Professional Documents

Culture Documents

PDD PDF

Uploaded by

rahil_sang0 ratings0% found this document useful (0 votes)

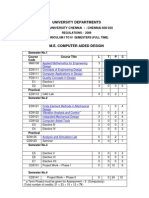

74 views7 pagesThe document outlines the scheme of examination for the M.Tech (Product Design and Development) program. It lists the subjects offered in each semester, including Product Design and Development, Materials and Manufacturing Technology, Computer Aided Geometric Design, Design for Manufacturing and Assembly, Product Interface Design, and Computer Aided Product Design. The subjects are 4 credits each and offered by the Mechanical Engineering Department. The third semester includes a State-of-the-Art Seminar and the fourth semester involves a thesis project.

Original Description:

Original Title

pdd.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document outlines the scheme of examination for the M.Tech (Product Design and Development) program. It lists the subjects offered in each semester, including Product Design and Development, Materials and Manufacturing Technology, Computer Aided Geometric Design, Design for Manufacturing and Assembly, Product Interface Design, and Computer Aided Product Design. The subjects are 4 credits each and offered by the Mechanical Engineering Department. The third semester includes a State-of-the-Art Seminar and the fourth semester involves a thesis project.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

74 views7 pagesPDD PDF

Uploaded by

rahil_sangThe document outlines the scheme of examination for the M.Tech (Product Design and Development) program. It lists the subjects offered in each semester, including Product Design and Development, Materials and Manufacturing Technology, Computer Aided Geometric Design, Design for Manufacturing and Assembly, Product Interface Design, and Computer Aided Product Design. The subjects are 4 credits each and offered by the Mechanical Engineering Department. The third semester includes a State-of-the-Art Seminar and the fourth semester involves a thesis project.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 7

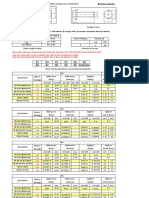

MECHANICAL ENGINEERING DEPARTMENT

MOTILAL NEHRU NATIONAL INSTITUTE OF TECHNOLOGY

ALLAHABAD-211004

Scheme of Examination

M. Tech. (Product Design and Development)

S.

No.

Semester

Name of Subject

Compulsory (C)/ Elective (E)

Subject

Credit

Code

Dept.

offering the

Weekly load

(hours

L

T

P

subject

1

Product Design and Development

ME 917

MED

Semester

Materials and Manufacturing

Technology

Computer Aided Geometric

Design

Elective I

ME 918

MED

ME 928

MED

MED

MED

Elective II

2

II

semester

Design for manufacturing and

Assembly

Product Interface Design

ME 924

MED

ME 929

MED

Computer aided Product Design

ME 930

MED

Project

ME 926

MED

MED

Elective-III

3.

4.

III

State-of-the-art Seminar

ME 998

MED

Semester

Thesis

ME 999

12

MED

IV

Thesis

ME 999

16

MED

Semester

SYLLABUS M. TECH. (PRODUCTION ENGINEERING)

FIRST SEMESTER

ME-917: PRODUCT DESIGN AND DEVELOPMENT

Introduction

Significance of product design, product design and development process, sequential

engineering design method, the challenges of product development,

Product Planning and Project Selection: Identifying opportunities, evaluate and

prioritize projects, allocation of resources

Identifying Customer Needs: Interpret raw data in terms of customers need, organize

needs in hierarchy and establish the relative importance of needs.,

Product Specifications: Establish target specifications, setting final specifications,

Concept Generation: Activities of concept generation, clarifying problem, search both

internally and externally, explore the output,

Industrial Design: Assessing need for industrial design, industrial design process,

management, assessing quality of industrial design,

Concept Selection: Overview, concept screening and concept scoring, methods of

selection.

Theory of inventive problem solving (TRIZ): Fundamentals, methods and techniques,

General Theory of Innovation and TRIZ, Value engineering Applications in Product

development and design, Model-based technology for generating innovative ideas

Concept Testing: Elements of testing: qualitative and quantitative methods including

survey, measurement of customers response,

Intellectual Property: Elements and outline, patenting procedures., claim procedure,

Design for Environment: Impact, regulations from government, ISO system.,

Text books and references:

1. Ulrich K. T, and Eppinger S.D, Product Design and Development, Tata McGraw Hill

2. Otto K, and Wood K, Product Design, Pearson

3. Engineering of creativity: introduction to TRIZ methodology of inventive Problem

Solving, By Semyon D. Savransky, CRC Press.

4. Inventive thinking through TRIZ: a practical guide, By Michael A. Orloff, Springer.

5. Systematic innovation: an introduction to TRIZ ; (theory of inventive Problem

Solving), By John Terninko, Alla Zusman, CRC Press.

ME-918: MATERIALS AND MANUFACTURING TECHNOLOGY

Scope and classification of Engineering Materials and Manufacturing Techniques.

Types, properties and uses of Metals and Alloys,

Manufacturing processes for shaping casting, deforming, sheet metal forming,

particulate processing, machining, and finishing and joining. , Advanced methods of

manufacturing: Abrasive jet cutting, Ultrasonic machining, Laser beam machining,

Electron beam and electrochemical machining.,

Superalloys: Types, properties, uses and their processing techniques. Nickel-base,

Cobalt- base and iron-base superalloys, remelting, Particulate processing, casting,

machining, rolling, forging and welding of superalloys,

Polymers: Classifications Plastics: Types, properties, uses and manufacturing processing

techniques. Thermoplastics, Thermosets, and Elastomers,

Composites: Types, properties, uses and manufacturing processing techniques. Metal

matrix composites, polymer matrix composites, ceramic matrix composites, FGM.,

Glass: Types, properties, uses and shaping processes,

Ceramics: Types, properties, uses and shaping processes,

Property enhancing and surface processing operations: cleaning and surface

treatments., Surface coating technology: Scope and classification of coating techniques.

Electroplating (metal or composite coatings), Electroless plating (metal or composite

coatings), Weld overlays (metal or ceramic coatings), Thermal spraying (metal, plastic,

ceramic, or composite coatings), Cladding (thick metal coatings), Chemical vapor

deposition (metals, graphite, diamond, diamond like carbon, and ceramics), Physical

vapor deposition (metals, ceramics, or solid lubricants), Thermoreactive

deposition/diffusion process (carbides, nitrides, or carbonitrides).,

Recent development in materials and manufacturing technology.,

REFERENCES

1.Groover, M.P., Fundamentals of Modern Manufacturing: Materials, Processes, and

Systems, Wiley Student Edition, John Wiley and Sons, 2005.

2.Budinski, K. G., (1998), Engineering Materials, Properties and Selection, Pub.

Prentice-Hall of India, New Delhi, India.

3.Batchelor, A.W., Lam, L.N. and Chandrasekaran, M, Materials Degradation and

its Control by Surface Engineering, 2nd Edition, Imperial College Press, 2003.

4.Bunshah, R. F., Handbook of Hard Coatings: Deposition Technologies, Properties

and Applications, Noyes Pub. Park Ridge, New Jersey, U. S. A./William Andrew

Publishing, LLC, Norwich, New York, U.S.A., 2001.

5.Sims, C. T., Stoloff, N. S., and Hagel, W.C., Superalloys II, John Wiley and Sons,

1987.

6.Callister W. D., Jr., Material Science and Engineering An Introduction, John Wiley

& Sons, Inc., 6th Ed., 2003.

7.Patton, W.J., Plastic Technology, Theory, Design and Manufacture; Lenton

Publishing Company.

8.Ashby, M.F., Materials Selection in Mechanical Design: Pergamon press, 1992.

ME 928: COMPUTER-AIDED GEOMETRIC DESIGN

Introduction: Design Methodology, Historical Development. Application of computers

in Product Development and Design.

Curve Modeling: Explicit and Implicit Equations, Intrinsic Equations, Parametric

Equations, Coordinate Systems, Hermite curve, four point form, Straight lines. Splines ,

Bezier curves, B-spline curves, Bezier and B-Spline curve fit. Rational Polynomials,

Introduction to NURBS.

Surface Modeling: Sixteen point form, Algebraic and Geometric form, Tangent and

Twist Vectors, Normal, Parametric space of a surface, Blending Functions, Four Curve

Form, Plane surface, Cylindrical Surface, Ruled surface, Surfaces of Revolution.

Introduction to Bezier Surface, B-Spline Surface and NURBS surface.

Solid Modeling: Introduction to solid Modeling: CSG and B-Rrep schemes.

Transformations: Translation, Rotation, Scaling Symmetry and Reflection,

Homogeneous Transformations.

Reverse Engineering: Place of Reverse Engineering in Product Development. Data

Acquisition Methods, Practical Problems in data acquisition, Preprocessing: Registration,

Segmentation, Triangulation, Definition, Surface Fitting Methods- Bezier, B-spline &

NURBS, CAD model creation.

Reference Books:

1. Mathematical Elements of Computer Graphics, Rogers and Adams, McGraw Hill.

1994

2. CAD CAM Theory and Practice: I. Zeid, Tata-McGraw Hill, 2006

3. Computer-Aided Design, R K Srivastava, Umesh Publications, Delhi, 2007, 3rd

edition

4. Geometric Modeling: Michael E. Mortenson, John Wiley, 1992.

5. Computer-Aided Engineering Design, B Sahay and A Saxena, 2004.

6. Kathryn A. Ingle, Reverse Engineering, McGraw-Hill, 2004.

7. Vinesh Raja, Kiran J. Fernades, Reverse Engineering: An Industrial Perspective,

Springer Verlag, 2006.

ME 924: DESIGN FOR MANUFACTURING AND ASSEMBLY

Introduction: Design philosophy steps in Design process General Design rules for

manufacturability basic principles of design Ling for economical production

creativity in design. Materials: Selection of Materials for design Developments in

Material technology -- criteria for material selection Material selection

interrelationship with process selection process

selection charts.

MACHINING PROCESS: Overview of various machining processes -- general design

rules for machining - Dimensional tolerance and surface roughness Design for

machining Ease Redesigning of components for machining ease with suitable

examples. General design recommendations for machined parts.

METAL CASTING: Appraisal of various casting processes, selection of casting

process, - general design considerations for casting casting tolerances use of

solidification simulation in casting design product design rules for sand casting.

METAL JOINING: Appraisal of various welding processes, Factors in design of

weidments general design guidelines pre and post treatment of welds effects of

thermal stresses in weld joints design of brazed joints. Forging Design factors for

Forging Closed die forging design parting lines of die5 drop forging die design

general design recommendations. Extrusion & Sheet Metal Work: Design guidelines for

extruded sections - design principles for Punching, Blanking, Bending, Deep Drawing

Keeler Goodman Forming Line Diagram Component Design for Blanking.

ASSEMBLE ADVANTAGES: Development of the assemble process, choice of

assemble method assemble advantages social effects of automation.

AUTOMATIC ASSEMBLY TRANSFER SYSTEMS : Continuous transfer,

intermittent transfer, indexing mechanisms, and operator - paced free transfer machine.

DESIGN OF MANUAL ASSEMBLY: Design for assembly fits in the design process,

general design guidelines for manual assembly, development of the systematic DFA

methodology, assembly efficiency, classification system for manual handling,

classification system for manual insertion and fastening, effect of part symmetry on

handling time, effect of part thickness and

size on handling time, effect of weight on handling time, parts requiring two hands for

manipulation, effects of combinations of factors, effect of symmetry effect of chamfer

design on insertion operations, estimation of insertion time.

REFERENCE BOOKS:

1. Geoffrey Boothroyd, "Assembly Automation and Product Design", Marcel

Dekker Inc., NY, 1992.

2. Engineering Design Material & Processing Approach George E. Deiter,

McGraw Hill Intl. 2nd Ed. 2000.

3. Geoffrey Boothroyd, "Hand Book of Product Design" Marcel and Dekken, N.Y.

1990.

4. A Delbainbre "Computer Aided Assembly London, 1992.

ME 929: PRODUCT INTERFACE DESIGN

Anthropometry

Anthropometric measures, reporting and use of anthropometric data, design procedure.

Workspace Design

Postural triangle, design for standing operator, design for sitting operator, design for hand

use, design for foot operation.

Auditory Interface

Process of hearing, auditory perception: pitch, loudness and timbre, digitization of sound.

Tactile Interface and Haptic Interface

Physiology of touch, haptic interface, force-feedback technologies, interaction of touch

and vision.

Visual Interface

Human eye, preattentive processing, detection, estimating magnitude, multiple attributes,

design principles.

Displays and Controls:

Visual displays: display technologies, information coding, physical characteristics.

Controls: control selection, identification.

Combining displays and controls.

Human Information Processing

Human information processing model, information coding, improving performance.

Graphic-user Interface

Screen design and layout, user action and control, appropriate appearance.

Hand Tool Design

Ergonomically oriented hand tool design, safe design for hand tool.

References :

1. Bailey, R. W., Human Performance Engineering: A guide for system designers,

Prentie Hall.

2. Sanders, S. M. and McCormick, E. J., Human Factors in Engineering and Design,

McGraw Hill.

3. Bridger, R. S., Introduction to Ergonomics, McGraw Hill.

4. Kroemer, K., Kroemer, H., and Kroemer-Elbert, K. E., Ergonomics - How to design

for ease and efficiency, Prentice Hall.

5. Dix, A., Finlay, J., Abowd, G. D. and Beale, R., Human Computer Interaction,

Pearson Education.

ME 930: COMPUTER AIDED PRODUCT DESIGN

Introduction: World Class manufacturing, Product definition, Engineering Design

Process, Prototype Design and Innovation, Impact of Cost, Quality and time, Key

Process Requirements for Rapid Prototyping.

Product Prototyping, Prototype planning and management, Prototype cost estimation,

Prototype Design Methods and tools. Materials Selection and Product Prototyping.

Phases of Prototyping. Fundamentals of R.P. Classification of R.P. Processes.

Rapid Prototyping Process: - Automated Processes, Difference between Additive and

Subtractive Processes, Process Chain, steps in involved in R.P.

Types of R.P. systems: - Liquid Based, Solid Based, & Powder Based.

Application of R.P. in Manufacturing and Rapid Tooling.

Rapid Prototyping and Manufacturing Benchmarking

Modeling practice on softwares such as IDEAS, UNIGRAPHICS, ProE, etc.

You might also like

- Product Design and Development SyllabusDocument7 pagesProduct Design and Development Syllabusharshottam2977No ratings yet

- JKDocument5 pagesJKafNo ratings yet

- Syllabus ADDocument4 pagesSyllabus ADselmarameshNo ratings yet

- Me Manufacturing Curriculum-2Document11 pagesMe Manufacturing Curriculum-2Arun KumarNo ratings yet

- MTECH Manufacturing EnggDocument10 pagesMTECH Manufacturing EnggSudhir KumarNo ratings yet

- ME Mechanical Engineering - CAD-CAMDocument29 pagesME Mechanical Engineering - CAD-CAMDilip SutariaNo ratings yet

- Fundamentals of Design and ManufacturingDocument6 pagesFundamentals of Design and Manufacturingabdul2030No ratings yet

- Part A Marks 50Document4 pagesPart A Marks 50Dhanraj PatilNo ratings yet

- Advanced ManufacturingDocument13 pagesAdvanced ManufacturingnagNo ratings yet

- Manufacturing Engineering - IDocument3 pagesManufacturing Engineering - Ias2faasbujsacNo ratings yet

- Preview of Introduction To Manufacturing Processes and Materials Manufacturing Engineering and Materials ProcessingDocument20 pagesPreview of Introduction To Manufacturing Processes and Materials Manufacturing Engineering and Materials ProcessingAnonymous 8209ZTNo ratings yet

- Fundamentals of Design and Manufacturing Material Science and Engineering Computing and Informatics Society and EnvironmentDocument3 pagesFundamentals of Design and Manufacturing Material Science and Engineering Computing and Informatics Society and EnvironmentocchityaNo ratings yet

- MNNIT, Engineering GraphicsDocument1 pageMNNIT, Engineering GraphicsMo AlamNo ratings yet

- Mechanical Pre PH.D JNTUH SyllabusDocument55 pagesMechanical Pre PH.D JNTUH SyllabusSrinivasa Reddy NallimilliNo ratings yet

- Advanced Materials and Their ProcessingDocument7 pagesAdvanced Materials and Their Processingviv84No ratings yet

- M.E. Mech (Prod Des & Devp)Document41 pagesM.E. Mech (Prod Des & Devp)Peter PushpanathanNo ratings yet

- AMIEDocument5 pagesAMIEpurushothamkrNo ratings yet

- Manufacturing Processes UTA026Document9 pagesManufacturing Processes UTA026Tania CENo ratings yet

- ManfDocument34 pagesManfAnantha NarayananNo ratings yet

- Engineering DesignDocument34 pagesEngineering DesignEmmanuel NicholasNo ratings yet

- AMIE Section B Syllabus MechanicalDocument23 pagesAMIE Section B Syllabus MechanicalparameshwaranpraveenNo ratings yet

- Fundamentals of Design and Manufacturing111111111Document10 pagesFundamentals of Design and Manufacturing111111111Pushpinder Singh Khalsa0% (1)

- Bmee304l Metal-Forming-And-Machining TH 1.0 67 Bmee304lDocument3 pagesBmee304l Metal-Forming-And-Machining TH 1.0 67 Bmee304lKrijayNo ratings yet

- Anna University, Chennai: Affiliated InstitutionsDocument36 pagesAnna University, Chennai: Affiliated InstitutionsAnonymous RCbfTbNo ratings yet

- Mn7203 Material Testing and Characterization L T P CDocument5 pagesMn7203 Material Testing and Characterization L T P CAnonymous p8bHAAxNo ratings yet

- FMP-611, 3 (2-1) Manufacturing and Reverse EngineeringDocument10 pagesFMP-611, 3 (2-1) Manufacturing and Reverse EngineeringMuhammad IrfanNo ratings yet

- Jntuk M Tech r16 Cad Cam SyllabusDocument29 pagesJntuk M Tech r16 Cad Cam Syllabusvenkata100% (1)

- Acecipe - 5. Design and Manufacturing EngineeringDocument3 pagesAcecipe - 5. Design and Manufacturing EngineeringMaryedNo ratings yet

- Section A (Diploma Stream) 1syllabusDocument4 pagesSection A (Diploma Stream) 1syllabusUjjwal ShresthaNo ratings yet

- Saurashtra University: Me Mech (Cad/Cam) 1Document19 pagesSaurashtra University: Me Mech (Cad/Cam) 1Raj K PatelNo ratings yet

- Nptel: Design For Manufacturing - Web CourseDocument3 pagesNptel: Design For Manufacturing - Web CourseChinnadurai LakshmananNo ratings yet

- Introduction, Press & MachiningDocument327 pagesIntroduction, Press & MachiningLucky DagaNo ratings yet

- Reverse Engineering SyllabusDocument2 pagesReverse Engineering SyllabusAyush SrivastavNo ratings yet

- Detailed SyllabusDocument81 pagesDetailed Syllabuspankajchandre30No ratings yet

- Section-A Syllabus AMIEDocument2 pagesSection-A Syllabus AMIEKhushbuNo ratings yet

- Computer Integrated Manufacturing 05 63xxDocument97 pagesComputer Integrated Manufacturing 05 63xxAnonymous mcFvPwzXNo ratings yet

- Jntuworld: Jawaharlal Nehru Technological University HyderabadDocument29 pagesJntuworld: Jawaharlal Nehru Technological University HyderabadpathanshamsheerkhanNo ratings yet

- ManufacturingDocument35 pagesManufacturingMichael EnglishNo ratings yet

- Manufacturing Processes SyllabusDocument14 pagesManufacturing Processes SyllabusdeekamittalNo ratings yet

- 3 0 3 3 0 3 3 0 3 3 0 3 Elective - I 3 0 3Document13 pages3 0 3 3 0 3 3 0 3 3 0 3 Elective - I 3 0 3Swaroop KumarNo ratings yet

- Rapid Prototyping and Tooling SyllabusDocument1 pageRapid Prototyping and Tooling SyllabusAravind SelvaNo ratings yet

- Rapid CastingDocument23 pagesRapid CastingquarkenNo ratings yet

- M.E. Computer Aided Design SyllabusDocument50 pagesM.E. Computer Aided Design SyllabusJoswa CaxtonNo ratings yet

- B.tech (Hons) Mechanical Course OutlineDocument16 pagesB.tech (Hons) Mechanical Course OutlineTableegi TehreekNo ratings yet

- ME CAD SyllabusDocument50 pagesME CAD Syllabussubha_aeroNo ratings yet

- Ms&e FD&MDocument2 pagesMs&e FD&Mnetwing2009No ratings yet

- r05010302 Engineering MechanicsDocument39 pagesr05010302 Engineering Mechanicsdassault megecNo ratings yet

- My PH D SyllabusDocument7 pagesMy PH D SyllabusRing MasterNo ratings yet

- NITK UG Curriculum 2014-1Document19 pagesNITK UG Curriculum 2014-1Vedang PavanjeNo ratings yet

- Microfabrication and Precision Engineering: Research and DevelopmentFrom EverandMicrofabrication and Precision Engineering: Research and DevelopmentNo ratings yet

- Engineering Applications: A Project Resource BookFrom EverandEngineering Applications: A Project Resource BookRating: 2.5 out of 5 stars2.5/5 (1)

- Ceramic Cutting Tools: Materials, Development and PerformanceFrom EverandCeramic Cutting Tools: Materials, Development and PerformanceRating: 3.5 out of 5 stars3.5/5 (3)

- Computers in Materials Technology: Proceedings of the International Conference Held at the Institute of Technology, Linköping University, Sweden, June 4-5, 1980From EverandComputers in Materials Technology: Proceedings of the International Conference Held at the Institute of Technology, Linköping University, Sweden, June 4-5, 1980T. EricssonRating: 5 out of 5 stars5/5 (1)

- SOLIDWORKS - Can't Add Forming Tool To A Part. WHY - Computer Aided TechnologyDocument8 pagesSOLIDWORKS - Can't Add Forming Tool To A Part. WHY - Computer Aided Technologyrahil_sangNo ratings yet

- Design As Art ReviewDocument9 pagesDesign As Art Reviewrahil_sangNo ratings yet

- Class Ix Commercial Studies: (Two Hours)Document4 pagesClass Ix Commercial Studies: (Two Hours)kumar utsav0% (1)

- Defining Polygon Tags-MaterialsDocument4 pagesDefining Polygon Tags-Materialsrahil_sangNo ratings yet

- Easily Reduce Size of Bloated PDF: Latest ReplyDocument7 pagesEasily Reduce Size of Bloated PDF: Latest Replyrahil_sangNo ratings yet

- Stegbar Windows Doors Standard Sizes BrochureDocument19 pagesStegbar Windows Doors Standard Sizes BrochureErika RamosNo ratings yet

- Vitris Gesamtprospekt UkDocument12 pagesVitris Gesamtprospekt Ukrahil_sangNo ratings yet

- The Designer's Story - Battista Pininfarina - PetroliciousDocument7 pagesThe Designer's Story - Battista Pininfarina - Petroliciousrahil_sangNo ratings yet

- Drag CoefficientDocument5 pagesDrag Coefficientrahil_sangNo ratings yet

- Sheet Metal Gauge Size Chart-1Document1 pageSheet Metal Gauge Size Chart-1rahil_sangNo ratings yet

- RoHS Compliance Guide - Regulations, 10 Substances, Exemptions, WEEEDocument1 pageRoHS Compliance Guide - Regulations, 10 Substances, Exemptions, WEEErahil_sangNo ratings yet

- Degrees of Protection IP, IK, NEMADocument3 pagesDegrees of Protection IP, IK, NEMArahil_sangNo ratings yet

- Gravity Component and Inlet Velocity - CFD Online Discussion ForumsDocument5 pagesGravity Component and Inlet Velocity - CFD Online Discussion Forumsrahil_sangNo ratings yet

- Australian Standards Ergonomics - The Human Factor v2 PDFDocument12 pagesAustralian Standards Ergonomics - The Human Factor v2 PDFrahil_sangNo ratings yet

- Design InspirationDocument27 pagesDesign Inspirationrahil_sangNo ratings yet

- Famous Architects - Famous BirthdaysDocument4 pagesFamous Architects - Famous Birthdaysrahil_sangNo ratings yet

- Irs B1 2001Document51 pagesIrs B1 2001ghaghra bridge100% (9)

- Lms CatalogcatalohoDocument96 pagesLms CatalogcatalohoIsmael Martinez NuñezNo ratings yet

- Whats New NX9.0.0 PDFDocument792 pagesWhats New NX9.0.0 PDFJesus Cruz SalvadorNo ratings yet

- Lab Report 06 MEMDocument12 pagesLab Report 06 MEMImdad JalaliNo ratings yet

- Library Punching TechnologyDocument96 pagesLibrary Punching TechnologyMilan Gavrovic100% (2)

- Sprintcut PDFDocument5 pagesSprintcut PDFpruthiviraj13100% (1)

- 6 Orthogonal and Oblique CuttingDocument12 pages6 Orthogonal and Oblique CuttingPRASAD326100% (6)

- Dimensions of Bolts and Nuts BS3692Document6 pagesDimensions of Bolts and Nuts BS3692azam RazzaqNo ratings yet

- Cast Iron Repair - Goltens 6Document1 pageCast Iron Repair - Goltens 6And jazNo ratings yet

- Journal of Manufacturing Processes: SciencedirectDocument13 pagesJournal of Manufacturing Processes: SciencedirectPrabhataNo ratings yet

- Development of ThreadDocument28 pagesDevelopment of ThreadAsiri UmayangaNo ratings yet

- Hyundai L2000sy L3000sy TurningcenterDocument40 pagesHyundai L2000sy L3000sy TurningcenterAndreas AnugerahNo ratings yet

- MM Buyers Guide Flange Facing-1.1Document38 pagesMM Buyers Guide Flange Facing-1.1muhamadrafie1975100% (1)

- Experimental Investigation of Mustard Oil Based Nano Cutting Fluid On CNC Turning OperationDocument13 pagesExperimental Investigation of Mustard Oil Based Nano Cutting Fluid On CNC Turning OperationIJRASETPublicationsNo ratings yet

- National Pipe Thread Chart OPT PDocument1 pageNational Pipe Thread Chart OPT PAbhi PrajapatiNo ratings yet

- Audit Criteria: AC7101/7 REV. DDocument13 pagesAudit Criteria: AC7101/7 REV. Dunknown1711No ratings yet

- v010-95001 Man2101en - V3.0Document90 pagesv010-95001 Man2101en - V3.0daniNo ratings yet

- Introduction To Work HoldingDocument29 pagesIntroduction To Work HoldingAndres Fitria FarrelNo ratings yet

- Grand Viva Questions (Mechanical 2013) - Form ResponsesDocument4 pagesGrand Viva Questions (Mechanical 2013) - Form ResponsesKalyan SinghNo ratings yet

- Mobil Machine Tool Lubricant PDFDocument66 pagesMobil Machine Tool Lubricant PDFarman chowdhuryNo ratings yet

- Prediction of CNC Machining Parameters For Teak Wood by Using SVM Method 1Document5 pagesPrediction of CNC Machining Parameters For Teak Wood by Using SVM Method 1OleksQNo ratings yet

- MPI 2023 - CNC Machining - LatheDocument15 pagesMPI 2023 - CNC Machining - LatheHisyamRedzuanNo ratings yet

- SAMPLE Mastercam X9 Multiaxis Professional CoursewareDocument33 pagesSAMPLE Mastercam X9 Multiaxis Professional CoursewareEduardo Aleman Reyna100% (1)

- Vargus - TM Solid 2018Document44 pagesVargus - TM Solid 2018jonatasgagNo ratings yet

- Wire Edm, Edg, EddgDocument23 pagesWire Edm, Edg, EddgKrishna GopalNo ratings yet

- 152 S 851 PDFDocument7 pages152 S 851 PDFDarling RajNo ratings yet

- Reverse Edm Collective Electrodes in Micro EcmDocument5 pagesReverse Edm Collective Electrodes in Micro EcmInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Vectric Cut 3d FrogmillDocument9 pagesVectric Cut 3d FrogmillDavid RuizNo ratings yet

- ELECTRON BEAM MACHINING PrashanthDocument20 pagesELECTRON BEAM MACHINING PrashanthSurender NarmetaNo ratings yet

- Ch-1 Basics of Metal Cutt PDFDocument106 pagesCh-1 Basics of Metal Cutt PDFAnkit AmbaniNo ratings yet