Professional Documents

Culture Documents

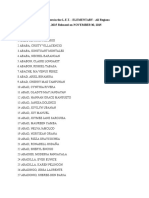

RACTU

Uploaded by

Joshua EspirituOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RACTU

Uploaded by

Joshua EspirituCopyright:

Available Formats

ACCUMULATOR

The accumulator must return refrigerantand oil to the

compressor at a sufficient rate to maintain both system

operating efficiency and proper crankcase oil level. To

make sure

these tasks are accomplished, system designers must

consider the following items:

A properly sized and protected oil return orifice is required to ensure positive

oil (and refrigerant) return to the compressor

The accumulator must have sufficient internal volume

The pressure drop across the accumulator should be as low as possible

FILTER-DRIER

The

remove

function of a filter-drier in a refrigeration system is to

contaminants that are harmful. If these

contaminants remain at elevated levels, they

will jeopardize

the longevity of the system. Contaminants that

are frequently found include moisture, acid, copper oxides, metal chips, wax-like

compounds and others.

CRANKCASE PRESSURE REGULATORS

A crankcase pressure regulator (CPR) is a common

accessory added to many low-temperature refrigeration

applications, such as walk-in and reach-in freezers. They

are designed to prevent the compressor's motor from

overloading when its crankcase pressure rises above its

designed working pressure. On many low-temperature

applications, this can occur during or after a defrost

cycle, or after a normal shutdown period. The CPR is an

outlet pressure regulator and will not allow the crankcase pressure to rise above a

predetermined level.

DEFROST HEATER

The heart of the defrost system is

the defrost control. The most

common control is a mechanical

defrost timer which is a motorized

device that opens and closes

several electrical contacts. Each

contact can be thought of as a simple light switch but instead of a light, one

connects the defrost heater circuit, another connects the cooling system. When one

of these is switched on, the other is switched off. A motor on the timer (NOT

illustrated) turns a cam that opens and closes these contacts at set intervals (see

below for other types).

HIGH PRESSURE SWITCH

In refrigeration

a control device

compressor is

motor of the

the

system the high pressure cut off switch is

which is used as safety control. The

stopped by cutting the power supply of the

compressor whenever the discharge pressure of

compressor becomes excessive. This is necessary to

prevent the possible damage of equipment.

When the pressure in discharge line raise above a certain limit of pressure, high

pressure control device operates and stops the compressor by cutting the power

supply given to the motor input.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Employment ContractDocument3 pagesEmployment ContractHASRET75% (4)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Joshua Espiritu - RESUMEDocument2 pagesJoshua Espiritu - RESUMEJoshua EspirituNo ratings yet

- ) ) ) ) ) ) ) ) ) ) ) ( ( ( ( ( ( ( ( ( ( ( (Document2 pages) ) ) ) ) ) ) ) ) ) ) ( ( ( ( ( ( ( ( ( ( ( (Joshua EspirituNo ratings yet

- 123 AdsdDocument6 pages123 AdsdJoshua EspirituNo ratings yet

- MLMLDocument110 pagesMLMLJoshua Espiritu100% (1)

- Thick Walled CylindersDocument9 pagesThick Walled CylinderskabangiNo ratings yet

- BEEDDocument802 pagesBEEDAngelica PioquidNo ratings yet

- Qiayshay 261617 y 236Document2 pagesQiayshay 261617 y 236Joshua EspirituNo ratings yet

- HahahaDocument1 pageHahahaJoshua EspirituNo ratings yet

- NecroBot 2016 09 04 16Document1 pageNecroBot 2016 09 04 16Joshua EspirituNo ratings yet

- RACTUDocument2 pagesRACTUJoshua EspirituNo ratings yet

- 123 AdsdDocument6 pages123 AdsdJoshua EspirituNo ratings yet

- SadsaddsadwasdwaDocument1 pageSadsaddsadwasdwaJoshua EspirituNo ratings yet

- KLJKLN HJH, VHBJN NBHNDocument11 pagesKLJKLN HJH, VHBJN NBHNJoshua EspirituNo ratings yet

- DasdsaxzcxzcxzcDocument3 pagesDasdsaxzcxzcxzcJoshua EspirituNo ratings yet

- EwanDocument3 pagesEwanJoshua EspirituNo ratings yet

- SDFSDLKFJKLDSFDSFSDFSDDocument2 pagesSDFSDLKFJKLDSFDSFSDFSDJoshua EspirituNo ratings yet

- Machine Design 1 Quiz-1 (Reviewer 500 Items)Document15 pagesMachine Design 1 Quiz-1 (Reviewer 500 Items)Joshua EspirituNo ratings yet

- EududuxcjcDocument54 pagesEududuxcjcJoshua EspirituNo ratings yet

- Heat 4e Chap01 LectureDocument46 pagesHeat 4e Chap01 LectureSubho SamantaNo ratings yet

- Ideal Gas Laws and Thermodynamic PropertiesDocument6 pagesIdeal Gas Laws and Thermodynamic PropertiesJoshua EspirituNo ratings yet

- Hddudufufuf 7 F 7 V 7 C 7 G 8 VicuvuviDocument1 pageHddudufufuf 7 F 7 V 7 C 7 G 8 VicuvuviJoshua EspirituNo ratings yet

- 21 To 30Document30 pages21 To 30Joshua EspirituNo ratings yet

- Hddudufufuf 7 F 7 V 7 C 7 G 8 VicuvuviDocument1 pageHddudufufuf 7 F 7 V 7 C 7 G 8 VicuvuviJoshua EspirituNo ratings yet