Professional Documents

Culture Documents

Avoidance of Premature Weld

Uploaded by

mahmoud_allam3Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Avoidance of Premature Weld

Uploaded by

mahmoud_allam3Copyright:

Available Formats

PS_225.

qxp

15/06/2005

10:31

Page 3

FOURCRACK ADVANCED COALFIRED POWER PLANT STEELS

OBJECTIVES

To generate and assess cross-weld creep rupture

data on welded joints failing by the Type IV HeatAffected Zone (HAZ) cracking mechanism in

steels for high temperature application in

advanced PF plant.

To assess the long term risks of welded plant

component failure.

To optimise steel selection for thick section high

alloy ferritic steel components in advanced coalfired power plant.

To provide a sound basis for determining

appropriate limiting plant design temperature and

stress conditions.

SUMMARY

Type IV cracking in the weld Heat-Affected Zone

(HAZ) is likely to be the critical problem which will

limit design conditions for satisfactory operation of

advanced PF plant. The FOURCRACK project carried

out high temperature creep testing of welds in

advanced high alloy steels with a range of

specifications, supplemented by specialised testing,

optical and electron metallography, weld simulation

and data assessment. Further work outside

FOURCRACK will extend testing to longer durations.

E.ON UK led the project and undertook metallurgical

investigation and assessment. Mitsui Babcock

carried out weld manufacture and creep rupture

testing. RWE npower investigated and characterised

a special weak material. In parallel work,

Loughborough University carried out electron

metallography and weld simulation. Five external

organisations also provided test materials and/or

weldments.

Avoidance of Premature Weld

Failure by Type IV cracking

PROJECT SUMMARY 304

CLEANER FOSSIL FUELS PROGRAMME

CLEANER COAL R&D PROGRAMME

PS_225.qxp

15/06/2005

10:31

Page 4

However, most of the long

term creep test data

currently available applies

only to the parent steels.

Figure 1. Type IV weld HAZ cracking in a FOURCRACK P122 weld creep

test specimen. (Courtesy of E.ON UK)

The results showed that stronger parent materials often

have stronger HAZs, but there is no direct correlation.

Future development should therefore focus on optimising

weld HAZ as well as parent material properties. The

results confirmed the conclusions of the earlier DTI Clean

Coal PIPPE project, and showed that they apply to

Japanese and US as well as European steels. Long term

weld HAZ creep strength typically falls to no more than

about 60% of that of parent material. Conservative

design will therefore be required for welded components

if recurrent plant maintenance and repair problems in

service are to be avoided.

BACKGROUND

Advanced coal-fired power plant, operating at higher

temperatures and pressures, can achieve substantial

improvements in thermal efficiency and hence reductions

in carbon dioxide emissions. However, these

opportunities may be lost if plant reliability, availability,

maintainability and operation cannot be guaranteed.

Because of the perceived technical risks and

uncertainties with advanced plant, established subcritical

power plant designs are still frequently successful on

the international market, despite their relatively poor

efficiencies. Lack of confidence in the long term

performance of welds in advanced ferritic steels is one of

the main concerns. It is becoming increasingly clear that

Type IV cracking in the weld heat-affected zone may

be the life-limiting failure mechanism in advanced high

temperature components such as superheater and

reheater headers and steam pipework, chests and valves.

If we choose which steel to

use on the basis of parent

data alone, we may not

make the best choice for

satisfactory long term weld

performance. If we design

components without taking

account of weld properties,

we risk incurring major weld

inspection, repair and

replacement costs during

the lifetime of the plant. If

we instead design

conservatively on the basis

of inadequate information,

we run the opposite risk of

an over-conservative and

hence uncompetitive plant

design. Project

FOURCRACK aimed to

overcome these

uncertainties, establish the

effective limits on power

plant design conditions and

operating temperature, and

thereby improve the market

prospects for cleaner coal

technology in the UK and

worldwide.

The earlier DTI supported

PIPPE project, undertaken

by Mitsui Babcock Energy

Limited (MBEL), British

Steel (now Corus) and

Powergen (now E.ON UK),

established the new

European E911 steel as a

viable high temperature

plant material in competition

with Japanese

developments. PIPPE

showed that E911 has good

creep properties and

PS_225.qxp

15/06/2005

10:32

Page 5

oxidation resistance and does not suffer

undue long term degradation in service.

However, the relatively short term creep

tests carried out on welded joints were less

encouraging. Extrapolation of the data

suggested that long term weld strength

might, because of Type IV cracking, fall to as

little as 50% of the parent material rupture

strength. This would put all welds - not just

those under substantial system loading - at

risk of early failure. However, the severe

extrapolation was subject to uncertainty.

Also, little comparative data assessment had

been carried out, and it was not clear to

what extent alternative high alloy steels

would be at comparable risk.

poor properties due to its adverse

aluminium / nitrogen ratio was also

investigated. Separate test series were

carried out after welding onto this material in

the as-manufactured, renormalised and

tempered (strengthened), and preaged

(weakened) conditions.

A novel test matrix was devised to

investigate variations in both stress and

temperature with four tests per weldment.

This made it possible to test as many as ten

weldments and obtain sufficient data to rank

their relative performance over a range of

test conditions. The programme was

supplemented by additional testing with a

special waisted specimen geometry,

comprehensive metadata compilation, weld

thermal simulation, a creep data

assessment project on E911 data supplied

by the European Creep Collaborative

Committee (ECCC), and optical and electron

metallographic investigation.

Figure 2. Newly installed P91 steel headers in

660MW Changshu spiral wound supercritical coalfired power plant.

(Courtesy of Mitsui Babcock Energy Ltd.)

THE FOURCRACK PROJECT

Outline

The project was designed to produce crossweld creep data on a wide range of

alternative advanced high alloy ferritic steels,

manufactured with different processing

routes, heat treatment conditions, and

chemical compositions. The European E911

steel was compared with the leading

Japanese alternatives P92 and P122 and

with the older established steel P91. The

welded materials tested included forging,

casting, plate, and pipe components. A

special cast of Grade 91 steel with known

Figure 3. Type IV crack on the header side toe of a

large P91 branch weld on a coal-fired power plant.

(Copyright and used by permission of RWE npower)

Results and Discussion

The assessment of the ECCC E911 database

was carried out at an early stage, in

collaboration with Dr C. Servetto of the

Italian Welding Institute. A larger data set

than that of PIPPE and an improved PD6605

based assessment procedure indicated that

weld creep rupture strength falls toward a

floor value of about 60% of the parent

strength in the longer term. Whilst this is

PS_225.qxp

15/06/2005

10:32

Page 6

slightly less pessimistic than the PIPPE

prediction, it confirms the general trends

and the scale of the problem. The

assessment also provided reference life

predictions for mean E911 weld

performance as a function of test

conditions. These provided a baseline for

comparison of the alternative welded

materials investigated in FOURCRACK.

The test results on the stronger P92 and

P122 parent materials included many short

term failures in the weld metal. Hence,

there is some concern that for these

stronger alloys, the creep properties of

matching weld metals cannot keep pace

with those of the parent materials. However,

there were clear trends toward HAZ as

opposed to weld metal failure as the test

temperature, and/or test stress, was

reduced to a lower value, closer to the

conditions which would apply to real

components. As both temperature and

stress acceleration promote weld metal

failure, it can be difficult to find test

conditions which produce Type IV failure

in a short term test. However, it can be

concluded that it is HAZ Type IV failure

which remains the greater long term risk

under advanced plant operating conditions.

Those weldments which did fail in the HAZ

showed significant differences in relative

creep rupture strength, and these proved

to be largely independent of the test

conditions. The HAZ failure data could

therefore be used to determine a broadly

consistent ranking order of the relative creep

rupture strengths of the different weldments.

Hence, in those cases where weld metal

failure did not intervene, short term

accelerated test HAZ failure data appeared

to be a reasonable guide to relative creep

rupture strength in the longer term.

An overall assessment of the data showed

a broad correlation between parent material

and cross-weld HAZ creep performance.

Stronger parent materials tend to have

stronger HAZs. However, the correlation

is far from perfect. Hence, future alloy

development should address the

optimisation of cross-weld, as well as

parent, material creep properties.

The main reason why parent and HAZ

properties are not always perfectly

correlated was identified as the effect of

variations in prior heat treatment. These can

substantially affect parent material

properties, but may have only a minor

influence on the properties of a subsequent

weld HAZ. Hence, thick section

components, with relatively poor parent

creep properties associated with long heat

treatment times, may tend to have relatively

good HAZ properties. The work on Grade 91

material provided the most striking

demonstration of the complex influence of

heat treatment. Renormalising and

tempering, while greatly strengthening the

weak parent material employed, actually had

a marginally adverse effect on the

performance of the subsequently

manufactured weldment.

In most cases, it was apparent that changes

in alloy chemistry which strengthen the

parent material also tend to strengthen the

HAZ. Thus, P92 and P122 generally

outperformed E911 both as parent materials

and as weldments, although the weaker

casts of these Japanese materials when

tested in FOURCRACK were not greatly

superior to the mean E911 weld data.

Conversely, the older Grade 91 (P91) material

is generally weaker than E911, both in tests

on the parent material and on the weldment.

However, the special high aluminium weak

Grade 91 material tested, which substantially

underperforms mean P91 parent creep data,

showed a lesser shortfall in its cross-weld

performance. It could therefore be that high

aluminium, which is known to combine with

nitrogen and suppress the formation of key

creep strengthening carbonitride

precipitates, has a more substantially

harmful effect on parent steel properties

than on those of the weld HAZ.

PS_225.qxp

15/06/2005

10:31

Page 1

In summary, the results confirmed the broad

conclusions of PIPPE, and showed that they

apply generally to Japanese and US steels

as well as to European steel E911. The

cross-weld creep strength falls to a level at

which weld HAZ cracking must generally be

expected to occur far in advance of parent

material life exhaustion. Conservative plant

design may therefore be essential to avoid

expensive long term maintenance and repair

costs.

the effect of prior heat treatment on

parent material strength.

Typically, weldment creep rupture

strength appears to fall toward a floor

value of the order of 60% of the parent

strength in the longer term.

However, different material casts show

significant differences in their weldment/

parent material creep strength ratios.

Hence, future alloy development should

focus on optimisation of cross-weld, as

well as parent, material creep properties.

Conservative design of advanced

supercritical PF plant may be essential to

avoid the risks of costly long term

maintenance and weld repair problems,

and to gain the confidence of new plant

buyers and operators.

POTENTIAL FOR FUTURE

DEVELOPMENT

Figure 4. FEGSEM electron micrograph showing

grain boundary microcracking close to the Type IV

zone fracture face in a FOURCRACK P92 weld test

specimen.

(Courtesy of Loughborough University)

CONCLUSIONS

Type IV cracking in the weld heat-affected

zone is likely to be the life-limiting failure

mechanism in advanced high temperature

plant components.

Weld HAZ creep performance shows a

broad, but far from perfect, correlation

with parent material performance.

Generally, weldments in the established

steel P91 are weakest, with E911

intermediate, and advanced materials P92

and P122 strongest. However, there is

substantial cast-to-cast variation.

The weaker of two parent material casts

can thus, in some cases, have the

stronger HAZ. The main reason for this is

At present, the prospects of developing new

high alloy ferritic steels or welding

processes which would eliminate the Type

IV cracking problem appear fairly slim.

However, it is much more likely that

materials selection to optimise weld

performance will achieve useful

improvements in achievable plant design

limits and operational reliability. New alloys,

for example those now being developed for

improved oxidation resistance under the

new COST 536 programme supported by

DTI, thus need to be critically evaluated

against established competitors both in

terms of cross-weld and parent material

creep performance.

FOURCRACK successfully obtained weld

creep rupture data to durations beyond

10,000 hours. However, truly long term

creep data, out to over 30,000 hours and

beyond, are normally required for design

purposes. Commonly, only parent material

data to these durations are available, and

plant is designed using simplified safety

PS_225.qxp

15/06/2005

10:31

Page 2

factors to allow for weld performance. For advanced high

alloy ferritic steels, therefore, there is a need for

genuinely long term cross-weld data. This will enable the

development of improved design philosophies which

recognise the critical importance of welds, and thereby

improve confidence in the future reliability and hence

market prospects for advanced coal-fired power plant.

The UK High Temperature Power Plant Forum (HTPPF)

has recognised these critical needs. A HTPPF test

programme which will use specimens from the

FOURCRACK Grade 91 weldments to extend the test

data out to 50,000 hours has just commenced, while a

second test programme on the FOURCRACK advanced

steel weldments is in preparation.

COST

The total cost of this project

is 304,000, with the

Department of Trade and

Industry (DTI) contributing

152,000, and E.ON UK,

Mitsui Babcock, and RWE

npower contributing the

balance.

DURATION

48 months January 2001

to December 2004.

CONTRACTOR

E.ON UK plc

Power Technology

Ratcliffe-on-Soar

Nottingham

Nottinghamshire

NG11 0EE

Tel: +44(0)115 9362497

Fax: +44(0)115 9362416

Email: david.allen@eonuk.com

COLLABORATORS

Mitsui Babcock Energy

Limited

RWE npower plc

Loughborough University

Further information on the Cleaner Fossil Fuels Programme, and

copies of publications, can be obtained from:

Cleaner Fossil Fuels Programme Helpline, Building 329,

Harwell International Business Centre, Didcot, Oxfordshire OX11 0QJ

Tel: +44 (0)870 190 6343 Fax: +44 (0)870 190 6713

E-mail: helpline@cleanercoal.org.uk

Web: www.dti.gov.uk/cct/

Crown copyright. First printed July 2005.

Printed on paper containing a minimum of 75% post-consumer waste.

DTI/Pub FES 05/954

You might also like

- Repair welding Cr-Mo steels without PWHT techniquesDocument3 pagesRepair welding Cr-Mo steels without PWHT techniquesAnonymous nw5AXJqjd25% (4)

- Graphitization of Steels in Elevated-Temperature Service: Introduction and BackgroundDocument2 pagesGraphitization of Steels in Elevated-Temperature Service: Introduction and BackgroundMuhammad Noman ButtNo ratings yet

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantFrom EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantRating: 3.5 out of 5 stars3.5/5 (3)

- SP-1173 - Welding of MetalsDocument15 pagesSP-1173 - Welding of Metalschandana kumar67% (3)

- AutoForm OneStepDocument96 pagesAutoForm OneSteplfsij67% (3)

- 57698Document109 pages57698sk84kNo ratings yet

- Advanced Modelling and TestingDocument43 pagesAdvanced Modelling and TestingSanjoo PaddeaNo ratings yet

- Literature Review On Carbon SteelDocument7 pagesLiterature Review On Carbon Steelc5p0cd99100% (1)

- Review of Type IV Cracking of Weldments in 9Document64 pagesReview of Type IV Cracking of Weldments in 9Krishnan SanthanarajNo ratings yet

- Weld Repair of Grade 91 Piping and Components in PDocument27 pagesWeld Repair of Grade 91 Piping and Components in PKyi HanNo ratings yet

- steel_foundryDocument9 pagessteel_foundryChris BothaNo ratings yet

- Alloy 690 in PWRDocument220 pagesAlloy 690 in PWRAndres_Pastor1987No ratings yet

- Tandem MIG process-WAAM in Stainless Steel-2018Document12 pagesTandem MIG process-WAAM in Stainless Steel-2018fereidoon marefatNo ratings yet

- Etd Epri p91 FailuresDocument9 pagesEtd Epri p91 FailuresJustin Morse100% (1)

- ParkerEPRIAdvancedMaterialspaper 2013finalDocument20 pagesParkerEPRIAdvancedMaterialspaper 2013finalpresleNo ratings yet

- Development of The Copper Motor RotorDocument13 pagesDevelopment of The Copper Motor RotorIjabiNo ratings yet

- Tandem Metal Inert Gas Process For High Productivity Wire Arc Additive Manufacturing in Stainless SteelDocument13 pagesTandem Metal Inert Gas Process For High Productivity Wire Arc Additive Manufacturing in Stainless Steelfereidoon marefatNo ratings yet

- Coatings and Overlays For Critical Valve ApplicationsDocument12 pagesCoatings and Overlays For Critical Valve Applicationsnavar001No ratings yet

- Wwelds in CreepDocument24 pagesWwelds in CreepJ.GuerhardNo ratings yet

- Advanced Material For Ultra Super Critical Boiler SystemDocument2 pagesAdvanced Material For Ultra Super Critical Boiler SystemgaotamaNo ratings yet

- 02 Whole X XXXXXXXXXXXXXX 80Document109 pages02 Whole X XXXXXXXXXXXXXX 80Danem HalasNo ratings yet

- Oil & Gas, Published Papers: Hydrogen induced stress cracking of duplex stainless steel subsea componentsDocument6 pagesOil & Gas, Published Papers: Hydrogen induced stress cracking of duplex stainless steel subsea componentsa_attarchiNo ratings yet

- Master: Nuclear Welding, Application For An LMFBRDocument38 pagesMaster: Nuclear Welding, Application For An LMFBRTrushar ParmarNo ratings yet

- TWI-2009-Improved Welding, Inspection and Integrity of Clad Pipeline Girth Welds First Progress Report PDFDocument60 pagesTWI-2009-Improved Welding, Inspection and Integrity of Clad Pipeline Girth Welds First Progress Report PDFRicardoSchayerSabinoNo ratings yet

- Mechanical Testing: Notched Bar or Impact Testing. Part IIDocument4 pagesMechanical Testing: Notched Bar or Impact Testing. Part IIMehmet Soysal100% (1)

- Weldability of High Performance SteelsDocument16 pagesWeldability of High Performance Steelsgowtham_venkat_4No ratings yet

- Investigation of Weld Repair Without Post-Weld Heat Treatment For P91 PDFDocument10 pagesInvestigation of Weld Repair Without Post-Weld Heat Treatment For P91 PDF55312714No ratings yet

- Friction Stir Spot Welding of Advanced High-Strength Steels - A Feasibility StudyDocument7 pagesFriction Stir Spot Welding of Advanced High-Strength Steels - A Feasibility StudyAlessandro NunesNo ratings yet

- Advanced Manufacturing For Nuclear Energy: JOM, Vol. 71, No. 8, 2019Document3 pagesAdvanced Manufacturing For Nuclear Energy: JOM, Vol. 71, No. 8, 2019salehqaidNo ratings yet

- Operating Temperature Windows For Fusion Reactor Structural MaterialsDocument17 pagesOperating Temperature Windows For Fusion Reactor Structural MaterialsW.t. HanNo ratings yet

- Life Assessment of High Temperature HeadersDocument31 pagesLife Assessment of High Temperature HeadersAnonymous UoHUag100% (1)

- Advanced Boiler TubeDocument2 pagesAdvanced Boiler TubeShailendra WaniNo ratings yet

- Effect of Hydrogen Charging On The Mechanical Properties of AHSSDocument10 pagesEffect of Hydrogen Charging On The Mechanical Properties of AHSSFernandoNo ratings yet

- Final Scientific Report Steel Foundry Refractory LDocument10 pagesFinal Scientific Report Steel Foundry Refractory LMaRio S TerrazasNo ratings yet

- Cryogenics: Qinyan Pan, Chuanjun Huang, Laifeng LiDocument7 pagesCryogenics: Qinyan Pan, Chuanjun Huang, Laifeng LipurnashisNo ratings yet

- Carrolo2022 Article DevelopmentOfMetallicTransitioDocument13 pagesCarrolo2022 Article DevelopmentOfMetallicTransitioLuis MoraesNo ratings yet

- In Uence of Alloying Elements On The Low-Temperature Properties of SteelDocument9 pagesIn Uence of Alloying Elements On The Low-Temperature Properties of SteelWasimullah KhanNo ratings yet

- 7.1 Conventional Approaches To Design Against Brittle FractureDocument7 pages7.1 Conventional Approaches To Design Against Brittle FracturemjinspectorNo ratings yet

- Experience With Lined and Clad PipelinesDocument17 pagesExperience With Lined and Clad Pipelinesjoni Mart Sitio100% (1)

- Steel Products For Shipbuilding: AbstractDocument8 pagesSteel Products For Shipbuilding: AbstractRoo FaNo ratings yet

- Yin 2015Document11 pagesYin 2015carlosNo ratings yet

- Thermal-Stress Analysis of RC Beams Reinforced With GFRP BarsDocument8 pagesThermal-Stress Analysis of RC Beams Reinforced With GFRP BarsMustapha HeshmatNo ratings yet

- T1 Orbital Welding of DuplexSSDocument9 pagesT1 Orbital Welding of DuplexSSssmith2007No ratings yet

- Materials 15 01248 v2Document12 pagesMaterials 15 01248 v2GAURI RAJENDRA MAHALLENo ratings yet

- A Study of Metallurgical Factors For Defect Formation in Electric Resistance Welded API Steel PipesDocument12 pagesA Study of Metallurgical Factors For Defect Formation in Electric Resistance Welded API Steel PipesSinan ChenNo ratings yet

- Literature Review of Mild SteelDocument4 pagesLiterature Review of Mild Steelc5hc4kgx100% (2)

- Steel Alerts Vol.5 No.3Document24 pagesSteel Alerts Vol.5 No.3Learnscoop Inc.No ratings yet

- Whisker Root Cause and Test ConditionsDocument4 pagesWhisker Root Cause and Test ConditionsLaercioNo ratings yet

- Analysis of Weld-Cracking and Improvement of The Weld-Repair Process of Superplastic Forming ToolsDocument23 pagesAnalysis of Weld-Cracking and Improvement of The Weld-Repair Process of Superplastic Forming Toolsl_aguilar_mNo ratings yet

- Kurji Coniglio 2014Document18 pagesKurji Coniglio 2014xaxafagaNo ratings yet

- Influence of Welding Process On Type IV PDFDocument11 pagesInfluence of Welding Process On Type IV PDFDiego AlonsoNo ratings yet

- EPRI Galvanic CorrosionDocument138 pagesEPRI Galvanic CorrosionJaime AndrewsNo ratings yet

- Materials Research for Ultra-Supercritical Steam TurbinesDocument12 pagesMaterials Research for Ultra-Supercritical Steam Turbinesmahmood750No ratings yet

- Friction Stir Welding Thesis PDFDocument8 pagesFriction Stir Welding Thesis PDFcarolinalewiswashington100% (2)

- VUT, FSI, UMVI, Technická 2896/2, 616 69 Brno, Česká Republika, Pavelsohaj@seznam - CZDocument6 pagesVUT, FSI, UMVI, Technická 2896/2, 616 69 Brno, Česká Republika, Pavelsohaj@seznam - CZRushabh PanjabiNo ratings yet

- Estimating Creep Damage in Low-Alloy Steel PipesDocument45 pagesEstimating Creep Damage in Low-Alloy Steel PipesDan DumbravescuNo ratings yet

- Site Cast Tilt Up Concrete Version 18 1Document4 pagesSite Cast Tilt Up Concrete Version 18 1Prakash RajNo ratings yet

- Manikandan 2016 IOP Conf. Ser.: Mater. Sci. Eng. 149 012020Document13 pagesManikandan 2016 IOP Conf. Ser.: Mater. Sci. Eng. 149 012020Sayiram GNo ratings yet

- Proceedings of the 2014 Energy Materials Conference: Xi'an, Shaanxi Province, China, November 4 - 6, 2014From EverandProceedings of the 2014 Energy Materials Conference: Xi'an, Shaanxi Province, China, November 4 - 6, 2014No ratings yet

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesFrom EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesNo ratings yet

- High-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesFrom EverandHigh-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesNo ratings yet

- Method For Mechanical Properties EvaluationDocument5 pagesMethod For Mechanical Properties Evaluationmahmoud_allam3No ratings yet

- Fracture Toughness of The Heat Affected Zone in Girth WeldsDocument7 pagesFracture Toughness of The Heat Affected Zone in Girth Weldsmahmoud_allam3No ratings yet

- Passivating Gel For Stainless SteelDocument2 pagesPassivating Gel For Stainless Steelmahmoud_allam3No ratings yet

- ASME New Code Case LetterDocument1 pageASME New Code Case Lettermahmoud_allam3No ratings yet

- 1english Reg Final Nov 2010 PDFDocument367 pages1english Reg Final Nov 2010 PDFmahmoud_allam3No ratings yet

- Request For Code CaseDocument2 pagesRequest For Code Casemahmoud_allam3No ratings yet

- Furnaces and RefractoriesDocument36 pagesFurnaces and Refractoriesengkassem100% (5)

- Study of Ductile-Brittle Transition Temperature of 9Cr-1Mo SteelsDocument2 pagesStudy of Ductile-Brittle Transition Temperature of 9Cr-1Mo Steelsmahmoud_allam3No ratings yet

- Steam Generators 2Document33 pagesSteam Generators 2gbharathreddysNo ratings yet

- PICKLING Gel FOR STAILESS STEEL PdsDocument2 pagesPICKLING Gel FOR STAILESS STEEL Pdsmahmoud_allam3No ratings yet

- Projects Follow UpDocument1 pageProjects Follow Upmahmoud_allam3No ratings yet

- Nitrogen Purging For Stainless SteelDocument4 pagesNitrogen Purging For Stainless Steelmahmoud_allam3No ratings yet

- Code Case 2891 U-2 CerDocument1 pageCode Case 2891 U-2 Cermahmoud_allam3No ratings yet

- Code Case 2891 U-2 CerDocument1 pageCode Case 2891 U-2 Cermahmoud_allam3No ratings yet

- Color Metallurgy of Cast IronDocument13 pagesColor Metallurgy of Cast Ironmahmoud_allam3No ratings yet

- Color Metallurgy of Cast IronDocument13 pagesColor Metallurgy of Cast Ironmahmoud_allam3No ratings yet

- 16-2819 Welders InterpretationDocument1 page16-2819 Welders Interpretationmahmoud_allam3No ratings yet

- Engineering, Steel Fabrication and Process Equipment ManufacturerDocument4 pagesEngineering, Steel Fabrication and Process Equipment Manufacturermahmoud_allam3No ratings yet

- Presentation For WeldingDocument31 pagesPresentation For Weldingmahmoud_allam3No ratings yet

- Heat Treatment of 9 CRDocument12 pagesHeat Treatment of 9 CRmahmoud_allam3No ratings yet

- 10 1 1 161 3015Document7 pages10 1 1 161 3015rinshadNo ratings yet

- Journal Modified 9% CR Steels For AdvancedDocument6 pagesJournal Modified 9% CR Steels For Advancedmahmoud_allam3No ratings yet

- Aluminim WPSDocument5 pagesAluminim WPSmahmoud_allam3No ratings yet

- Assessment of Welding ConsumablesDocument17 pagesAssessment of Welding Consumablesmahmoud_allam3No ratings yet

- Welding of P91Document10 pagesWelding of P91mahmoud_allam3No ratings yet

- WPS for GTAW Welding of Aluminum Butt JointsDocument2 pagesWPS for GTAW Welding of Aluminum Butt Jointsmahmoud_allam3No ratings yet

- Welding CrMo Steels for Power and Petrochemical ApplicationsDocument11 pagesWelding CrMo Steels for Power and Petrochemical Applicationsmahmoud_allam3100% (1)

- WPS for GTAW Welding of Aluminum Butt JointsDocument2 pagesWPS for GTAW Welding of Aluminum Butt Jointsmahmoud_allam3No ratings yet

- Aluminim WPSDocument5 pagesAluminim WPSmahmoud_allam3No ratings yet

- WPS for GTAW Welding of Aluminum Butt JointsDocument2 pagesWPS for GTAW Welding of Aluminum Butt Jointsmahmoud_allam3No ratings yet

- Saw Wire& Flux......Document41 pagesSaw Wire& Flux......Arul ChinnapillaiNo ratings yet

- #007 Hot Work Welding On Cargo Tank & Main Deck-01-03-10Document6 pages#007 Hot Work Welding On Cargo Tank & Main Deck-01-03-10Tolias EgwNo ratings yet

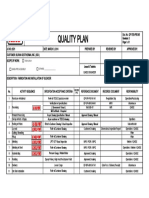

- Quality Plan for Fabrication and Installation of Silencer for Biliran Geothermal IncDocument1 pageQuality Plan for Fabrication and Installation of Silencer for Biliran Geothermal IncAldrin HernandezNo ratings yet

- Brochure - Valco - Marine Valves - EnglishDocument8 pagesBrochure - Valco - Marine Valves - EnglishMeet JaniNo ratings yet

- Premier Limited Plate Data SheetDocument14 pagesPremier Limited Plate Data SheetGurbir SinghNo ratings yet

- Root Gap PDFDocument6 pagesRoot Gap PDFmetasoniko81No ratings yet

- SECTION 05 31 00 Steel DeckingDocument11 pagesSECTION 05 31 00 Steel DeckingJuanPaoloYbañezNo ratings yet

- Filler Metal 70s-6Document1 pageFiller Metal 70s-6Hugo RodriguezNo ratings yet

- EDO WMS Fuel Storage Tank R01Document29 pagesEDO WMS Fuel Storage Tank R01ocayli100% (1)

- Joining Aluminum Sheet in The Automotive Industry - A 30 Year HistoryDocument12 pagesJoining Aluminum Sheet in The Automotive Industry - A 30 Year HistoryStupinean LarisaNo ratings yet

- Mig/Mag: Product Catalogue 3.1 / V1Document48 pagesMig/Mag: Product Catalogue 3.1 / V1Matija BušićNo ratings yet

- B02-S05 Rev 3 Sep 2017 Design, Fabri and Inst of GratingsDocument9 pagesB02-S05 Rev 3 Sep 2017 Design, Fabri and Inst of Gratings15150515715No ratings yet

- 8 Tips MIG Welding BeginnersDocument7 pages8 Tips MIG Welding BeginnerspeterNo ratings yet

- Hot Plate and Hot Gas WeldingDocument14 pagesHot Plate and Hot Gas WeldingВасил СавовскиNo ratings yet

- Welding CalculatorDocument18 pagesWelding CalculatorKhamdi AfandiNo ratings yet

- Thermoplastic Polyolefin Based Sheet Roofing: Standard Specification ForDocument3 pagesThermoplastic Polyolefin Based Sheet Roofing: Standard Specification Forasma hamzaNo ratings yet

- Ss Filler Wire SelectionDocument26 pagesSs Filler Wire Selectionlemuel bacsaNo ratings yet

- API 571 DamageDocument111 pagesAPI 571 DamageNatraji100% (16)

- Ultrasonic Testing ProcedureDocument19 pagesUltrasonic Testing ProcedureHASBIL HASSANNo ratings yet

- Ultrasonic Examination Procedure (Issue 2)Document14 pagesUltrasonic Examination Procedure (Issue 2)Li Liu100% (1)

- Shear Connections Part IDocument51 pagesShear Connections Part Iabou92No ratings yet

- Astm/Asme Reference: SpecificationDocument32 pagesAstm/Asme Reference: SpecificationÀngel RodriguezNo ratings yet

- Radiography Testing GuideDocument7 pagesRadiography Testing GuideAmirul Asyraf100% (1)

- Astm A928Document8 pagesAstm A928Malcolm DowNo ratings yet

- Hot Work ProcedureDocument16 pagesHot Work ProcedureAkmal YassinNo ratings yet

- Types of Steel Structure Connections: Riveted, Bolted, WeldedDocument10 pagesTypes of Steel Structure Connections: Riveted, Bolted, WeldedDIBYENDU MONDALNo ratings yet

- NEMA Product ScopesDocument39 pagesNEMA Product ScopesPaul AlvaradoNo ratings yet

- Abrasive Flow MachiningDocument28 pagesAbrasive Flow MachiningsnvijayanNo ratings yet