Professional Documents

Culture Documents

Bubblewrap

Uploaded by

Anonymous a8rdyKOCCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bubblewrap

Uploaded by

Anonymous a8rdyKOCCopyright:

Available Formats

Nothing Protects Better Than The Original

All standard grade Bubble Wrap Brand

cushioning contains 15% pre-consumer

recycled content.

Sealed Air Sustainability

See inside for our new Bubble Wrap Recycled Grade offering!

Cushioning/ Void Fill

Nothing Protects

Better Than The Original

As the inventors of Bubble Wrap brand cushioning over 50

years ago, our secret to a better bubble has always been starting

with a full air bubble and keeping a full air bubble. Simply stated,

in order to protect your products from the hazards of the shipping

environment, the air has to be there and stay there. How do we do it?

The Difference Is In The Barrier

Bubble Wrap Brand

Non-Barrier Brand

Air Retention

Barrier Seal

Air Loss

Sealed Air Barrier Bubble

Retains Cushioning Thickness

Other Non-Barrier Brands

Lose Cushioning Thickness

Surface Protection

Sealed Air Barrier Bubble

Technology Is A Better Value

Superior Cushioning Higher initial thickness and fullness

provide up to 30% greater protection.

Reduced Costs Less material is required for protection over

non-barrier brands.

Longer Lasting Protection Air retention layer maintains

consistent cushioning throughout the shipping cycle.

Environmental Benefits

Recycled Content All standard grades contain a minimum

of 15% pre-consumer recycled content.

Source Reduction Provides better protection using less

packaging material compared to loose fill or paper.

Damage Reduction Eliminates the need to ship

replacement products in additional packaging materials.

Reusable Air retention layer allows for multiple reuse.

Recyclable Can be recycled through Sealed Air

locations and at many independent recyclers.

For superior cushioning, surface protection,

void fill and specialty applications, look for

the Bubble Wrap brand symbol.

Specialty Products

Bubble Wrap Brand

Bubble Wrap Brand

Multi-Purpose Grade Cushioning

Limited Grade Protection

Addresses the need for:

Fragile or valuable products

Long or unpredictable distribution cycles

Cushioning heavy or more fragile products

Items requiring secure blocking and bracing

Meets the requirements of Mil. Spec

PPP-C-795D and CID A-A549.

Addresses the need for:

Light to medium-weight, less fragile products

Short or predictable distribution cycles

Products requiring surface protection,

interleaving, cushioning and void fill

Meets the requirements of commercial item

description CID A-A549.

Addresses the need for:

An efficient void fill alternative

Lowered material costs

Better protection than loose fill

No mess

Meets the requirements of commercial item

description CID A-A549.

Bubble Mask

Cold Seal Bubble Wrap Brand

Bubble Wrap Brand

Air cellular cushioning with an

adhesive coating.

Provides lightweight cushioning/surface protection

Adheres to a variety of clean surfaces

Saves labor and material costs

Available in a variety of Barrier Bubble heights

Air cellular cushioning material

with a cohesive coating.

Sticks to itself, not to the product

Applies easily

Saves labor by reducing handling

Eliminates tape

Food-safe air cellular material

for protecting food items.

Made from 100% virgin resin

Allows immediate contact with food substances

Moisture resistant

Heat sealable

Strong Grade Cushioning

Cohesive-Coated Cushioning

Adhesive-Coated Cushioning

Bubble Wrap Brand

Kraft Laminates

Designed for wood veneer

protection needs.

Excellent outer protection

Kraft backing allows easy application of

labeling, stenciling and manual markings

May eliminate outer carton for certain

applications

TempShield

Reflective Laminates

A lightweight, easy-to-use thermal

insulating material that protects

products from dramatic fluctuations

in temperature.

FDA approved materials

Metalized (72% reflective) Tougher

than foil

Foil (97% reflective) Best thermal

value for insulating purposes

Bubble Wrap Brand

FDAGrade Cushioning Material

ESD (Electrostatic

Discharge)

Protective Products

Designed to protect sensitive

electronic components, ESD

products include:

Anti-Static Barrier Bubble material

Cushionshield aluminum air cellular

static-shielding laminate bags

Bubble Wrap Brand

Bags

Saves time and labor.

Convenient peel-and-seal closure

10 standard size offerings

Available in regular and anti-static

Small bubble height

Bubblebags on a roll also available

as non-standard

Select The Right

Bubble Wrap Brand

Recycled Grade

Barrier Bubble Material For Your Application

Bubble Height

Addresses the need for:

Economic and environmentally sensible raw material

preservation

Consistent light-duty SealedAir Barrier Bubble

Technology for optimum performance

Color variation based on recycled mix

Meets the requirements of commercial item description

CID A-A549.

3rd Web Bubble Wrap Brand

Laminates

Small

Medium

BubbleWrap Brand

StrongGrade

Product

Height

CS

Small

Interleaving and/or surface protection.

TS

Medium

Cushioning of fragile, medium-weight products.

DS

Large

Multi-purpose cushioning applications. High performance

DS 2

DS 4

Suggested Uses

cushioning materials for extreme psi loading, blocking

and bracing. Available in (2) times & (4) times the normal

(DS)strength.

Multi-Purpose Grade

BUBBLE

LAYER

BASE

LAYER

Product

Size

Suggested Uses

CM

Small

CMAS

CMCO

CMAD

Cushioning of light to medium-weight products.

Available in Anti-Static (AS), Cohesive Cold Seal

(CO), and Adhesive Bubble Mask (AD) materials.

TM

Medium

Cushioning and/or void fill for light to medium-weight

products, which can replace 1/2 non-barrier material.

DM

Large

DMAS

DMAD

General purpose cushioning and/or void fill. Available

in Anti-Static (AS) and Adhesive Bubble Mask (AD)

materials.

Bubble Wrap Brand

Bubble Wrap Ready-To-Roll

LimitedGrade

Minimum 15%

Recycled Content

For surface protection and/or void fill/light cushioning applications with very

short known shipping cycles. CID A-A549 approved.

Product

Size

Suggested Uses

CL

Small

Surface protection and/or interleaving.

DL

Large

Void fill/light cushioning protection for lightweight,

less fragile products.

Bubble Wrap Brand

RecycledGrade

Ideal for use in mailrooms or small

shipping areas.

Self-dispensing and easy-tear convenience

Available in 12 or 24 widths

Standard Small and Medium bubble

height offerings

Minimum 15%

Recycled Content

For light to medium, semi-rugged products with shorter, predictable distribution

cycles. Meets requirements of commercial item description CID A-A549.

TOP LAYER

Air Cellular Dispenser Cartons

Minimum 15%

Recycled Content

For heavy, fragile and/or valuable products with long or unpredictable distribution

cycles. Meets requirements of Mil. Spec. PPP-C-795D and CID A-A549.

Bubble Wrap Brand

Addresses the need for:

Superior product cushioning

via triple-layer construction

Excellent surface protection

Outstanding resistance

to tears and punctures

Large

High Recycled

Content *

For surface protection and/or void fill/light cushioning applications with a very

short known shipping cycle. Contains 3 times more recycled content of the

above standard grades. *Visit www.bubblewrap.com/recycledgrade for current

minimum recycled percentages.

Product

Size

Suggested Uses

CR

Small

Surface protection.

DR

Large

Void fill/light cushioning protection for lightweight,

less fragile products.

Which Is The Right Product For You?

Call 1-800-648-9093 to contact a Sealed Air representative

or visit us online at www.bubblewrap.com.

The Sealed Air Barrier Bubble Advantage

Bubble Wrap brand offers many advantages over other types of cushioning, including reduced material, labor and

shipping costs with better cushioning performance.

Before First Drop

After Third Drop

Significant air retention equals better cushioning performance. Multiple impacts during the shipping cycle can cause material to compress without recovery,

resulting in a loss of thickness and cushioning performance. For example, paper does not recover well after impact. As can be seen in the photos above, under

a nominal 0.25 psi load, competitive paper product loses nearly half its original thickness after

only three drops from 24 inches while Sealed Air Barrier Bubble material

retains more than 90% of its protection.

The Systems Approach

Sealed Air can help you design a manual or automated

packaging system to increase the efficiency and overall productivity

of your work station or on-line packaging operation. Ask your Sealed Air representative for details.

Instasheeter

High-Speed Converting System

Instaslitter

Material-Roll-Slitter Equipment Option

Value Analysis And

Package Design Services

Your Sealed Air Consultative Sales Representative will provide you with

a detailed value/cost analysis of your entire packaging operation. This service

is designed to qualify and quantify your packaging needs, enabling us to make

recommendations aimed at improving overall efficiency. The analysis includes:

Accu-Cut

Automated Converting System

e

Valu

ysis

Anal

The best package design method for your application, utilizing our

worldwide network of PackagingDesign and Development Centers.

The ideal packaging material and system needed to solve your most

challenging packaging problems.

The value analysis of the cost and productivity savings associated with a Sealed Air solution.

The best training and support services in the industry to ensure that you are using Sealed Air

products effectively and economically, right from the start.

Creating World Class Packaging Solutions

Sealed Air is a leading global manufacturer of a wide range of fresh food, protective and

specialty packaging products. Reaching nearly 80 percent of the worlds population, many

Sealed Air brands are among the most respected names in their markets.

Our products protect and preserve our customers products from the plant or warehouse

through the rigors of the distribution chain. Many Sealed Air products also provide an

appealing merchandising presence for retail display.

Sealed Airs industry-leading investment in research and development and constant focus

on World Class Manufacturing principles allow us to continually deliver innovative packaging

solutions that add measurable value to our customers businesses around the world.

Jiffy Mailer

NewAir I.B.

Protective Shipping Products

Packaging Systems

Cell-Aire &

Cell-Aire Laminates

Foam Packaging

Instapak

Cryovac

Food Packaging

Fill-Air

Inflatable Packaging Systems

Polyethylene Foams

Protective Packaging

301 Mayhill Street

Saddle Brook, NJ 07663-5303

800-648-9093 Fax:201-712-7070

www.bubblewrap.com

Our Products Protect Your Products

Cryovac

Performance Shrink Films

CelluPlank

Polyethylene Foam

Stratocell

Laminated Foam

Additional Information or Questions:

E-mail: bubblewrap@sealedair.com

Corporate Office: Sealed Air Corporation (US)

200 Riverfront Boulevard, Elmwood Park, NJ 07407

www.sealedair.com

Reg. U.S. Pat. and TM Off. Sealed Air Corporation (US) 2010. All rights reserved.

The 9 Dot Logoand Sealed Air are registered trademarks of Sealed Air Corporation (US).

Printed in the U.S.A.

D-170 Rev. 04/10

You might also like

- AircapDocument8 pagesAircapigor6995No ratings yet

- Pregis Complete Packaging Guide 3-2012Document12 pagesPregis Complete Packaging Guide 3-2012bettie56No ratings yet

- Packaging TermsDocument32 pagesPackaging TermsAbhineet Shrivastava100% (1)

- Packaging Essential GlossaryDocument35 pagesPackaging Essential GlossarygisellaNo ratings yet

- Amcor Formpack Dessiflex enDocument2 pagesAmcor Formpack Dessiflex enTomasz BcłtromiukNo ratings yet

- Cell AireDocument4 pagesCell Aireigor6995No ratings yet

- Sika PDS E Sikagard-950Document4 pagesSika PDS E Sikagard-950lwin_oo2435No ratings yet

- Global Health, Hygiene & Productivity Solutions: The World of Healthcare Is ChangingDocument28 pagesGlobal Health, Hygiene & Productivity Solutions: The World of Healthcare Is ChangingDhairyasheel JagtapNo ratings yet

- PVC Packaging Testing GuideDocument17 pagesPVC Packaging Testing GuideAnshul GautampurkarNo ratings yet

- Kimberly ClarkDocument32 pagesKimberly ClarkPraesidium Potens d.o.o.No ratings yet

- Cor TuffDocument3 pagesCor Tuffigor6995No ratings yet

- FRP GRP Covering Systems PDFDocument2 pagesFRP GRP Covering Systems PDFAjay Krishna MNo ratings yet

- Sealing Products CatalogDocument20 pagesSealing Products Catalogtanase.gabriel1993No ratings yet

- BOSS® 326 Hi-Temp Red Silicone SealantDocument2 pagesBOSS® 326 Hi-Temp Red Silicone SealantRaghib HussainNo ratings yet

- Cradle To CradleDocument15 pagesCradle To CradleSanjana KadiyalaNo ratings yet

- Barrier Films and Vacuum Insulated Panels for Packaging and ConstructionDocument3 pagesBarrier Films and Vacuum Insulated Panels for Packaging and ConstructionSh Mati ElahiNo ratings yet

- Minimizing Heat Loss in High Temperature Industrial SystemsDocument7 pagesMinimizing Heat Loss in High Temperature Industrial SystemsTS WongNo ratings yet

- Presentation - SunglazeDocument25 pagesPresentation - SunglazeYogendra Pratap SinghNo ratings yet

- State of The Art InfrastructureDocument4 pagesState of The Art InfrastructuremohammedNo ratings yet

- Product Design Spec PDFDocument10 pagesProduct Design Spec PDFVinodh KumarNo ratings yet

- Aliphatic Acrylic Polyurethane Finish CoatDocument4 pagesAliphatic Acrylic Polyurethane Finish CoatDexter R. RoqueNo ratings yet

- Air Filters Direct Brochure Suitable For EmailDocument2 pagesAir Filters Direct Brochure Suitable For Emailjeff2398No ratings yet

- Flexitallic Products PDFDocument108 pagesFlexitallic Products PDFNguyễn Xuân NamNo ratings yet

- Dow Corning RTV InfoDocument20 pagesDow Corning RTV InfoLevent ÖnderNo ratings yet

- Blown Film ManualDocument20 pagesBlown Film ManualJohn P. Bandoquillo100% (2)

- HBR XL - Crosslink Closed Cell PDSDocument2 pagesHBR XL - Crosslink Closed Cell PDSHuy ThaiNo ratings yet

- Viledon Product Catalogue 2013 2014 PDFDocument132 pagesViledon Product Catalogue 2013 2014 PDFVictor GomezNo ratings yet

- Cabero CH Evaporator CatalogueDocument12 pagesCabero CH Evaporator Cataloguehungnn0503100% (2)

- Sylgard 160Document3 pagesSylgard 160diogocNo ratings yet

- Sikagard - 550W Elastic: Crack-Bridging Protective Coating For ConcreteDocument3 pagesSikagard - 550W Elastic: Crack-Bridging Protective Coating For Concretethe pilotNo ratings yet

- Drew Marine - Sealing Products CatalogDocument19 pagesDrew Marine - Sealing Products CatalogGauravNo ratings yet

- Wrap Around Packer DetailsDocument24 pagesWrap Around Packer DetailsUmair Younus100% (1)

- Next Generation Collation Shrink Film Solutions From Dow: ® Trademark of The Dow Chemical CompanyDocument4 pagesNext Generation Collation Shrink Film Solutions From Dow: ® Trademark of The Dow Chemical Companyductoan32No ratings yet

- Sigmadur Gloss: Description PRINCIPAL CHARACTERISTICS - Unlimited RecoatableDocument4 pagesSigmadur Gloss: Description PRINCIPAL CHARACTERISTICS - Unlimited RecoatableKopnang AristideNo ratings yet

- Roll Cover Development - Calendering: Executive SummaryDocument14 pagesRoll Cover Development - Calendering: Executive SummaryAdolfo GuillenhNo ratings yet

- PolyimidesDocument2 pagesPolyimidesthinnnhNo ratings yet

- Made in Europe: Advanced Flexitank ManufacturingDocument8 pagesMade in Europe: Advanced Flexitank ManufacturingPaulo DiasNo ratings yet

- Aeron Chair: Level Certification Design Story: Shifting ParadigmsDocument3 pagesAeron Chair: Level Certification Design Story: Shifting Paradigmscarlosfigdir2605No ratings yet

- Vacuum Technology Catalogue FipaDocument794 pagesVacuum Technology Catalogue FipaJoão SilvaNo ratings yet

- Technical Report: Optimal Protection, Optimal Cost EfficiencyDocument7 pagesTechnical Report: Optimal Protection, Optimal Cost EfficiencyInternational BusinessNo ratings yet

- Conveyor Belting THO 19458Document32 pagesConveyor Belting THO 19458N.B.PNo ratings yet

- TDS CapaPrimeDocument3 pagesTDS CapaPrimeMearg NgusseNo ratings yet

- Rubber MoldingDocument33 pagesRubber MoldingFurqan AlamNo ratings yet

- Chemco Marine BrochureDocument10 pagesChemco Marine BrochureLawrence de RijkNo ratings yet

- Assignment 3 PACK 750 Fall 2019 (GS)Document5 pagesAssignment 3 PACK 750 Fall 2019 (GS)Gwyneth SerraoNo ratings yet

- SEALED AIR - General BrochureDocument12 pagesSEALED AIR - General Brochuredanielaoana nastaseNo ratings yet

- Polyguard 600 CoatingsDocument2 pagesPolyguard 600 CoatingstechdocuNo ratings yet

- Atlas Copco: Quality Air SolutionsDocument12 pagesAtlas Copco: Quality Air SolutionsCleiton CastilhosNo ratings yet

- Structured Packings GasDocument20 pagesStructured Packings GasBowo Edhi WibowoNo ratings yet

- Boge Compressed Air TreatmentDocument36 pagesBoge Compressed Air TreatmentAir Repair, LLCNo ratings yet

- Eslingas DolezychDocument70 pagesEslingas DolezychOsvaldo RamirezNo ratings yet

- DesiccantsDocument25 pagesDesiccantsRajesh GalgalikarNo ratings yet

- LTD Flexitallic Product Services Brochure PDFDocument16 pagesLTD Flexitallic Product Services Brochure PDFermusatNo ratings yet

- Systems For Paint Facilities: Base Coat/clear CoatDocument2 pagesSystems For Paint Facilities: Base Coat/clear CoatBrayhan Alexander PalominoNo ratings yet

- Gasket Catalog - James WalkerDocument52 pagesGasket Catalog - James WalkerJaime Lozano GonzálezNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Family Handyman HacksFrom EverandFamily Handyman HacksFamily HandymanNo ratings yet

- Family Handyman Do-It-Yourself Basics Volume 2From EverandFamily Handyman Do-It-Yourself Basics Volume 2Family HandymanRating: 5 out of 5 stars5/5 (2)

- B 1254789545454e CseDocument1 pageB 1254789545454e CseAnonymous a8rdyKOCNo ratings yet

- Bcdadder Comparator124578 PDFDocument15 pagesBcdadder Comparator124578 PDFAnonymous a8rdyKOCNo ratings yet

- Introduction of K-Map (Karnaugh Map) - GATE No12564578tesDocument4 pagesIntroduction of K-Map (Karnaugh Map) - GATE No12564578tesAnonymous a8rdyKOCNo ratings yet

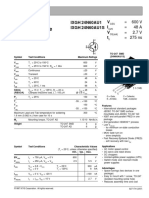

- Hiperfast Igbt With Diode: V I V T Ixgh 24N60Au1 Ixgh 24N60Au1SDocument6 pagesHiperfast Igbt With Diode: V I V T Ixgh 24N60Au1 Ixgh 24N60Au1SAnonymous a8rdyKOCNo ratings yet

- SN54LS31, SN74LS31 Delay Elements: Sdls157 - December 1983 - Revised March 1988Document4 pagesSN54LS31, SN74LS31 Delay Elements: Sdls157 - December 1983 - Revised March 1988Anonymous a8rdyKOCNo ratings yet

- Difference Between Half Adder and Full Adder12568978 PDFDocument1 pageDifference Between Half Adder and Full Adder12568978 PDFAnonymous a8rdyKOCNo ratings yet

- 60 DB Dual Directional Coupler: Model C5353Document1 page60 DB Dual Directional Coupler: Model C5353Anonymous a8rdyKOCNo ratings yet

- Online exam call letterDocument2 pagesOnline exam call letterAnonymous a8rdyKOCNo ratings yet

- State Industrial Profile - Tamil Nadu - 4316Document193 pagesState Industrial Profile - Tamil Nadu - 4316Anonymous a8rdyKOCNo ratings yet

- Revised SyllabusDocument44 pagesRevised SyllabusLatha Dona VenkatesanNo ratings yet

- BillDesk Payment GatewayDocument1 pageBillDesk Payment GatewayEr Rohit VermaNo ratings yet

- Industrial Development and Vision 2023 in Tamil NaduDocument30 pagesIndustrial Development and Vision 2023 in Tamil NaduAnonymous a8rdyKOCNo ratings yet

- How Do I Pay My Application Fee?Document6 pagesHow Do I Pay My Application Fee?Anonymous a8rdyKOCNo ratings yet

- Revised SyllabusDocument44 pagesRevised SyllabusLatha Dona VenkatesanNo ratings yet

- Revised SyllabusDocument44 pagesRevised SyllabusLatha Dona VenkatesanNo ratings yet

- Bubblewrap T110 & T120: Protective PackagingDocument1 pageBubblewrap T110 & T120: Protective PackagingAnonymous a8rdyKOCNo ratings yet

- HDPE Jumbo Bags Manufacturing IndustryDocument70 pagesHDPE Jumbo Bags Manufacturing IndustryAnonymous a8rdyKOC100% (1)

- Thanjavur District Industrial Profile 2020-21: Ministry of Micro, Small and Medium Enterprises Government of IndiaDocument75 pagesThanjavur District Industrial Profile 2020-21: Ministry of Micro, Small and Medium Enterprises Government of IndiaAnonymous a8rdyKOCNo ratings yet

- Gefran - Contact Address PDFDocument1 pageGefran - Contact Address PDFAnonymous a8rdyKOCNo ratings yet

- State Industrial Profile - Tamil Nadu 2014-2015Document6 pagesState Industrial Profile - Tamil Nadu 2014-2015Anonymous a8rdyKOCNo ratings yet

- State Industrial Profile - Tamil Nadu 2014-2015Document6 pagesState Industrial Profile - Tamil Nadu 2014-2015Anonymous a8rdyKOCNo ratings yet

- Bubble Wrap Manufacturing ProcessDocument13 pagesBubble Wrap Manufacturing ProcessAnonymous a8rdyKOCNo ratings yet

- 81101d Overview EngDocument8 pages81101d Overview EngAnonymous a8rdyKOCNo ratings yet

- Nothing Protects Better Than The Original: See Inside For Our New Bubble Wrap Recycled Grade Offering!Document6 pagesNothing Protects Better Than The Original: See Inside For Our New Bubble Wrap Recycled Grade Offering!Anonymous a8rdyKOCNo ratings yet

- Bubble Wrap Manufacturing ProcessDocument13 pagesBubble Wrap Manufacturing ProcessAnonymous a8rdyKOCNo ratings yet

- Immersion HeaterDocument3 pagesImmersion HeaterAnonymous a8rdyKOCNo ratings yet

- Seat MaterialDocument3 pagesSeat MaterialDeyci Yamile Peña SantosNo ratings yet

- Global Placement Application FormDocument2 pagesGlobal Placement Application FormAnonymous a8rdyKOC100% (1)

- Gefran - Contact Address PDFDocument1 pageGefran - Contact Address PDFAnonymous a8rdyKOCNo ratings yet

- Global Placement Application FormDocument2 pagesGlobal Placement Application FormAnonymous a8rdyKOC100% (1)