Professional Documents

Culture Documents

Model 933 H S Analyzer: Process Instruments Process Instruments

Uploaded by

Anonymous zMWvcTOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Model 933 H S Analyzer: Process Instruments Process Instruments

Uploaded by

Anonymous zMWvcTCopyright:

Available Formats

WESTERN RESEARCH

PROCESS INSTRUMENTS

Model 933 H2S Analyzer

Introduction

The measurement of hydrogen sulfide (H2S) is a critical

quality control parameter in natural gas and other process

industries. Conventional detection principles, such as

lead acetate tape devices, require frequent maintenance

intervention and disposal of potentially hazardous

materials (used cassette tapes). Additional problems

associated with lead acetate paper tape analyzers are:

the inherent difficulty handling H2S overload conditions

during process or pipeline upsets, sensitivity to changes in

ambient conditions and slow response speed.

The Solution

The AMETEK Western Research Model 933 is a unique

UV-based photometric analyzer system for H2S analysis

when present in concentrations below 100 ppm in

natural gas and other applications. The Model 933 uses

AMETEK Western Researchs proprietary auto carrier

chromatography sampling technique, combined with the

exceptionally high resolution, multi-wavelength AMETEK

900 Series UV optical bench to provide an accurate,

interference free measurement of H2S. The result is a

unique low level H2S analyzer that is designed to operate

unattended for six to nine months, or longer.

Class I, Div 1 and ATEX Zone 1 Version

Benefits

Extended, unattended operation for 6 9 months or longer

Self-recovery after high concentration H2S events

Fast response time to increasing or decreasing H2S concentrations

Concentration measurements of COS and methyl mercaptan (MeSH) optionally available

No consumables, reagents, or disposables other than zero gas

Applications

Gas sweetening

Pipeline quality / custody transfer

Synthetic natural gas (SNG)

Blending stations

CO2 purity

Biogas

www.ametekpi.com

AMETEK Western Researchs unique sample conditioning

system uses auto carrier frontal elution chromatography

to separate interfering species. This ensures an accurate

analysis of the H2S concentration in the gas via direct-UV

absorption spectroscopy. H2S is the first absorbing species

to elute through the chromatography column, followed by

carbonyl sulfide (COS) and methyl mercaptan (MeSH), which

are also independently measured. In normal operation, the

933 uses the analysis of the COS and MeSH concentrations

to provide real time compensation for the H2S. Optionally,

the 933 can be configured to output concentration values for

these compounds.

Two columns are employed in the 933, providing virtually

continuous monitoring of the H2S concentration. While the

first column is conditioning the gas sample, the standby

column is automatically regenerated. AMETEKs unique

frontal elution chromatography sampling system eliminates

the need for carrier gas, as the sample background gas is

used as the carrier. The Model 933 utilizes two onboard

microprocessors that provide concentration calculations, data

processing, calibration, sophisticated self-diagnostics, and

column switching control.

Class I, Div 2 Version

232.0

(9.1)

APPROX. 574.0 DOOR SWING

(22.6)

22.0

(0.87)

APPROXIMATELY

45.2 [25.4] DOOR SWING

780.0

(30.7)

656.0

(25.8)

USE

3/8" X 1-1/2" OR

M10 X 40MM

STUDS

(4 PLACES)

USE 3/8 X 1 OR

M10 x 40mm STUDS

(4 PLACES)

139.0

(5.47)

254 [10.0]

MM

(IN)

22 [0.87]

WESTERN RESEARCH

The Measurement

830 [32.7]

786 [30.9]

139

[5.47]

689

(27.1)

689 [27.1]

1185

(46.65)

1185

[46.65]

357.0

[14.1]

357

(14.1)

1016.0

(40.0)

RECOMMENDED

HEIGHT

1016 [40]

RECOMMENDED

HEIGHT

OPTIONS NOT SHOWN:

PRESSURE COMPENSATION

ENVIRONMENTAL PURGE

WHITE CELL FOR LOW RANGE

MAY NOT BE EXACTLY AS SHOWN

MAY NOT BE EXACTLY AS SHOWN

FLOOR

FLOOR

Class I, Div 1 and ATEX Zone 1 Version

Class I, Div 2 Version

Digital Communication: RS485 Modbus port; RS232/RS485

service port

Power Consumption: <500 W (excluding sample & vent line)

Power: 104 to 132 VAC, 47 to 63 Hz, <3A

207 to 264 VAC, 47 to 63 Hz, <2A

Ambient Temperature: 0C to 50C (32F to 122F)

Dimensions: HxWxD

1185 x 780 x 254 mm (46.65 x 30.7 x 9.97 in.)

Weight: Approximately 100 kg (220.5 lbs)

Approvals and Certifications:

CEC Class I, Division 1, Groups B,C,D; Ex d IIB+H2 T3

NEC Class I, Division 1, Groups B,C,D/Class 1, Zone 1,

AEx d IIB+H2 T3

Optional Class I, Division 2, Groups A, B, C, D purged

system available

ATEX II 2 G Ex d IIB T3 Gb (IIB+H2 unit verification pending)

EMC

Russian Ex Proof Certification; 1ExdIIBT3 X

Russian Gosstandart Pattern Approval

Complies with all relevant European directives

Methodology: Proprietary auto carrier frontal elution

sampling; non dispersive ultraviolet analysis for hydrogen

sulfide (H2S), carbonyl sulfide (COS) and methyl mercaptan

(MeSH)

Full Scale Ranges: ppm ranges are standard; mg/Nm3 and

other ranges are available

Standard Range:

H2S: 0 to 25 ppm min. to 0 to 100 ppm max.

COS option: 0 to 100 ppm min. to 0 to 500 ppm max.

MeSH option: 0 to 50 ppm min. to 0 to 250 ppm max.

CO2 option: 0 to 5%

Higher ranges are available upon request

Low Range:

H2S: 0 to 5 ppm min. to 0 to 50 ppm max.

COS option: 0 to 25 ppm min. to 0 to 250 ppm max.

MeSH option: 0 to 15 ppm min. to 0 to 100 ppm max.

CO2 option: 0 to 1%

Accuracy:

Standard range: 2% of full scale

Low range: 5% of full scale

Repeatability: Standard range: 2% of full scale

Zero Drift:

Standard range: less than 2% of full scale in 24 hours

Low range: less than 5% of full scale in 24 hours

Response Time, Excluding Sampling System

H2S: less than 30 seconds to 90% response

COS: less than 60 seconds to 90% response

MeSH: less than 180 seconds to 90% response

Sensitivity: 0.5% of full scale

Cross-interference: H2S concentration measurementless

than 2% of the sum of COS and MeSH

Sample Stream Requirements: Published specifications

are valid for operation in standard pipeline quality natural

gas and amine based contactor overheads. Performance

specifications may vary based upon review of detailed

stream composition for use in non-standard applications,

consult AMETEK for details

Zero Gas: Instrument zero purity carbon dioxide; UHP

nitrogen, or UHP methane. Minimum auto-zero interval is

once per 24 hours.

Process Pressure Requirement: 830 kPag to 13790 kPag

(120 psig to 2000 psig)

Maximum Sample Cell Pressure: 100 psig (6.9 barg)

Maximum Sample Gas Temperature: 50C (122F)

Typical Flow: 2.5 L/min. (5 SCFH)

Outputs: Up to 4 isolated 4-to-20 mA, loop or self-powered;

4 non-isolated 1 to 5 VDC; 5 independent sets of SPDT,

Form C, potential free alarm relay contacts, 2 A at 240 VAC

Options:

Pressure compensation

Various sample probe configurations

Heated and unheated inlet pressure regulation

Filters

Sample conditioning for non-standard

applications (includes sample pumps, sample

chiller/hydrocarbon removal)

Additional COS and MeSH component outputs

Integrated CO2 sensor

Sample and vent lines

Environmental protection (free standing

enclosure or shelter)

WESTERN RESEARCH

Performance Specifications

Model 933 H2S Analyzer

WESTERN RESEARCH

150 Freeport Road, Pittsburgh PA 15238 Tel: +1-412-828-9040, Fax: +1-412-826-0399

USA - Delaware

455 Corporate Blvd., Newark DE 19702 Tel: +1-302-456-4400, Fax: +1-302-456-4444

2876 Sunridge Way N.E., Calgary, AB T1Y 7H9

Ph. +1-403-235-8400 Fax +1-403-248-3550

www.ametekpi.com

2014, by AMETEK, Inc.

All rights reserved. Printed in the U.S.A.

F-0185 Rev 6 (0615)

Canada - Alberta

2876 Sunridge Way N.E., Calgary AB T1Y 7H2 Tel: +1-403-235-8400, Fax: +1-403-248-3550

WORLDWIDE SALES AND SERVICE LOCATIONS:

USA - Houston, Texas

Tel: +1-713-466-4900, Fax: +1-713-849-1924

FRANCE

Tel: +33 1 30 68 89 20, Fax: +33 1 30 68 89 99

BRAZIL

Tel: +55 19 2107 4100

GERMANY

Tel: +49 21 59 91 36 0, Fax: +49 21 59 91 3639

CHINA

Beijing / Tel: +86 10 8526 2111, Fax: +86 10 8526 2141

Chengdu / Tel: +86 28 8675 8111, Fax: +86 28-8675 8141

Shanghai / Tel: +86 21 6426 8111, Fax: +86 21 6426 7818

INDIA

Tel: +91 80 6782 3200, Fax: +91 80 6782 3232

One of a family of innovative process analyzer solutions from AMETEK Process Instruments.

Specifications subject to change without notice.

SINGAPORE

Tel: +65 6484 2388, Fax: +65 6481 6588

SALES, SERVICE AND MANUFACTURING:

USA - Pennsylvania

You might also like

- Product Overview For SIMATIC S7-1500Document9 pagesProduct Overview For SIMATIC S7-1500Anonymous zMWvcTNo ratings yet

- 9844 - Techdata RS 485Document2 pages9844 - Techdata RS 485Anonymous zMWvcTNo ratings yet

- Animals: Wearable Wireless Biosensor Technology For Monitoring Cattle: A ReviewDocument31 pagesAnimals: Wearable Wireless Biosensor Technology For Monitoring Cattle: A ReviewAnonymous zMWvcTNo ratings yet

- Francesco La Camera, at EBTKE ConexDocument12 pagesFrancesco La Camera, at EBTKE ConexAnonymous zMWvcTNo ratings yet

- Veryone Is A Division of Eurenco Dedicated To Cetane ImproverDocument2 pagesVeryone Is A Division of Eurenco Dedicated To Cetane ImproverAnonymous zMWvcTNo ratings yet

- PIMS YokogawaDocument15 pagesPIMS YokogawaAnonymous zMWvcTNo ratings yet

- MTL4600 - Dataset Line Fault DetectionDocument35 pagesMTL4600 - Dataset Line Fault DetectionAnonymous zMWvcTNo ratings yet

- PDS Fastron Diesel 15W 40 CI4 English VersionDocument1 pagePDS Fastron Diesel 15W 40 CI4 English VersionAnonymous zMWvcTNo ratings yet

- Amsoil Semi SyntheticDocument10 pagesAmsoil Semi SyntheticAnonymous zMWvcTNo ratings yet

- Fed Tapering This Time Would Be DifferentDocument15 pagesFed Tapering This Time Would Be DifferentAnonymous zMWvcTNo ratings yet

- Amsoil Semi SyntheticDocument10 pagesAmsoil Semi SyntheticAnonymous zMWvcTNo ratings yet

- Section 1. Identification: Safety Data SheetDocument12 pagesSection 1. Identification: Safety Data SheetAnonymous zMWvcTNo ratings yet

- Amsoil Semi SyntheticDocument10 pagesAmsoil Semi SyntheticAnonymous zMWvcTNo ratings yet

- LME Copper PDFDocument6 pagesLME Copper PDFcharansalkuti2759No ratings yet

- COVID-19 and Force Majeure Provisions in EPC Contracts and Other Construction ContractsDocument5 pagesCOVID-19 and Force Majeure Provisions in EPC Contracts and Other Construction ContractsAnonymous zMWvcTNo ratings yet

- LeisureSociety E4Document90 pagesLeisureSociety E4jelenazivkovicNo ratings yet

- Child Friendly Explanation of Coronavirus PDFDocument12 pagesChild Friendly Explanation of Coronavirus PDFNawa AndrianaNo ratings yet

- Yokogawa GS33J60F70-01ENDocument9 pagesYokogawa GS33J60F70-01ENAnonymous zMWvcTNo ratings yet

- How To Upgrade TP-LINK Pharos Devices PDFDocument3 pagesHow To Upgrade TP-LINK Pharos Devices PDFEduard José Acosta BuelvasNo ratings yet

- Virus Survival in The Environment: E.C. Pirtleandg.W. BeranDocument16 pagesVirus Survival in The Environment: E.C. Pirtleandg.W. BeranSoul LyricsNo ratings yet

- Fortune 500 CEOs Survey ResultsDocument3 pagesFortune 500 CEOs Survey ResultsPablo Pareja AyerbeNo ratings yet

- List Penyelenggara IKD Tercatat Per Januari 2020 PDFDocument6 pagesList Penyelenggara IKD Tercatat Per Januari 2020 PDFRizki Jalu HidayatNo ratings yet

- Rise and Fall of Nokia (2014)Document14 pagesRise and Fall of Nokia (2014)Amit71% (7)

- Motor 4D56TDocument76 pagesMotor 4D56TAnonymous MqPr4iNo ratings yet

- A Practitioner's Guide To Nudging PDFDocument36 pagesA Practitioner's Guide To Nudging PDFAnonymous zMWvcTNo ratings yet

- Saturated Steam FarenheitDocument22 pagesSaturated Steam FarenheitFathur Deka Aprianda0% (1)

- A Practitioner's Guide To Nudging PDFDocument36 pagesA Practitioner's Guide To Nudging PDFAnonymous zMWvcTNo ratings yet

- Tesla, Inc.'s Generic Strategy & Intensive Growth Strategies (Analysis) - Panmore InstituteDocument4 pagesTesla, Inc.'s Generic Strategy & Intensive Growth Strategies (Analysis) - Panmore InstituteAnonymous zMWvcTNo ratings yet

- CCTV PoleDocument180 pagesCCTV PoleAnonymous zMWvcTNo ratings yet

- Digital Sentry ControlPoint Operation ManualDocument62 pagesDigital Sentry ControlPoint Operation ManualAnonymous zMWvcTNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Guide To Forms of SeperationDocument32 pagesGuide To Forms of SeperationHồ ThànhNo ratings yet

- hd1000 1 Inch Pump Specs v1.1Document2 pageshd1000 1 Inch Pump Specs v1.1sf wNo ratings yet

- Daikin VRV II R-22Document346 pagesDaikin VRV II R-22Danilo FIloteo73% (11)

- Sodium-Hypochlorite - MsdsDocument3 pagesSodium-Hypochlorite - MsdsmehrNo ratings yet

- NCSE 2006 Integrated ScienceDocument19 pagesNCSE 2006 Integrated ScienceChristian PatriceNo ratings yet

- SWDocument7 pagesSWJose MontesNo ratings yet

- Bo Ride Nozzle CatalogDocument46 pagesBo Ride Nozzle CatalogsossieNo ratings yet

- Spargers - For Reaction Vessels: New From ACE..Document2 pagesSpargers - For Reaction Vessels: New From ACE..parykoochakNo ratings yet

- Equipment Erection ProcedureDocument6 pagesEquipment Erection Procedureคุณพ่อน้อง บิ๊กบอส100% (1)

- Reported by ACI/TMS Committee 216Document26 pagesReported by ACI/TMS Committee 216DIDIER ANGEL LOPEZ RINCONNo ratings yet

- End Sem Q PaperDocument2 pagesEnd Sem Q PapersantkabirNo ratings yet

- 193 Gmaw Zug Asme (Andhika Rolando 3g) WPQDocument1 page193 Gmaw Zug Asme (Andhika Rolando 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Speed TripleDocument379 pagesSpeed TriplecsavargaNo ratings yet

- Lesson 6-GlassDocument32 pagesLesson 6-Glasslewis imaNo ratings yet

- enDocument40 pagesenRegistr Registr91% (11)

- Honeywell Sensing Px3 SeriesDocument7 pagesHoneywell Sensing Px3 SeriesNicolas SirtakysNo ratings yet

- Few Aspects in Deep Drawing Process: D Swapna, Ch. Srinivasa Rao, S RadhikaDocument5 pagesFew Aspects in Deep Drawing Process: D Swapna, Ch. Srinivasa Rao, S RadhikaBoby Madesen100% (1)

- Internal Sizing of Paper - AKD - ASADocument71 pagesInternal Sizing of Paper - AKD - ASAelgendawyNo ratings yet

- Lec No.5 Screening RevDocument11 pagesLec No.5 Screening Revnoel50% (2)

- Section 05505 METAL FABRICATIONS PDFDocument13 pagesSection 05505 METAL FABRICATIONS PDFIm ChinithNo ratings yet

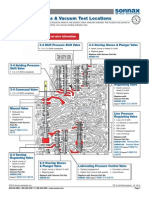

- 722 6 VacTestLocationsDocument4 pages722 6 VacTestLocationsUrszula WalczewskaNo ratings yet

- The Importance of Cleaning and Deposit Control in Improving Paper Machine EfficiencyDocument4 pagesThe Importance of Cleaning and Deposit Control in Improving Paper Machine EfficiencySelly YunitaNo ratings yet

- 2-Basic Concepts of Corrosion Science and EngineeringDocument31 pages2-Basic Concepts of Corrosion Science and EngineeringMarwin G CrispinoNo ratings yet

- Floor Sanding - Finishing TipsDocument13 pagesFloor Sanding - Finishing TipsJake LandreneauNo ratings yet

- Engineering Standard Specification For Steam TracingDocument53 pagesEngineering Standard Specification For Steam Tracingkaruna346100% (1)

- Service Manual: Tigercat T250B Track LoaderDocument176 pagesService Manual: Tigercat T250B Track LoaderGabriely MuriloNo ratings yet

- EVERBUILD® EVERFLEX® 565 Clean Room Silicone: Product Data SheetDocument3 pagesEVERBUILD® EVERFLEX® 565 Clean Room Silicone: Product Data Sheetsamira bashirvandNo ratings yet

- Hydronic Cooling - OikosDocument5 pagesHydronic Cooling - OikosShashank JainNo ratings yet

- Day 2 Chemical Engineering MCQsDocument2 pagesDay 2 Chemical Engineering MCQsRexel Reedus100% (1)

- Science Scavenger HuntDocument2 pagesScience Scavenger HuntJosie StewartNo ratings yet