Professional Documents

Culture Documents

ToolboxTalks Feb3 PDF

Uploaded by

vikubhardwaj92240 ratings0% found this document useful (0 votes)

20 views3 pagesOriginal Title

ToolboxTalks_Feb3.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

20 views3 pagesToolboxTalks Feb3 PDF

Uploaded by

vikubhardwaj9224Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

PROPER REPAIR OF ELECTRICAL CORDS

It shouldn't happen, but it does. Even

heavy duty extension cords become

damaged. Because they can be

expensive, you may be asked to make a

repair, rather than get a new cord. But

merely re-attaching and wrapping the

wires doesn't mean the repair is proper

or safe. Let's review the correct way to

repair electrical cords. The first obvious

step is often overlooked. Unplug the

cord and take control of both ends.

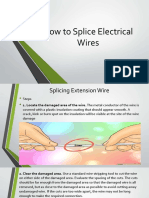

Splices: Cut back only enough of the

outer and inner insulation to make the

repair. Keep in mind that the colorcoded wires on one side need to be

connected to the like-colored wires on

the other. In other words, black-to-black,

white-to-white, green-to-green. Stagger

the lengths of the inner wire so that,

even if the insulation goes bad, the

conductors will not come in contact with

each other. If the black wire is long on

one side, it should be short on the other.

Make good mechanical connections.

Twist the conductors together and

solder, using electrical solder. The

splices now need to be insulated.

Electrical tape is not very reliable.

Shrink tubing works well. This is a

sleeve of plastic put over one of the

wires before it is connected to the other.

When the joint is completed, the sleeve

is slipped over the joint, and heated with

a small heat source. A hair dryer, match

or lighter will do. When heat is applied,

the tubing shrinks around the conductor,

forming tight insulation. We now need

to pay attention to the outer jacket. This

is important because the outer jacket

protects the inner wires from additional

damage. Shrink tubing could again be

used, although, for additional strength

and protection, it could also be wrapped

with electrical tape, duct tape, or other

durable, non-conductive material.

NOTE: See NFPA-70 (National Electric

Code) for restrictions on splicing

flexible cords.

Plugs: Remove only as much outer

jacket as is needed to make the repair.

The outer jacket must be long enough to

go into the plug or cap and be gripped by

the strain relief clamp. After the jacket

and wires are cut to length, we again

must pay attention to the color coding.

The black (or sometimes red) wire is

"hot." It goes to the smaller prong on the

plug, which has a brass screw for

attachment. The white wire is neutral. It

goes to the larger prong, which is

attached with a chrome screw. The

green wire is "ground." This goes to the

half-round or curved prong and is

attached with a green colored screw.

Make a good connection. All screws

must be tight. Reassemble the plug and

tighten the clamp until it is snug on the

cord. Do not over-tighten the clamp.

Testing: The repair is not done until the

cord has been tested. The easiest way to

check for continuity and correct wiring

is to use a simple, inexpensive test light.

This device plugs into the end of the

cord and, by way of three lights,

indicates if you have continuity and

proper polarity. If you do not, you must

redo the repair. You have created a

dangerous situation. Good repairs take

simple skills--but you cannot take

shortcuts. Incomplete or improper

repairs create fire and shock hazards. Do

the job right!

Date:

Company Name:

Project Number/Name:

Meeting Location:

Person Conducting Meeting:

Items Discussed: ______________________________________________________________________________

_____________________________________________________________________________________________

Problem Areas or Concerns: ___________________________________________________________________

_____________________________________________________________________________________________

Attendees: ___________________________________________________________________________________

_____________________________________________________________________________________________

Comments: __________________________________________________________________________________

____________________________________________________________________________________________

You might also like

- Electrical Supplies and MaterialsDocument3 pagesElectrical Supplies and Materialspartz200477% (39)

- Rebuilding The Kenwood Piggybacked Power SwitchDocument4 pagesRebuilding The Kenwood Piggybacked Power SwitchJohn Snyder100% (1)

- Electrical Cable Jointing ProceduresDocument10 pagesElectrical Cable Jointing Proceduresnt_long76No ratings yet

- Maried N T JointDocument9 pagesMaried N T JointHazmie Kun70% (10)

- Splices and JointsDocument5 pagesSplices and JointsKae OraNo ratings yet

- Phillips Screwdrivers: House Tools Used in Electrical ServicingDocument6 pagesPhillips Screwdrivers: House Tools Used in Electrical ServicingPaul OrbinoNo ratings yet

- Learn The Basics of Home Electrical WiringDocument3 pagesLearn The Basics of Home Electrical WiringZen Resti MaulanaNo ratings yet

- VU Arduino Schematic Nov 23Document16 pagesVU Arduino Schematic Nov 23Labeeb FarooqiNo ratings yet

- How To Wire A PlugDocument3 pagesHow To Wire A PlugmikigruNo ratings yet

- 05 18 Jones DEDocument14 pages05 18 Jones DEDe AbstruseNo ratings yet

- Electrical Wire Splice Basics & Definitions Splicing Electrical Wires - That Is, The Electrical Connection or Joining of Two or More Wires ThatDocument7 pagesElectrical Wire Splice Basics & Definitions Splicing Electrical Wires - That Is, The Electrical Connection or Joining of Two or More Wires ThatLee ShinrieNo ratings yet

- How To Wire A PlugDocument3 pagesHow To Wire A PlugpaulsmartNo ratings yet

- Assemble An Extension Cord: DescriptionDocument5 pagesAssemble An Extension Cord: DescriptionRichelle PilapilNo ratings yet

- Electrical Workshop - ExperimentsDocument7 pagesElectrical Workshop - ExperimentsMirza Bilal100% (1)

- 6 Common Wire Connection Problems and Their SolutionsDocument2 pages6 Common Wire Connection Problems and Their SolutionsISABELO III ALFEREZNo ratings yet

- Doble Bobina GS 125Document5 pagesDoble Bobina GS 125ROBINSON FERNEYNo ratings yet

- Ac Circuit LabDocument39 pagesAc Circuit LabmasakpNo ratings yet

- Ee04 801-EsdeDocument20 pagesEe04 801-EsdeChandra Bose KnNo ratings yet

- Working With Wire: Inside A Stranded WireDocument11 pagesWorking With Wire: Inside A Stranded WiremnamkyNo ratings yet

- css10 Week 5Document8 pagescss10 Week 5lesterNo ratings yet

- 230V LED Rope Light - Installation InstructionsDocument4 pages230V LED Rope Light - Installation InstructionsAvijit ShuklaNo ratings yet

- Types of Conductor SplicesDocument4 pagesTypes of Conductor SplicesEuropez AlaskhaNo ratings yet

- CSSDocument11 pagesCSSMichael LumanogNo ratings yet

- Extension BoardDocument4 pagesExtension BoardFiroz HKNo ratings yet

- LESSON 2 - Topic 2 - Laying Out CablesDocument4 pagesLESSON 2 - Topic 2 - Laying Out CablesMichael LaguitanNo ratings yet

- Lab No 2 PDFDocument5 pagesLab No 2 PDFaftab_sweet3024No ratings yet

- Splicing and Jointing Electrical WiresDocument35 pagesSplicing and Jointing Electrical WiresApril John ArbutanteNo ratings yet

- Ee04 801-EsdeDocument222 pagesEe04 801-EsdeChandra Bose Kn50% (2)

- Lecture On Wire Splicing and Termination: Prepared by Amit Kumer PodderDocument19 pagesLecture On Wire Splicing and Termination: Prepared by Amit Kumer PodderOxymoronic BlasphemyNo ratings yet

- Electrical EP LABDocument22 pagesElectrical EP LABsamkousNo ratings yet

- WWWWQQQQQQQQQQQQQQDocument33 pagesWWWWQQQQQQQQQQQQQQrigoberto otinianoNo ratings yet

- Engineering Immersion LabDocument30 pagesEngineering Immersion LabSudeepNo ratings yet

- Experiment # 10 Conductivity "Complete A Circuit" Stuff You NeedDocument15 pagesExperiment # 10 Conductivity "Complete A Circuit" Stuff You NeedsnholmesNo ratings yet

- Tle 8-ElectricityDocument24 pagesTle 8-ElectricityTin TinNo ratings yet

- Make The Joule Thief Circuit For Power A CFLDocument7 pagesMake The Joule Thief Circuit For Power A CFLRifi HadiNo ratings yet

- CCN - Lab 2Document5 pagesCCN - Lab 2Engr Mir Muhammad JunoNo ratings yet

- A Fish Tape Is Used To Pull Stranded or Solid Wire Through Metal or PVC ConduitDocument23 pagesA Fish Tape Is Used To Pull Stranded or Solid Wire Through Metal or PVC ConduitthewhiteeagleNo ratings yet

- Electroscopio ElectronicoDocument3 pagesElectroscopio ElectronicoavrahamscNo ratings yet

- Crimp and Test UTP Cables DemonstrationDocument6 pagesCrimp and Test UTP Cables DemonstrationYow Han LeeNo ratings yet

- How To Splice Electrical Wires: By: Raymar M. BaquilarDocument18 pagesHow To Splice Electrical Wires: By: Raymar M. BaquilarShema MerchsNo ratings yet

- Electrical Taps, Splices and JointsDocument17 pagesElectrical Taps, Splices and JointsMark PalomaresNo ratings yet

- Electrical - CT111L - LEARNING-MODULEDocument45 pagesElectrical - CT111L - LEARNING-MODULEmaling malinglingNo ratings yet

- Build It YourselfDocument6 pagesBuild It YourselfBooksNo ratings yet

- Cabos UtpDocument7 pagesCabos UtpRoberto RmoNo ratings yet

- How To Wire A Standard UK Plug: Wiring DiagramDocument1 pageHow To Wire A Standard UK Plug: Wiring DiagramrduranbNo ratings yet

- S1S2 Eee WSDocument37 pagesS1S2 Eee WShafizrahimmitNo ratings yet

- Study of Accessories, Tools Used in Wiring & Safety PrecautionsDocument38 pagesStudy of Accessories, Tools Used in Wiring & Safety Precautionssheela lNo ratings yet

- Introduction With Chapeters and WorkshopDocument10 pagesIntroduction With Chapeters and WorkshopAbrhaNo ratings yet

- General Lighting TipsDocument5 pagesGeneral Lighting TipsDeclan O'DonoghueNo ratings yet

- Electrical Wire SplicesDocument5 pagesElectrical Wire SplicesFlavy MandadoNo ratings yet

- Silver Jubilee Govt. College (A), Kurnool: Department of PhysicsDocument21 pagesSilver Jubilee Govt. College (A), Kurnool: Department of PhysicsTeja Krishna MutluriNo ratings yet

- Dual Core Balun Construction ProjectDocument7 pagesDual Core Balun Construction ProjectCarlos MerelloNo ratings yet

- Blitzpro's Step by Step Guide To Installing The Waterproof 2 Pin Connector Without The Use of Special Crimper ToolsDocument15 pagesBlitzpro's Step by Step Guide To Installing The Waterproof 2 Pin Connector Without The Use of Special Crimper Toolstypowah100% (1)

- Joe Carr's Radio Tech-Notes - Transmission LineDocument5 pagesJoe Carr's Radio Tech-Notes - Transmission LineBenjamin DoverNo ratings yet

- Application Note Fiber Optic Cable InstalllationDocument7 pagesApplication Note Fiber Optic Cable InstalllationAbduBuserNo ratings yet

- Tool ID - Electrical-AnimatedDocument67 pagesTool ID - Electrical-AnimatedAbdul QadirNo ratings yet

- Narrative ReportDocument1 pageNarrative Reportlac garcia100% (2)

- 29 Creative Conversation Strategies For The Shy Version 2 PDFDocument31 pages29 Creative Conversation Strategies For The Shy Version 2 PDFkkailaasamNo ratings yet

- The Art of Dealing With Difficult PeopleDocument30 pagesThe Art of Dealing With Difficult PeopleMarina Karamarko100% (3)

- The ThoughtsDocument28 pagesThe ThoughtsRajesh KumarNo ratings yet

- NOW Version1Document29 pagesNOW Version1vikubhardwaj9224No ratings yet

- The ThoughtsDocument28 pagesThe ThoughtsRajesh KumarNo ratings yet

- Ritschard Case Study Combustion EngineeringDocument6 pagesRitschard Case Study Combustion Engineeringvikubhardwaj9224No ratings yet

- Timeless Wisdom - Robin SharmaDocument63 pagesTimeless Wisdom - Robin Sharmasarojkrsingh100% (17)

- Gearbox Service Factor and Service Class Explained PDFDocument11 pagesGearbox Service Factor and Service Class Explained PDFvikubhardwaj9224No ratings yet

- Why Misalignment Continues To Rank As The Primary Source of Premature Rotating Machinery Failures - Michael L. SniderDocument19 pagesWhy Misalignment Continues To Rank As The Primary Source of Premature Rotating Machinery Failures - Michael L. SniderPrabhakar ChibNo ratings yet

- Hasler Process Performance Engineer at HolcimDocument10 pagesHasler Process Performance Engineer at Holcimvikubhardwaj9224No ratings yet

- Technical Development Program For Process Performance Engineers, 2008-2009Document20 pagesTechnical Development Program For Process Performance Engineers, 2008-2009vikubhardwaj9224No ratings yet

- Combustion Engineering: Technical Development Program For Process Performance EngineersDocument36 pagesCombustion Engineering: Technical Development Program For Process Performance Engineersvikubhardwaj9224100% (1)

- Burner - Standard Requirements: Technical Development Program For Process Performance EngineersDocument64 pagesBurner - Standard Requirements: Technical Development Program For Process Performance Engineersvikubhardwaj922488% (8)

- Hasler Process Performance Engineer at HolcimDocument10 pagesHasler Process Performance Engineer at Holcimvikubhardwaj9224No ratings yet

- Opening PPE Course 2008Document7 pagesOpening PPE Course 2008vikubhardwaj9224No ratings yet

- QuickGuide-Electrical Panel LabelingDocument2 pagesQuickGuide-Electrical Panel LabelingSalNo ratings yet

- Corporate Behavioural Skills - Soft Skills - TrainingDocument7 pagesCorporate Behavioural Skills - Soft Skills - Trainingvikubhardwaj9224No ratings yet

- Guide GembaDocument22 pagesGuide Gembaquycoctu100% (2)

- Safety & Standards ComplianceDocument2 pagesSafety & Standards Compliancemvijayk3No ratings yet

- Kiln Girth Gear Force CalculationDocument7 pagesKiln Girth Gear Force Calculationvikubhardwaj9224No ratings yet

- Reliability of Geared Systems PDFDocument27 pagesReliability of Geared Systems PDFvikubhardwaj9224No ratings yet

- Guide Kaizen PDFDocument17 pagesGuide Kaizen PDFArmando Palma100% (2)

- Condition Monitoring Applied To Industrial MachineryDocument9 pagesCondition Monitoring Applied To Industrial MachineryMohamed BelallNo ratings yet

- Air CompDocument21 pagesAir Compvikubhardwaj9224No ratings yet

- PumpSave 3.0 Users ManualDocument13 pagesPumpSave 3.0 Users Manualvikubhardwaj9224No ratings yet

- Why Misalignment Continues To Rank As The Primary Source of Premature Rotating Machinery Failures - Michael L. SniderDocument19 pagesWhy Misalignment Continues To Rank As The Primary Source of Premature Rotating Machinery Failures - Michael L. SniderPrabhakar ChibNo ratings yet

- Why Misalignment Continues To Rank1 ArticleDocument34 pagesWhy Misalignment Continues To Rank1 Articlevikubhardwaj9224No ratings yet

- Fluid CouplingsDocument52 pagesFluid Couplingsvikubhardwaj9224No ratings yet

- Ball Bearing StiffnessDocument14 pagesBall Bearing Stiffnessvikubhardwaj9224No ratings yet

- Introduction Energy Manager Role (Read-Only) PDFDocument18 pagesIntroduction Energy Manager Role (Read-Only) PDFvikubhardwaj9224No ratings yet