Professional Documents

Culture Documents

UOP 212-05 - Hydrogen Sulfide, Mercaptan Sulfur, and Carbonyl Sulfide in Hydrocarbon Gases by Po PDF

Uploaded by

Morteza SepehranOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

UOP 212-05 - Hydrogen Sulfide, Mercaptan Sulfur, and Carbonyl Sulfide in Hydrocarbon Gases by Po PDF

Uploaded by

Morteza SepehranCopyright:

Available Formats

uop

HYDROGEN SULFIDE, MERCAPTAN SULFUR,

AND CARBONYL SULFIDE

IN HYDROCARBON GASES

BY POTENTIOMETRIC TITRATION

UOP Method 212-05

SCOPE

This method is for determining hydrogen sulfide (H2S), mercaptan sulfur (RSH) and carbonyl

sulfide (COS) in gaseous hydrocarbons and in typical liquefied petroleum gas (LPG) consisting of C3

and/or C4 hydrocarbons. Also covered is the determination of mercaptan sulfur in LPG which may

contain a wide range of hydrocarbon types ranging from ethane to such gasoline boiling range

hydrocarbons as pentane and hexane. Each sulfur type can be determined from less than 1 to several

thousand mass-ppm sulfur (less than 0.1 to several thousand grains per 100 cu ft).

REFERENCES

ASTM Method D 1070, Relative Density of Gaseous Fuels, www.astm.org

ASTM Method D 6667, Total Volatile Sulfur in Gaseous Hydrocarbons and Liquefied Petroleum

Gases by Ultraviolet Fluorescence, www.astm.org

Bruss, D.B., Wyld, G.E.A., and Peters, E.D., Anal. Chem., 29, 807 (1957)

Handbook of Chemistry and Physics; www.crcpress.com

Lykken, L., and Tuemmler, F.D., Ind. Eng. Chem., Anal. Ed., 14, 67 (1942)

Tamele, M.W., Ryland, L.B., and Irvine, V.C., Ind. Eng. Chem., Anal. Ed., 13, 618 (1941)

UOP Method 163, Hydrogen Sulfide and Mercaptan Sulfur in Liquid Hydrocarbons,

www.astm.org

UOP Method 516, Sampling and Handling Gasolines, Distillate Fuels, and of C3-C4 Fractions,

www.astm.org

UOP Method 948, Relative Density of Gas Mixtures by Calculation from Composition,

www.astm.org

UOP Method 999, Precision Statements in UOP Methods, www.astm.org

IT IS THE USER'S RESPONSIBILITY TO ESTABLISH APPROPRIATE PRECAUTIONARY PRACTICES AND TO

DETERMINE THE APPLICABILITY OF REGULATORY LIMITATIONS PRIOR TO USE. EFFECTIVE HEALTH AND

SAFETY PRACTICES ARE TO BE FOLLOWED WHEN UTILIZING THIS PROCEDURE. FAILURE TO UTILIZE THIS

PROCEDURE IN THE MANNER PRESCRIBED HEREIN CAN BE HAZARDOUS. MATERIAL SAFETY DATA SHEETS

(MSDS) OR EXPERIMENTAL MATERIAL SAFETY DATA SHEETS (EMSDS) FOR ALL OF THE MATERIALS USED IN

THIS PROCEDURE SHOULD BE REVIEWED FOR SELECTION OF THE APPROPRIATE PERSONAL PROTECTION

EQUIPMENT (PPE).

COPYRIGHT 1959, 1968, 1972, 1977, 2003, 2004, 2005 UOP LLC. All rights reserved.

Nonconfidential UOP Methods are available from ASTM International, 100 Barr Harbor Drive, PO Box C700, West

Conshohocken, PA 19428-2959, United States. The UOP Methods may be obtained through the ASTM website,

www.astm.org, or by contacting Customer Service at service@astm.org, 610.832.9555 FAX, or 610.832.9585 PHONE.

2 of 25

OUTLINE OF METHOD

The sample, taken either from a sample cylinder or directly from a refinery stream according to the

procedures described in UOP Method 516, is scrubbed first through a potassium hydroxide solution

and then through a monoethanolamine solution. The potassium hydroxide solution contains chelating

agents which inhibits the oxidation of sulfur compounds by chelating heavy metals. A potentiometric

titration of the absorbed hydrogen sulfide and mercaptan sulfur in the potassium hydroxide solution

follows, using either an aqueous or an alcoholic silver nitrate titrant. The monoethanolamine

solution, which contains the absorbed carbonyl sulfide is titrated potentiometrically with alcoholic

silver nitrate in an acidic titration solvent. The electrode system for both titrations is a silver/silver

sulfide electrode with a glass reference electrode. The concentration of each analyzed component is

calculated from the titration curve. Either an automatic (preferred) or a manually-operated titrator

may be used.

APPARATUS

References to catalog numbers and suppliers are included as a convenience to the method user.

Other suppliers may be used if equivalent performance can be obtained.

In addition to the apparatus listed below, all of the sampling-related apparatus specified in UOP

Method 516 for C3-C4 fractions is also required for this method.

Balance, capable of weighing 5 kg to the nearest 0.5 g

Balance, readability 0.1-mg

Barometer, Fisher Scientific, Cat. No. 02-406

Beakers, electrolytic, 250-mL, Brinkmann Instruments, Cat. No. 020212209, two or more required

Beaker, stainless steel, 4000-mL, Fisher Scientific, Cat. No. 02-583G. Drill a hole in the bottom to

fit the selected neoprene stopper.

Cleaning pad, synthetic, mildly abrasive, Scotch-Brite, Runco Office Supply, Cat. No. MMM-96

Electrode, combination silver/glass titrode, Brinkmann Instruments, Cat. No. 020948507. The

electrode should be dedicated to sulfur analysis.

Flasks, volumetric, Class A, 250-, 500-, and 1000-mL, Fisher Scientific, Cat. Nos. 10-210-5E, -5F,

and -5G, respectively

Flask, volumetric, Class A, amber, for light sensitive materials, 100-mL, Fisher Scientific, Cat. No.

10-229C

Funnel, separatory, 250-mL, Fisher Scientific, Cat. No. 10-437-5C

Gas washing bottle, 125-mL. The type fitted with sintered glass disk of coarse porosity is suitable

and can be obtained commercially, Reliance Glass, Cat. No. LG-3761-100, or, Fisher Scientific,

Cat. No. 03-040A. Because light is the most serious factor affecting recovery of carbonyl sulfide,

completely mask the gas washing bottle with black tape. In order to view the bubbling, a vertical

slit, 2-3 mm wide, may be cut in the tape, which can taped over except when needed.

Gas washing bottle, 250-mL, Reliance Glass, Cat. No. LG-3690-110

Gas washing bottles, 250-mL. The type fitted with a sintered glass gas-distribution plate of coarse

porosity is suitable and this type can be obtained commercially, Reliance Glass, Cat. No. LG212-05

3 of 25

3762-102, or Fisher Scientific, Cat. No. 03-040B, two required. The maximum gas flow rate for

this type of gas washing bottle is about 30 L/hr (1 cu ft/hr).

If no COS scrubber is connected downstream of the caustic scrubbers, an alternative gas washing

bottle, suitable for a higher flow rate, may be used. This type is fitted with a perforated disk gas

distributor (see Figure 1), and is available on special order from Reliance Glass. The rate with

this distributor can be as high as 90 L/hr (3 cu ft/hr), provided that no COS scrubber is connected

downstream from the caustic scrubber. The scrubbing rate for the COS scrubber must not exceed

30 L/hr.

Gauge, pressure, stainless steel, 0 to 2800 kPa gauge (0 to 400 psig) range, Matheson Tri-Gas, Cat.

No. 63-2242, with adapter to fit the specific sample cylinders used

Graduated cylinders, 5-, 100-, and 1000-mL, Fisher Scientific, Cat. No. 08-550A, -550E, and 550H, respectively

Laboratory expansion valve, Swagelok Type SS-3NRS4 (regulating stem 316 stainless steel valve

and fittings), Swagelok. Wrap the valve with electrical heating tape and provide a variable

transformer to control the temperature of the tape. (See Figure 2 for laboratory expansion valve

apparatus arrangement.) To ensure that the valve provides a smooth, regular flow without any

blockages, it must be cleaned regularly, by rinsing with water,. Additional maintenance requires

either a rebuild kit, returning to the manufacturer for repair, or replacement.

212-05

4 of 25

Pipets, Class A, 1-, 2-, 3-, 5-, 10-, 15-, 25-, and 50-mL, Fisher Scientific, Cat. Nos. 13-650-2B, -2C,

-2D, -2F, -2L, -2M, -2P, and -2S, respectively

Pipet, Mohr, 5-mL, Fisher Scientific, Cat. No. 13-665K

Pipet filler, Fisher Scientific, Cat. No. 03-692-35

Refinery expansion valve, Swagelok Type SS-3NRS4 (regulating stem 316 stainless steel valve and

fittings), Swagelok. Since the use of electrically-heated expansion valves is not permitted in

refineries, use a hot water heating system for vaporizing an on-stream sample. (See Figure 3 for

refinery expansion valve apparatus arrangement.) To ensure that the valve provides a smooth,

regular flow without any blockages, it must be cleaned regularly, by rinsing with water.

Additional maintenance requires either a rebuild kit, returning to the manufacturer for repair, or

replacement.

Regulator, nitrogen, two-stage, high-purity, delivery pressure range 15-200 kPa (2-30 psi),

Matheson Tri-Gas, Model 3121-580

Stoppers, neoprene, sizes to fit specific apparatus. Fisher Scientific, Cat. No. 14-141*. Bore holes

as necessary using Boring Machine, Fisher Scientific, Cat. No. 07-855. *Select sizes to fit

containers.

Stopwatch, Fisher Scientific, Cat. No. 14-648-3

Tape, heating, electrical, Fisher Scientific, Cat. No. 11-463-54A

Tape, polyethylene, black, Fisher Scientific, Cat. No. 11-866-2

Thermometer or thermocouple, capable of reading heated expansion valve temperature of 38-43C

(100-110F)

212-05

5 of 25

Titrator, potentiometric, recording, 2000-mV range, 1-mV resolution, capable of reducing the

titration rate to a minimum in the vicinity of the endpoint, with dispenser having a volume

readout of 0.00 - 99.99 mL, 0.0001 of the buret volume resolution, Metrohm Model 836 Titrando

system with optional sample changer, and 20-mL buret, Brinkmann Instruments

Transformer, variable, Fisher Scientific, Cat. No. 11-472-76 (for 120V)

Tubing, rubber, 3/16 ID, Fisher Scientific, Cat. No. 14-167C

Tubing, stainless steel, OD, Alltech Associates, Cat. No. 30306ST

Wash bottle, for 2-propanol, Fisher Scientific, Cat. No. 03-409-20D

Wet test gas meter or calibrated gas receiver, 225 L/hr capacity, Meters & Controls, American

Meter, Cat. No. AL 17-1. An equivalent meter, calibrated in cu ft, is available as Cat. No. AL

17, see APPENDIX.

REAGENTS AND MATERIALS

References to catalog numbers and suppliers are included as a convenience to the method user.

Other suppliers may be used. References to water mean double deionized or distilled water purged

with nitrogen for 10 to 15 minutes before use to remove dissolved oxygen. Unqualified references to

solutions mean aqueous solutions.

In addition to the reagents and materials listed below, the reagents and materials specified in UOP

Method 516 for C3-C4 fractions are also required for this method.

Acetic acid, glacial, Certified ACS Plus, Fisher Scientific, Cat. No. A38-212

212-05

6 of 25

Acid titration solvent. Dissolve 2.7 g of sodium acetate trihydrate in 20 mL of water and 975 mL of

anhydrous ethyl alcohol. Add 4.6 mL of glacial acetic acid to the solution. Purge the solution

with nitrogen for 10 to 15 minutes prior to use to remove dissolved oxygen.

Ammonium hydroxide, concentrated, Certified ACS Plus, Fisher Scientific, Cat. No. A669-212

Cadmium chloride, Certified ACS, Fisher Scientific, Cat. No. C10-500

Cadmium chloride solution. Dissolve 100 g of cadmium chloride in 500 mL of water. Add 10 mL

of concentrated hydrochloric acid and make up to a final volume of 1 L with water. Purge with

nitrogen for 10 to 15 minutes before using.

Chelating solution, a solution of chelating agents found effective in reducing the deterioration of

sulfides and mercaptides in caustic solutions. The recommended usage is 2 mL/100 mL of caustic

solution. This chelating solution is made up from the constituent chemicals:

Diethylenetriamine pentaacetic acid, sodium salt (Na5DTPA), Acros Organics, Fisher

Scientific, Cat. No. 40729-0010 (40% aqueous solution)

Diethylenetriamine pentaacetic acid, sodium salt, 20 mass-% solution. Dilute diethylenetriamine pentaacetic acid, sodium salt, 40% aqueous solution, with water to make a 20 mass% solution.

N-(2-hydroxyethyl) ethylenediaminetriacetic acid, sodium salt, (Na3HODTA), Aldrich, Cat.

No. 16,153-5, or Acros Organics, Fisher Scientific, Cat. No. 34870-0010

N-(2-hydroxyethyl) ethylenediaminetriacetic acid, sodium salt, 20 mass-% solution. Dissolve

N-(2-hydroxyethyl) ethylenediaminetriacetic acid, sodium salt, in water to make a 20 mass-%

solution.

Ethylenediaminetetraacetic acid, sodium salt (Na4EDTA), Aldrich Chemical, Cat. No. E2,6290, or, Acros Organics, Fisher Scientific, Cat. No. 14786-5000

N,N-bis(2-hydroxyethyl)glycine (Bicine), Aldrich Chemical, Cat. No. 16,379-1, or, Acros

Organics, Fisher Scientific, Cat. No. 17265-1000

Mix 1:1 by weight ethylenediaminetetraacetic acid, sodium salt, and N,N-bis(2-hydroxyethyl)

glycine. Dissolve in water to make a 20 mass-% solution. Mix equal volumes of each of the

three 20 mass-% solutions to make the final chelating solutiuon.

Detergent, LiquiNox, Fisher Scientific, Cat. No. 04-322-15B

Ethyl alcohol, anhydrous, spectro grade, Acros Organics, Cat. No. 22409-5000

Hydrochloric acid, concentrated, Certified ACS Plus, Fisher Scientific, Cat. No. A144S-500

Lead acetate test paper, Fisher Scientific, Cat. No. 14-862

Leak test solution, soap solution, Snoop, Swagelok, Cat. No. MS-SNOOP-8OZ

Monoethanolamine (ethanolamine), 99%, Acros Organics, Cat. No. 14958-0025

Monoethanolamine, 5 vol-% solution in ethyl alcohol. Prepare by pipetting 5 mL of

monoethanolamine into an amber 100-mL volumetric flask. Fill to the mark with ethyl alcohol.

Store in a dark place. Purge with nitrogen for 10 to 15 minutes before using. Discard after one

day.

Nitrogen, high purity, 99.99%

212-05

7 of 25

Potassium hydroxide, 50 w/v-% solution, Fisher Scientific, Cat. No. LC19260-2

Potassium hydroxide, 40 w/v-% solution. Prepare by diluting four parts of 50 w/v-% solution with

one part of water. Purge with nitrogen for 10 to 15 minutes before using. Use only for samples

high in hydrogen sulfide.

Potassium hydroxide, 10 w/v-% solution, Fisher Scientific, Cat. No. LC19200-2

nitrogen for 10 to 15 minutes before using.

Purge with

2-Propanol, Certified ACS grade, Fisher Scientific, Cat. No. A416-4. Purge with nitrogen for 10 to

15 minutes before using.

Silver nitrate, 0.1-M solution, standardized at 25C against NIST potassium chloride, lot analysis

supplied, Fisher Scientific, Cat. No. SS72-4

Silver nitrate, 0.01-M standard aqueous solution. Prepare by pipetting 50 mL of the 0.1-M solution

into a 500-mL volumetric flask. Dilute to the mark with water, cap and invert several times to

mix thoroughly. The molarity of this solution is one-tenth the molarity of the purchased,

nominally 0.1-M solution.

Silver nitrate, 0.01-M standard alcoholic solution. Prepare by pipetting 50 mL of the 0.1-M solution

into a 500-mL volumetric flask. Dilute to the mark with 2-propanol, cap and invert several times

to mix thoroughly. The molarity of this solution is one-tenth the molarity of the purchased,

nominally 0.1-M solution.

Sodium acetate trihydrate, Certified ACS grade, Fisher Scientific, Cat. No. S209-500

Sodium carbonate, 5 w/v-% solution, Fisher Scientific, Cat. No. LC22970-2. Purge with nitrogen

before using.

Sodium hydroxide, 20 w/v-% solution, Fisher Scientific, Cat. No. LC24090-2

Sodium sulfide, 3 w/v-% solution, Fisher Scientific, Cat. No. LC24920-2

Wipers, Kimwipes, Ex-L, Fisher Scientific, Cat. No. 06-666A

SAMPLING

Refer to UOP Method 516, Sampling and Handling of Gasolines, Distillate Fuels, and C3-C4

Fractions, for the required sample cylinders (Silcosteel recommended), their preparation and cleaning,

and sampling procedures for C3-C4 fractions.

SCRUBBING OF GASES

If analysis of COS is not required, the COS scrubber may be eliminated, and, if desired, scrubbers

with perforated disk distributors may be used at the higher flow rate. In CALCULATIONS, it is

assumed that the gas is saturated with water when metered. For greatest accuracy, it is advisable to

provide a water saturator between the last scrubber and the meter.

Scrubbing in the Laboratory

CAUTION: This method involves venting a pressurized cylinder into vessels containing a caustic

solution. The pressure in the LPG cylinder should be checked with a pressure gauge prior to

scrubbing to ensure that the cylinder is under LPG vapor pressure only. Additional pressure may

212-05

8 of 25

deliver too high a flow rate into the caustic scrubbing solution and cause splashing. Also see NOTES

AND PRECAUTIONS.

Special care should be taken when handling the LPG during the scrubbing procedure to avoid caustic

splashing. Use a face shield during the scrubbing procedure.

All scrubbing operations should include the use of the chelating solution, 2 mL for each 100 mL of

potassium hydroxide, in order to reduce the deterioration of sulfides and mercaptides in caustic

solutions.

Scrubbing in a laboratory is carried out by mounting the sample cylinder and adapter (consisting of

connecting lines, expansion valve, and stainless steel tubing) vertically over the scrubber and

connecting it as shown in Figure 2.

1. Equip the first scrubber with a 2-hole neoprene stopper. One hole is to accept the stainless steel

tubing on the sample cylinder and the other is for the stainless steel tubing vent into the next

scrubber in the train.

2. Place the appropriate solutions in the gas washing bottles of the scrubbing train. See following

sections for specific solutions for each application.

3. Connect the last scrubber to a wet test meter to measure the volume and rate of scrubbing.

Vent the flow out of the wet test meter into a hood or other safe area.

Use a minimum length of rubber tubing for all connections, consistent with being able to connect the inlet

and the outlet of a scrubber with one piece of rubber tubing to maintain a closed system.

4. Purge the connected scrubbers with nitrogen for 10 min.

5. Mount the adapter vertically above the first scrubber.

6. Place the LPG sample cylinder in a vertical position in a hood or well-vented area. If the

cylinder has an outage tube, the outage tube must be at the top. Attach the gauge to the valve at

the top of the cylinder and check the pressure in the cylinder. See NOTE 1. Briefly open the

bottom valve (A) to check that no water or sediment is present in the LPG. If water or sediment

is determined to be present, discontinue the analysis and obtain a clean sample.

LPG samples are usually contained in a cylinder having valves on both ends or, in some cases, a

cylinder where one of the valves is connected to an eductor tube. If the sample cylinder contains an

eductor tube, invert the cylinder (both valves on the bottom) and briefly open the valve not connected to

the eductor tube to check that no water or sediment is present.

7. Weigh the sample cylinder to the nearest 0.5 g.

8. Position the cylinder directly over the adapter and connect it to the adapter. Pass the stainless

steel tubing through the remaining hole in the neoprene stopper to a depth of 1 cm from the

bottom of the scrubber.

9. Turn on the power to the heating tape and adjust the transformer so that the temperature of the

gas expansion valve is 38-43C.

10. Record the initial wet test meter readings (L) as well as the wet test meter temperature (C) and

the atmospheric pressure (mbar).

11. Ensure that the gas expansion valve is fully closed.

212-05

9 of 25

12. Open the lower valve of the sample cylinder all the way. Check for leaks at the fittings using

the leak test solution.

13. Slowly open the gas expansion valve and start the flow of sample through the scrubber and wet

test meter. Adjust the flow of gas so as not to exceed 30 L/hr (1.5 L in 3 minutes). (Excess flow

can cause the caustic scrubbing solution to splash). If the gas washing bottles are of the type

fitted with a perforated disk gas distributor, and no COS scrubber is connected downstream

from the caustic scrubber, the rate can be as high as 90 L/hr.

14. After the appropriate volume of sample has been scrubbed, turn off the heat and close the lower

valve of the sample cylinder.

15. After gas bubbles cease to come out of the tip of the adapter, disconnect the adapter from the

cylinder. Raise the adapter just high enough so that its tip is out of the scrubber solution and

wash the inside of the adapter with about 5 ml of water, collecting the washings in the scrubber

solution.

16. Remove the adapter from the scrubber and disconnect the vent line to the next scrubber. Cap

the first scrubber with a neoprene stopper. Disconnect the remaining scrubbers and quickly

connect the inlet of each scrubber to its own outlet with the rubber tubing used to connect the

scrubbers, thus minimizing exposure to air.

17. Record the volume of the gas metered. Reweigh the sample cylinder to the nearest 0.5 g to

determine the weight of sample scrubbed (see NOTES AND PRECAUTIONS).

Scrubbing in the Refinery

Scrubbing in the refinery follows the same procedures as scrubbing in the laboratory except for the

following changes. When the scrubbing of a gas or LPG sample is to be carried out in a refinery, an

electrically-heated expansion valve cannot be used because of the danger of explosion. Therefore, an

expansion valve heated by warm water is employed. Figure 3 shows the vaporization apparatus used

in on-stream scrubbing at the refinery. Follow all applicable refinery safety practices, modifying the

apparatus and procedure if necessary.

The heat necessary to warm the water is supplied by refinery steam lines. A cold-water jacket,

located upstream of the expansion valve, is necessary when using warm water to heat the expansion

valve in order to avoid conductive heating of the line upstream from the valve. The cold water for the

cooling jacket is supplied by the refinery water lines. Determine the weight of the sample from the

volume of gas scrubbed as measured by the wet test meter. Vent the meter in a safe area.

The following sample types (A through D) are typical of those found in various refinery streams.

Procedures can be modified for other sample types as necessary.

Samples Containing Relatively High Hydrogen Sulfide and Carbonyl Sulfide

Concentrations, and Low Mercaptan Concentration (Sample Type A)

For such samples as gases from catalytic cracking that contain in excess of 1000 ppm of hydrogen

sulfide and some carbonyl sulfide, more concentrated solution of potassium hydroxide is required.

The low (less than 100 ppm) mercaptan concentration is typically not measured. If it is necessary to

measure the low mercaptan concentration, repeat the analysis using the procedure in Sample Type C.

1. Place 50 mL of 40 w/v-% potassium hydroxide solution and 1 mL of the chelating solution into

each of two 250-mL scrubbers and mix by swirling.

212-05

10 of 25

The chelating solution is required to prevent loss of sulfide.

2. Place 20 mL of 5 vol-% alcoholic monoethanolamine solution into the third scrubber (125-mL),

which has been masked in black tape to exclude light.

3. Scrub about 60 L (2 cu ft) of gas.

4. Titrate the monoethanolamine scrubber solution as soon as possible after a sample has been

scrubbed (see PROCEDURE). Combine the two potassium hydroxide scrubber solutions and

titrate the same day (see PROCEDURE).

Samples Containing Relatively Low Hydrogen Sulfide, Mercaptan, and Carbonyl

Sulfide Concentrations (Sample Type B)

For purposes of this method, low concentrations of sulfur types are generally considered to be less

than 100 ppm.

1. Place 100 mL of 10 w/v-% potassium hydroxide solution and 2 mL of the chelating solution

into each of two 250-mL scrubbers and mix by swirling.

2. Place 50 mL of 5 vol-% alcoholic monoethanolamine solution into the third scrubber (125-mL),

which has been masked in black tape to exclude light.

3. Scrub about 300 L (10 cu ft) of gas.

4. Titrate the monoethanolamine scrubber solution as soon as possible after a sample has been

scrubbed (see PROCEDURE). Combine the two potassium hydroxide scrubber solutions and

titrate the combined solution the same day (see PROCEDURE).

Samples Containing Carbonyl Sulfide, Relatively High

Concentrations of Hydrogen Sulfide, and Low Concentrations of Mercaptan Sulfur

(Sample Type C)

For purposes of this method, high concentrations of sulfur types are generally considered to be

greater than 1000 ppm, and low concentrations of sulfur types are generally considered to be less than

100 ppm.

Mercaptan analysis: In some cases, samples will have a high ratio of hydrogen sulfide to mercaptan

sulfur. Where this condition exists, the accuracy of the mercaptan sulfur determination may be

affected adversely if additional scrubbers are not placed in the sampling train before the potassium

hydroxide scrubbers.

1. Charge the first 250-mL scrubber downstream from the expansion valve with 100 mL of 5 w/v% sodium carbonate solution. Charge the second 250-mL scrubber with 100 mL of 5 w/v-%

sodium carbonate solution.

2. Follow these 2 scrubbers with an empty scrubber which serves as a knockout trap, then follow

with two 250-mL gas scrubbers each containing 50 mL of 40 w/v-% potassium hydroxide

solution and 1 mL of chelating solution.

3. Scrub approximately 300 L (10 cu ft) of the gas.

212-05

11 of 25

4. Combine the two potassium hydroxide scrubber solutions and titrate the combined solution the

same day as described in the PROCEDURE.

A separate analysis must be carried out to determine the respective concentrations of hydrogen

sulfide and carbonyl sulfide in samples of this type. The sampling procedure is identical to that

described previously for gases which are relatively high in hydrogen sulfide (Sample type A).

Samples Containing Mercaptan Sulfur Only and Appreciable

Concentrations of Pentane and Higher Boiling Materials (Sample Type D)

For purposes of this section, appreciable concentrations of pentane and higher boiling materials

are indicated when, after the scrubbing is complete, there is at least a 5-10 mL hydrocarbon layer

present in the scrubber.

1. Place 100 mL of 10 w/v-% potassium hydroxide solution and 2 mL of the chelating solution in

each of two 250-mL scrubbers and mix by swirling.

2. Scrub about 60 L (2 cu ft) of gas.

3. If there is a hydrocarbon layer present in the scrubber after sampling, remove the hydrocarbon

layer by using a nitrogen-purged separatory funnel.

4. Return the aqueous portion to the scrubber and replace the bubbler to exclude air.

5. Analyze the hydrocarbon phase for mercaptan sulfur using UOP Method 163. Use the entire

weight of sample scrubbed as the sample weight in the calculation of mercaptan sulfur in

accordance with UOP Method 163.

6. Titrate the aqueous phase as described in the PROCEDURE.

7. Sum the results of the titration and U163 to obtain the total mercaptan content.

PROCEDURE

The analyst is expected to be familiar with general laboratory practices, the technique of titration,

and with the equipment being used.

Caustic solutions containing sulfur compounds are quite susceptible to oxidation in air. The

solutions should, therefore, be protected by blanketing with nitrogen or other inert gas. Titrate

solutions immediately after they are ready.

Silver/Glass Electrode Preparation and Reconditioning

Proper electrode preparation is essential to obtain reproducible and noise-free titration curves

having good endpoints. When in use, the electrode should be reconditioned on a weekly basis. An

electrode should be dedicated to sulfur analysis. If it is used for any other titrations, it must be

reconditioned before use. Prepare and recondition the silver-silver sulfide electrode as follows:

1. Clean the silver surface with a cleaning pad. Rinse with water and dry.

2. Immerse the electrodes in a solution containing 100 mL of 2-propanol, 1 mL of ammonium

hydroxide, and 3 mL of 3 w/v-% sodium sulfide solution.

212-05

12 of 25

3. While stirring at a moderate speed, slowly add approximately 10 mL of 0.01-M silver nitrate

solution over a period of 10 minutes. A film of silver sulfide will be deposited on the silver

electrode.

4. Wipe the excess silver sulfide from the electrode with a wiper.

The electrode should be cleaned after each titration by rinsing with water.

Hydrogen Sulfide and Mercaptans

1. Prepare the titrator for operation according to the instrument manufacturers instructions, with

the specified electrode in place and 0.01-M silver nitrate as the titrant.

Alcoholic silver nitrate may also be used for the sulfide and mercaptide titration to avoid changing titrant

for the carbonyl sulfide titration.

2. Check the contents of the caustic scrubbers qualitatively using lead acetate paper. If there is no

perceptible coloration of the paper, transfer the contents of the scrubbers into a 250-ml

electrolytic beaker. Proceed with Step 3. If the lead acetate paper shows any coloration,

quantitatively transfer the contents of the caustic scrubbers into a 250-ml volumetric flask.

Proceed with Step 4.

3. Wash the scrubbers (bottles and bubblers, not the rubber hose) with water and add the washings

to the same beaker. Add approximately 1 mL of concentrated ammonium hydroxide. Proceed

with Step 6.

4. Wash the scrubbers (bottles and bubblers, not the rubber hose) with water and add the washings

to the volumetric flask. Dilute to volume with water and mix by swirling. Again, check the

diluted solution with lead acetate paper and use Table 1 as a guide in selecting the proper

aliquot size.

Caustic solutions containing high levels of mercaptide and low levels of sulfide are titrated separately for

the two components. A sample is titrated as above to the mercaptide endpoint, and then a larger sample

is titrated only to the sulfide endpoint. The mercaptide concentration is determined by difference.

If the ratio of sulfide sulfur to mercaptide sulfur is greater than 10:1, then the mercaptide result is

considered to be qualitative.

Table 1

Selection of Aliquot Size

Color of lead acetate paper after

testing the diluted scrubber solution

dark brown

brown

light brown

Aliquot to be taken for

titration, mL

1 to 5

5 to 20

20 to 50

5. Pipet an aliquot into an electrolytic beaker. Add approximately 1 mL of concentrated

ammonium hydroxide. Dilute to about 50 mL with water.

6. Titrate with 0.01-M silver nitrate, automatically or manually (see Manual Titration) depending

on the equipment available.

Figure 4 shows three typical titration curves for samples containing mercaptan only, hydrogen

sulfide only, and both mercaptan and hydrogen sulfide in the same sample. Samples containing only

mercaptan will show an inflection in their titration curves at about 0.0 to +0.3V (Curve A). Samples

212-05

13 of 25

containing only hydrogen sulfide will show an inflection in their titration curves at about -0.4 to

+0.2V (Curve B). When both hydrogen sulfide and mercaptan are present, 2 inflections (Curve C)

will be seen. The first inflection, at about -0.4 to -0.2V. indicates hydrogen sulfide and the second, at

about 0.0 to +0.3V, indicates mercaptan.

Mercaptans Only

1.

Prepare the titrator in the same manner as for the sulfide and mercaptan titration.

2.

Transfer the caustic scrubber solution from each of the two scrubbers to two separate 250-mL

electrolytic beakers. Wash each scrubber (bottles and bubblers, not the rubber hose) with 50

mL of water and add the water washings to each respective beaker. Add approximately 1 mL

of concentrated ammonium hydroxide to each of the two beakers.

3.

Using 0.01-M silver nitrate as the titrant, titrate automatically or manually (see Manual

Titration) depending on the equipment available.

Figure 4 shows a typical titration curve for samples containing only mercaptan sulfur (Curve A).

Carbonyl Sulfide

1.

Prepare the titrator in the same manner as for the sulfide and mercaptide titration.

2.

Transfer the monoethanolamine scrubber solution to an electrolytic beaker. Wash the

scrubber (bottle and bubbler, not the rubber hose) with two 50-mL portions of the acid

titration solvent and add the washings to the electrolytic beaker.

212-05

14 of 25

3.

Using 0.01-M alcoholic silver nitrate, titrate automatically or manually (see Manual

Titration) depending on the equipment available.

Figure 5 shows a typical titration curve for samples containing carbonyl sulfide. The inflection

point on a carbonyl sulfide titration curve occurs at about -0.1 to +0.1V.

Manual Titration

Automatic titration using the listed equipment is recommended. However, if only manual titration

equipment is available, manual titration can be performed.

Add the silver nitrate solution in increments of 0.2 mL and record the emf after each addition until

the endpoint is approached. Then, reduce the increments to 0.1 mL. The endpoint is found where

emf/mL is a maximum, i.e., where the change in emf per increment of titrant added is the greatest.

If both sulfide and mercaptide are present, 2 inflections will be observed. Make a plot of the titration,

i.e., emf vs. volume of silver nitrate.

Estimate the midpoint of the inflections by inspecting the titration curve, or plot emf/mL and take

the maximum as the endpoint. Record the volumes of silver nitrate used for the titration of the sulfide

and mercaptide respectively. (See Figure 4 for typical titration curves.)

Use the same procedure when the carbonyl sulfide is titrated manually. (See Figure 5 for a typical

titration curve.)

CALCULATIONS

The calculations below use metric units. When calculating values using metered gas volumes of

sample, and the gas meter is calibrated in cubic feet, use the calculations in the APPENDIX. The

APPENDIX also includes calculations for reporting results in grains of sulfur per 100 cubic feet.

212-05

15 of 25

Hydrogen Sulfide

To calculate the concentration of hydrogen sulfide as sulfur, in mass-ppm, from the metered gas

volume of sample used, use Equation 1.

Hydrogen sulfide as sulfur, mass-ppm =

16030 AMY

VCDZ

(1)

where:

A = volume of standard silver nitrate solution used for titrating the sulfide, mL

C = factor for converting the metered gas volume to 15C and 1013 mbar,

calculated from Equation 2:

Correction factor =

288(P PV )

1013(273 + t )

(2)

where:

P = barometric pressure, mbar

PV = vapor pressure of water at temperature t, mbar. At normal room

temperature, 22C, the vapor pressure of water is about 27 mbar.

For a more precise number, or for a different temperature, consult a

technical handbook such as the Handbook of Chemistry and

Physics.

t = meter temperature, C

273 = absolute zero, C, absolute value

288 = 273, previously defined + 15, standard temperature, C

1013 = standard pressure, mbar

D = gas density corrected to 15C and 1013 mbar, g/L, (obtained by ASTM Method

D 1070, Relative Density of Gaseous Fuels, or UOP Method 948, Relative

Density of Gas Mixtures by Calculation from Composition)

M = molarity of the standard silver nitrate solution used for titration, moles/L

V = metered gas volume before correction to 15C and 1013 mbar, L

Y = total volume to which the potassium hydroxide scrubber solution is diluted

before aliquoting, mL. (If the entire scrubber contents are titrated, delete the

terms Y and Z from the equation since they become identical and cancel out.)

Z = volume of the aliquot taken for titration, mL

16030 = factor for converting to mass-ppm sulfur, equal to the product of:

(32.06)(10 6 )

(2)(10 3 )

where:

32.06 =

106 =

2=

103 =

molecular weight of sulfur, g/mole

conversion of g to g

conversion of moles of silver nitrate to moles of sulfur from H2S

conversion of L to mL

212-05

16 of 25

To calculate the concentration of hydrogen sulfide, in mass-ppm, from the measured cylinder

weight difference, use Equation 3.

Hydrogen sulfide as sulfur, mass-ppm =

16030 AMY

GZ

(3)

where:

G = weight of sample taken by cylinder difference, g

A, M, Y, Z = previously defined

16030 = previously defined

Mercaptan Sulfur

To calculate the concentration of mercaptan sulfur, in mass-ppm, from the metered gas volume of

sample used, use Equation 4.

Mercaptan sulfur as sulfur, mass-ppm =

32060BMY

VCDZ

(4)

where:

B = volume of standard alcoholic silver nitrate solution used for titrating the

mercaptide, mL

C, D, M, V, Y, Z = previously defined

32060 = factor for converting to mass-ppm sulfur, equal to the product of:

(32.06)(10 6 )

(10 3 )

where:

32.06 = molecular weight of sulfur, g/mole

106 = conversion of g to g

103 = conversion of L to mL

To calculate the concentration of mercaptan sulfur, in mass-ppm, from the measured cylinder

weight difference, use Equation 5.

Mercaptan sulfur as sulfur, mass-ppm =

32060BMY

GZ

(5)

where:

B, G, M, Y, Z = previously defined

32060 = previously defined

Carbonyl Sulfide

To calculate the concentration of carbonyl sulfide, in mass-ppm, from the metered gas volume of

sample used, use Equation 6.

Carbonyl sulfide as sulfur, mass-ppm =

16030EM

VCD

(6)

where:

E = volume of standard alcoholic silver nitrate solution used for titrating the

carbonyl sulfide, mL

212-05

17 of 25

C, D, M, V = previously defined

16030 = previously defined

To calculate the concentration of carbonyl sulfide, in mass-ppm, from the measured cylinder weight

difference, use Equation 7.

Carbonyl sulfide as sulfur, mass-ppm =

16030EM

G

(7)

where:

E, G, M = previously defined

16030 = previously defined

Report each sulfur type to the nearest 1 ppm as sulfur.

NOTES AND PRECAUTIONS

1. The sample cylinder should be pressure checked with a gauge before scrubbing to ensure that it is

only under LPG vapor pressure, and has not been additionally pressurized with a gas. Typically,

LPG-only pressure is not greater than 1000 kPa. Additional pressure may cause caustic splashes.

If the pressure is greater than 1000 kPa, check the source and history of the sample, and resample

if necessary.

2. The regulating stem of the expansion valve should be cleaned and maintained regularly to ensure

smooth delivery of the LPG into the caustic scrubber to avoid splashes. Cleaning is performed by

rinsing with water, to ensure that it provides a smooth, regular flow without any blockages.

Additional maintenance requires either a rebuild kit, returning to the manufacturer, or

replacement.

3. The use of a face shield is recommended during the scrubbing process in addition to the usual

safety glasses, gloves, and other appropriate personal protection equipment.

4. For refinery sampling, the sample lines should be as short as possible. Purge them with the

sample prior to attaching the scrubber.

5. Use rubber tubing to connect the scrubber to the sample point and to the wet test meter because of

its flexibility. Make the length as short as practical.

6. Analyze the absorber solutions as soon as possible, and protect them from air to minimize

oxidation of the sulfide and mercaptide.

7. Always pass the hydrocarbon gas through the scrubber before passing it through the wet test

meter. This prevents contamination of the meter with hydrogen sulfide.

8. Protect the monoethanolamine solution from exposure to light.

9. The calculations assume that, for practical purposes, the metered gas volume represents the

volume of gas analyzed. The difference represents the volume of hydrogen sulfide in the sample

which normally has no significant effect. For unusual samples which contain hydrogen sulfide in

the percent range, the analyst may refine the calculations to take this into account.

10. Dispose of all used solutions in an environmentally safe manner.

212-05

18 of 25

PRECISION AND BIAS

Precision statements were determined using UOP Method 999, from precision data obtained using a

Brinkmamm Metrohm Model 751GPD Titrino titrator with an automatic sample changer.

Intermediate Precision

A single sample was analyzed four times by each of two analysts over a period of eight days in one

laboratory. The precision data are summarized in Table 2. Two tests performed in one laboratory by

different analysts on different days should not differ by more than the intermediate precision

allowable difference with 95% confidence.

The data in Table 2 are an estimate of intermediate precision. When the test is run routinely, a

control standard and chart should be used to develop a better estimate of the long-term repeatability.

Table 2

Intermediate Precision, mass-ppm Sulfur

Intermediate

Precision

LPG Sample

Hydrogen sulfide

Mercaptan sulfur

Carbonyl sulfide

Mean

Value

2.8

5.2

0.7

WithinLab esd

0.27

0.27

0.05

Allowable

Difference

1.0

1.2

0.2

Reproducibility

There is insufficient data to calculate reproducibility of the test at this time.

Bias

The LPG sample that was used to develop the precision statement was also analyzed for total sulfur

by ASTM Method D 6667. D 6667 measured 8.6 mass-ppm total sulfur, compared to a sum of 8.7

mass-ppm sulfur for this method.

TIME FOR ANALYSIS

Samples Containing Hydrogen Sulfide, Mercaptan, and Carbonyl Sulfide Sulfur

The elapsed time for one analysis is four hours. The labor requirement is four hours. Additional

time is required to initially assemble the apparatus. Samples with very low sulfur levels may require

additional scrubbing time, up to a total of 10 hours.

Samples Containing Mercaptan Sulfur Only and Appreciable

Concentrations of Pentane and Higher Boiling Materials

The elapsed time for one analysis is three hours. The labor requirement is three hours.

212-05

19 of 25

SUGGESTED SUPPLIERS

Acros Organics, Fisher Scientific, 711 Forbes Ave., Pittsburgh, PA 15219-4785 (412-490-8300)

www.fishersci.com

Aldrich Chemical Company, 1000 West Saint Paul Ave., Milwaukee, WI 53233 (414-273-3850)

www.sigma-aldrich.com

Alltech Associates Inc., 2051 Waukegan Rd., Deerfield, IL 60015 (847-948-8600)

www.alltechweb.com

Brinkmann Instruments Co., One Cantiague Rd., Westbury NY 11590 (516-334-7500)

www.brinkmann.com

Fisher Scientific Co., 711 Forbes Ave., Pittsburgh, PA 15219-4785 (412-490-8300)

www.fishersci.com

Matheson Tri-Gas, 166 Keystone Drive, Montgomeryville, PA 18936 (215-641-2700)

www.mathesontrigas.com

Meters & Controls, 505 W. Wrightwood Ave., Elmhurst, IL 60126 (630-279-3800)

www.americanmeter.com

Reliance Glass, 2220 Gateway Road, Bensenville, IL 60106 (630-766-1816) www.lab-glass.com

Runco Office Supply, 1108 Lee St., Des Plaines, IL 60016 (847-297-7740) www.runcoonline.com

Swagelok, 1540 N. Old Rand Road, Wauconda, IL 60084-0847 (847-526-6900)

www.swagelok.com

212-05

20 of 25

APPENDIX

The appendix is written as a convenience for users who measure the sample quantity scrubbed from

the metered gas volume of sample used, and whose equipment for SCRUBBING OF GASES is

calibrated in English units (cu ft, F). Also included are calculations for reporting results in grains of

sulfur per 100 cubic feet.

CALCULATIONS

Hydrogen Sulfide

To calculate the concentration of hydrogen sulfide, in mass-ppm, from the metered gas volume of

sample used, use Equation A1.

Hydrogen sulfide as sulfur, mass-ppm =

566 AMY

VCDZ

( A1)

where:

A = volume of standard silver nitrate solution used for titrating the sulfide, mL

C = factor for converting the metered gas volume to 60F and 760 mm Hg. This can

be conveniently ascertained from the Gas Volume Correction Chart, Figures

A1 and A2. Alternatively, it can be calculated from Equation A2:

Correction factor =

520 (P PV )

760 (460 + t)

( A 2)

where:

P = barometric pressure, mm Hg

PV = vapor pressure of water at temperature t, mm Hg. At normal

room temperature, 72F, the vapor pressure of water is about 20

mm Hg. For a more precise number, or for a different

temperature, consult a technical handbook.

t = meter temperature, F

460 = absolute zero, F, absolute value

520 = 460, previously defined + 60, standard temperature, F

760 = standard pressure, mm Hg

D = gas density corrected to 60F and 760 mm Hg, g/L, (obtained by ASTM

Method D 1070, Relative Density of Gaseous Fuels, or UOP Method 948,

Relative Density of Gas Mixtures by Calculation from Composition)

M = molarity of the standard silver nitrate solution used

V = metered gas volume before correction to 60F and 760 mm Hg, cu ft

Y = total volume to which the potassium hydroxide scrubber solution is diluted

before aliquoting, mL. (If the entire scrubber contents are titrated, delete the

terms Y and Z from the equation since they become identical and cancel out.)

Z = volume of the aliquot taken for titration, mL

566 = factor for converting to mass-ppm sulfur, equal to the product of:

(32.06)(10 6 )

(2)(28.316)(10 3 )

212-05

21 of 25

where:

32.06 =

106 =

2=

28.316 =

103 =

molecular weight of sulfur, g/mole

conversion of g to g

conversion of moles of silver nitrate to moles of sulfur from H2S

conversion of cu ft to L of gas, L/cu ft

conversion of L to mL

To calculate the concentration of hydrogen sulfide in grains per 100 cu ft at standard temperature

and pressure (STP, 60F, 760 mm Hg), use Equation A3.

Hydrogen sulfide as sulfur, grains/100 cu ft at STP =

24.73 AMY

0.000418 AMY + VCZ

( A 3)

where:

A, C, M, V, Y, Z = previously defined

24.73 = factor for converting to grains of sulfur per 100 cu ft of gas at STP, equal to the

product of:

(32.06)(15.43)(10 2 )

(2)(10 3 )

where:

32.06 =

15.43 =

102 =

2=

103 =

molecular weight of sulfur, g/mole

conversion from grams of sulfur to grains of sulfur, grains/g

conversion from per cu ft of gas to per 100 cu ft of gas

conversion of moles of silver nitrate to moles of sulfur from H2S

conversion of L to mL

0.000418 = factor for correcting the metered gas volume for the volume of H2S adsorbed

by the scrubbers, equal to the product of:

(23.67)

(28.316)(2)(10 3 )

where:

23.67 =

28.316 =

2=

103 =

conversion from moles to liters of gas at STP, L/mole

conversion of cu ft to L of gas, L/cu ft

conversion of moles of silver nitrate to moles of sulfur from H2S

conversion of L to mL

For gases containing less than 200 grains of hydrogen sulfide per 100 cu ft, the term 0.000418

AMY in the denominator, which represents the cubic feet of hydrogen sulfide in the sample, is

negligible and may be eliminated from the formula. This simplifies the expression to Equation A4:

Hydrogen sulfide as sulfur, grains/100 cu ft at STP =

24.73 AMY

VCZ

( A 4)

where:

A, C, M, V, Y, Z = previously defined

24.73 = factor for converting to grains of sulfur per 100 cu ft of gas at STP, previously

defined

212-05

22 of 25

Mercaptan Sulfur

To calculate the concentration of mercaptan sulfur, in mass-ppm, from the metered gas volume of

sample used, use Equation A5.

Mercaptan sulfur as sulfur, mass-ppm =

1132BMY

VCDZ

( A5)

where:

B = volume of standard alcoholic silver nitrate solution used for titrating the

mercaptide, mL

C, D, M, V, Y, Z = previously defined

1132 = factor for converting to mass-ppm sulfur, equal to the product of:

(32.06)(10 6 )

(28.316)(10 3 )

where:

32.06 =

106 =

28.316 =

103 =

molecular weight of sulfur, g/mole

conversion of g to g

conversion of cu ft to L of gas, L/cu ft

conversion of L to mL

To calculate the concentration of mercaptan sulfur in grains per 100 cu ft at STP, use Equation A6.

Mercaptan sulfur as sulfur, grains/100 cu ft at STP =

49.47BMY

VCZ

( A 6)

where:

B, C, M, V, Y, Z = previously defined

49.47 = factor for converting to grains of sulfur per 100 cu ft of gas at STP, equal to the

product of:

(32.06)(15.43)(10 2 )

(10 3 )

where:

32.06 =

15.43 =

102 =

103 =

molecular weight of sulfur, g/mole

conversion from grams of sulfur to grains of sulfur, grains/g

conversion from per cu ft of gas to per 100 cu ft of gas

conversion of L to mL

Carbonyl Sulfide

To calculate the concentration of carbonyl sulfide, in mass-ppm, from the metered gas volume of

sample used, use Equation A7.

Carbonyl sulfide as sulfur, mass-ppm =

where:

212-05

566EM

VCD

( A 7)

23 of 25

E = volume of standard alcoholic silver nitrate solution used for titrating the

carbonyl sulfide, mL

C, D, M, V = previously defined

566 = factor for converting to mass-ppm sulfur, equal to the product of:

(32.06)(10 6 )

(2)(28.316)(10 3 )

where:

32.06 = molecular weight of sulfur, g/mole

106 = conversion of g to g

2 = conversion of moles of silver nitrate to moles of sulfur from

COS

28.316 = conversion of cu ft to L of gas, L/cu ft

103 = conversion of L to mL

Report all sulfur types to the nearest 1 ppm as sulfur, or to the nearest 0.1 grains per 100 cu ft at STP.

212-05

24 of 25

Figure A1

212-05

25 of 25

Figure A2

212-05

You might also like

- UOP 989-14 Trace Sulfur in LPG and Gaseous Hydrocarbons by Oxidative Combustion With UltravioletDocument7 pagesUOP 989-14 Trace Sulfur in LPG and Gaseous Hydrocarbons by Oxidative Combustion With UltravioletMorteza SepehranNo ratings yet

- UOP 1005-14 Trace Metals in Organics by ICP-MSDocument11 pagesUOP 1005-14 Trace Metals in Organics by ICP-MSMorteza SepehranNo ratings yet

- UOP 603 Trace CO and CO2 in Hydrogen and Light Gases Hydrocarbon by GCDocument6 pagesUOP 603 Trace CO and CO2 in Hydrogen and Light Gases Hydrocarbon by GCMorteza SepehranNo ratings yet

- Uop 987Document11 pagesUop 987pramod23septNo ratings yet

- UOP 163-10 Hydrogen Sulfide and Mercaptan Sulfur in Liquid Hydrocarbons by Potentiometric TitratDocument7 pagesUOP 163-10 Hydrogen Sulfide and Mercaptan Sulfur in Liquid Hydrocarbons by Potentiometric TitratBalas43100% (2)

- Doctor Test For Petroleum Distillates: UOP Method 41-74 ScopeDocument2 pagesDoctor Test For Petroleum Distillates: UOP Method 41-74 ScopeHamid Hamido Hamido100% (1)

- UOP 9 Hydrogen Sulphide in Gases by The Tutweiller MethodDocument4 pagesUOP 9 Hydrogen Sulphide in Gases by The Tutweiller MethodmkmejavierNo ratings yet

- Uop 269Document6 pagesUop 269Edwin V100% (3)

- Uop 46Document6 pagesUop 46Ceciliagorra100% (6)

- Total Chloride in Alumina Supported Catalysts by Wavelength Dispersive X-Ray FluorescenceDocument5 pagesTotal Chloride in Alumina Supported Catalysts by Wavelength Dispersive X-Ray FluorescenceJesus Gonzalez GracidaNo ratings yet

- ASTM D 6470-99 Salt in Crude Oils (Potentiometric Method) 1 PDFDocument6 pagesASTM D 6470-99 Salt in Crude Oils (Potentiometric Method) 1 PDFsofiane ouchaouaNo ratings yet

- Astm D4468Document5 pagesAstm D4468Anonymous xERghLP8V100% (2)

- UOP analytical methods subscription guideDocument5 pagesUOP analytical methods subscription guideHamid Heidari50% (2)

- Uop TocDocument8 pagesUop TocKatan T. ShamranNo ratings yet

- Alkalinity, Sulfide and Mercaptide Analyses of Used Refinery Caustic SolutionsDocument16 pagesAlkalinity, Sulfide and Mercaptide Analyses of Used Refinery Caustic Solutionssasan100% (6)

- Gpa 2286-95 PDFDocument22 pagesGpa 2286-95 PDFaidanNo ratings yet

- Astm D6730-19Document70 pagesAstm D6730-19Angel Murillo100% (1)

- Determination of Hydrocarbons and Non-Hydrocarbon Gases in Gaseous Mixtures by Gas ChromatographyDocument10 pagesDetermination of Hydrocarbons and Non-Hydrocarbon Gases in Gaseous Mixtures by Gas ChromatographyСамсонова НатальяNo ratings yet

- UOP 163 - 10 Hydrogen Sulfide and Mercaptan Sulfur in Liquid Hydrocarbons by Potentiometric TitrationDocument7 pagesUOP 163 - 10 Hydrogen Sulfide and Mercaptan Sulfur in Liquid Hydrocarbons by Potentiometric TitrationRuben Perez AyoNo ratings yet

- Uop 629-08Document17 pagesUop 629-08MiguelNo ratings yet

- Astm G170 PDFDocument17 pagesAstm G170 PDFVictor NietoNo ratings yet

- ASTM D 7039-15aDocument12 pagesASTM D 7039-15aIsrael Lopez RamirezNo ratings yet

- A-MDEA Analytical MethodsDocument8 pagesA-MDEA Analytical MethodsSHYAMKANHAIYA100% (3)

- D5002 Density and Relative Density of Crude Oils by Digital Density AnalyzerDocument5 pagesD5002 Density and Relative Density of Crude Oils by Digital Density AnalyzerSergey GrigoryevNo ratings yet

- Uop 614 Heptane-Insoluble Matter in Petroleum Oils Using A Membrane FilterDocument10 pagesUop 614 Heptane-Insoluble Matter in Petroleum Oils Using A Membrane FilterLuis Ernesto Marin JaimesNo ratings yet

- Astm d5453Document11 pagesAstm d5453Carlos PalominoNo ratings yet

- Prediction of Viscosities of Petroleum Fractions, Yavuz Yorulmaz, 2009Document13 pagesPrediction of Viscosities of Petroleum Fractions, Yavuz Yorulmaz, 2009Anonymous Xy309m9Sm9No ratings yet

- Oil and Grease Extraction MethodsDocument8 pagesOil and Grease Extraction Methodsoramas89No ratings yet

- Salinidad - ASTM D6470-10Document6 pagesSalinidad - ASTM D6470-10JuanP_Naranjo100% (2)

- The Asphaltene Dispersant TestDocument4 pagesThe Asphaltene Dispersant TestIrelena Romero100% (1)

- Uop 41Document2 pagesUop 41Julio Rivero100% (1)

- Astm UopDocument5 pagesAstm UopSaro HNo ratings yet

- D1159Document9 pagesD1159rpajaro75No ratings yet

- Astm D 4084-07 (2012)Document7 pagesAstm D 4084-07 (2012)David Garcia del AngelNo ratings yet

- PRPP 2013 Crude Oil PropertiesDocument7 pagesPRPP 2013 Crude Oil PropertiesMohamed AlaaNo ratings yet

- Astm 5453 - Stantard Test Method For Determination of Total Sulfur PDFDocument9 pagesAstm 5453 - Stantard Test Method For Determination of Total Sulfur PDFgaso99No ratings yet

- Electrical Conductivity of Aviation and Distillate Fuels: Standard Test Methods ForDocument11 pagesElectrical Conductivity of Aviation and Distillate Fuels: Standard Test Methods ForMuhammad KhairuddinNo ratings yet

- ASTM D6667 Azufre Total en GLPDocument7 pagesASTM D6667 Azufre Total en GLPFredy100% (1)

- Uop 163Document8 pagesUop 163Julio RiveroNo ratings yet

- Comparison of Chloride MethodDocument2 pagesComparison of Chloride Methodmbusairi100% (1)

- Astm D7061Document5 pagesAstm D7061Magadov Valery100% (1)

- Ash From Petroleum Products: Standard Test Method ForDocument4 pagesAsh From Petroleum Products: Standard Test Method ForNelson GomesNo ratings yet

- NGA ISO 6974 ManualDocument89 pagesNGA ISO 6974 ManualhopkhtnNo ratings yet

- Scavanger Injection RatesDocument6 pagesScavanger Injection RatesAnonymous QSfDsVxjZNo ratings yet

- Astm D4929 PDFDocument8 pagesAstm D4929 PDFMarisol ColoradoNo ratings yet

- ASTM D 5454 11 Humedad Con AnalizadorDocument3 pagesASTM D 5454 11 Humedad Con AnalizadorCarlos Lopez BlumenkronNo ratings yet

- UOP 555-10 Trace Impurities in Benzene by GCDocument11 pagesUOP 555-10 Trace Impurities in Benzene by GCMorteza SepehranNo ratings yet

- UOP291 Chloride Test MethodDocument11 pagesUOP291 Chloride Test Methodvkumaran100% (2)

- D2360 - 11 Standard Test Method For Trace Impurities in Monocyclic Aromatic Hydrocarbons by Gas Chromatography PDFDocument6 pagesD2360 - 11 Standard Test Method For Trace Impurities in Monocyclic Aromatic Hydrocarbons by Gas Chromatography PDFJacques BlueqNo ratings yet

- E359 - 17 PDFDocument11 pagesE359 - 17 PDFĐặng Anh TrungNo ratings yet

- Astm d4294Document9 pagesAstm d4294Danilo SolanoNo ratings yet

- Trace Hydrocarbons in Hydrogen or LPG by Gas ChromatographyDocument12 pagesTrace Hydrocarbons in Hydrogen or LPG by Gas ChromatographyDavinNo ratings yet

- Trace Chloride, Fluoride, and Bromide in Liquid Organics by Combustion Ion Chromatography (CIC)Document14 pagesTrace Chloride, Fluoride, and Bromide in Liquid Organics by Combustion Ion Chromatography (CIC)ZhaoYun1314No ratings yet

- Trace CO and CO in Hydrogen and Light Gaseous Hydrocarbons by GCDocument6 pagesTrace CO and CO in Hydrogen and Light Gaseous Hydrocarbons by GCgoodcharacter1No ratings yet

- UOP539Document17 pagesUOP539chakib bouchakourNo ratings yet

- To 2Document32 pagesTo 2Miguel MatallanaNo ratings yet

- Hydrogen Sulfide and Mercaptan Sulfur in Liquid Hydrocarbons by Potentiometric TitrationDocument8 pagesHydrogen Sulfide and Mercaptan Sulfur in Liquid Hydrocarbons by Potentiometric TitrationINOPETRO DO BRASILNo ratings yet

- D96Document7 pagesD96rpajaro75100% (1)

- Purgeable Aromatics by GC MethodDocument22 pagesPurgeable Aromatics by GC MethodSyedahmadraza BokhariNo ratings yet

- D1160Document18 pagesD1160guadalupegomezperezNo ratings yet

- UOP 826-81 Carbon Dioxide in Ammine SolutionDocument7 pagesUOP 826-81 Carbon Dioxide in Ammine SolutionMorteza Sepehran100% (1)

- Tetranex Solutions IncDocument2 pagesTetranex Solutions IncMorteza SepehranNo ratings yet

- How To Design Tank Heating Coils - Parte1Document2 pagesHow To Design Tank Heating Coils - Parte1Morteza SepehranNo ratings yet

- UOP 99-07 Pentane-Insoluble Matter in Petroleum Oils Using A Membrane FilterDocument10 pagesUOP 99-07 Pentane-Insoluble Matter in Petroleum Oils Using A Membrane FilterMorteza SepehranNo ratings yet

- Large-Scale Sulfur Recovery: AS RocessingDocument3 pagesLarge-Scale Sulfur Recovery: AS RocessingMorteza SepehranNo ratings yet

- UOP 555-10 Trace Impurities in Benzene by GCDocument11 pagesUOP 555-10 Trace Impurities in Benzene by GCMorteza SepehranNo ratings yet

- UOP 304-08 Bromine Number and Bromine Index of Hydrocarbons by Potentiometric TitrationDocument13 pagesUOP 304-08 Bromine Number and Bromine Index of Hydrocarbons by Potentiometric TitrationMorteza SepehranNo ratings yet

- UOP79Document18 pagesUOP79amishraiocNo ratings yet

- UOP 1006-14 Trace Silicon in Petroleum Liquids by ICP-MSDocument11 pagesUOP 1006-14 Trace Silicon in Petroleum Liquids by ICP-MSMorteza Sepehran100% (1)

- Process Analytics in ClausDocument9 pagesProcess Analytics in ClausMorteza SepehranNo ratings yet

- UOP79Document18 pagesUOP79amishraiocNo ratings yet

- UOP79Document18 pagesUOP79amishraiocNo ratings yet

- The Cascade Control Architecture - Control GuruDocument9 pagesThe Cascade Control Architecture - Control GuruMorteza SepehranNo ratings yet

- EE4CL4 Lecture31 PDFDocument16 pagesEE4CL4 Lecture31 PDFMorteza SepehranNo ratings yet

- MeroxDocument1 pageMeroxMorteza SepehranNo ratings yet

- Elec Eng 4Cl4:: Control System DesignDocument20 pagesElec Eng 4Cl4:: Control System DesignMorteza SepehranNo ratings yet

- Elec Eng 4Cl4:: Control System DesignDocument31 pagesElec Eng 4Cl4:: Control System DesignMorteza SepehranNo ratings yet

- Handout Jacobs CSS - Claus ProcessDocument1 pageHandout Jacobs CSS - Claus ProcessMorteza SepehranNo ratings yet

- Elec Eng 4Cl4:: Control System DesignDocument12 pagesElec Eng 4Cl4:: Control System DesignMorteza SepehranNo ratings yet

- Acid 3 PDFDocument1 pageAcid 3 PDFMorteza SepehranNo ratings yet

- Metallurgy and Corrosion Control in Oil and Gas ProductionDocument1 pageMetallurgy and Corrosion Control in Oil and Gas ProductionMorteza SepehranNo ratings yet

- Refining Industry Solutions: Experience, Knowledge, and Technology... in RefiningDocument44 pagesRefining Industry Solutions: Experience, Knowledge, and Technology... in RefiningMorteza SepehranNo ratings yet

- Pages From 08 - Condensate and LPG DehydrationDocument1 pagePages From 08 - Condensate and LPG DehydrationMorteza SepehranNo ratings yet

- 8-Dehydrations 10 PDFDocument1 page8-Dehydrations 10 PDFMorteza SepehranNo ratings yet

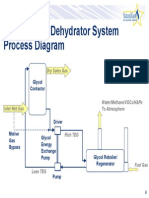

- Basic Glycol Dehydrator System Process Diagram: Dry Sales GasDocument1 pageBasic Glycol Dehydrator System Process Diagram: Dry Sales GasMorteza SepehranNo ratings yet

- 8-Dehydrations 9 PDFDocument1 page8-Dehydrations 9 PDFMorteza SepehranNo ratings yet

- Time of Setting of Hydraulic Cement by Vicat Needle: Standard Test Method ForDocument6 pagesTime of Setting of Hydraulic Cement by Vicat Needle: Standard Test Method ForAhmed AbidNo ratings yet

- Hempel NORSOK Coating Systems: NORSOK M-501: Frequently Asked QuestionsDocument1 pageHempel NORSOK Coating Systems: NORSOK M-501: Frequently Asked Questionspiscesguy78No ratings yet

- JL-98-November-December Restraint Moments in Precast Prestressed Concrete Continuous BridgesDocument18 pagesJL-98-November-December Restraint Moments in Precast Prestressed Concrete Continuous Bridgesjrobert123321No ratings yet

- Surface Prepairation STD For PC ASTM D6386Document4 pagesSurface Prepairation STD For PC ASTM D6386Rohit SangwanNo ratings yet

- Analysis Procedure Icpe9000Document45 pagesAnalysis Procedure Icpe9000achmadrb1971No ratings yet

- Stored Human Urine Supplemented With WoodAsh As FertilizerDocument6 pagesStored Human Urine Supplemented With WoodAsh As FertilizerReena BhattaNo ratings yet

- Naca TN 2579Document41 pagesNaca TN 2579maurizio.desio4992No ratings yet

- Design of Machine Elements GateDocument4 pagesDesign of Machine Elements GateshashankNo ratings yet

- Sika RepDocument2 pagesSika Repthe pilotNo ratings yet

- Sasolwax SP30 TDSDocument2 pagesSasolwax SP30 TDSLaboratorio Inkctech0% (1)

- Bamboo Reinforced ConcreteDocument14 pagesBamboo Reinforced ConcreteharisankarNo ratings yet

- 1 s2.0 S0048969704004279 Main PDFDocument22 pages1 s2.0 S0048969704004279 Main PDFnavri_nalhadNo ratings yet

- Flujo de Caja - Costos de ProducciónDocument11 pagesFlujo de Caja - Costos de ProducciónDanielIgnacioLuengoCordovaNo ratings yet

- LirioDocument220 pagesLirioAntonio MeseguerNo ratings yet

- Hydrometallurgical Process For TheDocument11 pagesHydrometallurgical Process For ThemanzoorNo ratings yet

- Jee Mains Force and Newton Laws of Motion Ezyexamsolution Sol-03Document6 pagesJee Mains Force and Newton Laws of Motion Ezyexamsolution Sol-03Oyas DubeyNo ratings yet

- ActivityDocument1 pageActivityTomy GeorgeNo ratings yet

- Iesc 103Document12 pagesIesc 103Debasish DeyNo ratings yet

- Production of Dishwashing Liquid Detergent (Base) : Cebu Institute of Technology - UniversityDocument10 pagesProduction of Dishwashing Liquid Detergent (Base) : Cebu Institute of Technology - UniversityNicely EleccionNo ratings yet

- Astm e 518Document5 pagesAstm e 518Pao Dela Cruz100% (1)

- Pharmacokinetics of Oral and Intravenous Paracetamol (Acetaminophen) When Co-Administered With Intravenous Morphine in Healthy Adult SubjectsDocument10 pagesPharmacokinetics of Oral and Intravenous Paracetamol (Acetaminophen) When Co-Administered With Intravenous Morphine in Healthy Adult SubjectsRara MaharrumNo ratings yet

- The Nuclear Reactions Involved in The Synthesis of New ElementsDocument3 pagesThe Nuclear Reactions Involved in The Synthesis of New ElementsChristian Isip67% (3)

- Grupo 5. LCA Chemical SolventDocument9 pagesGrupo 5. LCA Chemical SolventJuan Manuel FlorezNo ratings yet

- Venturi EffectDocument21 pagesVenturi Effectmuhammad ridNo ratings yet

- Welcome To This Course Physics 1Document31 pagesWelcome To This Course Physics 1andrewsiby63No ratings yet

- TOA DKK Water Quality Sensor Xseries PreDocument12 pagesTOA DKK Water Quality Sensor Xseries PrealdiniNo ratings yet

- Jadual Spesifikasi Ujian KimiaDocument14 pagesJadual Spesifikasi Ujian KimiaMuhammad Hatta HamzahNo ratings yet

- Twyman Lothian PpaerDocument8 pagesTwyman Lothian PpaerchristianNo ratings yet

- 연습문제 SolutionDocument156 pages연습문제 Solution박민지No ratings yet

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationFrom EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNo ratings yet

- Guidelines for Vapor Cloud Explosion, Pressure Vessel Burst, BLEVE, and Flash Fire HazardsFrom EverandGuidelines for Vapor Cloud Explosion, Pressure Vessel Burst, BLEVE, and Flash Fire HazardsNo ratings yet

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Perfume Engineering: Design, Performance and ClassificationFrom EverandPerfume Engineering: Design, Performance and ClassificationRating: 4 out of 5 stars4/5 (5)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksFrom EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksRating: 5 out of 5 stars5/5 (1)

- Chemical Process Safety: Learning from Case HistoriesFrom EverandChemical Process Safety: Learning from Case HistoriesRating: 4 out of 5 stars4/5 (14)

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- Guidelines for Siting and Layout of FacilitiesFrom EverandGuidelines for Siting and Layout of FacilitiesNo ratings yet

- Robotics: Designing the Mechanisms for Automated MachineryFrom EverandRobotics: Designing the Mechanisms for Automated MachineryRating: 4.5 out of 5 stars4.5/5 (8)

- Guidelines for Enabling Conditions and Conditional Modifiers in Layer of Protection AnalysisFrom EverandGuidelines for Enabling Conditions and Conditional Modifiers in Layer of Protection AnalysisNo ratings yet

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Process Plant Equipment: Operation, Control, and ReliabilityFrom EverandProcess Plant Equipment: Operation, Control, and ReliabilityRating: 5 out of 5 stars5/5 (1)

- Guidelines for the Management of Change for Process SafetyFrom EverandGuidelines for the Management of Change for Process SafetyNo ratings yet

- Guidelines for Developing Quantitative Safety Risk CriteriaFrom EverandGuidelines for Developing Quantitative Safety Risk CriteriaNo ratings yet

- Guidelines for Engineering Design for Process SafetyFrom EverandGuidelines for Engineering Design for Process SafetyNo ratings yet

- Bow Ties in Risk Management: A Concept Book for Process SafetyFrom EverandBow Ties in Risk Management: A Concept Book for Process SafetyNo ratings yet

- The HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesFrom EverandThe HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesNo ratings yet