Professional Documents

Culture Documents

Assessing The Technical Problems of Brick Production

Uploaded by

Aziff ShafzanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Assessing The Technical Problems of Brick Production

Uploaded by

Aziff ShafzanCopyright:

Available Formats

ASSESSING THE TECHNICAL

PROBLEMS OF BRICK

PRODUCTION

A GUIDE FOR BRICKMAKERS AND FIELD-WORKERS

Introduction

These notes should help identify

brickmakers technical problems. The

problems need to be identified correctly

for a solution to be found; not always

easy when faced with a faulty brick or

batch of bricks. So, the notes try to

highlight the main problems, the

reasons for them, and possible

solutions. We'll consider the final

product, the fired brick, and trace faults

back to their cause1. In reality smallscale brickmakers often face many

problems, such as marketing, business

management, record keeping, and fuel

Figure 2: A pile of fired bricks, Alto Mayo, Peru. To

scarcity. Quality control is only one

be noted are the cracks and deficiencies in the

aspect of running a successful

bricks. Photo: Practical Action / Theo Schilderman.

enterprise. In fact, the main problem is

seldom technical. For example, it's no good upgrading the output of a brickworks, causing

extra work and expense, if customers aren't prepared to pay more for improved quality.

Nevertheless, it is worth knowing where problems originate and how they might be solved,

particularly for brickworks suffering heavy losses or unable to meet the standard their market

demands.

Field testing

Specific defects are illustrated in the tables. However,

there are some simple tests which can be done in the

field. Firstly, when you handle a brick, see if it's soft.

Can you pick off the edges? Can you scratch the

surface with your fingernail? If so, the brick is

probably underfired - one of the most common

problems. Now, break a brick in half. Was it easy? Is

there a 'core' of different colour material? If the brick

breaks easily or has a core like this, then it's

underfired. What about the cross section? Are there

lumps or stones, internal cracks or holes? If so, the

soil probably wasn't mixed well enough.

Figure 1: Brick moulding,

Zimbabwe. Photo: Practical Action /

Theo Schilderman.

Practical Action, The Schumacher Centre, Bourton on Dunsmore, Rugby, Warwickshire, CV23 9QZ, UK

T +44 (0)1926 634400 | F +44 (0)1926 634401 | E infoserv@practicalaction.org.uk | W www.practicalaction.org

Practical Action is a registered charity and company limited by guarantee.

Company Reg. No. 871954, England | Reg. Charity No.247257 | VAT No. 880 9924 76 |

Patron HRH The Prince of Wales, KG, KT, GCB

Assessing brick production

Practical Action

You can tell a lot about bricks by soaking them in cold water for 48 hours. If you weigh bricks

before and after soaking, you can calculate the percentage of water they absorb. A good brick

shouldn't absorb more than 15% of its dry mass. If bricks are too absorbent they suck

moisture out of mortar and weaken the bond. You may find the brick dissolves altogether. In

this case, it's definitely underfired - and dangerous to use in any building. The presence of

lime may also be detected by soaking bricks. If lime is present as lumps, it may expand and

cause fractures, exposing powdery white deposits.

BRICK PROBLEM

PROBABLE REASON

POSSIBLE SOLUTION

1. SIZE

(a) Too big in all dimensions

(all types)

(i) Too many coarse particles

in raw material

(i) Sieve out coarse material or

crush soil before moulding

(ii)Underfired

(ii) Increase firing temperature

&/or time (increase fuel?)

(Either way,(i) or (ii), bricks

are not shrinking as allowed

for)

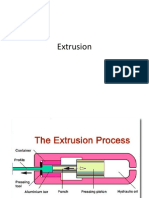

(iii) Replace

(iii) Mould or extrusion die is

too big - worn?

(b) Too thin (sand moulded &

slop moulded)

Squashed in handling probably when laid to dry on

edge

More care handling bricks &

try moulding a little drier

(c) Too thick (extruded bricks)

Cutting wires set wrongly

Adjust settings

(d) Too small in all dimension

(i) Die or mould too small

(i) Change

(ii) Too high clay content excessive drying shrinkage

(ii) Add sand

(iii) Overburned - excessive

firing shrinkage - may affect

bricks only in hot-spots in kiln

(iii) Use less fuel. Try to avoid

hot-spots by distributing fuel

differently

(all types)

Assessing brick production

Practical Action

2. SHAPE

(a) Slumping - one stretcher

face is wider with a bulge

running the length of the brick

(i) Too soft when moulded

(i) Use a drier mix

(ii) Handling too rough

(2) Take more care

(b) Rounded corners (sand

Not enough clay pressed into

mould box, or rough handling

Make sure mould box is filled,

or handle wet bricks more

gently

(slop

Corners stick to mould when

brick is released

Use sand in mould or make

sure mould is wet enough

(d) Stacking marks (all types)

Bricks moved too soon from

drying singly on edge to

stacking

Make sure bricks are dry

enough before stacking

(e) 'Lips' or 'flashing' (usually

sand or slop moulded)

Mould worn, clay 'seeps' out,

or moulder not 'striking off'

excess

Replace mould, or take more

care striking off excess flash

(f) 'Banana' shapes (all types)

Top drying faster than bottom

Gently turn bricks during drying

(all types)

moulded)

(c)

Raised

moulded)

corners

Assessing brick production

BRICK PROBLEM

Practical Action

PROBABLE REASON

POSSIBLE SOLUTION

(i) Underfired - detectable by

dull 'clunk' not sharp ring

when bricks are knocked

together

(i) Use more fuel, or change

fuel distribution, or modify

kiln design

(i) Drying too fast

Dry more slowly or add sand to

mix to decease shrinkage

(ii) Random surface cracks

Differential drying shrinkage

caused by presence of lumps

of drier material or stones

Mix better and/or sieve out

stones

(iii) Buling cracks or blisters

(i) Surface heated too quickly

- vitrifies before gases escape

(i) Slower firing - especially

around firing tunnels or near

fuel

3. STRENGTH/SOUNDNESS

(a) Weak and crumbly (all

types)

(b) Cracking (all types)

(i) Straight cracks at right

angles from one long face

(ii) Presence of lime in soil

causes blister - even 'popping'

(can appear after manufacture

- lime blowing)

4. APPEARANCE

(a) Contaminated or distorted

surface (all types)

(ii) Sieve out lime or crush

and mix better (powdered lime

can act as a flux and reduces

the energy/fuel needed)

Drying floor not clean or

smooth

Ensure floor is clean & smooth

(b) 'Spalling' - part of surface

'blown away' (all types but

Heating too fast in kiln,

residual water turns to steam

& explodes

Slow down initial kiln firing

process (up to 100C)

(c) Drag marks (extruded &

Cutting wires contaminated

with leaves or dry lumps of

clay

Soluble salts in clay or water

Make sure wires are clean &/or

lubricated with water

particularly extruded)

slop moulded)

(d) Efflorescence - crystalline

deposit on surface (all types -

appears after manufacture)

Salts tend to be near surface,

so discard top most soil

Assessing brick production

Practical Action

Laboratory tests

If bricks have to satisfy an official

standard, they will probably have

to be tested in a laboratory. These

tests will need to be repeated

periodically to maintain quality

control. Tests normally specify the

sizes for bricks and the acceptable

compressive strength - how much

weight they can bear before

crushing2. For example, in

Zimbabwe 'common' bricks are

nominally 220 x 105 x 75 mm

and have a crushing strength of 7

MPa. For certain uses, such as

damp-proof courses, water

absorption or suction rate may also

be specified.

Figure 3: Coal fired bricks drying in sun Zimbabwe.

Photo: Practical Action / Theo Schilderman.

Raw material tests

The quality of brick which can be made at a particular site is largely predetermined by the type

of soil available. There are some simple soil tests which don't need very special equipment. In

the sedimentation jar test, a sample of soil is dissolved in a jar of water. When the soil settles

you can get an idea of the fractions of clay, fine and coarse sand that are present. Another test

is the linear shrinkage test. A sample column of wetted and mixed soil is pressed into a mould

and allowed to dry. The shrinkage indicates how much clay there is in the soil and whether

problems can be expected when drying bricks3. Soil test are useful indicators, but you really

only find out whether good bricks can be made by firing samples. Before investing in a full

size kiln, however, it is possible to fire cubes or eggs of soil either in a laboratory kiln or a

simple field oven.

Conclusion

These guidelines will help field-workers judge the quality of bricks. Furthermore, if the

information presented is used as a basis by those working with brickmakers, it will go some

way to establishing an agreed approach to assessing the technical problems they face and

proposing appropriate solutions That is, solutions which make the best use of available

resources: are affordable, manageable, cost effective, and - ultimately - 'successful'4.

Reference and further reading

Ten Rules for Energy Efficient, Cost Effective Brick Firing: A Guide for Brickmakers

and Field-workers Practical Action Technical Brief

How to Measure the Energy Used to Fire Clay Bricks: A Practical Guide for

Brickmakers, Field-workers and Researchers Practical Action Technical Brief

Sustainable Small Scale Brick Production: A question of energy, Practical Action

Technical Brief

Drying of Clay Bricks and Tiles GTZ Technical Brief, Gerhard Merschmeyer, 1999,

Moulding of Clay GTZ Technical Brief, Gerhard Merschmeyer, 2001,

Brick Clamps GTZ Technical Brief, Tim Jones, 1995,

Bulls Trench Brick Kiln GTZ Technical Brief, Henrik Norske, 1995,

Hoffmann Kilns GTZ Technical Brief, Tim Jones, 1995,

The Vertical Shaft Brick Kiln GTZ Technical Brief, Tim Jones, 1997,

Firing of Clay Bricks & Tiles, GTZ Technical Brief, Gerhard Merschmeyer, 2000,

Preparation of clay for Brickmaking, Gerhard Merschmeyer, 1999,

Village Level Brickmaking, Anne Beamish & Will Donovan, GTZ / Friedr. Vieweg &

Sohn, Braunschweig, Wiesbaden, 1989,

The Clay Industry: Improvement of Resource Efficiency and Environmental

Assessing brick production

Practical Action

Performance, CleanerProduction.Com,

How to Start a Small Clay Brick and Tile Making Enterprise, GTZ Question & Answer,

Responses to Frequently Asked Questions,

What Type of Kiln Should Be Chosen for Firing Clay Brick and Roofing Tiles, GTZ

Question & Answer, Responses to Frequently Asked Questions,

Brick by Brick Kelvin Mason, Practical Action Publishing, 2001 ISBN 9781853395291

This technical brief was originally written for basin, Building Advisory Service and

Information Network, prepared by Kelvin Mason (June 1998).

Practical Action

The Schumacher Centre

Bourton-on-Dunsmore

Rugby, Warwickshire, CV23 9QZ

United Kingdom

Tel: +44 (0)1926 634400

Fax: +44 (0)1926 634401

E-mail: inforserv@practicalaction.org.uk

Website: http://practicalaction.org/practicalanswers/

This Technical Brief is possible thanks to the collaboration of DFID-UK and The Tony Bullard

Trust.

Practical Action is a development charity with a difference. We know the simplest ideas can have the

most profound, life-changing effect on poor people across the world. For over 40 years, we have been

working closely with some of the worlds poorest people - using simple technology to fight poverty and

transform their lives for the better. We currently work in 15 countries in Africa, South Asia and Latin

America.

See Brickmaking in Developing Countries (Parry, BRE, 1979) and Village-Level Brickmaking (Beamish

& Donovan, Vieweg, 1989) for additional information.

2

See Building Materials in Developing Countries (Spence & Cook, John Wiley, 1983) and Materials of

Construction (Smith & Andres, McGraw-Hill, 1988) for examples of specifications.

3

These and other tests are specified in Small Scale Brickmaking (Smith, ILO Technical Memorandum

No. 6)

4

Technology and Underdevelopment (Stewart, Macmillan, 1978)

1

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Solid and Liquid Silicone RubberDocument102 pagesSolid and Liquid Silicone Rubberdancercel100% (3)

- Gear ManufacturingDocument31 pagesGear Manufacturingvinu1175No ratings yet

- PVC Compound Project ProfileDocument11 pagesPVC Compound Project Profilehoneydoll67% (3)

- Fish Feed ExturderDocument7 pagesFish Feed ExturderpelletsmillmachineryNo ratings yet

- Unit 4 (CURVES)Document48 pagesUnit 4 (CURVES)Zara Nabilah79% (33)

- Unit 4 (CURVES)Document48 pagesUnit 4 (CURVES)Zara Nabilah79% (33)

- WRS Brochure PDFDocument8 pagesWRS Brochure PDFlutfi_ismailNo ratings yet

- TG BlowDocument67 pagesTG BlowVikas Singh100% (3)

- Tech. Specification For HT Power CableDocument21 pagesTech. Specification For HT Power CablePramod B.WankhadeNo ratings yet

- Aggregate Impact Test, Ten Percent Fines TestDocument6 pagesAggregate Impact Test, Ten Percent Fines TestEmrePınarcı75% (4)

- A Business Plan For The Production of Crumb Rubber by Solid State Shear Extrusion EnPRO351 Spring2003 Final ReportDocument29 pagesA Business Plan For The Production of Crumb Rubber by Solid State Shear Extrusion EnPRO351 Spring2003 Final ReportpedroNo ratings yet

- Introduction To Melt SpinningDocument7 pagesIntroduction To Melt Spinningsujal jha100% (1)

- NP-ISO - 3302 - 1 - Rubber Tolerances For Products PDFDocument13 pagesNP-ISO - 3302 - 1 - Rubber Tolerances For Products PDFluis martinezNo ratings yet

- Dryer Handbook - Second EditionDocument60 pagesDryer Handbook - Second EditionyoquieroopinarNo ratings yet

- Design Cover FileDocument2 pagesDesign Cover FileAziff ShafzanNo ratings yet

- GeoDocument7 pagesGeoAziff ShafzanNo ratings yet

- Chapter 4 - Survey 2Document6 pagesChapter 4 - Survey 2Aziff ShafzanNo ratings yet

- Civil Engineering Spot Speed StudyDocument4 pagesCivil Engineering Spot Speed StudyAziff ShafzanNo ratings yet

- Area and Volume: General ObjectiveDocument30 pagesArea and Volume: General ObjectiveAdron LimNo ratings yet

- Tutorial HighwayDocument3 pagesTutorial HighwayAziff ShafzanNo ratings yet

- Test 2: Aggregate Shape Test (Flakiness Index)Document2 pagesTest 2: Aggregate Shape Test (Flakiness Index)Aziff ShafzanNo ratings yet

- Test 2: Aggregate Shape Test (Flakiness Index)Document2 pagesTest 2: Aggregate Shape Test (Flakiness Index)Aziff ShafzanNo ratings yet

- Incident AccidentDocument7 pagesIncident AccidentAziff ShafzanNo ratings yet

- G+7 Watersupply, Septic AnkDocument633 pagesG+7 Watersupply, Septic AnkSantosh ChowdaryNo ratings yet

- Apollo Tyres LTD Is The Leading Tyre Manufacturing Company in IndiaDocument5 pagesApollo Tyres LTD Is The Leading Tyre Manufacturing Company in IndiaroiNo ratings yet

- MasterCAM X8 - Getting Started With Solids Tutorial PDFDocument78 pagesMasterCAM X8 - Getting Started With Solids Tutorial PDFSylvhiia PerezNo ratings yet

- High-Torque Direct Drives: Permanent-Field Synchronous MotorsDocument12 pagesHigh-Torque Direct Drives: Permanent-Field Synchronous MotorsCesare LucchiniNo ratings yet

- The Extrusion and Drawing Processes for Shaping MetalsDocument34 pagesThe Extrusion and Drawing Processes for Shaping MetalszubbbuNo ratings yet

- Dampers CatalogDocument318 pagesDampers CatalogEnnSeeNo ratings yet

- Manufacturing Process DiagramDocument3 pagesManufacturing Process DiagramCris Diane G. DatingginooNo ratings yet

- HS Code ClassificationDocument45 pagesHS Code Classificationraghav248No ratings yet

- RMS Extrusion LinesDocument2 pagesRMS Extrusion LinesJorge SánchezNo ratings yet

- Factsheet FD 244-55Document2 pagesFactsheet FD 244-55dmilanovic5395No ratings yet

- Rhino 590Document6 pagesRhino 590reda redaNo ratings yet

- US20100111453A1Document11 pagesUS20100111453A1Mumar Soluciones IngenierilesNo ratings yet

- MK 6Document4 pagesMK 6Lluque_19No ratings yet

- Tronxy X5SA-400 Installation GuideV6.2Document22 pagesTronxy X5SA-400 Installation GuideV6.2Leonardus Tonny75% (4)

- Advanced Modeling Tools for Sweeps, Blends, and ShellsDocument66 pagesAdvanced Modeling Tools for Sweeps, Blends, and ShellsJony M. TemnikarNo ratings yet

- KEC Induction Training Program OverviewDocument96 pagesKEC Induction Training Program OverviewShubhendu SinghNo ratings yet

- Sika Backing FillerDocument2 pagesSika Backing Fillerthe pilotNo ratings yet

- Welding MCQSDocument46 pagesWelding MCQSchin22222222No ratings yet

- How To Use Anodizing Defects Catalogue Photo Gallery: 3.1 Acid CorrosionDocument21 pagesHow To Use Anodizing Defects Catalogue Photo Gallery: 3.1 Acid CorrosionSatyendra PandeyNo ratings yet