Professional Documents

Culture Documents

Motor Ope. Mech. Type MT 50-100-17!03!08

Uploaded by

rpshvjuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Motor Ope. Mech. Type MT 50-100-17!03!08

Uploaded by

rpshvjuCopyright:

Available Formats

1 HDU 05004-YN Rev.

Motor Operated Mechanisms

Types MT50 and MT100

Instruction Manual

1 HDU 05004-YN Rev. C

2/16

For High-Voltage Disconnectors and

Earthing Switches

for Outdoor Installation

Table of Contents

Sr. Description

No.

Page

No.

General Remarks

Design

Optional Extras

Method of Operation

Technical Data

Transportation and Storage

Installation

Commissioning

Maintenance

10

10

Spare Parts

11

11

List of Components

12

1 HDU 05004-YN Rev. C

3/16

General remarks

Practical experience has shown that strict adherence to the recommendation of this instruction manual

will ensure the best possible safe performance of the equipment.

In an instruction manual it is not possible to cover every possible eventuality that might occur when

using technical apparatus. It is therefore requested that all incidences, in particular those for which the

instruction manual provides no plausible explanation, be reported to us directly or through our local

representatives.

These instructions are based on the present technical design. We reserve the right to make any

technical changes without prior notice.

We cannot accept any responsibility for damage resulting directly from incorrect handling or operation,

irrespective of whether specific reference is to be found in the instructions for erection and operation or

not.

With respect to this document we reserve all rights also in the event of a patent being issued and

registration being made under other commercial rights. Misuse, in particular copying and handing over

to third parties is prohibited and offenders can be prosecuted under civil and criminal law.

Design

The motor-operated mechanisms type MT50 and MT100 are designed for outdoor installation and

used for the electrical remote operation of disconnectors and earthing switches.

All components of the operating mechanism are installed in a polyurethane painted aluminium housing

(12) with a door (12a) at the front. Power transmission from the motor (1) to the operating spindle (2) is

via a gear train.

The control components are attached to a mounting plate (4) and wired to the terminal strip (5). The

length of the terminal strip support is designed to accommodate the maximum equipment

configuration. The terminal designations are consistently structured, i.e. the same terminal

designations are used for the same function in all possible versions.

A clearance of approx. 10 cm is provided for connecting the control cables to the terminal strip.

The connections to motor (1), limit switches (17), (if included) blocking magnet (19) are routed via a set

of terminals (27).

The basic version includes the fallowing:

-

a contactor control with self holding interlock scheme

an 8-pole Auxiliary switch with 4NC + 4NO contacts, Switching capacity of each contact is 2 A at

220 V DC, at T=20 ms.

Cross sectional area for all internal connections is 1.5 mm2 (except for motor which is 0.56 mm2)

flexible, grey for DC & Auxiliary switch wiring and black for AC wiring. All Auxiliary switch contacts are

wired upto terminals. In the case of AC operation, a rectifier (37) is installed upstream of the DC motor.

The door and the housing are connected with cable (26) to earth connection and angle. The incoming

and outgoing cables are passed from below through a 3 mm thick removable cable entry plate (9) made

of aluminium. Cable glands are not included in the standard scope of delivery, and must be provided by

the customer. An anticondensation heater (11) permanently connected to the voltage supply is

mounted on the mounting plate.

2.1

Manual Emergency Operation

Crank (18), which can be inserted into the auxiliary pin (8) for emergency operation, serves for

adjusting the unit and performing emergency operations. It is not permitted to use a drilling machine

instead of the emergency crank. The corresponding opening provided on the housing is closed by

cover (15). When the manual emergency crank is inserted into the auxiliary pin a safety contact (14)

interrupts the control circuit for the motor to ensure that actuation is possible only by using the

emergency crank.

The opening for manual emergency operation is located approx. 250 mm below the top edge of the box

on the right-hand side. It is sealed with a cover (15) incorporating bayonet lock.

1 HDU 05004-YN Rev. C

4/16

Unauthorised manual operation is restricted by providing a cover (15) alongwith a padlock

arrangement on the door. For manual operation first the front door to be opened after removing the

padlock and then cover (15) can be removed for insertion of the manual handle. Ensure blocking

magnet (19) (if provided) is energised or pulled up manually. For safety ensure Local-Remote selector

switch is in Local mode.

2.2

Blocking Magnet

Optionally a blocking magnet (19) can be installed. The blocking magnet de-energised prevents the

motor-operated mechanism from being operated manually. In this case it is not possible to insert the

hand crank (18) into the auxiliary pin (8) for emergency operation. In the case of AC operation, a

rectifier (37) is installed upstream of the blocking magnet. An additionally interlock switch (51), directly

attached and actuated by the blocking magnet (19) allows electrical operation only when the blocking

magnet is energised.

1 HDU 05004-YN Rev. C

5/16

21

20

2, 2a

10

37

13

14

12

27

29

39

15

3

19

11

39

12a

26

23

16

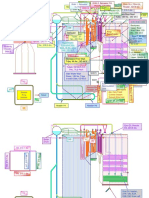

Figure 1 : Inside view of motor-operated mechanisms type MT 50 and MT 100

1

2

3

4

5

6

9

10

12

13

14

15

16

19

20

21

23

26

27

29

37

39

Motor (with cover 1a)

Operating spindle (with cover 2a) and gear-train

Auxiliary switch

Mounting plate

Terminal strip

Control contractor

Supply lead plate

Operating shaft

Housing (with door 12a)

Control disc

Safety contract

Cover for emergency operation

Venting hole with filter insert for ventilation

Blocking magnet

Push button (open & close)

Gasket

Earthing connection angle

Flexible earthing connection

Terminals

Changeover switch

Rectifier

Varistor

1 HDU 05004-YN Rev. C

6/16

Optional Extras

(depending on customers order)

3.1

Additional Auxiliary switch contacts upto max. 16 contacts in any combination can be provided.

Please refer to schematic drawing submitted against order for details.

Caution :Ensure Auxiliary switch elements positions are not

altered if removed for any maintenance. When

they are to be replaced, ensure that any two

elements of the same colour are not placed next to

each other. It is necessary to place elements of

blue and black colours alternatively.

Blue Blue

Wrong

Black Black

Wrong

Blue Black

Right

3.2

Local control system, consisting of:

3.2.1

One changeover switch (29) (local - remote) and two push buttons (20) (ON, OFF) or,

3.2.2

One changeover switch (29) (local - OFF - remote) and two push buttons (20) (ON, OFF)

3.3

Blocking magnet (19) for preventing maloperation during manual emergency operation.

3.4

Adjustable thermostat for Heater (11 )

3.5

Interior lighting (48), with ON/OFF switch

3.6

Handle (35).

Method of Operation

4.1

Method of Mechanical Operation

The motor-operated mechanism is fitted with a spindle, mounted on bearings in a housing closed at the

sides. The motor (1 ) is below the spindle (2) and arranged parallel to it, with a two-step gear train (for

MT50) or three-step gear train (for MT100) between them. Power is transmitted to the output shaft (10)

from the spindle via a slide with two transmission bolts onto an operating cross, which in each of its end

positions is arrested by one of these bolts. When the end position has been reached, the slide is halted

by a cup-spring stop, without the operating position altering any further. On request, the manual

emergency operation feature can be protected against maloperation by means of a blocking magnet

(19). When the blocking magnet is de-energised, the manual emergency crank (18) cannot be

inserted.

Unauthorised removing of cover (15) for manual emergency operation is prevented by built-on padlock

on the door.

4.2

Method of Electrical Operation

The motor-operated mechanism is normally controlled from a control room or a local control cubicle,

using an ON or OFF command (minimum pulse duration 25 ms). The control contactor picks up and

remains in hold on position through self holding contact. The operating angle of the output shaft (10) is

190 degrees. When either of the end positions is reached, a limit switch (17) cancels the hold on and

terminates the switching operation. The limit switches are tripped by the operating cross on the output

shaft. In the case of AC operation, a rectifier (37) is installed upstream of the DC motor.

Release of the contactors via Auxiliary switch contacts is not permissible!

Auxiliary switches (3) are actuated by the control disc (13) fitted to the operating shaft (10). The position

signal meets the requirements of IEC Publication IEC62271-102, third edition and VDE standard 0670,

1 HDU 05004-YN Rev. C

7/16

part 2. A CLOSED position signal is given after closing near the top dead center (i.e. after closing of

the current path of the disconnector and near top dead center interlocking by the operating linkage) and

is cancelled upon opening even before the top dead center is reached (i.e. before interlocking is

cancelled). The signal for the OPEN position is given analogously.

The safety contact (14) interrupts the control circuit for the motor when the manual emergency crank

(18) is inserted, so that the unit can now be operated only with the manual emergency crank.

The optional blocking magnet (19) when de-energised, prevents the motor-operated mechanism from

being operated manually, as it is not possible to insert the hand crank (18) into auxiliary pin (8) for

emergency operation. In the case of AC operation, a rectifier (37) is installed upstream of the blocking

magnet. An additional interlock switch (51), directly attached and actuated by the blocking magnet (19)

allows electrical operation only when the blocking magnet is energised.

1 HDU 05004-YN Rev. C

8/16

50 Hz 240 V AC

Figure 2a

Example of internal wiring diagram (MT50 standard design), for motor operation with DC supply.

1 HDU 05004-YN Rev. C

Figure 2b

Example of internal wiring diagram (MT50 standard design), for motor operation with single phase AC supply

9/16

1 HDU 05004-YN Rev. C

Technical Data

5.1

Technical data of the motor-operated mechanisms

Rated motor voltage

48,110,125,220, 250VDC,

Admissible deviation from the rated motor voltage

Rated motor output, short time duty

3f

415 VAC

+10% / -15%

470 W

Switching time (depending on load)

Number of switching cycles permissible per hour

(we recommend to wait 3 minutes after every

switching operation to allow the motor to cool down)

Rated torque on the operating shaft at rated voltage

Torque required at the operating shaft for

emergency operation

Revolution of the emergency crank for a 1 90 degree

switching angle of the operating shaft

Heating capacity

Heating voltage

Degree of protection against contact with live or moving

parts ingress of foreign bodies and water

Cross-section of internal wiring

(except motor)

Max. cross-section of supply leads

solid

stranded (with end sleeve)

Weight

5.2

type MT 50

&MT100

type MT 50

type MT 100

between 3 to 7 sec

or 6 to 12 sec

depending on system

10

type MT 50

type MT 100

500 Nm

1000 Nm

type MT 50

type MT 1 00

5 Nm

8 Nm

at least 70

approx. 25 W

220V AC

IP 54

1.5 mm2

(0.56 mm2)

4 mm2

2.5 mm2

44 kg approx.

Technical data of the built-in control contactors

Operating voltage

5.3

10/16

110, 125 or 220V DC,

110 or 220 VAC, 50/60 Hz

+10% / -15%

Admissible deviation from the operating voltage

Rated power consumption of magnet coils

when operated with DC

Pick-up/holding 7W/7W

when operated with AC

Minimum signal duration for self-holding

Pick-up/holding 60 VA / 9 VA (50 W/2.2 W)

25 ms

Technical data of the blocking magnets

Operating voltage

Admissible deviation from the operating voltage

Rated power consumption of magnet coil

Duration factor

110, 125 or 220V DC

+10% / -15%

approx. 6 W

100 %

Note: Due to continuous efforts to improve our products, the details given in this publication may be

changed without notice.

1 HDU 05004-YN Rev. C

5.4

11/16

Technical Data of the Auxiliary Switches

-

Switching capacity of each contact = 2 A at 220 V DC, T = 20 ms

Current carrying capacity = 10 A

0

9.50...17.50

9.5 ...17.5

NC contact

NO contact

00

Off

1900

On

Main contact of

disconnector

Auxiliary switch, functional diagram

Transportation and Storage

Each operating mechanism is specially packed before shipment.

As soon as the equipment arrives at the place of destination an inspection for damage in transit should

be carried out to find out the extent of damage, the cause of damage and, if necessary, its originator.

The damage report, if any, should immediately be sent to the appropriate forwarding agency to be

passed on to the transportation insurance company.

The operating mechanisms should be stored indoor. In dry climate the duration for transportation and

storage of the operating mechanisms must not exceed 6 month without heating. For longer times of

storage or if there is danger of moisture condensation the heater has to be connected unless

precautions were taken by appropriate packing or storage to prevent moisture condensation.

Installation

Every operating mechanism should be mounted in accordance with the mounting instructions for the

unit for which it is intended and relevant order bound drawings.

For direct attachment of the operating mechanisms to disconnectors or earthing switches designed for

wall mounting, special instructions if supplied alongwith the unit have to be observed. If the customer

decides at a later date to mount the equipment in this way, he should contact our sales department for

these instructions.

The interior parts of the operating mechanisms (e.g. Auxiliary switches, contactors, etc.) are not

resistant to the atmospheric conditions prevailing outdoors ; therefore, care must be taken to ensure

that parts are not exposed to humidity during installation.

Connection of the motor control components is made at terminal strip (5), and that of Auxiliary switch

(3) directly at the Auxiliary switch contacts or at the terminal strip (5), depending on customers order.

To avoid condensation it is absolutely necessary to connect the heater (11) . After installation the heater

is to be commissioned immediately even if the associated disconnectors and earthing switches have

not yet been commissioned.

1 HDU 05004-YN Rev. C

12/16

Commissioning

After connecting all cables, first operate the motor operated mechanism with the emergency crank. It is

not permitted to use a boring machine instead of the emergency crank. If the disconnector or earthing

switch engages properly according to the corresponding operating instructions, the operating

mechanism can be actuated electrically.

Make sure that safety contact (14) is functioning properly, i.e. the circuit must be interrupted when the

emergency hand crank (18) is inserted.

Also check the Auxiliary switch(es) (3) for proper contact make in the two end positions. Adjustments of

the Auxiliary switches are to be made by specialised personnel only.

Check blocking magnet (19) to make sure that its blocking pin is properly located before interlocking

disc when the magnet is de-energised and prevents insertion of the hand crank (18).

If the units are painted, keep the venting hole with filter free from paint.

Maintenance

The motor-operated mechanism hardly needs any maintenance.

It is recommended to have an inspection carried out together with the inspection of the corresponding

disconnector or earthing switch after the first 5 years of operation, at the latest, however, after 1,000

make and break operations. The inspection intervals mentioned above apply to normal ambient

conditions. For extraordinary conditions (e.g. use in tropical climate or at excessively low temperatures

or heavy pollution) these intervals should be reduced by 50%.

The following details should be observed during the inspection or random test:

a)

Stop electrical supply to disconnector and earthing switch. Care should be taken that heating

circuit and control voltage of the blocking magnet are disconnected.

b)

Observe IEC and national safety regulations.

c)

Carry out several test operations by hand.

d)

Check safety contact (14) (for details see section 8), limit switch (17) and heating resistor (11) for

proper functioning.

e)

Check Auxiliary switch(es) (3) for proper contact make in both switching positions. Adjustments

of the Auxiliary switch, if required, should only be made by specialists.

f)

Check proper functioning of blocking magnet (19) and interlock switch (51), for details see

section 8.

g)

Check whether the control and signalling cable are properly fitted to all terminals.

h)

Check whether the movement is properly transmitted from the operating shaft (10) to Auxiliary

switch (3) via control disc (13). If necessary, clean and grease the guides and running surfaces.

i)

Check for inadmissible ingress of foreign bodies and moisture.

k)

Clean filter insert of cable gland (16) in supply lead plate (9).

I)

Check gasket (21) of the door (12a) and replace, if necessary.

m)

After inspection, carry out a number of electrical test operations and reconnect the heating

circuit and the blocking magnet to the power supply.

CAUTION :-

Ensure that Auxiliary switch elements position or orientation is not altered if it is removed for

any maintenance work. This is because it has built-in blow out magnet.

Ensure blocking magnet (if provided) is in disengaged position.

Cleaning of any plastic parts must be done with dry cloth only.

1 HDU 05004-YN Rev. C

10

13/16

Spare Parts

It is recommeded to keep the following parts in stock so that, in case of disturbances, prolonged

periods of interruption are avoided by rapidly replacing the individual parts. When ordering spare

parts, indicate the following details :

a)

Type and serial number according to the rating plate of the specific unit.

b)

Designation of spare part, item no. and order no. in accordance with these instructions.

c)

Motor, control, heating and blocking magnet voltage.

Designation

Motor (with pinion) for MT 50/MT 100

operating voltage

110...125 V DC

220...250 V DC

Cabon brush for motor

Rectifier 15 A

Peak block voltage

500 V AC

Control contactor

operating voltage

220 V AC, 50 Hz

110 V DC

125 V DC

220 V DC

Additional : auxiliary contact

1 NC + 1 NO

1 NC + 3 NO

Miniature Circuit Breaker

6 A AC

for Motor and Control circuit

6 A AC

for Heating and Lighting circuit

3 A AC

Auxiliary switch elements with roller

BLUE

BLACK

Auxiliary switch elements without roller

(required for double decker

arrangement)

BLUE

BLACK

Limit switch

Safety contact

Blocking magnet

110 V DC

125 V DC

220 V DC

Inter-locking switch

(at blocking magnet)

Anticondensation heater

operating voltage

220...250 V AC

Thermostat

Door sealing gasket

Sealing ring

Molycote longterm 2 plus

Dowty seal

Retaining ring

Cylindrical pin f

12

Roll pin 3.5x16

Split pin 3.5x22

Identification Item Fig.

letter

Sr. No.

Quantity

per

operating

mechanism

Order No.

G1

37

2

1

K1E, K2A

1HYN050001R601

1HYN050001R602

1HYN350028P98

1HYN450040P1

1HYN450102P1

1HYN450102P2

1HYN450102P3

1HYN450102P4

1HYN450102P5

1HYN450102P23

1HYN450102P6

1HYN450102P8

1HYN450102P20

As per specific 1HYN450103R2

scheme and

order

108

90

1HYN450103R3

S1E, S2A

S3

Y1

17

14

19

1

1

1

2

1

1

1HYN450013P1

1HYN450017P1

1HYN350027P15

1HYN350027P13

1HYN350027P11

Y1-S3V

51

R1

23T

-

11

11

21

1

1

1

1HYN450039R1

1

1

1 piece

approx. 2 m

2

1 can 250 gm

2

2

1

1

1

MT430162P20

1HYN450182P1

1HYN450193P1

1HYN450038P1

GON598000P521

1HYN450042P111

1HYN450107P1

1HYN450095P1

MT430189P262

MT430405P2312

1 HDU 05004-YN Rev. C

11

14/16

List of Components

Item

No.

Designation

1

2

3

4

5

6

8

9

10

11

12

13

14

15

16

17

18

19

20

21

23

24

25

26

27

29

30

31

35

37

39

42

43

51

Motor (with cover 1a)

Operating spindle (with cover 2a) and gear-train

Auxiliary switch

Mounting plate

Terminal strip

Control contractor

Auxiliary pin for emergengy operation

Supply lead plate (with earthing connection angle 23 and ventilating hole 16)

Operating shaft

Anticondensation heater

Housing (with door 12a)

Control disc

Safety contract

Cover for emergency operation (undertachable by chain)

Cable gland with filter insert

Limit switch

Swivelling emergency crank

Blocking magnet

Push button

Door sealing gasket

Earthing connection angle

Mounting holes of operating mechanism (thread M16)

Miniature Circuit Breaker

Flexible earthing connection

Power block terminal strip

Changeover swith (Local-OFF-Remote)

Push button (Close-Open)

Operating lever

Handle

Rectifier

Varistor

Compartment for instructoin and wiring and diagrams

Rating plate

Interlock switch blocking magnet 19

Fig.

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

-

1 HDU 05004-YN Rev. C

Note :

15/16

1 HDU 05004-YN Rev. C 2008-03

"ABB is woking continuously to improve the products.

We therefore reserve the right to change designs, dimensions data without prior notice."

ABB Limited

Business Area : Disconnectors

Maneja, Vadodara 390 013 India

India

Tel. :

+91-265-2604080

+91-265-2604082/2604261

Fax : +91-265-2638927

www.abb.co.in

You might also like

- Option Trading StrategiesDocument0 pagesOption Trading StrategiesGarvit Garg100% (1)

- MRTPDocument20 pagesMRTPStephen Crawford100% (1)

- Rej 601Document20 pagesRej 601Ram RKNo ratings yet

- Ansi CodesDocument2 pagesAnsi CodesCristian Salgado CarrascoNo ratings yet

- NARI PCS-985G Generator RelayDocument316 pagesNARI PCS-985G Generator Relayt.o.i.n.g67% (3)

- Jin Kwang-Recloser-Mold Recloser (With R200C) Catalouge PDFDocument15 pagesJin Kwang-Recloser-Mold Recloser (With R200C) Catalouge PDFMd. zahidul IslamNo ratings yet

- Nse Options Strategies Explanation With ExamplesDocument60 pagesNse Options Strategies Explanation With ExamplesVatsal ShahNo ratings yet

- MctisalesenDocument6 pagesMctisalesenpisemude2706No ratings yet

- PCS-9611 Feeder Relay V1.01 PDFDocument46 pagesPCS-9611 Feeder Relay V1.01 PDFMuhammad Burhanuddin Fadhli RobbiNo ratings yet

- Manual DS +dse 150 KV PDFDocument116 pagesManual DS +dse 150 KV PDFerfin1No ratings yet

- PCS-9691 - X - Instruction Manual - EN - Overseas General - X - R1.03 PDFDocument292 pagesPCS-9691 - X - Instruction Manual - EN - Overseas General - X - R1.03 PDFBarry79x100% (2)

- Total power failure restoration and cold start up proceduresDocument8 pagesTotal power failure restoration and cold start up proceduresrpshvjuNo ratings yet

- MCB & ElcbDocument16 pagesMCB & ElcbRouny PaulNo ratings yet

- How To ApplyDocument129 pagesHow To ApplySasa KasaNo ratings yet

- Standards in Instrumentation ProjectsDocument4 pagesStandards in Instrumentation ProjectsAmeya DalviNo ratings yet

- RHH and LTSH links overviewDocument4 pagesRHH and LTSH links overviewrpshvjuNo ratings yet

- Steel QuantityDocument21 pagesSteel QuantityAshish Jain100% (1)

- DOMESTIC WIRING - PDFDocument133 pagesDOMESTIC WIRING - PDFAlbert Berteez KasekelaNo ratings yet

- PCS-985GE - X - Instruction Manual - EN - Overseas General - X - R1.02 PDFDocument464 pagesPCS-985GE - X - Instruction Manual - EN - Overseas General - X - R1.02 PDFarulsethuNo ratings yet

- NARI PCS 9611 X Instruction Manual EN Overseas General PDFDocument290 pagesNARI PCS 9611 X Instruction Manual EN Overseas General PDFKhoirin NidaNo ratings yet

- RCS-9626CN - 080191 Motor Management Relay Instruction Manual (EN - DYBH0443.0233.1101)Document139 pagesRCS-9626CN - 080191 Motor Management Relay Instruction Manual (EN - DYBH0443.0233.1101)jayapal100% (1)

- CP5 Amendment 1 27 Feb 2009 Fact SheetDocument4 pagesCP5 Amendment 1 27 Feb 2009 Fact Sheetkyawswarpm100% (1)

- Evinrude E-Tec Outboard Motor Service Manual Repair 75hp 90hp 2007 PDFDocument344 pagesEvinrude E-Tec Outboard Motor Service Manual Repair 75hp 90hp 2007 PDFadolfoc26175% (4)

- Workshop and Spare Parts Manual IQ & IQM MK3 ActuatorsDocument5 pagesWorkshop and Spare Parts Manual IQ & IQM MK3 ActuatorsfernandoNo ratings yet

- NISMDocument18 pagesNISMAbhinav PratapNo ratings yet

- O&M Manual - GL314F3Document224 pagesO&M Manual - GL314F3frank_538254342100% (2)

- 1.2 Data Schedule LTB245E1Document2 pages1.2 Data Schedule LTB245E1Jose Alberto Jorge JiménezNo ratings yet

- S2DA Type Centre-Break Disconnectors 72,5 KV To 300 KVDocument4 pagesS2DA Type Centre-Break Disconnectors 72,5 KV To 300 KVOscar Francisco Astudillo Paillamilla100% (1)

- MCset 1-2-3 Medium Voltage Switchgear User ManualDocument46 pagesMCset 1-2-3 Medium Voltage Switchgear User ManualAceel Fitch100% (4)

- Installation Manual for CAN NetworksDocument24 pagesInstallation Manual for CAN NetworksFariza DianNo ratings yet

- TRENCH IOSK 145 CT Instruction Manual RVDocument17 pagesTRENCH IOSK 145 CT Instruction Manual RVAnsel Garvey100% (3)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Motor protection relay user manualDocument13 pagesMotor protection relay user manualrpshvjuNo ratings yet

- TLKT DCL ABB Lo I SDF+DEADocument108 pagesTLKT DCL ABB Lo I SDF+DEADuy LuânNo ratings yet

- PCS-9611S X Communication Protocol Manual en Overseas General X R1.20Document211 pagesPCS-9611S X Communication Protocol Manual en Overseas General X R1.20parveen115No ratings yet

- Adhikary Plant CycleDocument19 pagesAdhikary Plant CyclerpshvjuNo ratings yet

- Adhikary Plant CycleDocument19 pagesAdhikary Plant CyclerpshvjuNo ratings yet

- Handbook On IRS Point Machine With Thick Web SwitchDocument30 pagesHandbook On IRS Point Machine With Thick Web SwitchN.r. Saravanan83% (6)

- PCS-931 - X - Instruction Manual - EN - Overseas General - X - R2.02 PDFDocument604 pagesPCS-931 - X - Instruction Manual - EN - Overseas General - X - R2.02 PDFjayofo8363No ratings yet

- High Voltage SF6 Circuit Breaker InstructionDocument24 pagesHigh Voltage SF6 Circuit Breaker InstructionHusein Okhonov100% (1)

- Manual Alstom S2DADocument50 pagesManual Alstom S2DABagla100% (2)

- PCS-921 - X - Instruction Manual - EN - Overseas General - X - R1.02 - (EN - FZBH5101.0086.0003) PDFDocument276 pagesPCS-921 - X - Instruction Manual - EN - Overseas General - X - R1.02 - (EN - FZBH5101.0086.0003) PDFLeister Carneiro TheodoroNo ratings yet

- Regulador de Voltage KVGC 202Document168 pagesRegulador de Voltage KVGC 202mimiii36No ratings yet

- PCS-915SC - X - Technical Manual - EN - Overseas General - X - R1.01Document263 pagesPCS-915SC - X - Technical Manual - EN - Overseas General - X - R1.01Kevin Carmona Toral100% (1)

- Isa Cba 1000Document137 pagesIsa Cba 1000MilosNo ratings yet

- NXAIR Design Catalogue PDFDocument51 pagesNXAIR Design Catalogue PDFZalatiel Mecott ArandaNo ratings yet

- PCS-931S - X - Technical Manual - EN - Overseas General - X - R1.00Document549 pagesPCS-931S - X - Technical Manual - EN - Overseas General - X - R1.00Rafael Rodríguez100% (1)

- IOSK 72,5 .550 KV: Instructions For Assembling and Maintenance of Current Transformer TypeDocument17 pagesIOSK 72,5 .550 KV: Instructions For Assembling and Maintenance of Current Transformer TypeRonald MoreiraNo ratings yet

- ALSTOM PASSONI-VILLA High Current BushingsDocument4 pagesALSTOM PASSONI-VILLA High Current BushingsM_ValentinNo ratings yet

- Interruptor Sieyuan PDFDocument30 pagesInterruptor Sieyuan PDFFrancisco Novoa VillarroelNo ratings yet

- Product Manual-En (LB7 40.5-300)Document20 pagesProduct Manual-En (LB7 40.5-300)Hoài Sơn Lê100% (1)

- TRAX Manual enDocument58 pagesTRAX Manual enJack Duff100% (3)

- TC LB7 MannualDocument16 pagesTC LB7 Mannualcostelchelariu100% (1)

- Troubleshooting: Micom Px4XDocument17 pagesTroubleshooting: Micom Px4Xdian JaelaniNo ratings yet

- Two Storey Load ScheduleDocument17 pagesTwo Storey Load ScheduleChristian Benedict SolomonNo ratings yet

- Manual - IMB 36-245 KVDocument11 pagesManual - IMB 36-245 KVasadmkh100% (1)

- Logic Timer From MiCOM P14x P141, P142, P143, P144 & P145 Feeder Management Relay Technical Manual-P14xEN MDe6+Gf7Document2 pagesLogic Timer From MiCOM P14x P141, P142, P143, P144 & P145 Feeder Management Relay Technical Manual-P14xEN MDe6+Gf7dennyyusufNo ratings yet

- Pocketbook On Condition Monitoring of Lightning Arrester by LCM IIIDocument2 pagesPocketbook On Condition Monitoring of Lightning Arrester by LCM IIISoledad Castro100% (1)

- PCS-9611 X Instruction Manual en Overseas General X R1.01 (En DYBH5301.0086.0002)Document286 pagesPCS-9611 X Instruction Manual en Overseas General X R1.01 (En DYBH5301.0086.0002)Doan Bao100% (9)

- FPXDocument18 pagesFPXRazvan SasuNo ratings yet

- TM 1600 ManualDocument32 pagesTM 1600 Manualcataconstantin100% (2)

- Synchroteq® Plus: Installation and WiringDocument38 pagesSynchroteq® Plus: Installation and WiringCô Nàng Song TửNo ratings yet

- 7SG14 - Duobias M Complete Technical Manual PDFDocument142 pages7SG14 - Duobias M Complete Technical Manual PDFsteve_osullivanNo ratings yet

- DGT801 TECHNICAL MANUAL V1.3-090108(印刷) PDFDocument108 pagesDGT801 TECHNICAL MANUAL V1.3-090108(印刷) PDFdwilaksmana0150% (2)

- Upto 145kV 40ka 3150A Operating ManualDocument64 pagesUpto 145kV 40ka 3150A Operating Manualthiago_gomes79530% (1)

- TRF Protection Relay Manual Spad PDFDocument16 pagesTRF Protection Relay Manual Spad PDFNesarkiran BagadeNo ratings yet

- NSR-376 Generator-Transformer Unit Protection DeviceV2.10.20200818Document287 pagesNSR-376 Generator-Transformer Unit Protection DeviceV2.10.20200818Александр КозловNo ratings yet

- Département Télécommunications - Document Technique: Alspa PLC 1790/B Technical Manual InstallationDocument26 pagesDépartement Télécommunications - Document Technique: Alspa PLC 1790/B Technical Manual Installationjrsk638742No ratings yet

- CSC-150 Numerical Busbar Protection Equipment Manual - F0SF.450.045 - Er - V1.10Document167 pagesCSC-150 Numerical Busbar Protection Equipment Manual - F0SF.450.045 - Er - V1.10NandgulabDeshmukh100% (1)

- PCS 931SDocument773 pagesPCS 931SMuhamad YasrinNo ratings yet

- NARI - PCS-9611 - X - Instruction Manual - EN - Overseas General PDFDocument290 pagesNARI - PCS-9611 - X - Instruction Manual - EN - Overseas General PDFKAREEM OLAWALE0% (1)

- PNO52 245 71687 v1 ENDocument8 pagesPNO52 245 71687 v1 ENjtcool74100% (1)

- Shinshen AcrDocument134 pagesShinshen Acrmd. ahsan habibNo ratings yet

- Type KAVR 130: Auto-Reclose and Check Synchronism RelayDocument120 pagesType KAVR 130: Auto-Reclose and Check Synchronism RelayThai Dang VuNo ratings yet

- Manual Filtro Of100Document28 pagesManual Filtro Of100enriqueuno100% (2)

- FsaDocument6 pagesFsainsan_soft6498No ratings yet

- BFT Mizar 6Document5 pagesBFT Mizar 6CésarSá100% (1)

- CCM B.T. - Flash Gard - Manual IM04302001EDocument36 pagesCCM B.T. - Flash Gard - Manual IM04302001Ejgonzalez19615268No ratings yet

- Welding Inverter Tecnica - 141-161Document20 pagesWelding Inverter Tecnica - 141-161IvanSHNo ratings yet

- BFT TIR 120 BrochureDocument9 pagesBFT TIR 120 BrochureRibeiroLuisNo ratings yet

- Bank Nifty Option Strategy For November Series - 09112020-1604902911Document2 pagesBank Nifty Option Strategy For November Series - 09112020-1604902911rpshvjuNo ratings yet

- Strategy Guide: Bull Call SpreadDocument14 pagesStrategy Guide: Bull Call SpreadworkNo ratings yet

- Option StrategyDocument59 pagesOption StrategyTarkeshwar MahatoNo ratings yet

- Purchase Requistion: Sagardighi Thermal Power ProjectDocument3 pagesPurchase Requistion: Sagardighi Thermal Power ProjectrpshvjuNo ratings yet

- Cooking TipsDocument1 pageCooking TipsrpshvjuNo ratings yet

- ZnO Gapless Lightning Arrester or Surge ArresterDocument8 pagesZnO Gapless Lightning Arrester or Surge ArresterrpshvjuNo ratings yet

- Budget Fin Year Department - Em-OphDocument10 pagesBudget Fin Year Department - Em-OphrpshvjuNo ratings yet

- Agency Blacklisting RulesDocument10 pagesAgency Blacklisting Rulesrpshvju100% (1)

- Welcome To: Cooling Water Treatment in Power Plants Recent Trends & Case StudyDocument17 pagesWelcome To: Cooling Water Treatment in Power Plants Recent Trends & Case StudyrpshvjuNo ratings yet

- Post No 6 - How To Move Your Website From Localhost To Online ServerDocument7 pagesPost No 6 - How To Move Your Website From Localhost To Online ServerrpshvjuNo ratings yet

- Chapter PDFDocument9 pagesChapter PDFVenkatramana Reddy KNo ratings yet

- Website Details Password and Id's: Website Address: 1. Domain Registrar and Hosting Company: HostingrajaDocument1 pageWebsite Details Password and Id's: Website Address: 1. Domain Registrar and Hosting Company: HostingrajarpshvjuNo ratings yet

- Intake To Filter Water SystemDocument3 pagesIntake To Filter Water SystemrpshvjuNo ratings yet

- Raw water 6.6Kv switchgear and DM Plant 415V MCC single line diagramsDocument2 pagesRaw water 6.6Kv switchgear and DM Plant 415V MCC single line diagramsrpshvjuNo ratings yet

- EXIDEDocument27 pagesEXIDErpshvjuNo ratings yet

- Resource 2: Three-Phase AC MachinesDocument11 pagesResource 2: Three-Phase AC MachinesrpshvjuNo ratings yet

- PLC Unity Pro Software Quantum Hot StandbyDocument28 pagesPLC Unity Pro Software Quantum Hot StandbyrpshvjuNo ratings yet

- Common HmiDocument7 pagesCommon HmirpshvjuNo ratings yet

- Intake Switchgear Layout Phase 2Document1 pageIntake Switchgear Layout Phase 2rpshvjuNo ratings yet

- Spam Relay Setting Guide PDFDocument28 pagesSpam Relay Setting Guide PDFrpshvju100% (1)

- Esld R07 ..Document1 pageEsld R07 ..rpshvjuNo ratings yet

- E&I Inspection Engineer, 5years - MumbaiDocument3 pagesE&I Inspection Engineer, 5years - MumbaiAbhishek IngaleNo ratings yet

- 2021-03 - RFP - SCADA Procurement and Installation ProjectDocument31 pages2021-03 - RFP - SCADA Procurement and Installation ProjectM. FakNo ratings yet

- 2VAA001695 en S Control NTCS04 Controller Station Termination UnitDocument43 pages2VAA001695 en S Control NTCS04 Controller Station Termination UnitanbarasanNo ratings yet

- Circuit Details and Test ResultsDocument2 pagesCircuit Details and Test ResultsVitaliy TymoshenkoNo ratings yet

- Manual AE119 enDocument34 pagesManual AE119 enAhmad SafiiNo ratings yet

- IDA COPIF May 2013Document162 pagesIDA COPIF May 2013Zhu Qi WangNo ratings yet

- Vibration Sensors CatalogDocument17 pagesVibration Sensors CatalogBATIAR2D2No ratings yet

- Splicing - Joining Electrical ConductorDocument35 pagesSplicing - Joining Electrical ConductorMARY ANN NUCEJANo ratings yet

- Distribution Enclosures: Workshop SpecificationsDocument37 pagesDistribution Enclosures: Workshop SpecificationsDaniel EneaNo ratings yet

- 1.0 2.0 The Importance of Maintenance 3.0 Maintenance Activites 4.0 Types of MaintenanceDocument11 pages1.0 2.0 The Importance of Maintenance 3.0 Maintenance Activites 4.0 Types of MaintenanceIstiQamahh MuhamadNo ratings yet

- MiniTwin PDFDocument20 pagesMiniTwin PDFvm.moreno8489No ratings yet

- Plant Equipment Tag GuideDocument24 pagesPlant Equipment Tag GuideMuhammed AslamNo ratings yet

- Quantm InspectionDocument64 pagesQuantm InspectionkristiueoNo ratings yet

- Cat-00043 Chapter 5Document108 pagesCat-00043 Chapter 5aguilavmNo ratings yet

- Ep1c Manual-EnDocument120 pagesEp1c Manual-Encarlos alfonso calderonNo ratings yet

- General Lighting Power DbsDocument2 pagesGeneral Lighting Power DbssanaNo ratings yet

- Cost Per KM - TCAS & ABS - Version 2Document3 pagesCost Per KM - TCAS & ABS - Version 2SSE PLANNINGNo ratings yet

- Three Times Only The Subjects in Which He Has Obtained The Grade Below 50%Document5 pagesThree Times Only The Subjects in Which He Has Obtained The Grade Below 50%Jevan CalaqueNo ratings yet