Professional Documents

Culture Documents

DS1103

Uploaded by

Sana SyedCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DS1103

Uploaded by

Sana SyedCopyright:

Available Formats

Single-Board Hardware / DS1103 PPC Controller Board

DS1103 PPC Controller Board

Powerful controller board for rapid control prototyping

Highlights

n Single-board system with real-time processor

and comprehensive I/O

n CAN interface and serial interfaces ideally suited

to automotive applications

n High I/O speed and accuracy

n PLL-driven UART for accurate baud rate selection

Application Areas

The DS1103 controller board is designed to meet the requirements of modern rapid control prototyping and is highly

suitable for applications such as:

n Automotive controllers

n Induction motor control

n Robotics

n Positioning systems and stepper motors

n Active vibration control

Key Benefits

The DS1103 is an all-rounder in rapid control prototyping. You can mount the board in a dSPACE Expansion Box

or dSPACE AutoBox to test your control functions in a

laboratory or directly in the vehicle. Its processing power

and fast I/O are vital for applications that involve numerous actuators and sensors. Used with Real-Time Interface

(RTI, p. 56), the controller board is fully programmable from

the Simulink block diagram environment. You can configure

all I/O graphically by using RTI. This is a quick and easy way

to implement your control functions on the board.

An integrated Infineon CAN microcontroller makes the

board an attractive tool for automotive and automation

applications.

Comprehensive Interfaces

The unparalleled number of I/O interfaces makes the DS1103

a versatile controller board for numerous applications. It

provides a great selection of interfaces, including 50 bitI/O channels, 36 A/D channels, and 8 D/A channels. For

additional I/O tasks, a DSP controller unit built around Texas

Instruments TM320F240 DSP is used as a subsystem.

314

Recording and Output of I/O Values

The control of electrical drives requires accurate recording

and output of I/O values. It is possible to synchronize the

A/D channels and D/A channels, and the position of the

incremental encoder interface, with an internal PWM signal

or an external trigger signal. Also, the serial interface (UART)

is driven by a phase-locked loop to achieve absolutely

accurate baud rate selection.

2014

dSPACE GmbH Rathenaustrae 26 33102 Paderborn Germany info@dspace.de www.dspace.com

Introduction

Single-Board Hardware / DS1103 PPC Controller Board

Technical Details

Parameter

Specification

Processor

PowerPC Type

n PPC 750GX

CPU clock

n 1 GHz

Cache

n 32 KB level 1 (L1) instruction cache

n 32 KB level 1 (L1) data cache

Memory

Timer

n 133 MHz

Temperature sensor

n Reads actual temperature at the PPC

Local memory

n 32 MB application SDRAM as program memory, cached

Global memory

n 96 MB communication SDRAM for data storage and data exchange with host

2 general-purpose timers

n One 32-bit down counter

Application Fields

n 1 MB level 2 (L2)

Bus frequency

n Reload by software

n 15-ns resolution

n One 32-bit up counter with compare register

n Reload by software

n 30-ns resolution

1 sampling rate timer (decrementer)

n 32-bit down counter

Software

n Reload by software

n 30-ns resolution

1 time base counter

n 64-bit up counter

n 30-ns resolution

n 3 timer interrupts

Interrupt controller

n 7 incremental encoder index line interrupts

n 1 UART (universal asynchronous receiver and transmitter) interrupt

n 1 CAN interrupt

n 1 slave DSP interrupt

n 2 slave DSP PWM interrupts

n 1 host interrupt

n 16 multiplexed channels equipped with 4 sample & hold A/D converters

(4 channels belong to one A/D converter. 4 consecutive samplings are necessary to sample

all channels belonging to one A/D converter.)

n 4 parallel channels each equipped with one sample & hold A/D converter

n Note: 8 A/D converter channels (4 multiplexed and 4 parallel) can be sampled simultaneously.

Resolution

n 16-bit

Input voltage range

n 10 V

Overvoltage protection

n 15 V

Conversion time

n Multiplexed channels: 1 s1)

D/A converter

Offset error

n 5 mV

Gain error

n 0.25%

Offset drift

n 40 V/K

Gain drift

n 50 ppm/K

Signal-to-noise ratio

n >83 dB

Channels

n 8 channels

Resolution

n 16-bit

Output range

n 10 V

Settling time

n 5 s (14-bit)

Offset error

n 1 mV

Gain error

n 0.5%

Offset drift

n 30 V/K

Gain drift

n 25 ppm/K

Speed and timing specifications describe the capabilities of the hardware components and circuits of our products.

Depending on the software complexity, the attainable overall performance figures can deviate significantly from the hardware

specifications.

Engineering

n Parallel channels: 800 ns1)

1)

dSPACE GmbH Rathenaustrae 26 33102 Paderborn Germany info@dspace.de www.dspace.com

2014

315

Support and Maintenance

Channels

Hardware

n 4 external interrupts (user interrupts)

A/D converter

Single-Board Hardware / DS1103 PPC Controller Board

Parameter

Specification

D/A converter

Digital I/O

Signal-to-noise ratio

n >83 dB

I max

n 5 mA

C I max

Channels

n 10 nF

n 32-bit parallel I/O

n Organized in four 8-bit groups

n Each 8-bit group can be set to input or output (programmable by software)

Digital incremental

encoder interface

Voltage range

n TTL input/output levels

I out, max

n 10 mA

Channels

n 6 independent channels

n Single-ended (TTL) or differential (RS422) input (software programmable for each channel)

Position counters

n 24-bit resolution

n Max. 1.65 MHz input frequency, i.e.,fourfold pulse count up to 6.6 MHz

n Counter reset or reload via software

Encoder supply voltage

n 5 V/1.5 A

n Shared with analog incremental encoder interface

Analog incremental

encoder interface

n 1 channel

Channels

n Sinusoidal signals: 1 Vpp differential or 11App differential (software programmable)

Position counters

n < 5 resolution

n 32-bit loadable position counter

n Max. 0.6 MHz input frequency, i.e., fourfold pulse count up to 2.4 MHz

A/D converter performance

n 6-bit resolution

n 10 MSPS

Encoder supply voltage

n 5 V/1.5 A

n Shared with digital incremental encoder interface

CAN interface

Configuration

n 1 channel based on SAB 80C164 microcontroller

n ISO DIS 11898-2 CAN high-speed standard

Serial interface

Baud rate

n Max. 1 Mbit/s

Configuration

n TL6C550C single UART with FIFO

n PLL-driven UART for accurate baud rate selection

n RS232/RS422 compatibility

n Up to 115.2 kBd (RS232)

Baud rate

n Up to 1 MBd (RS422)

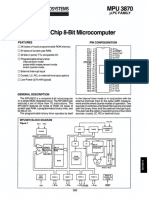

Slave DSP

Type

n Texas Instruments TMS320F240 DSP

Clock rate

n 20 MHz

Memory

n 64 Kx16 external code memory

n 28 Kx16 external data memory

n 4 Kx16 dual-port memory for communication

n 32 KB flash memory

I/O channels1)

n 16 A/D converter inputs

n 10 PWM outputs

n 4 capture inputs

n 2 serial ports

Input voltage range

n TTL input/output level

n A/D converter inputs: 0 5 V

Output current

Host interface

n Max. 13 mA

n Plug & Play support

n Requires a full-size 16-bit ISA slot

Physical

characteristics

Physical size

n 340 x 125 x 45 mm (13.4 x 4.9 x 1.77 in)

Ambient temperature

n 0 50 C (32 122 F)

Cooling

n Passive cooling

Power supply

n +5 V 5%, 4 A

n +12 V 5%, 0.75A

n -12 V 5%, 0.25A

316

2014

1)

The exact number of I/O channels depends on your configuration and is described in the user documentation.

dSPACE GmbH Rathenaustrae 26 33102 Paderborn Germany info@dspace.de www.dspace.com

Single-Board Hardware / DS1103 PPC Controller Board

Product

Order Number

DS1103 PPC Controller Board

n DS1103

Introduction

Order Information

Relevant Software and Hardware

Software

Order Number

n DS1103 Real-Time Library

n Experiment and Platform Manager for hardware management

Required

Optional

n Real-Time Interface (RTI) (p. 56)

n RTI

n Microtec C Compiler for PowerPC (p. 94)

n CCPPPC

n Real-Time Interface CAN Blockset (p. 68)

n RTICAN_BS

n Real-Time Interface CAN MultiMessage Blockset (p. 70)

n RTICANMM_BS

n ControlDesk Next Generation (p. 102 )

See p. 102

n Platform API Package (p. 168)

n PLATFORM_API

n MotionDesk (p. 134)

n MotionDesk

Order Number

Optional

n Connector Panel (p. 326)

n CP1103

n Connector/LED Combi Panel (p. 326)

n CLP1103

n Set of adapter cables for DS1103

n ADP_CAB1103

Software

Hardware

Application Fields

Included

PC

ISA Bus

Host

Interface

PowerPC

750GX

Hardware

Block Diagram

Slave

DSP I/O

96 MB

Communication

SDRAM

PWM

1 x 3-Phase

4 x 1-Phase

TMS320F240

DSP

Local Bus

2 General

Purpose

Timers

Interrupt

Controller

Dual Port

RAM

DAC

8 channels

16-bit

Incr. Encoder

7 channels

Digital I/O

32 channels

Serial

peripheral

interface

Serial

communication

interface

16- / 32-bit I/O Bus

ADC

20 channels

16-bit

Analog Input

16 ch. 10-bit

Serial

Interface

RS232/RS422

Dual Port

RAM

Digital I/O

18 bits

CAN Interface

on 80C164

Master PPC I/O

DS1103

2014

dSPACE GmbH Rathenaustrae 26 33102 Paderborn Germany info@dspace.de www.dspace.com

317

Support and Maintenance

32 MB

Application

SDRAM

Engineering

4 Capture

Inputs

Single-Board Hardware / DS1103 PPC Controller Board

Graphical Configuration of the Controller Board

Using RTI

With Real-Time Interface (RTI, p. 56), you can easily run your

Simulink models on the controller board. You can configure

all I/O graphically by using RTI. Thereby, the implementation

time is reduced to a minimum. With the RTI CAN Blockset

(p. 68), CAN configurations can be completely carried out

in a Simulink block diagram, with very little effort.

RTI CAN MultiMessage Blockset (p. 70) for graphical configuration

of CAN interfaces.

Real-Time Interface (p. 56) provides Simulink blocks for convenient

configuration of items such as A/D, D/A, digital I/O lines, incremental

encoder interface and PWM generation.

318

2014

dSPACE GmbH Rathenaustrae 26 33102 Paderborn Germany info@dspace.de www.dspace.com

Introduction

Single-Board Hardware / DS1103 PPC Controller Board

Robotics

Easy Handling

In the example below, the controller board replaces the

position controller. The easy programmability of the DS1103

enables you to implement and test different control algorithms very quickly, which reduces design iteration times

to a minimum. The prototyping hardware allows easy

parameter changing and modification, without any hardware

setup changes.

Application Fields

Rapid Control Prototyping in Robotics

The DS1103 provides six digital incremental encoder inter

faces. This is sufficient to pick up all the movements of

a six-joint robot. Thus, this cost-effective single-board

hardware makes it possible to perform rapid control

prototyping in robotics.

Hardware

Software

Calculating Values

The real-time system picks up the robots six incremental

encoder signals to determine the current robot position.

Then this data is compared with the reference values.

Afterwards, the DS1103 calculates the control algorithm

and sends the controller output for example, data on

positions and velocities back to the robot.

Further Processing Potential

All reference values are calculated in real-time, even for

inverse kinematics with highly nonlinear functions. External sensors such as axis-force momentum sensors can be

included. Performing trajectory planning and advanced

algorithms for collision avoidance is also very convenient

with the DS1103 PPC Controller Board.

2014

dSPACE GmbH Rathenaustrae 26 33102 Paderborn Germany info@dspace.de www.dspace.com

319

Support and Maintenance

Engineering

Calculating a control algorithm for robotics on a DS1103 PPC Controller Board.

You might also like

- A Statement of MotivationDocument1 pageA Statement of MotivationSana SyedNo ratings yet

- Recommendation Form STD Room PDFDocument1 pageRecommendation Form STD Room PDFSana SyedNo ratings yet

- Approved A Cad Cal 20171816 FebDocument9 pagesApproved A Cad Cal 20171816 FebSana SyedNo ratings yet

- 17 en 170 Lstage DatasheetDocument1 page17 en 170 Lstage DatasheetSana SyedNo ratings yet

- Recommendation Form STD Room PDFDocument1 pageRecommendation Form STD Room PDFSana SyedNo ratings yet

- Elvis UmDocument98 pagesElvis UmMaría Soledad BosmedianoNo ratings yet

- Buckling Cylindrical ShellDocument10 pagesBuckling Cylindrical ShellSana SyedNo ratings yet

- Linear Algebra Done WrongDocument284 pagesLinear Algebra Done WrongJamieP89100% (2)

- Linear ProgrammingDocument66 pagesLinear ProgrammingsagarbolisettiNo ratings yet

- Introduction To Linear ProgrammingDocument12 pagesIntroduction To Linear ProgrammingSana SyedNo ratings yet

- 1st Sem RegistrationDocument2 pages1st Sem RegistrationSana SyedNo ratings yet

- Guidelines For Preparing ThesisDocument12 pagesGuidelines For Preparing ThesisSana SyedNo ratings yet

- Guidelines For Preparing ThesisDocument12 pagesGuidelines For Preparing ThesisSana SyedNo ratings yet

- Triple Point ExperimentDocument2 pagesTriple Point ExperimentSana SyedNo ratings yet

- Very Imp Univ InfoDocument14 pagesVery Imp Univ InfoSana SyedNo ratings yet

- Application of CryogenicsDocument15 pagesApplication of CryogenicsSana SyedNo ratings yet

- Gate 2009 MechDocument12 pagesGate 2009 MechJithender GoudNo ratings yet

- Introduction To Matlab: Basic TutorialDocument6 pagesIntroduction To Matlab: Basic TutorialSana SyedNo ratings yet

- The Stock Market For BeginnersDocument6 pagesThe Stock Market For BeginnersSana SyedNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Xerox Phaser - 7700 Service ManualDocument380 pagesXerox Phaser - 7700 Service ManualSaranovicu KrstoNo ratings yet

- Iq7a DS en UsDocument2 pagesIq7a DS en Usdfgdgg dagaggNo ratings yet

- Simpledsp: A Fast and Flexible DSP Processor Model: (Extended Abstract)Document6 pagesSimpledsp: A Fast and Flexible DSP Processor Model: (Extended Abstract)Alex ObrejanNo ratings yet

- EC-Type Examination Certificate: Bureau VeritasDocument3 pagesEC-Type Examination Certificate: Bureau VeritasJAntonio De la CruzNo ratings yet

- HP Printer Common Failure SolutionsDocument21 pagesHP Printer Common Failure SolutionsMichael Chong ANo ratings yet

- Festo Products For Your Everyday Automation NeedsDocument7 pagesFesto Products For Your Everyday Automation NeedsDeddy TandraNo ratings yet

- Assignment-1 Microwave Transmission Lines: Microwaves and Radar 10EC54Document2 pagesAssignment-1 Microwave Transmission Lines: Microwaves and Radar 10EC54Mr saifan and Mr shehzadNo ratings yet

- THZ Channel For 6GDocument40 pagesTHZ Channel For 6Gshahnaz1981fatNo ratings yet

- Ceramic Materials For 5g Wireless CommunicationsDocument14 pagesCeramic Materials For 5g Wireless CommunicationsMirela CimpanuNo ratings yet

- Introduction To Linear OptimizationDocument5 pagesIntroduction To Linear Optimizationhadj salimNo ratings yet

- Error Correction Coding: Part 5Document9 pagesError Correction Coding: Part 5logikkNo ratings yet

- Standard Microsystems Corporation: Features Pin ConfigurationDocument8 pagesStandard Microsystems Corporation: Features Pin ConfigurationВячеслав НебесныйNo ratings yet

- Digital IC List AlllllDocument3 pagesDigital IC List AlllllDeepa DevarajNo ratings yet

- G2-32 Circuit Breakers and Trip Units Molded Case Circuit Breakers - Trip UnitsDocument2 pagesG2-32 Circuit Breakers and Trip Units Molded Case Circuit Breakers - Trip Unitsbaskaranjay5502No ratings yet

- PD-T0414 - End of LineDocument7 pagesPD-T0414 - End of LineFer Escalona100% (1)

- Pozar 4ed Prob-Ch3Document4 pagesPozar 4ed Prob-Ch3Arlyn BatistaNo ratings yet

- Esp32-Pico-V3-02 DatasheetDocument33 pagesEsp32-Pico-V3-02 Datasheetuuu_raduNo ratings yet

- Introduction To Digital AgeDocument5 pagesIntroduction To Digital AgeRylleMatthanCorderoNo ratings yet

- Lesson Plan in ComputerDocument3 pagesLesson Plan in ComputerAngelo SorianoNo ratings yet

- PendriveDocument6 pagesPendriveSubodh SonawaneNo ratings yet

- URC2981 All Languages NO LearningDocument72 pagesURC2981 All Languages NO LearningFernando Gabriel Vizcarra QuirozNo ratings yet

- Lab 06Document4 pagesLab 06AafaqIqbalNo ratings yet

- R5888C Quadramho A4RBDocument336 pagesR5888C Quadramho A4RBdbeard811100% (1)

- Ipasolink Series: System OverviewDocument69 pagesIpasolink Series: System Overviewธนวรรณ โภคาอนนต์100% (3)

- Diffrerential Amp. Tut.Document56 pagesDiffrerential Amp. Tut.Hassan Al BaityNo ratings yet

- EENG 271 Signals and Systems: Linear FunctionDocument13 pagesEENG 271 Signals and Systems: Linear Functionmohammed alansariNo ratings yet

- Storage DevicesDocument35 pagesStorage Devicesابن الدولهNo ratings yet

- Netpro Operation Manual 2k0 4k0 Va PDFDocument20 pagesNetpro Operation Manual 2k0 4k0 Va PDFArieHardiansyahNo ratings yet

- Semiconductor KTA1266: Technical DataDocument2 pagesSemiconductor KTA1266: Technical Dataserrano.flia.coNo ratings yet

- Argus For Asia Sae Ue Ms Cu WeDocument2 pagesArgus For Asia Sae Ue Ms Cu WeAANo ratings yet