Professional Documents

Culture Documents

5 Why Incident Investigation Report

Uploaded by

Shelley BattenOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5 Why Incident Investigation Report

Uploaded by

Shelley BattenCopyright:

Available Formats

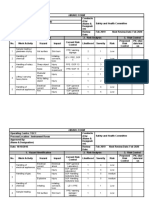

Investigation 5 Why Incident Report Card

Investigation 5 Why

Complete all 10 sections on this form

1. Investigation details

Safeguard incident number

Date investigation began

31/01/2014

Investigation lead (name)

Investigation facilitator (name)

Other investigation team members

(if any)

2. Brief description of the incident: (refer to Incident Initial Details form)

Two Heat Treatment Technicians received an electric shock (60V) while setting up pre-weld heating

equipment

3. 5 WHYs

1. Why did the above

happen?

Verification

2. Why did 1 happen?

Verification

3. Why did 2 happen?

Verification

4. Why did 3 happen?

Verification

5. Why did 4 happen?

Verification

6. Why did 5 happen?

Verification

7. Why did 6 happen?

Verification

8. Why did 7 happen?

Verification

Investigation 5 Why Incident Report Card

4. Main root cause category

Assessments or Audits

Assessment or audit failed to uncover

inadequacies

Assessment or audit not conducted

Results of assessment or audit not acted

upon

Communications

Inadequate shift turnover communication

Inadequate signage

Inadequate signalling

Inadequate verbal communication

Inadequate written communication

Contractor Health, Environment, and

Safety Management

Contractor Health, Environment, and Safety

Management

Pre-Startup Safety Reviews

Failed to uncover inadequacies in

procedures and/or equipment

Not conducted

Results were not acted upon

Preventive Maintenance, Inspection,

Testing, or Repair

Inadequate

Inadequate maintenance planning

Not conducted

Program does not exist

Results were not acted upon

Incident and Near Miss Investigation

Incident and Near Miss Investigation

Procedures and Safe Work Practices

HES Procedures or Safe Work Practices not

available

HES Procedures or Safe Work Practices did

not exist

HES Procedures or Safe Work Practices

difficult to use

HES Procedures or Safe Work Practices

inadequate

HES Procedures or Safe Work Practices not

used

Maintenance Procedures not available

Maintenance Procedures not used

Maintenance Procedures did not exist

Maintenance Procedures difficult to use

Maintenance Procedures inadequate

Operations Procedures not available

Operations Procedures not used

Operations Procedures did not exist

Operations Procedures difficult to use

Operations Procedures inadequate

Quality Control or Acceptance Testing

Inadequate

Not conducted

Not required

Results not acted on

Risk Management/JSA

Controls or preventive systems inadequate

Hazard not recognised

No Risk Assessment

Potential consequences not understood

Leadership Accountability

Deviation is accepted

Inadequate resource allocation

Management expectations inadequately

documented, communicated, or enforced

Supervision/Work Direction

Inadequate selection of worker(s)

Inadequate work direction or unclear

expectations

Inadequate work oversight or enforcement

of work standards

Design

Design did not anticipate the conditions

Design did not consider human factors

Design review failed to uncover

inadequacies in design

Design standards did not exist

Design standards inadequate

Design standards not used

Emergency Response

Emergency response

Human Performance

Mental overload

Mistake or mental slip

Wilful deviation

Management of Change

Inadequate for design change

Inadequate for organisational change

Not used

Natural Phenomenon

Insect, reptiles, or other animals

Weather/wildfire

Training/Competency

No training exists

Trained but lack of competency/fluency

Training exists but inadequate

Training exists but individual was not

trained

Investigation 5 Why Incident Report Card

Description of root causes:

5. Tenets broken

Address abnormal situations

Involve the right people in decisions

Comply with all rules and regulations

Maintain integrity of dedicated systems

Ensure safety devices are in place and

functional

Meet or exceed customer requirements

Operate in a safe and controlled condition

Follow safe work practices and procedures

Operate within design and environment limits

Follow written procedures for high-risk/unusual

situations

6. Actions Item (1)

Task title:

Task

description:

Allocate action

to:

Scheduled

date:

Controls

hierarchy

Administrative

Tick to mark this

complete

Responsible

department:

Elimination

Engineering

PPE

Substitution

Action note:

7. Actions Item (2)

Task title:

Task

description:

Allocate action

to:

Scheduled

date:

Controls

hierarchy

Administrative

Tick to mark this

complete

Responsible

department:

Elimination

Engineering

PPE

Substitution

Action note:

8. Actions Item (3)

Task title:

Task

description:

Allocate action

to:

Scheduled

date:

Controls

hierarchy

Administrative

Action note:

Tick to mark this

complete

Responsible

department:

Elimination

Engineering

PPE

Substitution

Investigation 5 Why Incident Report Card

9. Actions Item (4)

Task title:

Task

description:

Allocate action

to:

Scheduled

date:

Controls

hierarchy

Administrative

Tick to mark this

complete

Responsible

department:

Elimination

Engineering

PPE

Substitution

Action note:

10. Investigation close-out

Does the investigation require restricted viewing in SafeGuard? (sensitive incidents only)

No

List of documents to attach to

investigation (if any):

Yes

You might also like

- Ehs Plan - JSSLDocument61 pagesEhs Plan - JSSLneerajgulabNo ratings yet

- RA Every ActvityDocument38 pagesRA Every ActvityvijayNo ratings yet

- The Behavior Survival Guide For Kids PDFDocument177 pagesThe Behavior Survival Guide For Kids PDFmelycr17100% (1)

- Visitors HSES InductionDocument30 pagesVisitors HSES InductionPradeep KunduNo ratings yet

- PPE MatrixDocument4 pagesPPE Matrixb_chiradipNo ratings yet

- 09.00AM to11.00PM Clear: TCE EffwaDocument3 pages09.00AM to11.00PM Clear: TCE EffwaAjayNo ratings yet

- Monthwise EHS theme planDocument6 pagesMonthwise EHS theme planSafety DeptNo ratings yet

- Appendix 3 01 Health Safety and Fire Regulations 3rd EditionDocument168 pagesAppendix 3 01 Health Safety and Fire Regulations 3rd EditionB.Peer Muhammad NishathNo ratings yet

- Near Miss Reporting and ManagementDocument28 pagesNear Miss Reporting and ManagementWahyu ArdaniNo ratings yet

- Spill Response Procedures OCLDocument14 pagesSpill Response Procedures OCLThusithaNo ratings yet

- Unsafe Act, Unsafe Condition, Nearmiss & IncidentaccidentDocument5 pagesUnsafe Act, Unsafe Condition, Nearmiss & IncidentaccidentTayyab Hasnain Saadat JanjuaNo ratings yet

- Emergency Rescue Plan For Electric Shock (29!10!19)Document4 pagesEmergency Rescue Plan For Electric Shock (29!10!19)Ashok sNo ratings yet

- HSE InductionDocument20 pagesHSE InductionShailendraNo ratings yet

- December 2019 EHS Calendar with Daily Safety ActivitiesDocument1 pageDecember 2019 EHS Calendar with Daily Safety ActivitiesSiddharth RanaNo ratings yet

- HSE Training History FormDocument4 pagesHSE Training History FormAnonymous 1wDPsonNo ratings yet

- 3RD Quarter Grade 8 PeDocument11 pages3RD Quarter Grade 8 PeKath Leen100% (3)

- SAFETY ALERT, No.07-December 2009: Driving in FogDocument1 pageSAFETY ALERT, No.07-December 2009: Driving in FogratkoNo ratings yet

- EHS Calendar September 2019 Training Fire Safety PPE AuditsDocument1 pageEHS Calendar September 2019 Training Fire Safety PPE AuditsSiddharth RanaNo ratings yet

- SEC-EHV-Risk-assesment-form-Rev.-2.. Line CrossingDocument3 pagesSEC-EHV-Risk-assesment-form-Rev.-2.. Line CrossingSn AhsanNo ratings yet

- Hirarc Form-PoDocument2 pagesHirarc Form-PoSaiful SelamatNo ratings yet

- HSE PresentationDocument10 pagesHSE PresentationjeffNo ratings yet

- The Dynamic AAC Goals Grid 2: DAGG-2Document20 pagesThe Dynamic AAC Goals Grid 2: DAGG-2DEAN MIKO BULLONo ratings yet

- Lock Out Tag Out Procedure For - : TitleDocument12 pagesLock Out Tag Out Procedure For - : TitleerwinNo ratings yet

- Waste ManagementDocument2 pagesWaste ManagementMohamed RizwanNo ratings yet

- 2) SOP-01 Handling Hazardous ChemicalDocument6 pages2) SOP-01 Handling Hazardous ChemicalMohd ZaeinNo ratings yet

- Management of ChangeDocument85 pagesManagement of ChangeHerik renaldoNo ratings yet

- Leadership' Role in Driving A Safety Culture: Tata Steel ExperienceDocument27 pagesLeadership' Role in Driving A Safety Culture: Tata Steel ExperiencefullaNo ratings yet

- Marketing Management - Gold GymDocument23 pagesMarketing Management - Gold Gymakshaykg67% (3)

- Contractor's EHSS Evaluation by PMT EHSS PK CLC Project FMO Jan 2020Document5 pagesContractor's EHSS Evaluation by PMT EHSS PK CLC Project FMO Jan 2020ManPower RecruitingNo ratings yet

- JSA For Refurbishing and Repainting 23oct2017 (Woqod LPG Plant) UpdatedDocument13 pagesJSA For Refurbishing and Repainting 23oct2017 (Woqod LPG Plant) UpdatedJoseph PerezNo ratings yet

- 4.4.3.3 Data and Trend AnalysisDocument6 pages4.4.3.3 Data and Trend AnalysisIndermohan MehtaNo ratings yet

- Health and Safety Induction ChecklistDocument2 pagesHealth and Safety Induction ChecklistYathawan Nair ThamutharamNo ratings yet

- NSCI Awards 2018 ApplicationDocument7 pagesNSCI Awards 2018 ApplicationJason Smith100% (1)

- Award and Penalty ProcedureDocument2 pagesAward and Penalty ProcedurePanchdev KumarNo ratings yet

- WHS P11 Fatigue Management ProcedureDocument8 pagesWHS P11 Fatigue Management Procedurehse bptNo ratings yet

- Autoclaves - Generic Assessment - L Use of AutoclavesDocument1 pageAutoclaves - Generic Assessment - L Use of AutoclavesaKureishiNo ratings yet

- JsaDocument10 pagesJsaTanzeel LiaqatNo ratings yet

- Form-11 Third Party Monthly & End of Contract EHSS ReportDocument9 pagesForm-11 Third Party Monthly & End of Contract EHSS ReportMohammad GouseNo ratings yet

- Electrical Safety Hazards and PreventionDocument38 pagesElectrical Safety Hazards and PreventionYvonne TohNo ratings yet

- Consequence Management Sytem EsepplDocument1 pageConsequence Management Sytem Eseppluttam mishra100% (2)

- IGC 1 Question and Answer HarisDocument24 pagesIGC 1 Question and Answer HarisSyed Haris100% (1)

- Eil Permit For Energy Isolation & De-IsolationDocument1 pageEil Permit For Energy Isolation & De-IsolationAvesh ChauahanNo ratings yet

- Safety Alert 49 - Cable Pulling IncidentDocument1 pageSafety Alert 49 - Cable Pulling IncidentTareq Ziad KhalifaNo ratings yet

- Digital Etiquette Lesson PlanDocument6 pagesDigital Etiquette Lesson Planapi-281885955No ratings yet

- HSE Operational Control Procedure For Electrical WorkDocument3 pagesHSE Operational Control Procedure For Electrical Workalit2No ratings yet

- Safety Engineer JobDocument3 pagesSafety Engineer Jobخلف الله التوم0% (1)

- 7 Global Golden Rules of Safety - Rule 5 - LOTO & Work Permit - DraftDocument5 pages7 Global Golden Rules of Safety - Rule 5 - LOTO & Work Permit - DraftPedro ViegasNo ratings yet

- Schedule For Inspection Feb 2020Document2 pagesSchedule For Inspection Feb 2020Siddharth RanaNo ratings yet

- Five Models of Staff DevelopmentDocument34 pagesFive Models of Staff DevelopmentZulaiha Abdul Rahman100% (3)

- SHEMDocument6 pagesSHEMAjith Kumar AjithNo ratings yet

- Safety Manual Blue PeterDocument102 pagesSafety Manual Blue Peterfaraz ahmedNo ratings yet

- Lockout Tagout Program GuideDocument2 pagesLockout Tagout Program Guiderenjithv_4No ratings yet

- Mod10 Work at Height QuizDocument11 pagesMod10 Work at Height QuizMhanna AYNo ratings yet

- Job Safety Analysis for Caustic and Sulfuric Acid UnloadingDocument2 pagesJob Safety Analysis for Caustic and Sulfuric Acid UnloadingifoodNo ratings yet

- Pera JackhammerDocument7 pagesPera Jackhammerjumansyahamid1988No ratings yet

- RISK and Oppurtunity ISO 45001Document5 pagesRISK and Oppurtunity ISO 45001AnkurNo ratings yet

- SHEM-SP-08.01 - OMS-316.01General SHE RulesDocument40 pagesSHEM-SP-08.01 - OMS-316.01General SHE RulesAjith Kumar AjithNo ratings yet

- HIRA FormatDocument2 pagesHIRA FormatSachin Yashwant kumbharNo ratings yet

- Lockout Tagout Permit FormDocument9 pagesLockout Tagout Permit FormJoey GNo ratings yet

- Improve Emergency Response with Mock Drill TestingDocument10 pagesImprove Emergency Response with Mock Drill TestingGobindaSahu100% (1)

- JSA Format Erection of Column 901-C-01Document9 pagesJSA Format Erection of Column 901-C-01sakthi venkatNo ratings yet

- Health and Safety Induction SampleDocument5 pagesHealth and Safety Induction SampleMohamad Hafiz100% (1)

- Appendix-AC, Guide For Working at HeightsDocument23 pagesAppendix-AC, Guide For Working at HeightsApm FoumilNo ratings yet

- Part 3 ObservationsDocument7 pagesPart 3 ObservationsAmjadNo ratings yet

- National Board of Accreditation: Pro-Forma For Pre-Qualifiers TIER-I InstitutionsDocument9 pagesNational Board of Accreditation: Pro-Forma For Pre-Qualifiers TIER-I InstitutionsSivasakthivelPsNo ratings yet

- BSP Circular 949Document6 pagesBSP Circular 949MARC CHRISTIAN LOPEZNo ratings yet

- Admit Card AMITYDocument2 pagesAdmit Card AMITYAnonymous tOgAKZ8No ratings yet

- Reading in English International Standardized Tests-: Nida Husna Eed-Fes UIN Jakarta 2021Document15 pagesReading in English International Standardized Tests-: Nida Husna Eed-Fes UIN Jakarta 2021Putri Septiarini MufidahNo ratings yet

- Project Based Learning Science (Form 1) : Useful WebsiteDocument2 pagesProject Based Learning Science (Form 1) : Useful WebsiteNg Chiew Ping100% (1)

- Crackias - Upsc Topical AnalysisDocument31 pagesCrackias - Upsc Topical Analysisujjawal dewashishNo ratings yet

- Mitchell Mcdonald: ProfileDocument1 pageMitchell Mcdonald: ProfileMitchellNo ratings yet

- Philosophy of NursingDocument1 pagePhilosophy of Nursingapi-508609843No ratings yet

- Master's in Architecture Programs in GermanyDocument3 pagesMaster's in Architecture Programs in GermanyRuchit PavasiyaNo ratings yet

- SAQ OF THE PLACE OF ART IN EDUCATION - Nandalal Bose (Class Xi of Wbchse) - Sure Success Tutorial HomeDocument8 pagesSAQ OF THE PLACE OF ART IN EDUCATION - Nandalal Bose (Class Xi of Wbchse) - Sure Success Tutorial HomeSurajit DasNo ratings yet

- Earlscliffe Application Form SCREENDocument2 pagesEarlscliffe Application Form SCREENErjusXNo ratings yet

- Good Practice Note: Managing Retrenchment (August 2005)Document28 pagesGood Practice Note: Managing Retrenchment (August 2005)IFC Sustainability100% (1)

- Diversities in Diverse LocationsDocument3 pagesDiversities in Diverse Locationsjohn torres100% (1)

- The Icelandic Coast Guard: "Always Prepared"Document16 pagesThe Icelandic Coast Guard: "Always Prepared"Julie ClarkNo ratings yet

- Internet of Things Based Intelligent Drowsiness Alert SystemDocument5 pagesInternet of Things Based Intelligent Drowsiness Alert SystemFlavio CarvalhoNo ratings yet

- FINAL Sharmila BDP PDFDocument70 pagesFINAL Sharmila BDP PDFTrader NepalNo ratings yet

- Lesson 4: John Rawls' Theory of JusticeDocument10 pagesLesson 4: John Rawls' Theory of JusticeAndrea ValdezNo ratings yet

- Lindale Abrameit Hines Aff Michigan Debate Tournament Round1Document31 pagesLindale Abrameit Hines Aff Michigan Debate Tournament Round1IanNo ratings yet

- DLL En6 Q2 W4 PDFDocument4 pagesDLL En6 Q2 W4 PDFAimee Pesimo SaldoNo ratings yet

- Political ProjectDocument16 pagesPolitical ProjectPrashant singhNo ratings yet

- Lesson 2 Fitness Concept and AssessmentDocument4 pagesLesson 2 Fitness Concept and AssessmentNabi BratzchNo ratings yet

- Filipino First Policy EnshrinedDocument24 pagesFilipino First Policy EnshrinedJANNNo ratings yet

- Teacher Education in Pakistan PDFDocument37 pagesTeacher Education in Pakistan PDFOptimistic Veteran100% (1)

- IA2021 Schedule-Foundation - LevelDocument1 pageIA2021 Schedule-Foundation - LevelPadmasri GirirajanNo ratings yet