Professional Documents

Culture Documents

Numerical Analysis of Heat Transfer and Thermal Performance Analysis of Surface With Circular Profile Fins

Uploaded by

SEP-PublisherOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Numerical Analysis of Heat Transfer and Thermal Performance Analysis of Surface With Circular Profile Fins

Uploaded by

SEP-PublisherCopyright:

Available Formats

International Journal of Energy Science

IJES

Numerical Analysis of Heat Transfer and Thermal

Performance Analysis of Surface with Circular

Profile Fins

Sunil Chamoli, Ranchan Chauhan, N.S. Thakur

Centre for Excellence in Energy and Environment

National Institute of Technology, Hamirpur H.P. India

Abstract-In the present work a Computational Fluid Dynamics

(CFD) study was conducted to investigate the heat transfer and

friction loss characteristics in a horizontal rectangular channel

having attachments of circular profile fins over one of its

heated surface. The Reynolds number based on the flow

averaged inlet velocity and the hydraulic diameter, ranged

from 5000 to 30,000. The circular profile fins considered are of

5 cm height and diameter of 2 cm dimensions mounted on a

heating surface vertically. Reynolds number, fin arrangement

and fin pitch in the flow direction are the numerical

parameters. The in-line and staggered fin arrangement was

studied for one-fixed span wise (Sx/d = 3) and four different

stream wise (Sy/d = 3, 3.75, 5 and 7.5) distances. Different

turbulent models have been used for the analysis and their

results are compared. Realizable k- model based results have

been found a good agreement and thus this model is used to

predict the heat transfer and friction factor in the duct. The

overall enhancement ratio has been calculated in order to

discuss the overall effect of fin spacing and operating

parameters. A maximum value of enhancement ratio is found

1.2 for the range of parameters investigated.

Keywords-Finned surface; Thermal performance;

CFD; Heat transfer; Friction; turbulence

NOMENCLATURE

S

P itch in m

d

Diameter of the fin in m

Ntot

Total number of fins

Heat transfer rate

Mass flow rate of air in kg/s

Cp

Specific heat of air in J/ kg-o

temperature of fluid in oC

Heat transfer coefficient in W/m2

Area in m2

Ts

Average plate temperature.

Width of the plate in m

Length of the finned plate in m

Height of the fin in m

Pressure in Pascal

Dh

Hydraulic diameter in m

Mean inlet velocity in m/s

Fluid density in kg/m3

Subscript

Con

Conduction

Conv

Rad

Convection

Rad iat io n

in, out Inlet and Ou tlet

x, y

Span-wise and Stream-w is e

Drop

Surface

av

Average

. INTRODUCTION

Straight fin with concave parabolic profile provides

maximum heat dissipation for a given profile area [1]. As

the concave shape is costly and difficult to manufacture, the

rectangular profile is preferred even though it is not utilize

the material most efficiently [2]. For example, in a study

performed by Tahat et al [3], pin fins were employed on the

heating surface in a rectangular channel; and Bilen et al. [4]

investigated the heat transfer and friction loss characteristics

of a surface with cylindrical fins arranged both inline and

staggered in a channel having rectangular section. The

maximum amount of heat transfer occurred at Sy/D=2.94. A

thermal performance analysis is also worthwhile for the

evaluation of net energy gain. One of the ways to evaluate

the heat transfer performance is the comparison of the heat

transfer coefficients at the constant pumping power [4-6].

Many studies have been done for different types of fin

arrays, for example one reported in [7], but still there is lack

of knowledge of the forced convection heat transfer from a

surface with vertical mounted hollow rectangular profile

fins. The experimental analysis was carried out to study the

heat transfer and friction loss characteristics; the relation

was deprived for nusselt number and friction factor [8].

CFD analysis has been done by various investigators to

enhance heat transfer from a surface. CFD analysis of solar

air heater provided with different metal ribs of circular,

square and triangular cross-section with 600 inclination to

air flow was studied [10] and found 30% increase in heat

transfer.

Ozceyhan et al. [11] conducted numerical

IJES Vol.1 No.1 2011 PP.11-18 www.ijesci.org

C World Academic Publishing

~ 11 ~

International Journal of Energy Science

IJES

investigation on heat transfer enhancement in tube with the

circular cross-sectional rings. Iaccarino et al. [12] studied

effect of thermal boundary Conditions in numerical heat

transfer predictions in rib-roughened passages. CFD

analysis of heat Transfer and ow analysis due to roughness

in the form of ribs was carried out by these investigators

using 2-D models only.

In the present work the study of fluid flow and heat

transfer in a rectangular channel with circular vertically

mounted fins using computational fluid dynamics has been

carried out which reduces time and cost . The fin number

and the distance between the fins are given in the Table 1,

and the arrangement of the fins in the test section is shown

in Fig. 1 and 2.

Fig 1: Inline arrangement for Sy/d=3.75

Fig 2: Staggered arrangement for Sy/d=3.75

the flow, have been insulated, thus it can be thought that the

conductive heat loss from the heated plate will be mainly

from its back surface into the environment through the

bottom wall of the channel.

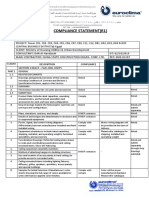

Table 1: Number of circular profile fins for 2cm diameter

and Sx/d=3

Sy/d

3

3.75

5

7.5

Ny

5

4

3

2

Nx

Ntot(in-line)

Ntot (Stag)

15

13

12

10

9

8

6

5

B.

II. ANALYSIS

Methodology

The heat transfer mode of interest of this system is

conduction, convection, radiation through the air. The

magnitude of each mode depends on the temperature of pin

fin array base, the geometry and the flow rate. Heat balance

for the whole system is

A.

Tot

=Q

Con

+Q

Conv

The pressure drops over the test section in the model

were measured. The pressure drop were arranged in non

dimensional form by using the following equation

+Q

Rad

f =

(1)

Conv

= m c p (T Out T in )

= hav As T s T out T in (3)

Conv

2

Surface area As= W x L+ d Nx Ny (H - d/4)

The total radiative heat losses from a similar test surface

would be about 0.5% of the total electrical input. This was

also reported by Tahat et al [3].

Since in the experimental setup the sidewalls are

adiabatic walls the conductive heat loss from the side walls

can be neglected in comparison to that from the bottom

surface of the test section. Moreover, as mentioned above,

the bottom surface of the test plate which is not exposed to

2p

L

(2)

Solution domain

Fins arrangements both in line and staggered at different

stream-wise pitches (Sy= 3, 3.75, 5, 7.5) and a fixed span

wise pitch (Sx=3) has been considered. The duct used for

CFD analysis having the height (H) of 10 cm and width of

(W) of 18 cm. A 2.8 cm wooden Planck is considered at the

sides of the duct for insulation. A uniform heat flux of

1000W/m2 was considered for analysis. The fins are

considered on the heated plate and other sides are

considered as smooth surfaces.

(4)

C.

Grid

The chosen geometry is such that secondary flows

condition are bound to occur thus using a 2D domain is

ruled out .Thus 3D solution domain and grid were selected.

In order to examine flow, boundary layer phenomena and

heat transfer at the fins surface finer meshing is done at

these locations. In the other region coarser mesh is used. For

the relevance of the solution, all simulations were repeated

with twice the number of the grid points in each spatial

direction. No noticeable differences in the solutions were

observed.

D.

CFD analysis

Under the present study, commercial code FLUENT

version 12.0.16 was used. As the secondary flows takes

IJES Vol.1 No.1 2011 PP.11-18 www.ijesci.org

C World Academic Publishing

~ 12 ~

International Journal of Energy Science

place thus 3D model has been setup instead of 2D model to

simulate flow and heat transfer.

The assumptions were made in mathematical model:

1.

The flow is considered fully developed, turbulent

and three dimensional.

2. The thermal conductivity does not vary with

temperature.

3. The duct wall and fins material is homogeneous

and isotropic.

The working fluid, air is assumed to be incompressible

for the operating range of finned duct since variation is very

less. The mean inlet velocity of the flow was calculated

using Reynolds number. Velocity boundary condition has

been considered as inlet boundary condition and outflow at

outlet. Second order upwind and SIMPLE algorithm were

used to discreitize the governing equations.

The FLUENT software solves the following

mathematical equations which governs fluid flow, heat

transfer and related phenomena for a given physical

problem. The equations are the

Continuity equation

( dv) + Vds = 0

t

v

(5)

+

E.

p xy yz zx

+

+

+

)dxdydz

x

x

y

z

dxdydz

(6)

Fins geometry and range of parameter

III. RESULTS AND DISCUSSIONS

Selection and validation of the model

Different models namely standard k-epsilon model,

realizable and RNG k-epsilon model have been tested for

smooth duct having same dimension of the computational

domain for validity of the models The results obtain by

different models have been compared with result correlated

with nusselt number for smooth channel.

A.

D

Nu s = 0.036 Re ( L h )

0.8

0.055

(7)

Fig 3 shows the variation of nusselt number with

Reynolds number for different turbulence models and the

results compared with the correlation available in the

literature for smooth duct. It has been observed that the

results obtained with realizable k-epsilon model are in good

agreement with the results from the correlation.

B.

Momentum equation

Fx = (

IJES

Aluminum fins of diameter 2cm and height of 5cm were

used and number of fins on the heater plate depends on the

pitch. The fixed pitch across span direction (Sx/d=3) and

variable pitch (Sy/d= 3, 3.75, 5, 7.5) along steam wise

direction is considered. The number of fins for inline,

staggered fin arrangement pattern at different pitches is

shown in table 1. The range of Reynolds number is taken

from 5000 to 30000.

Temperature Contours, Velocity contours and vectors

The flow and heat transfer characteristics get affected in

the flow direction due to fins provided. Fig 4 shows

numerical solution of the flow at Sy/d=3.75 and Sx/d=3. It

can be seen from the figure that the flow for the lower Sy/d

has to negotiate a serpentine path through the pin fin arrays

whereas for the higher Sy/d, the flow is able to pass through

the array without much resistance. It was observed that the

fluid flow at larger Sy/d has minimal interaction with the

pins surfaces. The phenomenon contributes greatly to the

reduction of pressure drop.

Fig: 3: Turbulence model comparison for smooth duct

IJES Vol.1 No.1 2011 PP.11-18 www.ijesci.org

C World Academic Publishing

~ 13 ~

International Journal of Energy Science

IJES

Fig 4: Velocity contour at Sy/d=3.75

From the Fig. 6 it is found that more vortices are making

in the flow direction thus creating turbulence and the nusselt

number increases. The flow is distributed by blockage due

to presence of fins the first fins along the flow direction put

much obstruction for fluid flow in inline arrangement but

for staggered flow is much smooth. The shedding of

vortices also causes additional loss of energy resulting in

increased friction factor. Thus nusselt number and friction

factor for finned duct is higher compared to smooth duct.

Fig 5 and Fig 6 shows static temperature on the finned

surfaces. It shows that temperature of air increasing along

length of the duct, as the primary heated air moves along the

heated fins. Hence the temperature at the base of the fin is

higher. As the heated primary air is swapped by the fin then

lower temperature secondary air comes in contact with hot

surface result in to increasing heat transfer coefficient

.

Fig 5: Velocity vectors colored by static temperature at Sy/d=3.75

C.

Thermo-hydraulic performance of finned duct:

Fig 8 and Fig 9 shows the pin fin array Nusselt number

as a function of Reynolds number for inline and staggered

arrangement at all Sy/d considered in the study. It is seen

that the pin spacing along the stream wise direction have

influence on the rate of average heat transfer. Increasing or

decreasing the pin distance would reduce or increase the

number of pin rows of a fixed base length. Thus by

increasing or decreasing the Sy/d with the pin diameter and

length being kept constant, the total surface area in contact

with the fluid will decrease or increase accordingly. It can

be seen from Fig that the average Nusselt number is the

lowest when the Sy/d =7.5 and the highest average Nusselt

number is at Sy/d = 3. While there is an appreciable increase

in average Nusselt number when the Sx/d is reduced from

Sx/d = 5 to Sx/d = 3 and from Sx/d =7.5 to Sx/d =5. The

results of the staggered arrangement are found good for all

pin spacing compared to inline arrangement and

enhancement originated from the increasing intensity of the

turbulence and better mixing of fluid.

IJES Vol.1 No.1 2011 PP.11-18 www.ijesci.org

C World Academic Publishing

~ 14 ~

International Journal of Energy Science

IJES

Fig 6: Velocity vectors colored by velocity magnitude at Sy/d=3.75

Fig 7: Contours of temperature at Sy/d=3.75, Re=5000

Fig. 10 and Fig. 11 shows a plot of friction factor as a

function of Reynolds number for inline and staggered

arrangement at all the Sy/d being studied. The plots clearly

show that the friction factor varies significantly with

changes in Sy/d. The entire configuration has similar

characteristic and trends showing that the friction factor

decreases with increasing Sy/d. When Sy/d is decreases, the

smaller stream wise spacing shrink the entrance area to the

fluid flow and thus fluid flow at higher velocity and thus

increases the pressure drop to occur. On contrary, increasing

Sy/d will open up the flow passage and flow is allowed to

pass more smoothly through the array section with relatively

less resistance. This explains the lower friction factor that

was observed for higher Sy/d. The values of pressure drop

for inline arrangement at lower Reynolds number is higher

than the staggered arrangement due to fact originated from

more blockage to the fluid flow in inline arrangement.

IJES Vol.1 No.1 2011 PP.11-18 www.ijesci.org

C World Academic Publishing

~ 15 ~

International Journal of Energy Science

Fig.8: Variation of Nusselt number with Re for inline arrangement

IJES

Fig.9 Variation of Nusselt number with Re for staggered arrangement

Fig.10 Shows variation of Friction factor

Fig.11 Shows variation of Friction factor with

with Reynolds number for inline arrangement

Reynolds number for staggered arrangement

Overall enhancement ratio is defined by the following

expression [13].

Overall enhancement ratio=

Nu

Nu

f

(

)

f

r

s

r 1/ 3

s

IJES Vol.1 No.1 2011 PP.11-18 www.ijesci.org

C World Academic Publishing

~ 16 ~

(8)

International Journal of Energy Science

IJES

Fig. 12: Shows variation of overall enhancement ratio with Reynolds number

Fig. 12 shows overall enhancement ratio of finned duct

for reynolds number range from 5000 to 30000. It has been

found that overall enhancement ratio at stream wise pitch

Sy/d=3, 3.75 is greater than unity for operating range of

reynolds number. The overall enhancement ratio decreases

sharply up-to 10000 reynolds number and a little decrement

was observed from 10000 to 30000 reynolds number.

Further overall enhancement ratio found maximum for

stream wise pitch of Sy/d=3 at 5000 reynolds number

Overall enhancement ratio with a maximum value of 1.2

is found for the stream-wise pitch of Sy/d=3 at 5000

Reynolds number.

IV. CONCLUSION

An attempt has been made to carry out CFD based

analysis to fluid flow and heat transfer characteristics of a

hollow rectangular duct attached with circular profile fins.

Combined effect of swirling motion, detachment and

reattachment of fluid which was considered to be

responsible in the increase in the heat transfer rate has been

observed during CFD analysis. Nusselt number found

increase with increase in Reynolds number while Friction

factor decreases with increase in Reynolds number at all set

of stream wise pitches for both the inline and staggered

arrangement of fins geometries.

[3]

CFD results have also been validated for smooth duct

and different CFD turbulence model has been compared

with empirical correlation for smooth duct. Among the

entire models realizable k-epsilon model found good

agreement with empirical correlation.

REFERENCES

[1]

[2]

[4]

[5]

[6]

[7]

[8]

[9]

Q.D. Kern, D.A. Kraus, Extended Surface Heat Transfer, Mc GrawHill, New York, 1972.

L. T. Yu, C.K. Chen, Application of Taylor transformation to

Optimize rectangular ns with variable thermal parameters, Applied

Mathematical Modeling 22 (1998) 1121.

M. A. Tahat, R. F. Babus Haq, S.D. Probert, Forced steady state

Convections from pin n arrays, Applied Energy 48 (1994) 335 351.

K. Bilen, U.Akyol, S.Yapici, Heat transfer and friction Correlation

and thermal performances analysis fornned

a

surface, Energy

Conversion and Management 42 (2001) 10711083.

P. Dutta, S. Dutta, E ect of ba e size, perforation, and Orientation

on internal heat transfer enhancement, International Journal of Heat

and Mass Transfer 41 (1998) 30053013.

J. J. Hwang, T. M. Liou, Heat transfer and friction in a low-aspectRatio rectangular channel with staggered perforated ribs on two

opposite ows, ASME Journal of Heat Transfer 117 (11) (1995) 843

850.

K. Bilen, U. Akyol, S.Yapici, Thermal performance analysis of a tube

nned surface, International Journal of Energy Research 26

(2002)321333.

A Ugur, K Bilen Heat transfer and thermal performance analysis of a

surface with hollow rectangular fins, Applied thermal Engineering 26

(2006) 209-216

S.V Karmare, A.N Tikekar, Analysis of fluid flow and heat transfer in

a rib grit roughened surface solar air heater using CFD, Solar Energy,

84 (2010) 409-417

IJES Vol.1 No.1 2011 PP.11-18 www.ijesci.org

C World Academic Publishing

~ 17 ~

International Journal of Energy Science

[10] Ozceyhan Veysel, Gunes Sibel, Buyu kalaca Orhan, Altuntop Necdet.

Heat Transfer enhancement in tube using circular cross-sectional

rings separated from wall. Applied Energy 2008; 85: 9881001.

[11] Iaccarino G, O oiA, Durbin PA, Behnia M. Conjugate heat transfer

predictions in two dimensional ribbed passages. International Journal

of Heat and Fluid Flow 2002; 23: 3405.

[12] Wang L, Sunden B, Performance comparison of some tube inserts.

International Communication in Heat and Mass Transfer 2002; 29(1);

45-56

IJES Vol.1 No.1 2011 PP.11-18 www.ijesci.org

C World Academic Publishing

~ 18 ~

IJES

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Mill's Critique of Bentham's UtilitarianismDocument9 pagesMill's Critique of Bentham's UtilitarianismSEP-PublisherNo ratings yet

- compliance sheet of euroclima加承包商Document9 pagescompliance sheet of euroclima加承包商Li Liu100% (1)

- External Dimensions and Piping Details: PX Pressure Exchanger Energy Recovery DeviceDocument2 pagesExternal Dimensions and Piping Details: PX Pressure Exchanger Energy Recovery Deviceprasad5034No ratings yet

- Improving of Motor and Tractor's Reliability by The Use of Metalorganic Lubricant AdditivesDocument5 pagesImproving of Motor and Tractor's Reliability by The Use of Metalorganic Lubricant AdditivesSEP-PublisherNo ratings yet

- Influence of Aluminum Oxide Nanofibers Reinforcing Polyethylene Coating On The Abrasive WearDocument13 pagesInfluence of Aluminum Oxide Nanofibers Reinforcing Polyethylene Coating On The Abrasive WearSEP-PublisherNo ratings yet

- Contact Characteristics of Metallic Materials in Conditions of Heavy Loading by Friction or by Electric CurrentDocument7 pagesContact Characteristics of Metallic Materials in Conditions of Heavy Loading by Friction or by Electric CurrentSEP-PublisherNo ratings yet

- Experimental Investigation of Friction Coefficient and Wear Rate of Stainless Steel 202 Sliding Against Smooth and Rough Stainless Steel 304 Couter-FacesDocument8 pagesExperimental Investigation of Friction Coefficient and Wear Rate of Stainless Steel 202 Sliding Against Smooth and Rough Stainless Steel 304 Couter-FacesSEP-PublisherNo ratings yet

- Microstructure and Wear Properties of Laser Clad NiCrBSi-MoS2 CoatingDocument5 pagesMicrostructure and Wear Properties of Laser Clad NiCrBSi-MoS2 CoatingSEP-PublisherNo ratings yet

- Effect of Slip Velocity On The Performance of A Magnetic Fluid Based Squeeze Film in Porous Rough Infinitely Long Parallel PlatesDocument11 pagesEffect of Slip Velocity On The Performance of A Magnetic Fluid Based Squeeze Film in Porous Rough Infinitely Long Parallel PlatesSEP-PublisherNo ratings yet

- Quantum Meditation: The Self-Spirit ProjectionDocument8 pagesQuantum Meditation: The Self-Spirit ProjectionSEP-PublisherNo ratings yet

- Isage: A Virtual Philosopher System For Learning Traditional Chinese PhilosophyDocument8 pagesIsage: A Virtual Philosopher System For Learning Traditional Chinese PhilosophySEP-PublisherNo ratings yet

- Microstructural Development in Friction Welded Aluminum Alloy With Different Alumina Specimen GeometriesDocument7 pagesMicrostructural Development in Friction Welded Aluminum Alloy With Different Alumina Specimen GeometriesSEP-PublisherNo ratings yet

- Device For Checking The Surface Finish of Substrates by Tribometry MethodDocument5 pagesDevice For Checking The Surface Finish of Substrates by Tribometry MethodSEP-PublisherNo ratings yet

- Reaction Between Polyol-Esters and Phosphate Esters in The Presence of Metal CarbidesDocument9 pagesReaction Between Polyol-Esters and Phosphate Esters in The Presence of Metal CarbidesSEP-PublisherNo ratings yet

- FWR008Document5 pagesFWR008sreejith2786No ratings yet

- Enhancing Wear Resistance of En45 Spring Steel Using Cryogenic TreatmentDocument6 pagesEnhancing Wear Resistance of En45 Spring Steel Using Cryogenic TreatmentSEP-PublisherNo ratings yet

- Enhanced Causation For DesignDocument14 pagesEnhanced Causation For DesignSEP-PublisherNo ratings yet

- Delightful: The Saturation Spirit Energy DistributionDocument4 pagesDelightful: The Saturation Spirit Energy DistributionSEP-PublisherNo ratings yet

- Mindfulness and Happiness: The Empirical FoundationDocument7 pagesMindfulness and Happiness: The Empirical FoundationSEP-PublisherNo ratings yet

- Metaphysics of AdvertisingDocument10 pagesMetaphysics of AdvertisingSEP-PublisherNo ratings yet

- Social Conflicts in Virtual Reality of Computer GamesDocument5 pagesSocial Conflicts in Virtual Reality of Computer GamesSEP-PublisherNo ratings yet

- Cold Mind: The Released Suffering StabilityDocument3 pagesCold Mind: The Released Suffering StabilitySEP-PublisherNo ratings yet

- Technological Mediation of Ontologies: The Need For Tools To Help Designers in Materializing EthicsDocument9 pagesTechnological Mediation of Ontologies: The Need For Tools To Help Designers in Materializing EthicsSEP-PublisherNo ratings yet

- Computational Fluid Dynamics Based Design of Sump of A Hydraulic Pumping System-CFD Based Design of SumpDocument6 pagesComputational Fluid Dynamics Based Design of Sump of A Hydraulic Pumping System-CFD Based Design of SumpSEP-PublisherNo ratings yet

- The Effect of Boundary Conditions On The Natural Vibration Characteristics of Deep-Hole Bulkhead GateDocument8 pagesThe Effect of Boundary Conditions On The Natural Vibration Characteristics of Deep-Hole Bulkhead GateSEP-PublisherNo ratings yet

- A Tentative Study On The View of Marxist Philosophy of Human NatureDocument4 pagesA Tentative Study On The View of Marxist Philosophy of Human NatureSEP-PublisherNo ratings yet

- Architectural Images in Buddhist Scriptures, Buddhism Truth and Oriental Spirit WorldDocument5 pagesArchitectural Images in Buddhist Scriptures, Buddhism Truth and Oriental Spirit WorldSEP-PublisherNo ratings yet

- Ontology-Based Testing System For Evaluation of Student's KnowledgeDocument8 pagesOntology-Based Testing System For Evaluation of Student's KnowledgeSEP-PublisherNo ratings yet

- Legal Distinctions Between Clinical Research and Clinical Investigation:Lessons From A Professional Misconduct TrialDocument4 pagesLegal Distinctions Between Clinical Research and Clinical Investigation:Lessons From A Professional Misconduct TrialSEP-PublisherNo ratings yet

- Damage Structures Modal Analysis Virtual Flexibility Matrix (VFM) IdentificationDocument10 pagesDamage Structures Modal Analysis Virtual Flexibility Matrix (VFM) IdentificationSEP-PublisherNo ratings yet

- MP EM Ass 12: DC CircuitsDocument10 pagesMP EM Ass 12: DC CircuitsBlueAstroNo ratings yet

- WWTFSP - App.F14 - Sludge and Biogas CharacterizationDocument48 pagesWWTFSP - App.F14 - Sludge and Biogas CharacterizationHuy Nguyen100% (1)

- DC Motor Speed System Modeling (Final Report)Document41 pagesDC Motor Speed System Modeling (Final Report)Khubaib Ahmed80% (5)

- KD2250-F-SDMO (Alternator Data Sheet SDMO 2000KVA Prime Generator Set)Document6 pagesKD2250-F-SDMO (Alternator Data Sheet SDMO 2000KVA Prime Generator Set)schraz4575No ratings yet

- ASHRAE RP-1455: Advanced Control Sequences For HVAC SystemsDocument30 pagesASHRAE RP-1455: Advanced Control Sequences For HVAC SystemscarlcrowNo ratings yet

- Assignment 2 V2 TM 18ME54Document1 pageAssignment 2 V2 TM 18ME54rudresh JmNo ratings yet

- BUK-306 Pillard Flame ScannersDocument4 pagesBUK-306 Pillard Flame ScannersMoez hannachiNo ratings yet

- T-23 BOQ (Katol)Document40 pagesT-23 BOQ (Katol)rajesh kumarNo ratings yet

- Fault MVA Calc - PPT (Compatibility MDocument20 pagesFault MVA Calc - PPT (Compatibility MK.T.100% (1)

- Advances in Water Research - Vol32no1Document40 pagesAdvances in Water Research - Vol32no1LeilNo ratings yet

- Super Critical Fluids and Its Application Seminar PresentationDocument12 pagesSuper Critical Fluids and Its Application Seminar PresentationParth BrahmbhattNo ratings yet

- Vehicular Emissions TrinidadDocument4 pagesVehicular Emissions Trinidadstephen_debique9455No ratings yet

- Single & Double Piston EffectDocument3 pagesSingle & Double Piston EffectMuhammad RidwanNo ratings yet

- 1SCA022620R7200 Ozxt2 Terminal SetDocument2 pages1SCA022620R7200 Ozxt2 Terminal SetJorge Salas CabanaNo ratings yet

- VMC Ideo 325Document9 pagesVMC Ideo 325Patrick CarapinhaNo ratings yet

- ZTE Rectifier SettingsDocument4 pagesZTE Rectifier SettingsRicardo Chavarria50% (2)

- EMD 645 Marine Emissions Kits A4Document2 pagesEMD 645 Marine Emissions Kits A4Martin KratkyNo ratings yet

- Map Tomat CerryDocument14 pagesMap Tomat CerrySteFunnie YolalandhaNo ratings yet

- Economic Solutions To Environmental Problems: The Market ApproachDocument38 pagesEconomic Solutions To Environmental Problems: The Market ApproachStenerth NeretabaNo ratings yet

- DR - Swapna BhowmikDocument21 pagesDR - Swapna BhowmikAnil Anil ChoudharyNo ratings yet

- As3000 Service Manual PDFDocument180 pagesAs3000 Service Manual PDFsambadeeNo ratings yet

- Volume-I - (Coal) 2014636129985100886136 PDFDocument153 pagesVolume-I - (Coal) 2014636129985100886136 PDFAzhar KhanNo ratings yet

- Datasheet For On/Off Valve (Xv-001) Datasheet For On/Off Valve (Xv-001)Document2 pagesDatasheet For On/Off Valve (Xv-001) Datasheet For On/Off Valve (Xv-001)usama666No ratings yet

- Valvula Compuerta FS RDocument6 pagesValvula Compuerta FS RAngie LondoñoNo ratings yet

- UntitledDocument3 pagesUntitledUsama aliNo ratings yet

- Operation & Maintenance Manual Sebu9100-01-00-AllDocument120 pagesOperation & Maintenance Manual Sebu9100-01-00-AllecrNo ratings yet