Professional Documents

Culture Documents

Catalog Series 83 84 85 DBB

Uploaded by

CarlosIkedaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Catalog Series 83 84 85 DBB

Uploaded by

CarlosIkedaCopyright:

Available Formats

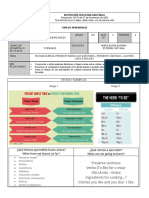

Series 52/53/83/84/85 & 86

Double Block & Bleed Ball Valves

Double block and bleed ball valves are specifically designed to

take full advantage of the positive sealing of pressurized media on

both sides of the valve from leaking through the valve and

becoming mixed.

APPLICATIONS

A single double block and bleed valve can do the job of

two conventional single-seated valves. Two pairs of

conventional valves must be used for block and bleed

service in a fuel oil and gasoline storage system. A single

double block and bleed valve replaces each pair of these

valves. The pipe tees are eliminated since the valves have

a drain hole in their base for verification of positive sealing if

desired. Standard Series 83, 84, 85 & 86 valves are fire-tested

to API 607 for flow through the valve in either direction. To meet

requirements of this specification, ball valves of floating-ball design

(Class 150 and 300 valves) rely on upstream pressure forcing the ball

downstream for effective shutoff. In double block and bleed applications with pressurized media on both

sides of the valve, shutoff in the event of a fire can be expected only if there is significant differential

pressure across the valve. Further, the body cavity must be protected against fluid thermal expansion (as

required by ANSI B16.34), which can be done by commercially available fire-tested relief devices.

AVAILABLE VALVES

VALBOL DBB ball valves available as double block and bleed valves include:

Series 82, 83, 84, 85 & 86 Full-Bore and Series 51, 52 & 53 Standard-Bore

SEAT MATERIALS AND RATINGS

Double block and bleed valve seats have an integral elastomer O-ring that maintains upstream sealing

over an extremely wide range of conditions. Standard seat material is filled PTFE (R). Standard O-ring

materials are Buna-N, providing ideal combination of chemical resistance and temperature up to +200F

and Viton, with temperatures to +300F.

BLEED HOLE

Valve bodies are available drilled and tapped to allow for flow out of the body cavity. Standard size for the

bleed port is . The port is supplied with a plug to prevent flow when the valve is being opened or is in

the full open position. If a bleed valve is required, the Fire-Safe Series F44 ball valve is recommended. In

cases where fluctuations in temperature occur, the bleed line should be equipped with a relief valve to

guard against excessive pressure build-up of fluid trapped in the body cavity of the valve.

HOW TO ORDER

Add (DBB) to the standard valve.

Example: 4" ANSI Class 600 full-port valve in double-block-and-bleed construction (DBB) with raisedface flanges, carbon-steel body, 316 stainless-steel trim with filled-PTFE seats and seals, and Buna-N

O-rings:

8440046RTRM (DBB)

Vlvulas Worcester de Argentina S.A.

Osvaldo Cruz 3333 - (C1293DL) Buenos Aires - Argentina

Tel: 54(11)4303-0037 Fax: 54(11)4301-8694

e.mail:mail@valbol.com Internet: www.valbol.com

Bul. VB82/3 03-2

You might also like

- B16-11 2016 ErrataDocument6 pagesB16-11 2016 ErrataCarlosIkeda100% (1)

- Astm A106 - A106m-2019Document12 pagesAstm A106 - A106m-2019CarlosIkeda100% (4)

- B564 Plfy402430879val PDFDocument11 pagesB564 Plfy402430879val PDFCarlosIkeda100% (1)

- Testing Chromate Coatings On Zinc and Cadmium Surfaces: Standard Practice ForDocument3 pagesTesting Chromate Coatings On Zinc and Cadmium Surfaces: Standard Practice ForCarlosIkedaNo ratings yet

- MSS SP25 2018Document42 pagesMSS SP25 2018CarlosIkeda93% (14)

- Astm A788-18Document22 pagesAstm A788-18CarlosIkedaNo ratings yet

- Astm A487 14e1Document6 pagesAstm A487 14e1CarlosIkedaNo ratings yet

- SP 44 2016 - Errata - 9 6 2017 PDFDocument5 pagesSP 44 2016 - Errata - 9 6 2017 PDFCarlosIkedaNo ratings yet

- DR Engp I 1.1 - R9Document904 pagesDR Engp I 1.1 - R9CarlosIkeda50% (2)

- Astm B637-18Document7 pagesAstm B637-18CarlosIkeda100% (1)

- Asme B36.10M-2018 PDFDocument36 pagesAsme B36.10M-2018 PDFCarlosIkeda100% (4)

- Oil and Gas Shapes enDocument5 pagesOil and Gas Shapes enCarlosIkedaNo ratings yet

- Typical F Valve Style Modifier Values Catalog 12: (From IEC534) Page 1-1 June 2014Document352 pagesTypical F Valve Style Modifier Values Catalog 12: (From IEC534) Page 1-1 June 2014CarlosIkedaNo ratings yet

- Piping Standard and Material For Oil Production and Process FacilitiesDocument1,277 pagesPiping Standard and Material For Oil Production and Process FacilitiesCarlosIkedaNo ratings yet

- Ansi Isa 75 01 01 2012 60534 2 1 PDFDocument70 pagesAnsi Isa 75 01 01 2012 60534 2 1 PDFCarlosIkeda100% (1)

- I Et 3000.00 1200 956 Pci 001 - ADocument24 pagesI Et 3000.00 1200 956 Pci 001 - ACarlosIkedaNo ratings yet

- Errata To ASME B18.2.1-2012 Square, Hex, Heavy Hex, and Askew Head Bolts and Hex, Heavy Hex, Hex Flange, Lobed Head, and Lag Screws (Inch Series)Document2 pagesErrata To ASME B18.2.1-2012 Square, Hex, Heavy Hex, and Askew Head Bolts and Hex, Heavy Hex, Hex Flange, Lobed Head, and Lag Screws (Inch Series)tungxuanbrNo ratings yet

- Face To Face Flangeless Flangeless Control ValveDocument16 pagesFace To Face Flangeless Flangeless Control ValveCarlosIkeda100% (2)

- Devlon v-API OriginalDocument1 pageDevlon v-API OriginalCarlosIkedaNo ratings yet

- Stresses and Deformation of Compressed Elastomeric O-Ring SealsDocument13 pagesStresses and Deformation of Compressed Elastomeric O-Ring SealsCarlosIkedaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Truckee Channel LineupDocument2 pagesTruckee Channel LineupschlittyNo ratings yet

- Epic 40K AeronauticaDocument25 pagesEpic 40K AeronauticaAlex KeelingNo ratings yet

- Chinese Car Auto Parts For Russia Market From Cina Auto PartsDocument131 pagesChinese Car Auto Parts For Russia Market From Cina Auto PartsCINA auto partsNo ratings yet

- Daily Inspection Checklist (Revised 02)Document14 pagesDaily Inspection Checklist (Revised 02)Dlraje DlrajeNo ratings yet

- 220810DTST24002 Exde01Document33 pages220810DTST24002 Exde01Mikail Idris KartadipuraNo ratings yet

- Sway - The Pussycat Dolls - Lyre CoverDocument6 pagesSway - The Pussycat Dolls - Lyre CoverRommel SelgaNo ratings yet

- Taller Adicional de Cinemática: Física 1 Universidad Autónoma de Occidente 1Document3 pagesTaller Adicional de Cinemática: Física 1 Universidad Autónoma de Occidente 1Melissa GarciaNo ratings yet

- World of Darkness Template ListDocument3 pagesWorld of Darkness Template Listjfc87100% (2)

- Driveline: SectionDocument263 pagesDriveline: SectionАндрей НадточийNo ratings yet

- H) Adaptation of Fuel Injection and Ignition Maps With Resistance Trimming PlugDocument3 pagesH) Adaptation of Fuel Injection and Ignition Maps With Resistance Trimming Plugalexcus1539No ratings yet

- The Adventures of Ash and The Latis!Document22 pagesThe Adventures of Ash and The Latis!Colson DemseyNo ratings yet

- Jewish Football South AfricaDocument8 pagesJewish Football South Africayesno876No ratings yet

- Motoring SchoolsDocument3 pagesMotoring Schoolsdiegoesquinca.7No ratings yet

- Les Baer 2014Document72 pagesLes Baer 2014powersbNo ratings yet

- Guia # 5 ENGLISHDocument8 pagesGuia # 5 ENGLISHDiego LopezNo ratings yet

- IMOU Pricelist - MD+Dealer Price January 2023Document1 pageIMOU Pricelist - MD+Dealer Price January 2023CCTV PonorogoNo ratings yet

- Management Assignment (Nike)Document15 pagesManagement Assignment (Nike)KAI YANG LIMNo ratings yet

- Presentation of Club de FootballDocument3 pagesPresentation of Club de FootballzagogNo ratings yet

- DR Frost Mechanics 24/03Document7 pagesDR Frost Mechanics 24/03Shawn HardingNo ratings yet

- Street Fighter Footsies HandbookDocument124 pagesStreet Fighter Footsies HandbookAngel OcoróNo ratings yet

- Physical Activity and Fitness Education: Pathfit 2Document25 pagesPhysical Activity and Fitness Education: Pathfit 2Mayeth Edmilao95% (19)

- Module 4 Pathfit 1 Activity Physical ExerciseDocument6 pagesModule 4 Pathfit 1 Activity Physical Exercisecristian ricopertoNo ratings yet

- Listofvoters2017 PDFDocument18 pagesListofvoters2017 PDFajilani2014No ratings yet

- UpDog Game StrategiesDocument16 pagesUpDog Game StrategiesRon WatsonNo ratings yet

- TATA320 Crane ManualDocument45 pagesTATA320 Crane Manualkatepol826450% (4)

- Smart Machine TCMDocument5 pagesSmart Machine TCMIqbal Khan0% (1)

- Comparative Sports StudiesDocument18 pagesComparative Sports StudiesnesstleNo ratings yet

- APPEDocument120 pagesAPPEShashiNo ratings yet

- Spam 1Document2 pagesSpam 1Em GrunwellNo ratings yet

- Petermann p4 p7 p10 and p16 Automatic LathesDocument10 pagesPetermann p4 p7 p10 and p16 Automatic LathesMuhammed ShoaibNo ratings yet