Professional Documents

Culture Documents

PT316 - Topic 3-2 - Sedimentation PDF

Uploaded by

ChemEngGirl89Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PT316 - Topic 3-2 - Sedimentation PDF

Uploaded by

ChemEngGirl89Copyright:

Available Formats

Multiple Particles in Liquids - Where are we NOW

Have developed equations for hindered settling velocity in batch settling :

UT = terminal velocity of single particle (dilute suspensions)

UrelT = hindered settling velocity (concentrated suspensions)

For batch settling:

Q p = - Qf

= =

leads to

Up = particle settling velocity relative to vessel wall

=

Have various correlations for n

hence can calculate Up for any Rep

Dept of Process Engineering

Stellenbosch University

Particle Technology 316

Multiple Particles in Liquids - Where are we now

Have introduced Particle Flux Plots : Ups vs C

Particle(solids) volumetric settling flux

S = Qp/A

= particle velocity relative to vessel x particle concentration

= Up (1-) = Up C

= Ups

Dept of Process Engineering

Stellenbosch University

Particle Technology 316

Multiple Particles in Liquids - Where are we now

Flux plots (Ups vs C):

Indicate the unique settling characteristics of specific suspension

Are the cornerstones of design procedures for thickeners and

clarifiers

For UNIFORM SIZED SPHERES, plot can be predicted from theory

For real suspensions (distribution of sizes), plot cannot easily be

predicted from theory (theory generally based on uniform,

spherical spheres)

Usually determined from laboratory

experiments (batch settling tests)

Dept of Process Engineering

Stellenbosch University

Particle Technology 316

Multiple Particles in Liquids - Where are we now

Approaches to determine flux plots:

Multiple batch settling tests

Interpolation from a single batch settling test

Dept of Process Engineering

Stellenbosch University

Particle Technology 316

Multiple Particles in Liquids - Batch settling tests

Procedure Batch Settling Tests:

Suspension of particles of known concentration (CB)

prepared in measuring cylinder

Cylinder shaken to thoroughly mix suspension

Cylinder placed on level surface to allow settling

Positions of interfaces are monitored over time

Height-time curve

Particle fluxes are calculated for different concentrations

Flux plot

Dept of Process Engineering

Stellenbosch University

Particle Technology 316

Multiple Particles in Liquids - Types of sedimentation

Two types of sedimentation

Depending on initial concentration CB

Differ in terms of zones of concentration formed

Type 1 sedimentation:

Three zones

Clear liquid zone (A)

Initial concentration zone (B)

Sediment zone (S)

Type 2 sedimentation:

Four zones

Clear liquid zone (A)

Initial concentration zone (B)

Variable concentration zone (E)

Sediment zone (S)

Dept of Process Engineering

Stellenbosch University

Particle Technology 316

Multiple Particles in Liquids - Type 1 sedimentation

Type 1 sedimentation

Zone A: Clear liquid zone (C = 0)

Zone B: Initial concentration zone (C = CB)

Zone S: Sediment concentration zone (C = CS)

Figure from

Rhodes (2008)

Dept of Process Engineering

Stellenbosch University

Particle Technology 316

Multiple Particles in Liquids Type 1 sedimentation

Type 1 sedimentation

Figure from

Rhodes (2008)

Example of height-time curve:

Slopes give velocities of different interfaces

Interface AB descends at constant velocity

Interface BS rises at constant velocity

Interface AS is stationary (end of batch settling test)

Dept of Process Engineering

Stellenbosch University

Particle Technology 316

Multiple Particles in Liquids Type 2 sedimentation

Figure from

Rhodes (2008)

Type 2 sedimentation

Zone A: Clear liquid zone (C = 0)

Zone B: Initial concentration zone (C = CB)

Zone E: Variable concentration zone (CEmin C CEmax)

CEmin and CEmax constant

Zone S: Sediment concentration zone (C = CS)

Dept of Process Engineering

Stellenbosch University

(NB: error in Rhodes)

Particle Technology 316

Multiple Particles in Liquids Type 2 sedimentation

Type 2 sedimentation

Example of height-time curve:

Figure from

Rhodes (2008)

Linear slopes give velocities of different interfaces

Interface AB initially descends at constant velocity

Interfaces BEmin and BEmax rise at constant velocity

Interface AS is stationary (end of batch settling test)

Dept of Process Engineering

Stellenbosch University

Particle Technology 316

Multiple Particles in Liquids - Determination of Type 1 or Type 2

Types of sedimentation

Depending on initial concentration

If interface BX (CB CX CS) rises faster than interface BS:

Zone of variable concentration will form

Therefore Type 2 sedimentation

From flux plot:

Figure from

Rhodes (2008)

Tangent drawn from (CS, 0)

Intersection point: CB1

Tangent point: CB2

Type 1 sedimentation:

CB < CB1 or CB > CB2

Type 2 sedimentation:

CB1 CB CB2

Dept of Process Engineering

Stellenbosch University

Particle Technology 316

Multiple Particles in Liquids - Output of settling tests: H-t curve

Height-time curve

Plot of interface AB position over time

Figure from

Rhodes (2008)

Dept of Process Engineering

Stellenbosch University

Particle Technology 316

Multiple Particles in Liquids Experimental H-t curve

Height-time curves from video data

Influence of type of colour scale

colormap function in Matlab

Influence of range of colour scale

Clim axes property in Matlab

Dept of Process Engineering

Stellenbosch University

Particle Technology 316

Multiple Particles in Liquids - Flux plots from H-t curves

Deriving flux plots from height-time curve:

Approach 1: get h-t curves for multiple starting

concentrations

Approach 2: derive flux plot from a single height-time curve

Figure from

Rhodes (2008)

Dept of Process Engineering

Stellenbosch University

Particle Technology 316

Multiple Particles in Liquids - Batch settling

Approach 1:

Experimentally determine H-t plots for different starting concentrations

Calculate initial slopes for each concentration

Hence get flux for each concentration

v3

v2

c3

v1

c2

US1=v1c1

ps1=v1c1

US2=v2c2

ps2=v2c2

S3=v3c3 etc

Ups3=v3c3

(kg/m2.s)

c1

time

Dept of Process Engineering

Stellenbosch University

Ups S

c (kg/m3)

C

Particle Technology 316

Multiple Particles in Liquids - .

Approach 2 (based on Kynch Theory):

Velocity of interface between clear liquid (A) and

suspension of concentration C at time t:

=

h1 = projected tangential height

Interface velocity from mass balance:

=

, = 0

Velocity of particles at interface

Relative to wall

=

Figure from

Rhodes (2008)

Dept of Process Engineering

Stellenbosch University

Particle Technology 316

Multiple Particles in Liquids - Summary thus far

Deriving flux plot from height-time curve

Plane of concentration C rising from base of vessel:

At time t, this plane has risen h, therefore plane velocity is h/t

Velocity of particles relative to plane of concentration C:

+

Figures from

Rhodes (2008)

Dept of Process Engineering

Stellenbosch University

Particle Technology 316

Multiple Particles in Liquids - Summary thus far

Deriving flux plot from height-time curve

Volume of particles passed through plane of concentration

C after time t is:

= +

This plane is interfacing with clear liquid

All particles have passed through it: 0

Figures from

Rhodes (2008)

Dept of Process Engineering

Stellenbosch University

Particle Technology 316

Multiple Particles in Liquids - Particle Fluxes

Deriving flux plot from height-time curve

1

above

0 = +

Substituting =

0

=

1

gives concentration relation:

Figures from

Rhodes (2008)

Dept of Process Engineering

Stellenbosch University

Particle Technology 316

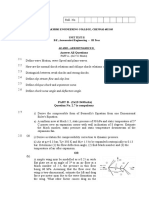

Multiple Particles in Liquids - Particle flux plot

Summary of Approach 2:

Consider the following batch setting curve, obtained for a suspension

that was initially at a concentration of co and a height of ho.

h0 A

interface

height

hi

i

C

time

Dept of Process Engineering

Stellenbosch University

Particle Technology 316

Multiple Particles in Liquids - Particle flux plot

Summary of Approach 2 (contd):

For the curve AB, the concentration is co, and the settling velocity is vo.

Hence the flux for co may be obtained.

For the variable concentration part of the curve, BC, the following

procedure is applied :

draw a tangent to the curve at any point i , to intersect the h axis at hi.

According to Kynchs theory the concentration of the interface at this point is

given by :

ci hi = co ho

Hence, ci may be calculated.

the settling velocity, vi, at this point is obtained from the gradient of the line hii.

Hence, the flux Upsi for the concentration ci may be calculated.

The above is repeated for various points along BC and CD. Hence, the flux plot is

obtained.

Dept of Process Engineering

Stellenbosch University

Particle Technology 316

Multiple Particles in Liquids - Particle flux plot

Summary of Approach 2 (contd):

The slope of the line from the origin to the point i indicates the velocity at

which a zone of concentration ci propagates upwards

h0 A

interface

height

hi

i

C

grad=vci

time

Dept of Process Engineering

Stellenbosch University

Particle Technology 316

Multiple Particles in Liquids - Summary of lecture

What did we achieve today ?

Know about the different types of settling (Type 1 and Type 2)

Can develop a flux curve (Ups vs c) from multiple settling curves obtained

for different starting concentrations

Can develop a flux curve by construction from a single settling curve

Can calculate the velocity of upward propagation of a zone of any

concentration

Dept of Process Engineering

Stellenbosch University

Particle Technology 316

Multiple Particles in Liquids - Summary of lecture

Important note

We have used flux plots of Volumetric Flux (Ups in m/s) vs Volumetric

Concentration (C)

Many texts use flux plots of Mass flux (S in kg/m2.s) vs Mass Concentration

The form of the plot is similar and the manipulation is the same

Ups S

(m/s)

(kg/m2.s)

(kg/m2.s)

c (kg/m3)

C

Dept of Process Engineering

Stellenbosch University

c (kg/m3)

Particle Technology 316

You might also like

- Buta Market and FeedstocksDocument49 pagesButa Market and FeedstocksChemEngGirl89No ratings yet

- Capital Cost Estimation Chapter from Turton Process EngineeringDocument21 pagesCapital Cost Estimation Chapter from Turton Process EngineeringChemEngGirl89No ratings yet

- TS 112 Process and Instrument DiagramsDocument27 pagesTS 112 Process and Instrument DiagramsGeetha_jagadish30100% (1)

- The Basics of API 650 Standard for Storage TanksDocument52 pagesThe Basics of API 650 Standard for Storage Tanksferdad79% (19)

- Inherent SafetyDocument46 pagesInherent SafetyChemEngGirl89No ratings yet

- Air Cooled Exchangers PDFDocument18 pagesAir Cooled Exchangers PDFRaghav SharmaNo ratings yet

- 2 Crude Vaccum DistillationDocument15 pages2 Crude Vaccum DistillationChemEngGirl89No ratings yet

- Variable Costs R/tonneDocument3 pagesVariable Costs R/tonneChemEngGirl89No ratings yet

- JS Activated Economics Plus V84Document14 pagesJS Activated Economics Plus V84Jessica CehNo ratings yet

- Boiler ControlDocument5 pagesBoiler ControlChemEngGirl89No ratings yet

- CB-7853 Boiler Room Guide - LR PDFDocument90 pagesCB-7853 Boiler Room Guide - LR PDFcewaleed2590No ratings yet

- ISA SymbolsDocument1 pageISA SymbolsmustafasandikciNo ratings yet

- Calcs HETPDocument50 pagesCalcs HETPChemEngGirl89No ratings yet

- Butadiene Mechanism ExplainedDocument7 pagesButadiene Mechanism ExplainedChemEngGirl89No ratings yet

- Exam Notes For PT316Document3 pagesExam Notes For PT316ChemEngGirl89No ratings yet

- Part Tech Tut Test 2 2009Document3 pagesPart Tech Tut Test 2 2009ChemEngGirl89No ratings yet

- 1 s2.0 S0021951714001067 MainDocument9 pages1 s2.0 S0021951714001067 MainChemEngGirl89No ratings yet

- Control Exam1-Solution v4Document6 pagesControl Exam1-Solution v4ChemEngGirl89No ratings yet

- A2 2014Document9 pagesA2 2014ChemEngGirl89No ratings yet

- Project Management 412 2012 Exam 1Document8 pagesProject Management 412 2012 Exam 1ChemEngGirl89No ratings yet

- MP415 Assignment 3 2017Document16 pagesMP415 Assignment 3 2017ChemEngGirl89No ratings yet

- PM 412 2013 Exam 1 ReconstructedDocument3 pagesPM 412 2013 Exam 1 ReconstructedChemEngGirl89No ratings yet

- Chemical Engineering 317 - 2016: Additional Notes Extension of PVT Models To MixturesDocument3 pagesChemical Engineering 317 - 2016: Additional Notes Extension of PVT Models To MixturesChemEngGirl89No ratings yet

- PM Chapter 10 - Risk v6 PubDocument48 pagesPM Chapter 10 - Risk v6 PubChemEngGirl89No ratings yet

- 07 - Topic 3 Class Examples PDFDocument7 pages07 - Topic 3 Class Examples PDFChemEngGirl89No ratings yet

- PT316 - Topic 3-1 - Sedimentation PDFDocument24 pagesPT316 - Topic 3-1 - Sedimentation PDFChemEngGirl89No ratings yet

- Section 1 - Presentation1Document29 pagesSection 1 - Presentation1ChemEngGirl89No ratings yet

- Reacting System ExamplesDocument12 pagesReacting System Examplessaliljain2001No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Stability - AISC's Direct Analysis Method - How To EngineerDocument13 pagesStability - AISC's Direct Analysis Method - How To Engineerpatricklim1982No ratings yet

- AOE 5104 Class Notes and ScheduleDocument26 pagesAOE 5104 Class Notes and ScheduleverbicarNo ratings yet

- FLUENT Tutorial 5 - BlowerDocument26 pagesFLUENT Tutorial 5 - BlowerKwanchai ChoicharoenNo ratings yet

- Modeling of Dynamic Systems: An Introduction to Quantities, Models, and Model Solution MethodsDocument666 pagesModeling of Dynamic Systems: An Introduction to Quantities, Models, and Model Solution MethodsZahid RontyNo ratings yet

- CH 9 WeldingDocument18 pagesCH 9 WeldingHazim KhalilNo ratings yet

- Advanced Steel Design PPT in PDFDocument88 pagesAdvanced Steel Design PPT in PDFaskcmiitmNo ratings yet

- Couple Line CouplerDocument14 pagesCouple Line CouplerFiq La Stella NeraNo ratings yet

- Tổng hợp tải trọng Summation phần mềm MIDASDocument8 pagesTổng hợp tải trọng Summation phần mềm MIDASAnonymous DNb6yWERfBNo ratings yet

- P113A Homework 5 Griffith's Quantum Mechanics, Prof. DenninDocument15 pagesP113A Homework 5 Griffith's Quantum Mechanics, Prof. DenninpalisonNo ratings yet

- Gujarat Technological University: W.E.F. AY 2018-19Document2 pagesGujarat Technological University: W.E.F. AY 2018-19Priyank ChhatriwalaNo ratings yet

- Lintels Problems - STEEL STRUCTURESDocument8 pagesLintels Problems - STEEL STRUCTURESDarya Memon100% (1)

- PPTDocument13 pagesPPTAJINKYANo ratings yet

- Physics Ia FinalDocument11 pagesPhysics Ia FinalscarletNo ratings yet

- KENDRIYA VIDYALAYA SANGATHAN SCIENCE SAMPLE PAPERDocument5 pagesKENDRIYA VIDYALAYA SANGATHAN SCIENCE SAMPLE PAPERrajman1990No ratings yet

- Amca 204Document26 pagesAmca 204TotogoNo ratings yet

- Iso 6336-2-2006Document40 pagesIso 6336-2-2006SaiKrishnaImmaneniNo ratings yet

- Midas Civil ManualDocument33 pagesMidas Civil ManualAyoola Oluwadotun100% (2)

- Simple Joints JaspartDocument50 pagesSimple Joints JaspartSargunam Sankaravadivel100% (1)

- Projectile and Circular Motion GuideDocument10 pagesProjectile and Circular Motion GuideBryanHarold BrooNo ratings yet

- Abutment 2Document63 pagesAbutment 2aminjoles100% (2)

- Chapter-Two Part 1Document26 pagesChapter-Two Part 1Wiz Nati XvNo ratings yet

- Atoms and the Atomic TheoryDocument2 pagesAtoms and the Atomic Theoryfaithphotos2019No ratings yet

- Astrological Concepts and Applications DiscussedDocument2 pagesAstrological Concepts and Applications Discusseddevesh parwaniNo ratings yet

- NPTELDocument48 pagesNPTELLuma BlossomsNo ratings yet

- Modeling of Surface-Mounted PMSM in Different Frames of ReferenceDocument19 pagesModeling of Surface-Mounted PMSM in Different Frames of ReferenceAnonymous XKlkx7cr2INo ratings yet

- John Dirk Walecka - Introduction To Classical Mechanics-WSPC (2020)Document184 pagesJohn Dirk Walecka - Introduction To Classical Mechanics-WSPC (2020)Saiyad AliNo ratings yet

- Rohini 84650769189Document14 pagesRohini 84650769189adultankanNo ratings yet

- Principle of Operation of An AccelerometerDocument5 pagesPrinciple of Operation of An AccelerometersangeethsreeniNo ratings yet

- Applications of DerivativesDocument4 pagesApplications of DerivativesSharaine CastilloNo ratings yet

- Ad II (Ae6503)Document2 pagesAd II (Ae6503)Raahini IzanaNo ratings yet