Professional Documents

Culture Documents

OIL AND GAS SKID INSPECTION PLAN

Uploaded by

bmanojkumar16Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

OIL AND GAS SKID INSPECTION PLAN

Uploaded by

bmanojkumar16Copyright:

Available Formats

OIL AND NATURAL GAS CORPORATION LIMITED

PAGE

1 of 3

MUMBAI HIGH SOUTH REDEVELOPMENT

PHASE-III PROJECT (MHSRD-III)

DATE

20-May-2016

CONTRACT NO. : MR/ES/MM/MHSRD-III/09/2014 (P851C14006)

DOC. NO. : 5090 ITP018

REV. 01

ITP

INSPECTION TEST PLAN

Aker Engineering Malaysia Sdn Bhd

SAPURAKENCANA HL SDN BHD

(Formerly known as Kencana HL Sdn Bhd)

PREPARED & SUBMITTED BY -

01

20-05-2016

IFA

SSM

SSM

JG

00

11-05-2016

IFA

SSM

SSM

JG

REV.

DATE

REASON FOR ISSUE

PREPD CHKD. APPD.

MANUFACTURING QUALITY PLAN

Supplier : ACCUDYNE INDUSTRIES INDIA LTD

Project ; MHSRD - III

SKHL PO No : 3300000056

Customer : SAPURAKENCANA HL SDN BHD

Item : Chemical Injection Skids (3 nos)

AIIPL QAP Ref : 15XPR08, REV. 0, DT : 11.05.2016

End User : OIL AND NATURAL GAS CORPORATION LIMITED

Category - B

IRT NO - MHSRD-III / M / 006, Inspection

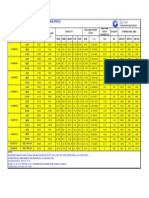

S.No

Component

Characteristic

Class

Type of check

Quantum of

check

6

Ref.Doc

Acceptance Norms

Format of records

CODE ONGC 5100 W

Inspection Agency

P

W

R

10

11

12

Remarks

13

1. BASEFRAME & STRUCTURALS

1

1.1

Raw material

Chemical & Physical

Major

Document Review / Visual

100%

Relevant Material Spec.

Relevant Material Spec.

Dimensions

Overall dimensions

Major

Measure

100%

Approved drawing

Approved drawing

MTC

1,4

IR

1,4

MTC / MCC

1,4

Witness of point

No.6.1

2.PUMP

2.1

Raw Material (Fluid Wetted)

2.2

Final testing

Chemical & Mechanical

Properties

Major

Document Review / MTC

1 / Heat

Flow at 100% stroke &

Working Pressure

Critical

Measure

100%

Repeatability .lineraity

Critical

Measure

100%

Approved drawing / Datasheets Approved Material Spec.

Datasheet

More than rated Capacity / +/3% of rated capacity

PTR

1,2,4

Datasheet

More than rated Capacity / +/3% of rated capacity

PTR

1,2,4

PTR

1,2,4

For TPI/Customer,

Inspection will be

1 / Model

Steady State Accuracy

Critical

Measure

200%

Datasheet

More than rated Capacity / +/3% of rated capacity

Hydrostatic Pr.Test

Critical

Pressure Retention

100%

1.5 times x Working pressure

No Leak for 30 Mins

PTR

1,2,4

Mfg, TC 3.1 Type

1,2,4

IR

1,2

-----

1,2

Weld summary

1,2,4

WPS, PQR, to be

Reviewed.

NDT reports

1,2,4

10% RT for Butt

Joints & 100% DP for

Welds.

Mfg, TC 3.1 Type

1,2,4

Mfg TC

2,4

3.PIPES,FITTINGS,FLANGES

3.1

Pipes,Fitings,Flanges

Raw Material

Identifiation,Chemical &

Mechanical properties

Major

Visual, Chemcial Analysis &

Mechanical Properties

1/Heat

Approved drawing/

ASME Sec II Part A

Approved drawing/

ASME Sec II Part A

3.2

HydroTest (Pipe Spools)

Leak

Critical

Pressure retention

100%

1.5 times x Working pressure

No Leak

3.3

Fit up

Visual

Major

Visual,dimension

100%

Approved drawing

Approved drawing

3.4

Welding

Visual

Major

Visual

100%

ASME Sec IX.

ASME Sec IX.

3.5

NDT

Review of RT/DP Procedure

Major

Review

ASME SEC V.

ASME SEC VIII DIV 1

PMI, IGC Test Will be

Carried out for SS

Pipes,Flanges &

Fittings.

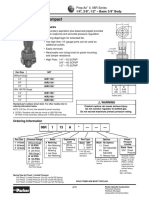

4. Valves

4.1

Valves (Raw Material)

4.2

Valves

Chemical & Physical

properties.

Performance test including

hydrotest

Major

Review

1/Heat

Approved Datasheets

Appd.Matl Spec.

2009F

Major

Review

100%

Approved Datasheets

No Leak

PMI report Will be

shown for review.

MANUFACTURING QUALITY PLAN

Supplier : ACCUDYNE INDUSTRIES INDIA LTD

Project ; MHSRD - III

SKHL PO No : 3300000056

Customer : SAPURAKENCANA HL SDN BHD

Item : Chemical Injection Skids (3 nos)

AIIPL QAP Ref : 15XPR08, REV. 0, DT : 11.05.2016

End User : OIL AND NATURAL GAS CORPORATION LIMITED

Category - B

IRT NO - MHSRD-III / M / 006, Inspection

S.No

Component

Characteristic

Class

Type of check

Quantum of

check

6

Ref.Doc

Acceptance Norms

Format of records

CODE ONGC 5100 W

Inspection Agency

P

W

R

10

11

12

Remarks

13

5. INSTRUMENTATION - ( Pressure gauge, Pressure Control Valve, Flow Meter and Pressure Relief Valve )

5.1

Instrumentation Items

Chemical & Physical

properties for major parts

Major

Review

1/Heat

Approved Datasheets

Approved Datasheets

Mfg TC

1,2,4

5.2

Instrumentation Items

Test Report

Major

Review

100%

Approved Datasheets

Approved Datasheets

Mfg TC

1,2,4

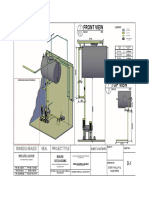

6. FINAL ASSEMBLY (Entire Skid)

6.1

Dimension

Overall dimension

Major

Review

100%

Approved Drawing & ONGC

5100W

Approved Drawing

IR

1,2,4

6.2

Visual

Physical condition

completeness,workmanship

Major

Review

100%

Approved Drawing

Approved Drawing

IR

1,2,4

6.3

Pneumatic Test (Pipe Spools)

Leak

Critical

Pressure retention @ 1 Bar

100%

ONGC Spec.2004 B Rev.3

Clauses 9.3.10

No Leak

IR

1,2,4

6.4

Performance Test

Smooth operation

Major

Performance

100%

Approved Drawing

Trouble free operation

IR

1,2,4

6.5

Painting

Finish

Major

Visual/Measures

Random

Approved Drawing / Spec.

Approved Drawing / Spec.

IR

1,2

6.6

Inspection reports & Release

Note

Final completion

Major

Visual,Document review

100%

1,2,4

Legends:

P - Perform

R - Review

W - Witness

H - Hold

1. SKHL & SKHL Inspection Agency

2. AIIPL

3. Subvendor

4. ONGC/Cerfication Agency (CA)

IR - Inspection Report, PTR - PerformanceTtest Report , TC - Test Certificate , MCC - Material Compliance Certificate

Notes:

1. IRN Shall be issued by SKHL / Inspection Agency , Documents review by CA

2. Stage 6 is an optional for CA.

PREPARED BY

APPROVED BY

APPROVED BY

INSPECTION AGENCY

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- 3.3 Reciprocating (LP-HP)Document3 pages3.3 Reciprocating (LP-HP)bmanojkumar16No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- PF0009 SLB CV SPC 0001Document19 pagesPF0009 SLB CV SPC 0001bmanojkumar16No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Aug 2023Document1 pageAug 2023bmanojkumar16No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- TP-WMS-05969-DAS-A4-D1-K - Demulsifier DatasheetDocument9 pagesTP-WMS-05969-DAS-A4-D1-K - Demulsifier Datasheetbmanojkumar16No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- PF0009 SLB MR DAT 0010 - Rev.00Document7 pagesPF0009 SLB MR DAT 0010 - Rev.00bmanojkumar16No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- GBRG1-MX7771-00001-R02-Mech Spec For Mobile NAG Well Equalisation and Killing Facility PackageDocument22 pagesGBRG1-MX7771-00001-R02-Mech Spec For Mobile NAG Well Equalisation and Killing Facility Packagebmanojkumar16No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- PF0009 SLB MR DAT 0007 - Rev.0Document7 pagesPF0009 SLB MR DAT 0007 - Rev.0bmanojkumar16No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- PF0009 SLB MR DAT 0011 - Rev.00Document7 pagesPF0009 SLB MR DAT 0011 - Rev.00bmanojkumar16No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- PF0009 SLB MR DAT 0008 - Rev.00Document7 pagesPF0009 SLB MR DAT 0008 - Rev.00bmanojkumar16No ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- PF0009 SLB MR DAT 0009 - Rev.00Document7 pagesPF0009 SLB MR DAT 0009 - Rev.00bmanojkumar16No ratings yet

- TP-WMS-05940-SPC-A4-D1-L-Specification For ValvesDocument34 pagesTP-WMS-05940-SPC-A4-D1-L-Specification For Valvesbmanojkumar16No ratings yet

- Aug 2023Document1 pageAug 2023bmanojkumar16No ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- MATERIAL LIST AND TECHNICAL DETAILS FOR FLANGE HOLE ORI. COMPDocument1 pageMATERIAL LIST AND TECHNICAL DETAILS FOR FLANGE HOLE ORI. COMPbmanojkumar16No ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- TP-WMS-05816-DAS-A4-D1-L - Swing Check Valve DatasheetDocument1 pageTP-WMS-05816-DAS-A4-D1-L - Swing Check Valve Datasheetbmanojkumar16No ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Marechal DX2 Decontactor Range enDocument2 pagesMarechal DX2 Decontactor Range enbmanojkumar16No ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Cover Page - LG DSDocument2 pagesCover Page - LG DSbmanojkumar16No ratings yet

- 21DBBV12M-7 42inch (In) DimensionADoubleBlockandBleedNeedleValvewithFullBoreDocument3 pages21DBBV12M-7 42inch (In) DimensionADoubleBlockandBleedNeedleValvewithFullBorebmanojkumar16No ratings yet

- SKid GAD CRS - Revised FormatDocument1 pageSKid GAD CRS - Revised Formatbmanojkumar16No ratings yet

- Marechal PNCX Range enDocument2 pagesMarechal PNCX Range enbmanojkumar16No ratings yet

- Haliba Well Chemical Injection Package GADDocument2 pagesHaliba Well Chemical Injection Package GADbmanojkumar16No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Installation and Maintenance Manual for Chemical Injection PackagesDocument10 pagesInstallation and Maintenance Manual for Chemical Injection Packagesbmanojkumar16No ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Line List - All PackagesDocument42 pagesLine List - All Packagesbmanojkumar16No ratings yet

- IG 81 MESC 14d - 2021Document1 pageIG 81 MESC 14d - 2021bmanojkumar16No ratings yet

- IHA AssessmentDocument4 pagesIHA Assessmentbmanojkumar16No ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- IG 77 MESC 14d - 2021Document5 pagesIG 77 MESC 14d - 2021bmanojkumar16No ratings yet

- P105576 IC IDF 203 - Rev01Document5 pagesP105576 IC IDF 203 - Rev01bmanojkumar16No ratings yet

- Line List - Methanol SkidDocument3 pagesLine List - Methanol Skidbmanojkumar16No ratings yet

- IG 85 MESC 14d - 2021Document1 pageIG 85 MESC 14d - 2021bmanojkumar16No ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- IG 76 MESC 14d - 2021Document3 pagesIG 76 MESC 14d - 2021bmanojkumar16No ratings yet

- IG 74 MESC 14d - 2021Document3 pagesIG 74 MESC 14d - 2021bmanojkumar16No ratings yet

- Electrical Fittings Catalog - TopazDocument148 pagesElectrical Fittings Catalog - TopazLesly Ramirez0% (1)

- Carlyle Compressor O6D/EDocument72 pagesCarlyle Compressor O6D/Erlynch33100% (6)

- 875c Series Api Dust Cap Data SheetDocument2 pages875c Series Api Dust Cap Data SheetL.kolekarNo ratings yet

- BESCK104 Aset 1Document4 pagesBESCK104 Aset 1BEZAWADA SNo ratings yet

- PGP/PGM zp21 Bushing Design: 300/400 SeriesDocument27 pagesPGP/PGM zp21 Bushing Design: 300/400 SeriestitanwlxNo ratings yet

- 06r ParkerDocument2 pages06r ParkerAnonymous YqkTPzVF0No ratings yet

- Chapter 3 - Machines - Selina Solutions Concise Physics Class 10 ICSE - KnowledgeBoatDocument81 pagesChapter 3 - Machines - Selina Solutions Concise Physics Class 10 ICSE - KnowledgeBoatskjNo ratings yet

- Saic N 2033Document5 pagesSaic N 2033aamirapiNo ratings yet

- 2.4m Integrated Antenna Installation ManualDocument23 pages2.4m Integrated Antenna Installation ManualАлексей ГончарукNo ratings yet

- TEHRI PSP DPR 31.07. 2020Document8 pagesTEHRI PSP DPR 31.07. 2020Bhagat DeepakNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Boiler recover-BOILERDocument1 pageBoiler recover-BOILERTrish M.M.No ratings yet

- D16 Torque SpecsDocument3 pagesD16 Torque SpecsKamal BimmerNo ratings yet

- Lennox Serial Number NomenclatureDocument13 pagesLennox Serial Number NomenclatureRichard Johnson100% (2)

- TP, TPD Union and Low Head: Service InstructionsDocument10 pagesTP, TPD Union and Low Head: Service InstructionsGergely DancsNo ratings yet

- Soil, Waste & Vent Piping System GuideDocument16 pagesSoil, Waste & Vent Piping System GuideFLYNAS LOGISTICSNo ratings yet

- Dop1 - Catalog - Ford - CargoDocument47 pagesDop1 - Catalog - Ford - CargoАлексейNo ratings yet

- Serie Ir-V StucchiDocument4 pagesSerie Ir-V StucchiHIDRAFLUIDNo ratings yet

- Digital Control Valve Model BV88: Technical DataDocument4 pagesDigital Control Valve Model BV88: Technical Datajoana ramirezNo ratings yet

- SAIDI Butterfly Valves PDFDocument218 pagesSAIDI Butterfly Valves PDFHARSHANo ratings yet

- Carrier 40lm Series Fan Coil Unit@ 45-55 CHW - Quick Selection Data TableDocument1 pageCarrier 40lm Series Fan Coil Unit@ 45-55 CHW - Quick Selection Data TableMiahsaheb Rafeeq100% (1)

- Grease Trap Calculator 03Document2 pagesGrease Trap Calculator 03Sharon LambertNo ratings yet

- Bakery Counters Spec SheetDocument2 pagesBakery Counters Spec Sheetedna regoNo ratings yet

- Catalogue 2019-LD: Belt Maintenance Equipment - Belt Lacing 750kN/mDocument80 pagesCatalogue 2019-LD: Belt Maintenance Equipment - Belt Lacing 750kN/mSaúl Mauricio FernandezNo ratings yet

- WWD0096Document1 pageWWD0096jlledwinestebanNo ratings yet

- 200 Wog Globe ValveDocument1 page200 Wog Globe ValveSandi AslanNo ratings yet

- DDL 900bDocument2 pagesDDL 900bAbhinandan BenganiNo ratings yet

- Aizer: Single Roll Crusher - Type E 1100 L/SDocument2 pagesAizer: Single Roll Crusher - Type E 1100 L/SnehalNo ratings yet

- Pilot LockoutDocument6 pagesPilot LockoutDu TrầnNo ratings yet

- CLASS-VIII SUB-MATHEMATICS MENSURATION(SURFACE AREA AND VOLUME) Worksheet-3(AdvanceDocument4 pagesCLASS-VIII SUB-MATHEMATICS MENSURATION(SURFACE AREA AND VOLUME) Worksheet-3(Advancetarun arora100% (1)

- 4597 AAB SC 07 Addendum 2 R0v0 30Document1 page4597 AAB SC 07 Addendum 2 R0v0 30danieldumapitNo ratings yet