Professional Documents

Culture Documents

SOP Terminal Tractor01

Uploaded by

vozefjadavCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SOP Terminal Tractor01

Uploaded by

vozefjadavCopyright:

Available Formats

SOP Terminal Tractor

STANDRAD OPERATING PROCEUDRE FOR

MAINTENANCE OF

TERMINAL TRACOTR

SOP Terminal Tractor

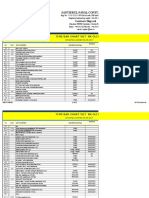

INDEX

1.0

DAILY CHECK UP

2.0

MAINTENANCE PROCEDURES

2.1

Drive chain adjustment

1 DAILY CHECK UP

1) Check oil level before starting

2) Check the hydraulic oil level

3) Check the coolant level in the radiator

4) Check the coolant level in the coolant reservoir

5) Lubricate the designated locations

6) Drain the water separator

7) check the operation of all switches

8) Check operation of all controls

9) Check level of window washer liquid

MAINTENANCE PROCEDURES

SOP Terminal Tractor

2.1

Removal of cab suspension assembly -

Responsibility: In-Charge, Shift Engineer, Work Leader

Purpose:

Description of procedure for removal of cab suspension assembly.

Scope:

To be done at recommended interval.

Operating Procedures

TOOLS AND MATERIAL REQUIRED: Tool box,

1) Park the vehicle on firm level ground.

2) Raise and support the cab.

3) After the cab is raised and supported, briefly press the cab tilt switch to the DOWN position.

This will evacuate extra fluid from the cylinder.

4) Turn off the sir supply to the cab suspension by turning the small T-handle valve clockwise. It is

located next to the latch bar plate on the bottom of the deck.

5) Disconnect and cap the hydraulic lines connected to the latch at the top of the suspension

assembly.

6) Disconnect the airline from the levelling valve on the suspension assembly

7) Remove the found mounting bolts securing the suspension assembly to the frame rail (driver

side)

2.2

Installation of cab suspension assembly -

SOP Terminal Tractor

Responsibility: In-Charge, Shift Engineer, Work Leader

Purpose:

Description of procedure for installation of cab suspension assembly

Scope:

To be done at recommended interval.

Operating Procedures

TOOLS AND MATERIAL REQUIRED: Tool box,

1) From the inner side of the frame rail, inset bolts into the two lower suspension mounting holes.

These bolts will supports the suspension assembly as it is placed in position in the next step.

2) Align the air suspension assembly with the lower mounting bolts and place it in position against

the frame rail.

3) Install the bolts, washers and locknuts in the upper mounting holes to secure the suspension

assembly to the frame.

4) Install the washers and locknuts on the lower mounting bolts. Tighten all four mounting bolts

and nuts to 200 ft-lbs.

5) Reconnect the hydraulic lines to the latch at the top of the assembly.

6) Reconnect the airline to the suspension leveling valve.

7) Secure all hydraulic lines away from moving parts

8) Loosen the cab latch bar plate on the bottom of the cab deck.

9) Lower the cab slowly until the cab latch bar plate makes contact with the air suspension latch.

Adjust the latch bar plate until it is centered in the latch and hand tighten the outer mounting

nuts.

10) Raise and support the cab. Then, tighten all four of the latch bar plate mounting nuts to 65 ft-lbs.

11) Make sure all lines are routed away from the rubber bumper contact area on the deck. Reroute

and secure the lines if necessary.

2.3

Adjustment of air ride level -

Responsibility: In-Charge, Shift Engineer, Work Leader

Purpose:

Description of procedure for Adjustment of air ride level

Scope:

To be done at recommended interval.

Operating Procedures

TOOLS AND MATERIAL REQUIRED: Tool box,

SOP Terminal Tractor

1)

2)

3)

4)

Park the vehicle on firm level ground.

Start and run the engine until air system has a minimum of 100 psi of air pressure.

Shut the engine down.

Turn on the air supply to the cab suspension by turning the T-handle valve on the bottom of the

deck counter-clockwise.

5) Remove the plastic clip in the center of the plastic linkage rod connected to the control arm on

the suspension assembly.

6) Use tape to mark linkage rods current position.

7) Adjust the linkage rod length as required to set proper ride height. Disengage the seated lower

end of the rod from the serrated portion of its upper sleeve.

To raise ride level Decrease the rod length by placing the rod deeper into the upper sleeve

To lower ride level Increase the rod length by reducing the insertion of the rod in the sleeve

NOTE: one inch of clearance is required between the stop bumpers on the air suspension

assembly and the channel at the bottom of the cab deck for proper ride height.

2.4

Removal and installation of shock absorbers -

Responsibility: In-Charge, Shift Engineer, Work Leader

Purpose:

Description of procedure for Removal and installation of shock absorbers

Scope:

To be done at recommended interval.

Operating Procedures

TOOLS AND MATERIAL REQUIRED: Tool box,

Shock absorber Removal:

Replacement of the shock absorber is necessary if the cab ride becomes too bouncy under normal

operating condition.

1) Raise the cab and lock in the full-tilt position.

2) Remove the nuts from the 7/16 inch mounting bolts securing the shock absorber in the top and

bottom mounting brackets at one side of the suspension assembly.

3) Remove the bolts and remove the shock absorber from the assembly.

4) Repeat the procedure to remove the second shock absorber at the opposite side of the

assembly.

Shock absorbers installation:

SOP Terminal Tractor

1) Place the shock absorber in position between the mounting brackets at the side of the

suspension assembly.

2) Install the 7/16 inch bolts and nuts to secure the shock absorber in the top and bottom mounting

brackets.

3) Tighten the bolts and nuts to specification.

4) Repeat the procedure to install the second shock absorber at the opposite side of the assembly.

5) Unlock the cab tilt cylinder and lower the cab.

2.5

Adjustment of latch bar plate-

Responsibility: In-Charge, Shift Engineer, Work Leader

Purpose:

Description of procedure for Adjustment of latch bar plate

Scope:

To be done at recommended interval.

Operating Procedures

TOOLS AND MATERIAL REQUIRED: Tool box,

The position of the cab latch bar plate is important. When properly positioned, it relives stress on the

cab/deck assembly. To properly position the cab latch bar plate, use this procedure.

1) Raise the cab and loosen all four nuts securing the cab latch bar plate to the bottom of the cab

deck.

2) With the plate loosened, lower the cab slowly ensuring the latch bar properly seats in the hold

down latch at the top of the suspension assembly.

3) Make adjustments (side-to-side, fore and aft) to center the bar in the latch.

4) Tighten the two nuts which are accessible at the outer end of the cab latch bar plate.

5) Raise the cab and tighten all four cab latch bar plate mounting nuts to specification.

6) Lower the cab and recheck the position of the bar in the latch. Readjust if necessary.

2.6

Removal/installation of cab tilt cylinder -

SOP Terminal Tractor

Responsibility: In-Charge, Shift Engineer, Work Leader

Purpose:

Description of procedure for removal/installation of cab tilt cylinder

Scope:

To be done at recommended interval.

Operating Procedures

TOOLS AND MATERIAL REQUIRED: Tool box,

Cylinder removal:

1) Raise the cab using cab tilt system.

2) Place a safety bar between the bottom of the deck and the frame in a manner that prohibits the

safety bar from slipping.

3) Using the cab tilt switch, lower the cab until it rests on the safety bar and all pressure is

removed from the cylinder.

4) Clean the area around the hose fitting on the pump with compressed air to reduce the

possibility of contamination.

5) Position a catch can under the fitting to prevent spills.

6) Remove the hydraulic line from the cylinder.

7) Plug or cap the hose end to prevent contamination; secure the line above the frame rail to

prevent loss of hydraulic fluid.

8) Remove the cotter key from the support pin securing the lower end of the cylinder to the lower

cylinder mounting bracket. While supporting the cylinder, remove the locknut and bolt securing

the upper end of the cylinder the deck.

Cylinder installation:

1) Prior to reassembly, inspect all fasteners, including support pins, bolts, nuts, etc for damage

and/or wear. Replace all parts that are damaged or show wear.

2) Support the cab tilt cylinder in place on the vehicle while installing the locknuts and bolts to

attach the rear end of the cylinder to the mounting brackets on the frame trail. Tighten the

locknuts and bolts to 200 ft-lbs.

3) Install an adjustable collar around the cylinder and through the mounting bracket and cylinder

eye.

4) Unplug the hydraulic hose end and connect it to the cylinder port.

5) Connect the electrical cables to the replay on the bottom of the cylinder.

6) Using the cab tilt switch, raise the cab and remove the safety bar.

7) Again, using the cab tilt switch, raise and lower the cab to bleed all air from the system; the

system is self-bleeding

8) Check all hoses and fittings for leaks.

9) Check the fluid level in the hydraulic tank; adjust as necessary.

2.7

Removal/installation of cab tilt pump and motor -

SOP Terminal Tractor

Responsibility: In-Charge, Shift Engineer, Work Leader

Purpose:

Description of procedure for removal/installation of cab tilt pump and motor

Scope:

To be done at recommended interval.

Operating Procedures

TOOLS AND MATERIAL REQUIRED: Tool box,

The cab tilt pump and motor are located on a bracket below the left main frame rail just rear of the

engine with the cab tilt cylinder.

Pump and motor removal:

1)

2)

3)

4)

Disconnect the negative cable from battery.

Locate and disconnect the two wires at the solenoid under the pump motor.

Locate and disconnect the battery cable at the pump motor.

Clean the area around the hydraulic hose fittings on the pump with compressed air to reduce

the possibility of contamination.

5) Position a catch can under the valve to prevent spills.

6) Disconnect and cap the two hydraulic line attached to pump.

7) Remove the two mounting bolts, flat washers and locknuts; remove the adjustable collar from

around the center of the pump and then remove the pump and motor assembly.

Pump and motor installation:

1) Place the cable tilt pump and motor assembly in position on the frame rail mounting bracket.

Install the two mounting bolts, flat washers and lock nuts; tighten securely. Install the adjustable

collar around the centre of the pump.

Uncap the hose ends and connect the two hydraulic lines to the pump.

Connect the two wires to the solenoid under the pump motor.

Connect the battery cable to the pump motor.

Check the fluid level in the hydraulic tank.

Connect the negative cables from the batteries.

Using the cab tilt switch, raise and lower the cab to bleed all air from the

system; the system is self-bleeding.

8) Check all hoses and fittings for leaks.

9) Check the fluid level in the hydraulic tank; adjust as necessary.

2)

3)

4)

5)

6)

7)

2.8

Removal/installation of pivot bushing -

SOP Terminal Tractor

Responsibility: In-Charge, Shift Engineer, Work Leader

Purpose:

Description of procedure for removal/installation of pivot bushing

Scope:

To be done at recommended interval.

Operating Procedures

TOOLS AND MATERIAL REQUIRED: Tool box,

Pivot bushing removal:

1) Raise the cab to the full tilt position and make sure the safety arm is in place.

2) Remove the bolts from the left front corner of the frame across member and from the bottom of

the cab channel. Allow the bolts to hang loose.

3) Remove the p-clamp that secures the frame and engine harnesses at the left front corner of the

front cross member.

4) Remove the heater hose p-clamp at the front right top of the frame cross member.

5) Remove the spacer bracket at the front left cab pivot pin.

6) Remove the cab pivot retainers from the pivot pins at the left and right sides of the cab.

7) Remove both front headlight buckets.

8) Place 4X4X6 inch blocks on the top of the frame rails to support the cab, then lower the cab

onto the block. This will help stabilize the cab while removing the cab bushings

NOTE: the blocks should be of sufficient thickness to fill the space between the frame rails, cab

deck channels and pivot brackets. This will supports the cabin the ride level position when the pivot

pins are removed.

9) Stabilize the right rear of the cab deck by chaining it down.

10) Using a drift, drive the front cab pivot pins out.

11) Using the cab tilt switch. Operate the switch in the UP position until the cab deck has cleared

the cab tilt bushings in the frame.

12) Support the front of the cab deck by placing additional blocks between the deck and frame.

13) Using a drift, drive the old bushings out the left and right cab pivot blocks.

Pivot bushing installation:

1) Install new bushings into the cab pivot blocks.

2) Remove the additional blocks places in position to support the cab in the raise position after the

pivot pins were removed.

3) Using the cab tilt switch, lower the cab deck down to the desired height on the original blocks

placed in position to support the cab. Install the cab tilt pins.

4) Install the cab pivot retainer at each pivot pin.

5) Install the spacer bracket at the front left cab pivot pin.

6) Install both front headlight buckets.

7) Install the p-clamp that secures the frame and engine harnesses at the left corner of the front

cross member.

8) Install the bolts at the front left corner of the frame cross member and from the bottom of the

cab channel.

SOP Terminal Tractor

9) Lower the cab and check for hose routing issues.

2.9

Adjustment of rear door -

Responsibility: In-Charge, Shift Engineer, Work Leader

Purpose:

Description of procedure for Adjustment of rear door

Scope:

To be done at recommended interval.

Operating Procedures

TOOLS AND MATERIAL REQUIRED: Tool box,

1) Measure the gap between the closed door and the upper corner of the door frame.

2) If the measurement is not 9/16 inch, loosen the cap screws that holds the rollers.

3) Move the door in the appropriate direction to reach 9/16 inch, then tighten the cap screws to

specification.

4) Measure the gap between the closed door and the lower corners of the door frame.

5) If the measurement is not 9/16 inch, adjust the lower guide and/or rollers as follows:

a) Check the rollers with the door in both the open and closed positions and determine where

the rollers are closed to the guide.

b) At the closet position, adjust the rollers so that they are snug against the lower guide. Adjust

the outer rollers first and then the center rollers.

c) Once the rollers are adjusted to the lower guide, close the door and adjust the lower roller

mountings plate to a gap of 9/16 inch.

10

SOP Terminal Tractor

11

You might also like

- SOP Reach Stacker01Document7 pagesSOP Reach Stacker01vozefjadav100% (1)

- 0manual Calibracion Lmi PDFDocument32 pages0manual Calibracion Lmi PDFRoxana Elizabeth Valencia Navarrte100% (1)

- Grove Rt890Document30 pagesGrove Rt890Christian Misajel JimenezNo ratings yet

- 20t Franna ManualDocument28 pages20t Franna Manualmilo_122_100% (1)

- Model m25 Free Fall Service ManualDocument44 pagesModel m25 Free Fall Service ManualManuel Rodriguez100% (1)

- Sideboom Operator Training Standard1Document17 pagesSideboom Operator Training Standard1SamuelFarfanNo ratings yet

- Crane Wire Renewal ProcedureDocument4 pagesCrane Wire Renewal ProcedureArun Alappad JNo ratings yet

- Pcm120 Brochure PDFDocument2 pagesPcm120 Brochure PDFshyroro2010No ratings yet

- Fifth Wheel Coupling and Uncoupling ProceduresDocument3 pagesFifth Wheel Coupling and Uncoupling ProceduresAbrar HussainNo ratings yet

- 4818 DB1 OpsMan R0Document661 pages4818 DB1 OpsMan R0sep650cengrNo ratings yet

- XR843-B-Ops-Man-24980-000-C MANUAL OPERARIODocument82 pagesXR843-B-Ops-Man-24980-000-C MANUAL OPERARIOfercho_50No ratings yet

- Rubber Tyre Gantry ReportDocument2 pagesRubber Tyre Gantry Reportdjrashid100% (1)

- Tg500m Tadano Lift ChartDocument6 pagesTg500m Tadano Lift ChartTaufik Singgih100% (1)

- RTG Konecranes Booklet RTG Retrofits 2015 enDocument28 pagesRTG Konecranes Booklet RTG Retrofits 2015 enFendy KurniadiNo ratings yet

- Anti SkewDocument2 pagesAnti SkewvozefjadavNo ratings yet

- JOST-World Portfolio en Web PDFDocument8 pagesJOST-World Portfolio en Web PDFJuarezGeronimoNo ratings yet

- Articulated Boom Lift SafetyDocument8 pagesArticulated Boom Lift Safetyrandhir1112No ratings yet

- Prezentare Stivuitor 4500 KGDocument6 pagesPrezentare Stivuitor 4500 KGErna BogdanNo ratings yet

- P&H 50t EscaleraDocument19 pagesP&H 50t EscaleraOmanuel CapraNo ratings yet

- Truck Crane stc1300cDocument23 pagesTruck Crane stc1300cTatamulia Bumi Raya MallNo ratings yet

- TD 800 en Eu - L PDFDocument52 pagesTD 800 en Eu - L PDFGerald Leon Flores0% (1)

- Telescopic Handler Student ManualDocument41 pagesTelescopic Handler Student ManualingcalderonNo ratings yet

- Crane Inspection Process - EnglishDocument2 pagesCrane Inspection Process - EnglishMohamed TohamyNo ratings yet

- RHN Owners Manual - HoistsDocument112 pagesRHN Owners Manual - HoistsDaniel ConwayNo ratings yet

- Testing A Double Acting Hydraulic Cylinder: Retract TestDocument1 pageTesting A Double Acting Hydraulic Cylinder: Retract TestAhmetNo ratings yet

- r14 20 enDocument6 pagesr14 20 eningenioso23No ratings yet

- Operating Manual For Disc Brake Type: SB 8.11 14-0602-01/1Document12 pagesOperating Manual For Disc Brake Type: SB 8.11 14-0602-01/1conimec100% (1)

- Design and Analysis of A Lift Assist WalkerDocument124 pagesDesign and Analysis of A Lift Assist WalkerxavicojmNo ratings yet

- Bromma TukanDocument430 pagesBromma TukanNgà NguyễnNo ratings yet

- Weight Reduction of Reach Stacker (Konecrane)Document111 pagesWeight Reduction of Reach Stacker (Konecrane)Bruno SantosNo ratings yet

- Mobile Crane Operator Course at Aims Tech Institute IndiaDocument14 pagesMobile Crane Operator Course at Aims Tech Institute IndiaAnonymous LFgO4WbIDNo ratings yet

- Safety in Maintenance of EOT CranesDocument31 pagesSafety in Maintenance of EOT CranesSwapnil pupulwadNo ratings yet

- Nul 120 PDFDocument2 pagesNul 120 PDFjuneNo ratings yet

- Method Statement For Lifting Operations: 1 - IntroductionDocument3 pagesMethod Statement For Lifting Operations: 1 - Introductiontravman1No ratings yet

- Crosby G-450 Wire Rope Clips SpecsDocument2 pagesCrosby G-450 Wire Rope Clips SpecsUlises CastroNo ratings yet

- Mobile Crane Operator Candidate Handbook - 120122aDocument33 pagesMobile Crane Operator Candidate Handbook - 120122a전우영No ratings yet

- Engine Powered Forklift: 2.0 - 3.0 Ton FDZNDocument4 pagesEngine Powered Forklift: 2.0 - 3.0 Ton FDZNrahna pristiNo ratings yet

- XR1045 ComprimidoDocument82 pagesXR1045 ComprimidoMAQUINARIA CUVISANo ratings yet

- Petrogas Holding B.V.: Terex - Tadano Crane Model DEMAG AC 100-4LDocument9 pagesPetrogas Holding B.V.: Terex - Tadano Crane Model DEMAG AC 100-4Lkarol1301100% (1)

- RopstecDocument4 pagesRopstecfrank kamuhandaNo ratings yet

- Eonwire 230: Safety Data SheetDocument8 pagesEonwire 230: Safety Data SheetBismar AlrianNo ratings yet

- Al Tasnim SOP For Periodic Maintenance and Repair FDocument90 pagesAl Tasnim SOP For Periodic Maintenance and Repair Franvijay dubeyNo ratings yet

- HeinWerner - HW93642 Service JackDocument8 pagesHeinWerner - HW93642 Service JackmoquitiNo ratings yet

- Service Manual Armadillo 9X Series: ModelsDocument38 pagesService Manual Armadillo 9X Series: ModelsChung ChungNo ratings yet

- Word QuestionnaireDocument4 pagesWord QuestionnaireViswanathan SubramanianNo ratings yet

- Crane Safety SignDocument7 pagesCrane Safety SignPinto MendesNo ratings yet

- MAINTENANCE fORKLIFT 2Document2 pagesMAINTENANCE fORKLIFT 2Ye Min HtikeNo ratings yet

- Scope of Work For EOT CRANE Repairing and ServicingDocument24 pagesScope of Work For EOT CRANE Repairing and ServicingPrince RaviNo ratings yet

- Maintowac Grove RT770EDocument28 pagesMaintowac Grove RT770EAshok SubramaniyanNo ratings yet

- Offshore Crane OperationsDocument1 pageOffshore Crane OperationsAnonymous cekPJylABoNo ratings yet

- Tele HandlerDocument18 pagesTele HandlerOmosigho OsaroNo ratings yet

- Brake Systems For Container CranesDocument105 pagesBrake Systems For Container CranesUrip S. SetyadjiNo ratings yet

- Lifting+Matters+Q3+2021 210930 WEB LRDocument36 pagesLifting+Matters+Q3+2021 210930 WEB LRAlex Sandro Borges PereiraNo ratings yet

- Technical Proposal ECrane 1000 Series EH7359Document16 pagesTechnical Proposal ECrane 1000 Series EH7359Satrio Agung WijonarkoNo ratings yet

- MPBA Acop Lorry LoadersDocument22 pagesMPBA Acop Lorry LoadersRichu PaliNo ratings yet

- Boa Operator & Maintenance ManualDocument27 pagesBoa Operator & Maintenance ManualXe Nâng Hàng YaleNo ratings yet

- SOP - Bob CatDocument37 pagesSOP - Bob CatvozefjadavNo ratings yet

- 7000 Series Field Operations Manual PDFDocument45 pages7000 Series Field Operations Manual PDFmanzanaNo ratings yet

- For BSDocument23 pagesFor BSFrancis Mark AriraoNo ratings yet

- Maxtrong Port Tire and Ind TireDocument34 pagesMaxtrong Port Tire and Ind TirevozefjadavNo ratings yet

- Coupling - Hoist Cam Switch PDFDocument14 pagesCoupling - Hoist Cam Switch PDFvozefjadavNo ratings yet

- SOP - Bob CatDocument37 pagesSOP - Bob CatvozefjadavNo ratings yet

- Cartridge Valve PDFDocument3 pagesCartridge Valve PDFvozefjadavNo ratings yet

- Anti SkewDocument2 pagesAnti SkewvozefjadavNo ratings yet

- Service Bulletin - Piston Rings:: Piston Ring Failure Diagnosis - Foreign Particle ContaminationDocument0 pagesService Bulletin - Piston Rings:: Piston Ring Failure Diagnosis - Foreign Particle ContaminationVelshankar MJNo ratings yet

- A5sr1 Sorenteo PDFDocument64 pagesA5sr1 Sorenteo PDFjuan100% (1)

- SIP TP550 - 206 Pressure WasherDocument14 pagesSIP TP550 - 206 Pressure WasheradpierceNo ratings yet

- S04.s1 - Semana 04Document9 pagesS04.s1 - Semana 04Yadhira KiramNo ratings yet

- SFT 1Document34 pagesSFT 1Dheeraj ThakurNo ratings yet

- BBC VTC214Document201 pagesBBC VTC214engkos koswaraNo ratings yet

- Chrysler Neon - Turn Signal - Hazzard Warning SystemsDocument6 pagesChrysler Neon - Turn Signal - Hazzard Warning SystemseephantomNo ratings yet

- Room Air Conditioner: SVC MANUAL (Exploded View)Document8 pagesRoom Air Conditioner: SVC MANUAL (Exploded View)Charles FalcaoNo ratings yet

- Oil Pumps: Air-OperatedDocument25 pagesOil Pumps: Air-OperatedskyNo ratings yet

- Chain Drives: Why Use A Chain Drive?Document6 pagesChain Drives: Why Use A Chain Drive?Syed Raheel AdeelNo ratings yet

- Komatsu Forklift PEE07E1-01 Spare Parts Manuals ENDocument272 pagesKomatsu Forklift PEE07E1-01 Spare Parts Manuals ENvasl100% (2)

- Drenth Display Unit USB Manual 2013-5Document20 pagesDrenth Display Unit USB Manual 2013-5Lucas Nicolás MartinezNo ratings yet

- 2022 Alexrims Catalog WEB 0318Document74 pages2022 Alexrims Catalog WEB 0318car0985l4No ratings yet

- XCMG Hydraulic Excavator: Surat Bhubaneshwar MumbaiDocument8 pagesXCMG Hydraulic Excavator: Surat Bhubaneshwar MumbaiAvijitSinharoyNo ratings yet

- Daikin Applied Product Line Card - ASP 31-312LRDocument6 pagesDaikin Applied Product Line Card - ASP 31-312LROscar MauroNo ratings yet

- Engine: Engine Mechanical (4Hk1, 6Hk1)Document178 pagesEngine: Engine Mechanical (4Hk1, 6Hk1)dmitry esaulkovNo ratings yet

- Procedure For Crankshafts That Will Not Rotate After Installation During A Rebuild (1000, 1202)Document10 pagesProcedure For Crankshafts That Will Not Rotate After Installation During A Rebuild (1000, 1202)TASHKEELNo ratings yet

- Allison at 500, at 1500 Series Parts CatalogDocument7 pagesAllison at 500, at 1500 Series Parts Catalogamin chaabenNo ratings yet

- Stepper MotorsDocument26 pagesStepper MotorsRam Kumar GogadaNo ratings yet

- Model TA Belt Alignment ControlDocument4 pagesModel TA Belt Alignment ControlRobertoNo ratings yet

- Peerless Pump Company Vertical Turbine Pumps Enclosed Line Shaft Construction Installation, Operation and Maintenance InstructionsDocument23 pagesPeerless Pump Company Vertical Turbine Pumps Enclosed Line Shaft Construction Installation, Operation and Maintenance InstructionsMuhammad ZainNo ratings yet

- Pump VLR-16Document2 pagesPump VLR-16Nguyễn Hoàng PhúcNo ratings yet

- SS15 CPGKDocument4 pagesSS15 CPGKDenzo RyugaNo ratings yet

- Motors For Rotax Kiln DriveDocument17 pagesMotors For Rotax Kiln DrivesreeganeshrNo ratings yet

- MT&T Selection GuideDocument5 pagesMT&T Selection GuideCykhong KhongNo ratings yet

- Ajuste de Bomba VRZDocument37 pagesAjuste de Bomba VRZJose David Huanca Taype100% (1)

- Service Manual For Chery QQ6 - SQR473F Engine-Mechanical PDFDocument58 pagesService Manual For Chery QQ6 - SQR473F Engine-Mechanical PDFPedro Emilio Miguez Castrillon100% (1)

- Santierul Naval Constanta SaDocument9 pagesSantierul Naval Constanta SacpîndaruNo ratings yet

- Mil P 17639FDocument60 pagesMil P 17639FcarlosloucaoNo ratings yet

- Copie de GS - EP - PVV - 112 - EN 1Document13 pagesCopie de GS - EP - PVV - 112 - EN 1Tien HaNo ratings yet