Professional Documents

Culture Documents

Comments Resolution Sheet (CRS) : No. QP Comments Contractor Response

Uploaded by

Anonymous OAMBsCrBOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Comments Resolution Sheet (CRS) : No. QP Comments Contractor Response

Uploaded by

Anonymous OAMBsCrBCopyright:

Available Formats

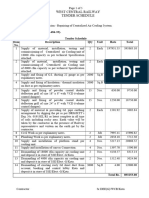

COMMENTS

RESOLUTION SHEET [

CRS ]

CONTRACT NUMBER : GC14104300

QP PROJECT

3788

NUMBER

CONTRACT TITLE : EPIC FOR NEW SOUR GAS COMPRESSOR AT NGL-3 PLANT, MESAIEED

QP EXTERNAL TRANSMITTAL REFERENCE :

EDM/GC14104300/EXT/TN/2828

DOCUMENT NUMBER : 3788-M3MP-1-19-0017

DATE

05-05-16

DOCUMENT

0

REVISION

DOCUMENT TITLE : Method Statement for Installation of Temporary Supports for Valve Assembly in

Cooler Area

No.

10

QP COMMENTS

All weld joints carried out for the purpose of providing

temporary support to be approved after conducting

proper inspection tests.

In JSA 1. Activity no.3 - Add: No simultaneous works below

the scaffolding.

2. Activity no.6 - Add: in control measures for

electrocution, ensure proper earthing to the

equipment and records to be kept at site. All power

tools to be double insulated.

3. Activity no.6 - In Hazards column, add sharp

edges.

4. 4. Add activity - refixing of existing support to the

newly cast concrete. Include

the corresponding

hazards and control measures.

5. 5. Include waste management as separate activity.

In JSA 1. Activity no.3 - Add: No simultaneous works below

the scaffolding.

2. Activity no.6 - Add: in control measures for

electrocution, ensure proper earthing to the

equipment and records to be kept at site. All power

CONTRACTOR RESPONSE

Noted and added. See Item 8.7

1. Activity no.3 has been revised,

2. Note, and added. See Activity no.6

3. Added in Activity no.6.

4. Noted, please see revised activity no.08

5. Noted, new section added. Please see activity no.09

Comments repeated (See CONTRACTOR response above in No#02)

tools to be double insulated.

3. Activity no.6 - In Hazards column, add sharp

edges.

4. Add activity - refixing of existing support to the

newly cast concrete. Include the corresponding

hazards and control measures.

5. 5. Include waste management as separate activity.

Cutting, demolition of the existing pavement below

and very near the existing pipes, cable trays, and

structures shall be done manually.

For any use of Mechanical equipment for the

works, It shall be discussed on site and after QP

NGL Safety &

Operations approval the work may proceed.

A Full time Safety Officer shall be placed on this

area specifically to monitor the Safe work

procedure.

Finally, this shall be subject to approval from the

End User.

In Section :1. Upon completion of the inspection stated in item #

7, all existing anchor bolts connecting the supports

to the existing pavement slab shall be removed

prior to pavement breaking. These bolts shall be

cast in during the reinstatement of the same

pavement.

2. Concrete chipped and the post drilled bolt holes

made on existing pavement as per item # 4 of this

section shall be repaired and re-instated with

approved concrete repair grout and mortar after

removal of the temporary supports.

3. Cast in site temporary pipe support foundation /

sleeper (item # 2) shall be provided with proper

lifting hooks or sleeves to enable removal of this

foundation after the removal of the temporary

supports.

Item 5 states: Beams will be placed manually?

Please specify the weight of these beams.

Noted. Please see Item 8.11

All equipment will be inspected prior to mobilization and will

be indicated in permit. Approval of permit will be considered

as approval of operations to commence work.

A full time safety Office will be placed in the area during

working period.

Approval of this method statement and permit will be

considered as approval from end user.

Noted and incorporated. Please see Item 8.10 & 8.15

Noted and incorporated. Please see Item 8.16

Temporary foundation will be demolished and debris disposed

in designated area. Please see item 8.17

Maximum member weight is 400 Kg.

Shifting of beams under the pipe rack to the location by using Manual

Hydraulic trolley, Placing the Temporary supports to its location by

using lifting tools (Slings, Ropes, etc.) & Manual Hydraulic trolley.

Please see item 8.4

Also consider adding: "...or by use of mechanical aids

(chain blocks)".

6 7.3 If there is a likelihood that the excavation could

reach 1.2m depth, then it is much better to focus on the

higher severity risk and treat this activity as a confined

space and have all the standard controls in place i.e. all

personnel shall undergo confined space training, gas

monitoring, access/egress, emergency response etc.

Due to the existing services and the space constraint, mechanical

lifting is not possible.

IP-OPS-027 - Gas Operations-Confined Space will be followed.

Please see 7.3.6

Please add: Detailed review of the latest as-built underground information/drawings with QP Asset Holder.

Noted and incorporated. Please see Item 7.1.4

Add Vibrator to the list of equipment

Added. Please see Item 6.1.13. Works will be carried out as per

Approved Method statement for concrete works referred in Item 3.

Due to the existing services lifting operations cannot be carried out

using equipment. Hence, lifting will be manual means only.

Item 7.2.4, Contractor to include Approved lifting plan

prior to work start.

b) Item 8.0.9, Contractor to include Surround equipment

as-built elevation, to provide survey report reference to

monitor if any settlement occurred during construction &

completion of work.

c) Item 8.0, Contractor to include requirements for civil

activities for compaction test for formation level prior to

blinding & backfilling layer by layer as per projects specs

requirements.

d) Temporary support requires design calculations &

approval by engineer prior to implementation /

execution.

Approved project survey bench mark will be used to record level.

Please see Item 8.9

Works will be carried out as per Approved Method statement for

Earthworks referred in Item 3. Please see Item 8.14

Document approved in Code-2. AFC document will be available prior

to commencement of work.

You might also like

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideFrom EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideRating: 4 out of 5 stars4/5 (8)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Building Specification (MPWT) បទដ្ឋានសំណង់ PDFDocument56 pagesBuilding Specification (MPWT) បទដ្ឋានសំណង់ PDFMonny MOM100% (1)

- Industrial Process Plant Construction Estimating and Man-Hour AnalysisFrom EverandIndustrial Process Plant Construction Estimating and Man-Hour AnalysisRating: 5 out of 5 stars5/5 (1)

- GRP ProcedureDocument42 pagesGRP Proceduremansih45775% (4)

- Wip - Mepfs ChecklistsDocument12 pagesWip - Mepfs Checklistsdanny50No ratings yet

- Planning Scheduling and Reporting ProcedureDocument18 pagesPlanning Scheduling and Reporting Procedureendika alfan100% (2)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- RFP RefDocument31 pagesRFP RefHicham MedgazNo ratings yet

- 1.0 ITP - Pole Inspection and Test Plan R1Document7 pages1.0 ITP - Pole Inspection and Test Plan R1iobtecNo ratings yet

- Erection of DPC Clinker Silo Extraction-2Document7 pagesErection of DPC Clinker Silo Extraction-2RajuNo ratings yet

- Job Procedure For Pile Load TestDocument30 pagesJob Procedure For Pile Load Testpratimwhite100% (1)

- Radiography - Film Quality ChecklistDocument4 pagesRadiography - Film Quality ChecklistNatraji100% (1)

- Dokumen - Tips - Lighting High Mast Installation ProcedureDocument41 pagesDokumen - Tips - Lighting High Mast Installation Procedurekatiki216No ratings yet

- CV-0013-002 - Method Statement For Soil Improvement WorkDocument14 pagesCV-0013-002 - Method Statement For Soil Improvement Work한상호No ratings yet

- Method Statement For CB Replacement Job at MarmulDocument4 pagesMethod Statement For CB Replacement Job at MarmulJohn George100% (2)

- Method Statement Piping Works DABBIYADocument11 pagesMethod Statement Piping Works DABBIYAsivaparthiban100% (3)

- 16P038 Alehasa-BOQ Type 1 - With PC RatesDocument80 pages16P038 Alehasa-BOQ Type 1 - With PC RatesjatinNo ratings yet

- Cable Tray BKM 7105Document8 pagesCable Tray BKM 7105Utku Can KılıçNo ratings yet

- Ms Ahu, Fcuand FansDocument36 pagesMs Ahu, Fcuand FansUmair Liaqat100% (1)

- Epic For Upgrade of Port Control Tower and Systems at RlicDocument8 pagesEpic For Upgrade of Port Control Tower and Systems at RlicsreeNo ratings yet

- Book To PrintDocument291 pagesBook To PrintIan Untalan67% (6)

- Major Process Equipment Maintenance and RepairFrom EverandMajor Process Equipment Maintenance and RepairRating: 4 out of 5 stars4/5 (4)

- Method Statement For Sheet PilingDocument8 pagesMethod Statement For Sheet PilingAbdul Muneer PalapraNo ratings yet

- API 510 VesselsDocument11 pagesAPI 510 Vesselsmoonstar_dmeNo ratings yet

- Mackintosh Probe TestDocument9 pagesMackintosh Probe Testmyke_0101100% (2)

- Spe 76-201 Sep 2012Document9 pagesSpe 76-201 Sep 2012akashdruva892No ratings yet

- MS-M-063 Rev. 1 - Air Fin Cooler InstallationDocument6 pagesMS-M-063 Rev. 1 - Air Fin Cooler InstallationwalitedisonNo ratings yet

- Catalyst Loading by Sock Method Single Bed Reactor Normal AtmosphereDocument5 pagesCatalyst Loading by Sock Method Single Bed Reactor Normal Atmospherevishal bailurNo ratings yet

- Aux Boiler - Karan REV.03Document14 pagesAux Boiler - Karan REV.03sharif339No ratings yet

- 420kV Reactor - Rev - 08Document83 pages420kV Reactor - Rev - 08Anil Marturi100% (1)

- Escalator Rehabilitation Specifications - Rev 1Document58 pagesEscalator Rehabilitation Specifications - Rev 1Nordiana IdrisNo ratings yet

- Method Statement For Drainage & Vent PipingDocument6 pagesMethod Statement For Drainage & Vent Pipingsujan198050% (2)

- Plant & Guide Wall ConstructionDocument10 pagesPlant & Guide Wall ConstructionAnonymous S7Cq7ZDgPNo ratings yet

- Skimming Job GeneralDocument5 pagesSkimming Job Generalvishal bailurNo ratings yet

- 3281-RP124-2!19!0001 (Method S... Ment Cable Installation) 1Document16 pages3281-RP124-2!19!0001 (Method S... Ment Cable Installation) 1Pradeep Kumar MaraptlaNo ratings yet

- Method Statement For Execution of Jet Grout Columns Works - 2nd CommentDocument3 pagesMethod Statement For Execution of Jet Grout Columns Works - 2nd Commenthessian123100% (1)

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- Method Statement For Installation of Diesel Generator SetDocument7 pagesMethod Statement For Installation of Diesel Generator SetAnonymous 8xHUWB100% (5)

- JPK-056-07-Q-0794 - Rev 1Document84 pagesJPK-056-07-Q-0794 - Rev 1aibekNo ratings yet

- GIS Specification 28.12Document265 pagesGIS Specification 28.12Som Prakash Gangwar100% (2)

- Visual Inspection Pr.Document7 pagesVisual Inspection Pr.mtariqmasood100% (1)

- 025-Pro For Sewer & Drainage PDFDocument25 pages025-Pro For Sewer & Drainage PDFKöksal PatanNo ratings yet

- Method Statement For Room Control UnitDocument14 pagesMethod Statement For Room Control UnitshareyhouNo ratings yet

- ProfessionalPractice - FAQ (For BEM's Website) PDFDocument17 pagesProfessionalPractice - FAQ (For BEM's Website) PDFgilbert850507No ratings yet

- Commissioning of Combined Heat and Power PlantsDocument27 pagesCommissioning of Combined Heat and Power PlantscmdcscribdNo ratings yet

- Catalyst Loading by Dense Method (SingleBed) in Inert AtmosphereDocument5 pagesCatalyst Loading by Dense Method (SingleBed) in Inert Atmospherevishal bailurNo ratings yet

- Technical SpecificationsDocument135 pagesTechnical SpecificationsSrinivasan RajenderanNo ratings yet

- Loading of ReactorsDocument3 pagesLoading of ReactorsVishal BailurNo ratings yet

- JCT Suite PDFDocument18 pagesJCT Suite PDFTamer KhalifaNo ratings yet

- Comments Resolution Sheet (CRS) : No. QP Comments Contractor ResponseDocument3 pagesComments Resolution Sheet (CRS) : No. QP Comments Contractor ResponseMyjaz JazNo ratings yet

- Section 555 Directional Bore 555-1 DescriptionDocument7 pagesSection 555 Directional Bore 555-1 Descriptiongplese0No ratings yet

- NTPC Singrauli 1-2021-03-30-04 21 23Document28 pagesNTPC Singrauli 1-2021-03-30-04 21 23Shashivendra ShuklaNo ratings yet

- Check List For: Screed Works: Subcontractor Contractor Section of Work: Civil LOCATION: Parcel 18, Plot 405 LevelDocument6 pagesCheck List For: Screed Works: Subcontractor Contractor Section of Work: Civil LOCATION: Parcel 18, Plot 405 LevelAminovic PlusNo ratings yet

- TTender Schedule EL-50-67-2020-21Document5 pagesTTender Schedule EL-50-67-2020-21kaygupta301102No ratings yet

- Rotating Equipment Installation ProcedureDocument2 pagesRotating Equipment Installation ProcedureathithancapeNo ratings yet

- HybridDocument187 pagesHybridKamila WehbeNo ratings yet

- Section 5 Construction PhilosophyDocument11 pagesSection 5 Construction Philosophyjeya vasanthNo ratings yet

- If TCCDocument38 pagesIf TCCKasturi MJNo ratings yet

- OregonDocument8 pagesOregonPriya NaiduNo ratings yet

- Fire Protetion Alarm Check ValveDocument7 pagesFire Protetion Alarm Check ValveAbdul HakkimNo ratings yet

- JMS - Snuffing Pipe Installation Rev 1Document17 pagesJMS - Snuffing Pipe Installation Rev 1mohd as shahiddin jafriNo ratings yet

- Method StatementDocument9 pagesMethod Statementtmopeli3130No ratings yet

- Important ErectionDocument15 pagesImportant ErectionVino Sankar100% (1)

- 8 NCC Etp Vol II Sec C1-ADocument4 pages8 NCC Etp Vol II Sec C1-AShanjiNo ratings yet

- Petrol & Gas Construction Co.: Elevator Shaft ErectionDocument9 pagesPetrol & Gas Construction Co.: Elevator Shaft ErectionBoj MingiNo ratings yet

- Method StatementDocument4 pagesMethod StatementshyankaranNo ratings yet

- MS For Removal and Reinstatement of Wind Dust BarrierDocument7 pagesMS For Removal and Reinstatement of Wind Dust BarrierPartheeban SkpNo ratings yet

- DT 5474-012 (Submission of Internal KIRK DWGS)Document1 pageDT 5474-012 (Submission of Internal KIRK DWGS)Anonymous OAMBsCrBNo ratings yet

- Concrete Paving Paiint For Instrument Cable Trench - Green: Doc. No.: 3788-MS-CIV-0079 Rev.1 Page 17 of 35Document3 pagesConcrete Paving Paiint For Instrument Cable Trench - Green: Doc. No.: 3788-MS-CIV-0079 Rev.1 Page 17 of 35Anonymous OAMBsCrBNo ratings yet

- Q CON Emergency NumbersDocument2 pagesQ CON Emergency NumbersAnonymous OAMBsCrBNo ratings yet

- Chiyoda Almana Chiyoda AlmanaDocument1 pageChiyoda Almana Chiyoda AlmanaAnonymous OAMBsCrBNo ratings yet

- Weekly Meeting Minutes of Meeting: Qcon Head Office-C Ring RoadDocument2 pagesWeekly Meeting Minutes of Meeting: Qcon Head Office-C Ring RoadAnonymous OAMBsCrBNo ratings yet

- C002 802 SC 001 Rev 0 SCADocument13 pagesC002 802 SC 001 Rev 0 SCAAnonymous OAMBsCrBNo ratings yet

- LETTER of INTENT (RGCP-475) Site Preparation, Grading and Installation O...Document4 pagesLETTER of INTENT (RGCP-475) Site Preparation, Grading and Installation O...Anonymous OAMBsCrBNo ratings yet

- Part 1 - Division 1 - General RequirementsDocument143 pagesPart 1 - Division 1 - General RequirementssrivasthuNo ratings yet

- Planning Guide Hans en Pole BuildingsDocument8 pagesPlanning Guide Hans en Pole BuildingsSandy MundrickNo ratings yet

- 01 50 00 Temporary Facilities and ControlsDocument15 pages01 50 00 Temporary Facilities and ControlsShahid AkramNo ratings yet

- Up PWD Standard Bidding Document T-2Document61 pagesUp PWD Standard Bidding Document T-2Hs ChopraNo ratings yet

- Opss - Prov 100 Apr10Document81 pagesOpss - Prov 100 Apr10Dan OrrettNo ratings yet

- Agreement Between Owner & ConctractorDocument4 pagesAgreement Between Owner & ConctractorValesh MonisNo ratings yet

- Notice Inviting TenderDocument52 pagesNotice Inviting Tenderruchita vishnoiNo ratings yet

- Tendernotice 1 PDFDocument43 pagesTendernotice 1 PDFKrunal SiddhapathakNo ratings yet

- Part 3 Practice Note 2 - Architects Responsibility in Setting Out BuildingDocument3 pagesPart 3 Practice Note 2 - Architects Responsibility in Setting Out BuildingzamsiranNo ratings yet

- Full CatalogueDocument80 pagesFull Cataloguegeorgeh101No ratings yet

- CEPMDocument37 pagesCEPMTanmaya Kumar SahooNo ratings yet

- AHM Abdur RazzakDocument8 pagesAHM Abdur RazzakMd. Juwel MondolNo ratings yet

- Factors Affecting Subcontracting StrategyDocument12 pagesFactors Affecting Subcontracting StrategyAbdulrahman NogsaneNo ratings yet

- Contractor RIghts To Finish EarlyDocument12 pagesContractor RIghts To Finish EarlysckchrisNo ratings yet

- Relation Between Employer and Subcontractor and Its Effect On EmployeeDocument7 pagesRelation Between Employer and Subcontractor and Its Effect On EmployeeAmbrielLNo ratings yet

- Construction and Projects in Oman: OverviewDocument11 pagesConstruction and Projects in Oman: OverviewU4rayNo ratings yet

- Adopting Design and Build D and B As AnDocument12 pagesAdopting Design and Build D and B As AnPyramid ConsultNo ratings yet

- Ankerlig Additional Storage TanksDocument48 pagesAnkerlig Additional Storage Tanksmarina890416No ratings yet

- CC Commissioning PlanDocument65 pagesCC Commissioning PlanMohammed MuzakkirNo ratings yet

- QCS 2014 01-1 General IntroductionDocument10 pagesQCS 2014 01-1 General IntroductionFreeOccupiedNo ratings yet

- Assignment No 6 - PUPOU MSCM Project ManagementDocument6 pagesAssignment No 6 - PUPOU MSCM Project ManagementLeandro Dar JuanNo ratings yet