Professional Documents

Culture Documents

Ductile Iron Pipe

Uploaded by

garyckfanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ductile Iron Pipe

Uploaded by

garyckfanCopyright:

Available Formats

DUCTILE

IRON PIPE

& FITTINGS

For your nearest branch visit

www.frazer.eu.com or see pages 175-190

Ductile Iron Pipe & Fittings

122

INTRODUCTION

Frazer are closely associated with Saint-Gobain Pipelines, the UKs largest

supplier of Ductile Iron Water Pipe systems for both potable and waste water.

Thousands of kilometres of Ductile Iron Mains are laid in the UK every year.

SGPL, are constantly looking to develop new products to ensure we can offer

our customers the longest possible service life. The mechanical properties of

Ductile Iron, combined with internal lining and external coating systems,

ensure that Ductile Iron Mains provide assured long term performance.

Principle Properties of Ductile Iron

P Minimum Tensile Strength: 420 Mn/m

P Minimum Elongation: Pipes 10% DN < 1000

2

P

P

7% DN > 1200

Fittings 5%

Modulus of elasticity: 170 GN/m2

Exceptional impact strength

Features

Benefits

Material

The inherent characteristics of Ductile Iron include a high safety factor

capable of withstanding many unforeseen site hazards or changes in

future demand.

Strength

Its ability to withstand exceptional internal pressures and external

loadings.

Jointing

A proven range of jointing systems for

every requirement.

Range

A comprehensive choice of pipes and fittings for all applications and

design requirements.

Performance

The long-term reliability and integrity of performance.

Coatings & Linings

The long-term durability of coatings and linings.

Installation

The ease and simplicity of installation, testing

and commissioning.

Cost-effective

The overall cost-effectiveness of ductile iron pipelines which comes

from all of these attributes.

For details of your nearest branch see pages 175-190

Ductile Iron Pipe & Fittings

123

Quality and Standards

Saint-Gobain Pipelines regard quality as essential to the success

of the business.

From chemical and physical analysis of the molten metal to tight

control of the coating and lining applications, quality procedures

have been developed to ensure consistent high quality of each

individual pipe and fitting. Additionally, every pipe and fitting is

tested in accordance with BS EN598 (sewer applications)

and BS EN545 (water application) to ensure permanently

high performance.

The quality-is-key principle applies to every stage of the life of our products and also includes:

P Validation of suppliers and/or their materials

P Continuous assessment of quality systems

P On-going monitoring of product quality

P Technical support prior to and after sales

P On-time delivery of products and supporting information

Compliance with Standards

Saint-Gobain Pipelines products comply with and are tested

according to the relevant British, European and International

Standards. All our pipes and fittings are manufactured under

the quality management system BS EN ISO 9001.

Our ductile iron pipes and fittings for sewerage application

conform to BS EN598 (sewer applications) and BS EN545

(water application) and are kitemarked under the BSI

registered approval scheme.

All our integral pipes and fittings conform to standards and instructions outlined in the

Civil Engineering specification for Water Industries Sewers for Adoption.

WRc Approved Soil Assessments

Saint-Gobain Pipelines offer a WRc approved soil assessment

service to determine local ground conditions. In this way we

are able to provide excellent customer support,

recommending appropriate external protection for ductile

iron pipes and fittings.

For details of your nearest branch visit www.frazer.eu.com

Ductile Iron Pipe & Fittings

124

Integral Advantages of Ductile Mains

P Suitable for above or below ground installations

P Sewer and water capability pipelines for use in country or urban areas

P Gravity or high pressure

P Corrosion resistant

P High pipe stiffness minimises embedment requirements

P Full range of diameters and fittings available

P Variety of jointing systems to suit different ground conditions and pressure ratings

P Simple and quick to install

P Hydraulically smooth

P Resistance to septicity and abrasion (sewer)

P High beam strength allows pipe to cope with uneven longitudinal loading

P Resistance to second corner damage and disruption

P Resistance to abrasion

Below Ground Further Benefits

P Simple, inexpensive embedment

and backfilling

P Joints not susceptible to roof

infestation

P Suitable for narrow trenching as

pipe is not reliant on side fill

support

For details of your nearest branch see pages 175-190

Ductile Iron Pipe & Fittings

125

PAM Natural Pipe (Primary Core Range)

Description

Size

(mm)

Frazer

Code

Supplier

Code

80 Natural Tyton Pipe 5.5m Blue Epoxy

80

70150010 P508 BLUE

100 Natural Tyton Pipe 5.5m Blue Epoxy

100

70150020 P510 BLUE

150 Natural Tyton Pipe 5.5m Blue Epoxy

150

70150030 P515 BLUE

PAM Natural Pipe (Extended Range)

Description

Size

(mm)

Frazer

Code

200 Natural Push-fit Pipe EN545 6.0m Blue Epoxy

200

70280540

250 Natural Push-fit Pipe EN545 6.0m Blue Epoxy

250

70280550

300 Natural Push-fit Pipe EN545 6.0m Blue Epoxy

300

70280560

PAM Natural product range

The new PAM Natural pipe is available for potable water applications in the diameter

range DN80-DN800.

PAM Natural Exceptional Protection

PAM Natural is a truly revolutionary and evolutionary pipeline product and is an example of

Saint-Gobain Pipelines response to developments and technological advances within the

water industry.

PAM Natural pipe with its new, exceptional external protection is the state-of-the-art pipeline

system that allows for the broadest range of applications, eliminating the need for polyethylene

sleeving. PAM Natural pipe can be laid in over 90% of all natural soils in the UK.

Put simply PAM Natural:

P Extends asset lifetime

P Reduces rise

P Further increases speed of installation

Yet PAM Natural pipe retains all the traditional advantages of ductile iron pipeline systems:

P Tough and reliable

P Simple to lay using push fit joints

P Self-anchoring

P High safety factor Put simply, PAM Natural pipe is the most innovative and universal ductile pipe

system on the market today.

Internal Lining

PAM Natural Ductile Iron pipes are intended for conveying potable water under pressure. Internally

the PAM Natural is lined with seal coat applied to cement mortar lining. An approved coating is applied

to the joint area. This system has been approved by the Secretary of State under Regulation 31 as

Saint-Gobain Pipelines System XL.

For details of your nearest branch visit www.frazer.eu.com

Ductile Iron Pipe & Fittings

126

PAM Natural Fittings (Extended Range)

Size

(mm)

Frazer

Code

80 DI Push-fit 45 Bend EN545 Water

80

70400030

80 DI Push-fit 90 Bend EN545 Water

80

70400040

100 DI Push-fit 45 Bend EN545 Water

100

70400170

100 DI Push-fit 90 Bend EN545 Water

100

70400180

100 DI Push-fit 111/4 Bend EN545 Water

100

70400150

100 DI Push-fit 221/2 Bend EN545 Water

100

70400160

150 DI Push-fit 45 Bend EN545 Water

150

70400370

150 DI Push-fit 90 Bend EN545 Water

150

70400380

150 DI Push-fit 111/4 Bend EN545 Water

150

70400350

150 DI Push-fit 221/2 Bend EN545 Water

150

70400360

200 DI Push-fit 111/4 Bend EN545 Water

200

70400560

200 DI Push-fit 221/2 Bend EN545 Water

200

70400570

200 DI Push-fit 45 Bend EN545 Water

200

70400580

200 DI Push-fit 90 Bend EN545 Water

200

70400590

250 DI Push-fit 111/4 Bend EN545 Water

250

70400800

250 DI Push-fit 221/2 Bend EN545 Water

250

70400810

250 DI Push-fit 45 Bend EN545 Water

250

70400820

250 DI Push-fit 90 Bend EN545 Water

250

70400830

300 DI Push-fit 45 Bend EN545 Water

300

70401080

300 DI Push-fit 90 Bend EN545 Water

300

70401090

300 DI Push-fit 111/4 Bend EN545 Water

300

70401060

300 DI Push-fit 221/2 Bend EN545 Water

300

70401070

Description

Better Coating, Better Performance

The new, blue, epoxy coating greatly improves the performance of the fittings.

It also brings further improvements to the PAM Natural system, as the colour co-ordinated fittings now:

P Form a complete, unified system with the new pipe

P Offer the same high level of protection as the pipe

P Simple to joint and easy to clean

P Modern and attractive in appearance

P Have the potential to reduce pumping costs by increasing hydraulic flow and reducing

build-up of deposits

For details of your nearest branch see pages 175-190

Ductile Iron Pipe & Fittings

127

PAM Natural Flanged Fittings (Primary Core Range)

Size

(mm)

Frazer

Code

Supplier

Code

80 DI Flanged 45 Bend EN545 Water

80

70600200

H2022 BLUE

80 DI Flanged 90 SR Bend EN545 Water

80

70600210

H0206 BLUE

80X80 DI Flanged Tee EN545 Water

80

70600270

H0222 BLUE

100 DI Flanged 45 Bend EN545 Water

100

70600530

H0211 BLUE

100 DI Flanged 90 SR Bend EN545 Water

100

70600540

H0210 BLUE

100X80 DI Flanged Tee EN545 Water

100 x 80

70600600

E0223 BLUE

100X100 DI Flanged Tee EN545 Water

100 x 100

70600610

H0225 BLUE

100X80 DI Flanged Con Taper EN545 Water

100 x 80

70600670

E0242 BLUE

100 DI Flanged 11.1/4 Bend EN545 Water

100

70600510

E0213 BLUE

150 DI Flanged 45 Bend EN545 Water

150

70600860

H0215 BLUE

H0214 BLUE

Description

150 DI Flanged 90 SR Bend EN545 Water

150

70600870

150X80 DI Flanged Tee EN545 Water

150 x 80

70600930

E2003 BLUE

150X150 DI Flanged Tee EN545 Water

150 x 150

70600950

H0227 BLUE

150X100 DI Flanged Con Taper EN545 Water

150 x 100

70601020

E0244 BLUE

150 DI Flanged 11.1/4 Bend EN545 Water

150

70600840

E0217 BLUE

150 DI Flanged 22.1/2 Bend EN545 Water

150

70600850

E0216 BLUE

PAM Natural Flanged Fittings (Extended Range)

Description

Size

(mm)

Frazer

Code

Supplier

Code

H0661 BLUE

80 DI Flanged 90 Duckfoot Bend EN545 Water

80

70600230

100 DI Flanged 221/2 Bend EN545 Water

100

70600520

E0212 BLUE

100 x 80 DI Flanged 90 D/Foot Bend EN545 Water

100 x 80

70600565

V164B BLUE

150 x 100 DI Flanged Tee EN545 Water

150 x 100

70600940

E2004 BLUE

150 x 80 DI Flanged Con Taper EN545 Water

150 x 80

70601010

E2011 BLUE

200

70601240

H2025 BLUE

200 DI FLD 90 SR Bend EN545 Water

200

70601250

VO690 BLUE

200 x 80 DI Flanged Tee EN545 Water

200 x 80

70601300

E0539 BLUE

200 x 150 DI Flanged Con Taper EN545 Water

200 x 150

70601410

E2043 BLUE

200

70601220

E2023 BLUE

200 DI FLD 221/2 Bend EN545 Water

200

70601230

E2024 BLUE

200 x 150 DI Flanged Tee EN545 Water

200 x 150

70601320

E0543 BLUE

200 x 200 DI Flanged Tee EN545 Water

200 x 200

70601330

V0546 BLUE

200 DI FLD 45 Bend EN545 Water

200 DI FLD 111/4 Bend EN545 Water

For details of your nearest branch visit www.frazer.eu.com

Ductile Iron Pipe & Fittings

128

Coatings and Linings

The blue epoxy coating is applied to Class A internally and to Class B externally. That is:

Class A

250m minimum coating thickness, holiday free

Class B

250m minimum coating thickness, no more than 20 holiday/m2

Standards and Approvals

PAM Natural pipe is approved by the Secretary of State under Regulation 31 as

Saint-Gobain Pipeline System XL.

Regulation 31:

The blue epoxy coating in contact with potable water used on PAM Natural fittings is approved to BS

6920, therefore the fittings may be used under Regulation 31.

BS EN545:

PAM Natural pipe fittings fully comply with the requirements of the British Standard EN545.

WRAS Approved:

The blue epoxy coating materials used by Saint-Gobain Pipelines are listed in the current WRAS Water

Fittings and Materials Directory as materials which have passed full tests of effect on water quality.

Our branches carry a comprehensive range

of Pipes and Fittings.

Please call your local branch for

prices and availability.

PAM Integral Plus (Primary Core Range)

Effective external protection in all environments

Following the successful introduction of the PAM Natural coating

for water pipe and in response to customer demand, Saint-Gobain

Pipelines is now able to offer the same revolutionary coating

technology on its PAM Integral sewer pipe range.

The use of a zinc-aluminium alloy, applied at a thickness greater than that of the traditional zinc

coating, plus a tough but porous epoxy barrier, allows PAM Integral Plus pipes to be used effectively in

over 86% of all UK soil conditions. The few instances in which additional protection will be required are

easily identified, thereby simplifying the task of specifying the right product.

For details of your nearest branch see pages 175-190

Ductile Iron Pipe & Fittings

Features

129

Advantages of specifying PAM Integral Plus

Active external

Eliminates the need for polyethylene sleeving and muffs

protection system Risk of specifying inappropriate protective coating is virtually eliminated

Universal

suitability

Can be used in over 86% of all UK soils

Compatible with PAM Integral fittings, which are also suitable for the same soil conditions

Cost-effective

Increases ease and speed of pipe laying

Longevity of active protective layer extends asset lifetime

Universal soil suitability could lead to reduced stock levels throughout entire supply chain

Takes cost out of the pipe system supply chain

Superior performance of ductile iron is retained

Good performance against corrosion in a wide range of environments

Tough and reliable Robust coating withstands extremes of handling, storing and laying of pipe

Rigorously tested and developed to ensure high degree of confidence and exceed expectations

All PAM Integral Plus ductile iron pipes and fittings are fully standardised and approved

PAM Integral Pipe (Primary Core Range)

Description

Size

(mm)

Frazer

Code

Supplier

Code

100 Integral Hac Lined K7 Pipe

100

70280220

P810 7

150 Integral Hac Lined K7 Pipe

150

70280230

P815 7

Size

(mm)

Frazer

Code

Supplier

Code

PAM Integral Pipe (Extended Range)

Description

80 Integral Hac Lined

80

70280200

P808 7

200 Integral Hac Lined

200

70280240

P820 7

250 Integral Hac Lined

250

70280250

P825 7

300 Integral Hac Lined

300

70280260

P830 7

For sewerage applications Saint-Gobain Pipelines offers a comprehensive range of ductile pipes and fittings from DN80 to DN1800.

PAM Integral pipes are available as standard with a High Alumina cement mortar lining capable of conveying

effluents in the pH range 4 to 12. The standard coating for integral pipes is zinc plus a tough red epoxy finish

coat. The same revolutionary coating technology offered on water pipes can now also be offered on sewer pipes

with exceptional protection given. Through exceptional

coating PAM Integral Plus fittings are lined and coated

with the same red epoxy this offers the benefit of clear

identification as being suitable for sewerage application.

In addition, a range of proven external coatings is

available to suit all types of ground conditions and above

ground applications, such as pumping stations and

treatment works. PAM Integral pipeline products are

straightforward and cost effective to install. Joints can be

made using standard site equipment without the need

for specialist tools. PAM Integral pipes and fittings are

available with a range of jointing systems to suit

particular applications and feature a rapid joint as

standard. The flexibility of the products allows site

variations to be easily accommodated.

For details of your nearest branch visit www.frazer.eu.com

Ductile Iron Pipe & Fittings

130

PAM Integral Fittings (Primary Core Range)

Size

(mm)

Frazer

Code

Supplier

Code

80 DI Tyton 45 Bend EN545 Water

80

70400030

H0125 BLUE

80 DI Tyton 90 Bend EN545 Water

80

70400040

H0124 BLUE

100 DI Tyton 45 Bend EN545 Water

100

70400170

H0129 BLUE

100 DI Tyton 90 Bend EN545 Water

100

70400180

H0128 BLUE

150 DI Tyton 45 Bend EN545 Water

150

70400370

H0133 BLUE

Description

PAM Integral Fittings (Extended Range)

Description

Size

(mm)

Frazer

Code

Supplier

Code

100 x 45 Integral Rapid Bend c/w Gasket

100

70380170

RF422 1

100 x 90 Integral Rapid Bend c/w Gasket

100

70380180

RF417 1

100 x 100 Integral Rapid Tee c/w Gasket

100

70380240

RF830 1

100 x 111/4 Integral Rapid Bend c/w Gasket

100

70380150

RF448 1

100 x 221/2 Integral Rapid Bend c/w Gasket

100

70380160

RF435 1

150 x 45 Integral Rapid Bend c/w Gasket

150

70380370

RF423 1

150 x 90 Integral Rapid Bend c/w Gasket

150

70380380

RF418 1

150 x 150 Integral Rapid Tee c/w Gasket

150

70380450

RF832 1

150 x 111/4 Integral Rapid Bend c/w Gasket

150

70380350

RF449 1

150 x 221/2 Integral Rapid Bend c/w Gasket

150

70380360

RF436 1

150 x 100 Integral Rapid Tee c/w Gasket

150

70380440

RF831 1

200 x 45 Integral Rapid Bend c/w Gasket

200

70380580

RF424 1

200 x 90 Integral Rapid Bend c/w Gasket

200

70380590

RF419 1

200 x 111/4 Integral Rapid Bend c/w Gasket

200

70380560

RF450 1

200 x 221/2 Integral Rapid Bend c/w Gasket

200

70380570

RF437 1

250 x 45 Integral Rapid Bend c/w Gasket

250

70380820

RF425 1

250 x 90 Integral Rapid Bend c/w Gasket

250

70380830

RF420 1

250 x 111/4 Integral Rapid Bend c/w Gasket

250

70380800

RF451 1

250 x 221/2 Integral Rapid Bend c/w Gasket

250

70380810

RF438 1

300 x 45 Integral Rapid Bend c/w Gasket

300

70381080

RF409 1

300 x 90 Integral Rapid Bend c/w Gasket

300

70381090

RF421 1

300 x 111/4 Integral Rapid Bend c/w Gasket

300

70381060

RF408 1

300 x 221/2 Integral Rapid Bend c/w Gasket

300

70381070

RF407 1

Bolt Sets and Gaskets (Primary Core Range)

Description

80/100mm NP16 Galvanised Bolt Set

Size

(mm)

Frazer

Code

Supplier

Code

80/100

74403000

150mm NP16 Galvanised Bolt Set M20 X 70 X 8mm

150

74403010

200mm NP16 Galvanised Bolt Set M20 X 70 X 12mm

200

74403020

250/300

74403030

80 EPDM Full Face Gasket NP16

80

79300410

100 EPDM Full Face Gasket NP16

100

79300420

150 EPDM Full Face Gasket NP16

150

79300430

200 EPDM Full Face Gasket NP16

200

79300440

250 EPDM Full Face Gasket NP16

250

79300450

300 EPDM Full Face Gasket NP16

300

79300460

250/300mm NP16 Galvanised Bolt Set

For details of your nearest branch see pages 175-190

Ductile Iron Pipe & Fittings

131

PAM Integral Flanged Fittings (Primary Core Range)

Size

(mm)

Frazer

Code

Supplier

Code

80 Integral 45 FLG Bend

80

70580030

H2022 RED

80 Integral 90 SR FLG Bend

80

70580040

H0206 RED

80 x 80

70580090

H0222 RED

100 Integral 45 FLD Bend

100

70580530

H0211 RED

100 Integral 90 SR FLD Bend

100

70580540

H0210 RED

100 x 100

70580610

H0225 RED

100 Integral 11.1/4 FLG Bend

100

70580510

E0213 RED

100 Integral 22.1/2 FLD Bend

100

70580520

E0212 RED

100 Integral 90 LR FLD Bend

100

70580550

V0482 RED

100 Integral 90 D/FOOT Bend

100

70580560

H0655 RED

100 Integral Blank Flange

100

70580580

H2155 RED

100X100 Integral FLD Radial Tee

100 x 100

70580620

V0536 RED

100X80 Integral FLD Conc Taper

100 x 80

70580670

E0242 RED

Description

80X80 Integral FLG Tee

100X100 Integral FLD Tee

PAM Integral Flanged Fittings (Extended Range)

Size

(mm)

Frazer

Code

Supplier

Code

80 Integral 111/4 FLG Bend

80

70580010

E2020 RED

80 Integral 221/2 FLG Bend

80

70580020

E2021 RED

80 Integral 90 FLG Duckfoot Bend

80

70580060

H0661 RED

80 Integral Blank Flange

80

70580080

H2154 RED

100 Integral FLD Bellmouth

100

70580570

H2151 RED

100 x 100

70580650

V0535 RED

150

70580860

H0215 RED

150 Integral 90 SR FLD Bend

150

70580870

H0214 RED

150 x 150 Integral FLD Tee

150 x 150

70580950

H0227 RED

150

70580840

E0217 RED

150 Integral 221/2 FLD Bend

150

70580850

E0216 RED

150 Integral 90 LR FLD Bend

150

70580880

V0487 RED

150 Integral 90 D/Foot Bend

150

70580890

H1652 RED

150 Integral FLD Bellmouth

150

70580900

H2031 RED

150 Integral Blank Flange

150

70580910

H2156 RED

150 x 80 Integral FLD Tee

150 x 80

70580930

E2003 RED

150 x 100 Integral FLD Tee

150 x 100

70580940

E2004 RED

150 x 150 Integral FLD Radial Tee

150 x 150

70580960

V2154 RED

150 x 100 Integral FLD Conc Taper

150 x 100

70581020

E0244 RED

150 x 100 Integral FLD Flat Taper

150 x 100

70581040

H2014 RED

Description

100 x 100 Integral FLD Angle Tee 45

150 Integral 45 FLD Bend

150 Integral 111/4 FLD Bend

For details of your nearest branch visit www.frazer.eu.com

Ductile Iron Pipe & Fittings

132

Flanged Fittings 200mm to 300mm (Extended Range)

Size

(mm)

Frazer

Code

200 Integral 45 FLD Bend

200

70581240

200 Integral 90 SR FLD Bend

200

70581250

200 x 200 Integral FLD Tee

200 x 200

70581330

200

70581220

200 Integral 221/2 FLD Bend

200

70581230

200 Integral 90 LR FLD Bend

200

70581260

200 Integral Blank Flange

200

70581290

200 x 80 Integral FLD Tee

200 x 80

70581300

200 x 200 Integral FLD Radial Tee

200 x 200

70581340

200 x 150 Integral FLD Conc Taper

200 x 150

70581410

250 Integral 45 FLD Bend

250

70581600

250 Integral 90 SR FLD Bend

250

70581610

250 Integral 111/4 FLD Bend

250

70581580

250 Integral 221/2 FLD Bend

250

70581590

250 Integral Blank Flange

250

70581650

250 x 80 Integral FLD Tee

250 x 80

70581668

250 x 250 Integral FLD Tee

250 x 250

70581700

250 x 200 Integral FLD Conc Taper

250 x 200

70581780

250 Integral FLD & Spigot x 420

250

70581865

300 Integral 45 FLD Bend

300

70581970

300 Integral 90 SR FLD Bend

300

70581980

300 Integral 221/2 FLD Bend

300

70581960

300 Integral 90 LR FLD Bend

300

70581990

300 Integral FLD Bellmouth

300

70582010

300 Integral Blank Flange

300

70582020

300 x 80 Integral FLD Tee

300 x 80

70582030

300 x 300 Integral FLD Tee

300 x 300

70582080

300

70581950

Description

200 Integral 111/4 FLD Bend

300 Integral 111/4 FLD Bend

Saint-Gobain Pipelines aims to develop new and innovative product solutions to meet specific customer

requirements. A great example is PAM Directional, an innovative ductile iron pipe which is suitable for

installation using directional drilling techniques.

For further information and solutions

that Frazer can offer, please contact any

one of our branches.

For details of your nearest branch see pages 175-190

You might also like

- GRP Pipe SystemsDocument6 pagesGRP Pipe Systemsgc_panchaNo ratings yet

- Ductile Iron Fittings & Specials - by NeoDocument59 pagesDuctile Iron Fittings & Specials - by NeoSomu DahiyaNo ratings yet

- PVC Awwa c900 BluebruteDocument20 pagesPVC Awwa c900 BluebruteRicardo LugoNo ratings yet

- Piping TutorialDocument25 pagesPiping TutorialgagaresantoshNo ratings yet

- Mechanical and Electrical Services Capability StatementDocument4 pagesMechanical and Electrical Services Capability StatementTata Steel ProjectsNo ratings yet

- NPS - 'Nominal Pipe Size' and DN - 'Diametre Nominal'Document4 pagesNPS - 'Nominal Pipe Size' and DN - 'Diametre Nominal'Mr. ANo ratings yet

- Gas Furnace GuidelineDocument41 pagesGas Furnace GuidelineLisbethMNo ratings yet

- Malleable Iron Pipe Fittings: BS StandardDocument22 pagesMalleable Iron Pipe Fittings: BS StandardDANNYNo ratings yet

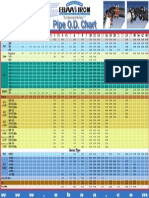

- Pipe OD ChartDocument1 pagePipe OD Chartfiercecat100% (1)

- Clad MetalsDocument16 pagesClad MetalsVenkateswaran KrishnamurthyNo ratings yet

- 1a Aquaflow HDPE Pipe CatalogueDocument12 pages1a Aquaflow HDPE Pipe CatalogueNick BesterNo ratings yet

- SDR 11Document20 pagesSDR 11rupayan.baruaNo ratings yet

- Norguard Eagle - Horizontal and Vertical Lifeline SystemsDocument4 pagesNorguard Eagle - Horizontal and Vertical Lifeline SystemsnorguardNo ratings yet

- Aluminium Cladding For Pipe Insulation - HaomeiDocument2 pagesAluminium Cladding For Pipe Insulation - HaomeiHaytham ElsayedNo ratings yet

- BS 7159Document90 pagesBS 7159Fenner ElectromechanicalNo ratings yet

- Britt Support Cat 9710Document47 pagesBritt Support Cat 9710Jim SkoranskiNo ratings yet

- Liquid Press Drop in PipeDocument4 pagesLiquid Press Drop in PipePanner2009No ratings yet

- Villa MEP-BOQDocument3 pagesVilla MEP-BOQMohamedNo ratings yet

- Pipe & Pipe Fittings - RevDocument15 pagesPipe & Pipe Fittings - RevLuis Gabriel BautistaNo ratings yet

- 01 Technical Dossier On GRP Pipes PDFDocument23 pages01 Technical Dossier On GRP Pipes PDFSuhail PashaNo ratings yet

- Pipe Support TemplatesDocument31 pagesPipe Support TemplatesasdfdfNo ratings yet

- Oxygen Systems: Loctite Products ForDocument2 pagesOxygen Systems: Loctite Products ForayazNo ratings yet

- Cable Tray SelectionDocument8 pagesCable Tray SelectionrumioyNo ratings yet

- Streamline SWR (S) - Rev - 00-04-2019 PDFDocument2 pagesStreamline SWR (S) - Rev - 00-04-2019 PDFarjun 11No ratings yet

- Development of Second Phase Ash Bund A T SGTPS, BirsinghpurDocument7 pagesDevelopment of Second Phase Ash Bund A T SGTPS, BirsinghpuraashuranjanNo ratings yet

- Mechanical Building Services Specification 2007Document167 pagesMechanical Building Services Specification 2007Son Cao ThanhNo ratings yet

- Voltage Drop Calculation Based On National Electrical CodeDocument4 pagesVoltage Drop Calculation Based On National Electrical Codetheengineer3No ratings yet

- 2021 Sanitary Sewer Spec Fi CatDocument29 pages2021 Sanitary Sewer Spec Fi CatAnonymous riBDrDGiNo ratings yet

- Technical Mannual Ductile Irone PipesDocument139 pagesTechnical Mannual Ductile Irone Pipessziza100% (2)

- Di InspectioninDocument38 pagesDi InspectioninJanith Saumya BandaraNo ratings yet

- Cost Estimation-3Document9 pagesCost Estimation-3prasadparulekarNo ratings yet

- Plumbing Data SheetDocument2 pagesPlumbing Data SheetzhobeysNo ratings yet

- 1319 3 Guidelines For WeldingDocument64 pages1319 3 Guidelines For Weldingg_sanchetiNo ratings yet

- Fire Resistant Coaxial CablesDocument38 pagesFire Resistant Coaxial Cablesrose chenNo ratings yet

- S&T Stainless Catalogue May 2016 01Document76 pagesS&T Stainless Catalogue May 2016 01AnthonyNo ratings yet

- Nominal Pipe Size Conversion To Metric SizeDocument2 pagesNominal Pipe Size Conversion To Metric SizetowiwaNo ratings yet

- Technical Specifications MetalsDocument3 pagesTechnical Specifications Metalsshem4funNo ratings yet

- 9.0 Abro Tape FSK Data SheetDocument3 pages9.0 Abro Tape FSK Data SheetProcurement AlamcoNo ratings yet

- GF Piping Systems Contain-IT PLUSDocument12 pagesGF Piping Systems Contain-IT PLUSRon Don jrNo ratings yet

- Bill of Quantities For Plant Room FloorDocument3 pagesBill of Quantities For Plant Room FloorAwais JalaliNo ratings yet

- ABB Electrical Wiring AccessoriesDocument2 pagesABB Electrical Wiring Accessoriesവർഗീസ് ജോസഫ്0% (1)

- Villa MEP BOQDocument3 pagesVilla MEP BOQIsuru Deshan WijewardanaNo ratings yet

- Financial Tender ElectricalDocument6 pagesFinancial Tender ElectricalTaiwo MorakinyoNo ratings yet

- Puddle FlangeDocument11 pagesPuddle Flangeviresh haldankarNo ratings yet

- 09 IRC Fuel Gas Piping ChecklistDocument3 pages09 IRC Fuel Gas Piping ChecklistMochammad Nur HidayatNo ratings yet

- Hanger Support Spacing and Rod Size For Horizontal PipesDocument8 pagesHanger Support Spacing and Rod Size For Horizontal Pipesyarzar17No ratings yet

- Checklist For T&C Mvac Format New 24.11.14Document15 pagesChecklist For T&C Mvac Format New 24.11.14Ichild Cucu MeoNo ratings yet

- Heat Tracing Products: Training ManualDocument76 pagesHeat Tracing Products: Training Manualalokedas11No ratings yet

- MS SAIL TolerancesDocument30 pagesMS SAIL TolerancesAmirthasubash Rajendran100% (1)

- Electrical Thumb Rules - (Part 1)Document8 pagesElectrical Thumb Rules - (Part 1)AriesFranandaPanjaitanNo ratings yet

- Type of Cable TrayDocument10 pagesType of Cable TrayregistraraNo ratings yet

- Piping & Piping ComponentsDocument39 pagesPiping & Piping ComponentsRamesh mudunuri100% (1)

- Nfpa PresentationDocument38 pagesNfpa PresentationReativa EngenhariaNo ratings yet

- Underground Pipe CertDocument2 pagesUnderground Pipe CertnomarblesNo ratings yet

- Apex Piping Revised 2Document36 pagesApex Piping Revised 2Eng Aggrey OsumaNo ratings yet

- Apex Piping Catalogue 2020Document36 pagesApex Piping Catalogue 2020Insta PumpsNo ratings yet

- Hepworth BG Plastics TPL 040711Document90 pagesHepworth BG Plastics TPL 040711Nick VincentNo ratings yet

- Simona Pipes, FittingsDocument56 pagesSimona Pipes, FittingsKristy DavisNo ratings yet

- Hepworth BG Plastics TPL 010512 Rev1 PDFDocument98 pagesHepworth BG Plastics TPL 010512 Rev1 PDFbrutalcutieNo ratings yet

- Terrain Below Ground Drainage Dimensional DataDocument16 pagesTerrain Below Ground Drainage Dimensional DatamealysrNo ratings yet

- HINCOL Patchwork ProductDocument1 pageHINCOL Patchwork ProductJagan Mohana Rao ChinnalaNo ratings yet

- Failure Analysis of Ball ValvesDocument12 pagesFailure Analysis of Ball ValvesvelusankarNo ratings yet

- Astm B584Document7 pagesAstm B584Francisco Villasmil OlivaresNo ratings yet

- Biocomposites Reinforced With Natural FibersDocument46 pagesBiocomposites Reinforced With Natural FibersCarlos ChavesNo ratings yet

- Comparison of Specific Strength of MaterialsDocument7 pagesComparison of Specific Strength of MaterialsnsitvarNo ratings yet

- PLATE KapalDocument11 pagesPLATE KapalRizal HidayatullahNo ratings yet

- BaxiDocument83 pagesBaxicelso0007No ratings yet

- Exxon™ Butyl 365S: RubberDocument2 pagesExxon™ Butyl 365S: RubberMaram YasserNo ratings yet

- EstimatesDocument36 pagesEstimatesNathaniel HamotNo ratings yet

- Chryso-Reinjecto 8370 4441Document2 pagesChryso-Reinjecto 8370 4441velmurug_balaNo ratings yet

- Gas Cutting WLDNG Process - 06-Rev.4Document81 pagesGas Cutting WLDNG Process - 06-Rev.4Asad Bin Ala QatariNo ratings yet

- Technical Bulletin: Chloroprene RubberDocument5 pagesTechnical Bulletin: Chloroprene RubberPrashantha NandavarNo ratings yet

- Data Sheet 173 Armox 440T 2016-04-22 34 371857150 enDocument3 pagesData Sheet 173 Armox 440T 2016-04-22 34 371857150 enJose ManuelNo ratings yet

- HandBookHW PDFDocument30 pagesHandBookHW PDFjosean_246No ratings yet

- EHB - en - File - 9.7.3 Equivalent ASME EN Materials PDFDocument3 pagesEHB - en - File - 9.7.3 Equivalent ASME EN Materials PDFks2000n1No ratings yet

- CPCCPB3004A Fix Wet Area Sheets TAP PDFDocument16 pagesCPCCPB3004A Fix Wet Area Sheets TAP PDFOwen PerrinNo ratings yet

- Materials For Engineering Unit II 20ME11T DTE KarnataksDocument18 pagesMaterials For Engineering Unit II 20ME11T DTE KarnataksThanmay JS100% (4)

- Metal Casting Processes: Review QuestionsDocument10 pagesMetal Casting Processes: Review QuestionsKhaled ShaabanNo ratings yet

- Vulcan WB10 / WB12 Vertical Weatherboard: Sheet Index Sheet No: Revision: Sheet NameDocument44 pagesVulcan WB10 / WB12 Vertical Weatherboard: Sheet Index Sheet No: Revision: Sheet NameLiam DevineNo ratings yet

- Asme IxDocument132 pagesAsme IxAhmed Shaban Kotb100% (1)

- India Import Iron ScrapDocument9 pagesIndia Import Iron ScrapdheeruyadavNo ratings yet

- MTC Er70s 2Document1 pageMTC Er70s 2Mirza BaigNo ratings yet

- Proposed Nugen 5 Storey Apartment Building Makati City Bill of Materials: Fire Protection System Item / Description Qty. / Unit Unit Cost AmountDocument4 pagesProposed Nugen 5 Storey Apartment Building Makati City Bill of Materials: Fire Protection System Item / Description Qty. / Unit Unit Cost Amountroland09No ratings yet

- Flygt Repair Kits InfoDocument32 pagesFlygt Repair Kits Infokztro066No ratings yet

- ROCKCOTE Natural Materials BookDocument32 pagesROCKCOTE Natural Materials BookramaxxNo ratings yet

- Slamp TestDocument10 pagesSlamp TestHasif AsyrafNo ratings yet

- Arubis Catalogue2015 ENG PDFDocument15 pagesArubis Catalogue2015 ENG PDFCiprian CretuNo ratings yet

- Zhang 2013 SpecificationsDocument42 pagesZhang 2013 SpecificationsAndy ChoNo ratings yet

- M 35Document11 pagesM 35Ssainaggdeep DeepNo ratings yet

- Pestan KG Pipes and FitingsDocument12 pagesPestan KG Pipes and FitingsChandima K PriyamalNo ratings yet

- Bridge Engineering: Classifications, Design Loading, and Analysis MethodsFrom EverandBridge Engineering: Classifications, Design Loading, and Analysis MethodsRating: 4 out of 5 stars4/5 (16)

- To Engineer Is Human: The Role of Failure in Successful DesignFrom EverandTo Engineer Is Human: The Role of Failure in Successful DesignRating: 4 out of 5 stars4/5 (138)

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresFrom EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresRating: 1 out of 5 stars1/5 (2)

- Piping Engineering Leadership for Process Plant ProjectsFrom EverandPiping Engineering Leadership for Process Plant ProjectsRating: 5 out of 5 stars5/5 (1)

- Onshore Structural Design Calculations: Power Plant and Energy Processing FacilitiesFrom EverandOnshore Structural Design Calculations: Power Plant and Energy Processing FacilitiesRating: 4.5 out of 5 stars4.5/5 (13)

- Mechanics of Flow-Induced Sound and Vibration, Volume 2: Complex Flow-Structure InteractionsFrom EverandMechanics of Flow-Induced Sound and Vibration, Volume 2: Complex Flow-Structure InteractionsNo ratings yet

- Non-destructive Testing and Evaluation of Civil Engineering StructuresFrom EverandNon-destructive Testing and Evaluation of Civil Engineering StructuresJean-Paul BalayssacNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Working Guide to Pump and Pumping Stations: Calculations and SimulationsFrom EverandWorking Guide to Pump and Pumping Stations: Calculations and SimulationsRating: 5 out of 5 stars5/5 (3)

- Advanced Modelling Techniques in Structural DesignFrom EverandAdvanced Modelling Techniques in Structural DesignRating: 5 out of 5 stars5/5 (3)

- Structural Cross Sections: Analysis and DesignFrom EverandStructural Cross Sections: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (19)

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- Earthquake-Resistant Structures: Design, Build, and RetrofitFrom EverandEarthquake-Resistant Structures: Design, Build, and RetrofitRating: 4.5 out of 5 stars4.5/5 (8)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsNo ratings yet

- Marine Structural Design CalculationsFrom EverandMarine Structural Design CalculationsRating: 4.5 out of 5 stars4.5/5 (13)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Net Zero Energy Buildings (NZEB): Concepts, Frameworks and Roadmap for Project Analysis and ImplementationFrom EverandNet Zero Energy Buildings (NZEB): Concepts, Frameworks and Roadmap for Project Analysis and ImplementationRating: 5 out of 5 stars5/5 (1)

- Super Structures: The Science of Bridges, Buildings, Dams, and Other Feats of EngineeringFrom EverandSuper Structures: The Science of Bridges, Buildings, Dams, and Other Feats of EngineeringRating: 4 out of 5 stars4/5 (1)

- Green Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsFrom EverandGreen Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsNo ratings yet