Dual Retriggerable Precision Monostable MultivibratorDocument17 pagesGeneral Description: Dual Retriggerable Precision Monostable Multivibratorsajad hejaziNo ratings yet

- VCS Commands Ease Coverage Efforts - Speed Simulation PDFDocument6 pagesVCS Commands Ease Coverage Efforts - Speed Simulation PDFAnonymous k2nUzQgO6HNo ratings yet

- SS2 Agv200 0300 01Document12 pagesSS2 Agv200 0300 01RaymondIlyasNo ratings yet

- Camara Vivotek IP7361Document74 pagesCamara Vivotek IP7361TecnoSmartNo ratings yet

- General Purpose Hydraulic Valves: Float Level Control ValveDocument2 pagesGeneral Purpose Hydraulic Valves: Float Level Control Valvevelikimag87No ratings yet

- When the Body Says No by Gabor Maté: Key Takeaways, Summary & AnalysisFrom EverandWhen the Body Says No by Gabor Maté: Key Takeaways, Summary & AnalysisRating: 3.5 out of 5 stars3.5/5 (2)

- Gut: the new and revised Sunday Times bestsellerFrom EverandGut: the new and revised Sunday Times bestsellerRating: 4 out of 5 stars4/5 (392)

- Why We Die: The New Science of Aging and the Quest for ImmortalityFrom EverandWhy We Die: The New Science of Aging and the Quest for ImmortalityRating: 4 out of 5 stars4/5 (3)

- Gut: The Inside Story of Our Body's Most Underrated Organ (Revised Edition)From EverandGut: The Inside Story of Our Body's Most Underrated Organ (Revised Edition)Rating: 4 out of 5 stars4/5 (378)

- Tales from Both Sides of the Brain: A Life in NeuroscienceFrom EverandTales from Both Sides of the Brain: A Life in NeuroscienceRating: 3 out of 5 stars3/5 (18)

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincFrom EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincRating: 3.5 out of 5 stars3.5/5 (137)

- Alex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessFrom EverandAlex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessNo ratings yet

- Dark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseFrom EverandDark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseRating: 3.5 out of 5 stars3.5/5 (69)

- The Molecule of More: How a Single Chemical in Your Brain Drives Love, Sex, and Creativity--and Will Determine the Fate of the Human RaceFrom EverandThe Molecule of More: How a Single Chemical in Your Brain Drives Love, Sex, and Creativity--and Will Determine the Fate of the Human RaceRating: 4.5 out of 5 stars4.5/5 (516)

- A Brief History of Intelligence: Evolution, AI, and the Five Breakthroughs That Made Our BrainsFrom EverandA Brief History of Intelligence: Evolution, AI, and the Five Breakthroughs That Made Our BrainsRating: 4 out of 5 stars4/5 (5)

- The Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionFrom EverandThe Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionRating: 4 out of 5 stars4/5 (811)

- A Series of Fortunate Events: Chance and the Making of the Planet, Life, and YouFrom EverandA Series of Fortunate Events: Chance and the Making of the Planet, Life, and YouRating: 4.5 out of 5 stars4.5/5 (62)

- The Other End of the Leash: Why We Do What We Do Around DogsFrom EverandThe Other End of the Leash: Why We Do What We Do Around DogsRating: 5 out of 5 stars5/5 (65)

- 10% Human: How Your Body's Microbes Hold the Key to Health and HappinessFrom Everand10% Human: How Your Body's Microbes Hold the Key to Health and HappinessRating: 4 out of 5 stars4/5 (33)

- Water: The Epic Struggle for Wealth, Power, and CivilizationFrom EverandWater: The Epic Struggle for Wealth, Power, and CivilizationRating: 3.5 out of 5 stars3.5/5 (37)

- Water to the Angels: William Mulholland, His Monumental Aqueduct, and the Rise of Los AngelesFrom EverandWater to the Angels: William Mulholland, His Monumental Aqueduct, and the Rise of Los AngelesRating: 4 out of 5 stars4/5 (21)

- Who's in Charge?: Free Will and the Science of the BrainFrom EverandWho's in Charge?: Free Will and the Science of the BrainRating: 4 out of 5 stars4/5 (65)

- Fast Asleep: Improve Brain Function, Lose Weight, Boost Your Mood, Reduce Stress, and Become a Better SleeperFrom EverandFast Asleep: Improve Brain Function, Lose Weight, Boost Your Mood, Reduce Stress, and Become a Better SleeperRating: 4.5 out of 5 stars4.5/5 (15)

- Smokejumper: A Memoir by One of America's Most Select Airborne FirefightersFrom EverandSmokejumper: A Memoir by One of America's Most Select Airborne FirefightersNo ratings yet

- The Storm of the Century: Tragedy, Heroism, Survival, and the Epic True Story of America's Deadliest Natural DisasterFrom EverandThe Storm of the Century: Tragedy, Heroism, Survival, and the Epic True Story of America's Deadliest Natural DisasterNo ratings yet