Professional Documents

Culture Documents

Perfect Feeder Design: Casting Design and Simulation 2012

Uploaded by

vijesh1432Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Perfect Feeder Design: Casting Design and Simulation 2012

Uploaded by

vijesh1432Copyright:

Available Formats

CastingDesignandSimulation

2012

CastingDesignandSimulation

Prof.B.Ravi,I.I.T.Bombay

Feedability

Prof.B.Ravi,I.I.T.Bombay

Controlledprogressivedirectionalsolidificationathighestyield

Nohotspotsinsidecasting

PerfectFeederDesign

Feedershape anddimensions(modulus)

Feedpathsconverginginfeeders

Feederlocation&position,Neckconnection

Slowcoolingofconnectingsections

Feedability

FeederSize

NeckSize

FeedPath

Feedaids,Partmodification(padding/fins)

Optimalfeedingefficiency

Feederspercasting,castingsperfeeder

Feederyield

EFoundry,I.I.T.Bombay

FeederModulus(TopFeeders)

Rectangular

Cylindrical

Prof.B.Ravi,I.I.T.Bombay

FeederModulus(SideFeeders)

Rectangular

SphericalTop

CylinderTapered

Prof.B.Ravi,I.I.T.Bombay

SphericalBottom

D =1.5W,H=1.5D

DN =60,HN =50

H=1.5D

DN =60

H=1.5D

DN =60

Blind

0.15D

0.21D

0.23D

Open

0.10D

0.14D

D =1.5W,H=1.5D

DN =60,HN =50

H=1.5D

DN =60

H=1.5D

DN=70

Blind

0.16D

0.19D

0.24D

Open

0.12D

0.15D

0.18D

Assumenoheattransfer(cooling)fromfeederbottom

FeederModulus

Assumenoheattransfer(cooling)fromfeederneckregion

Prof.B.Ravi,I.I.T.Bombay

FeederSize

Prof.B.Ravi,I.I.T.Bombay

STEP1: Ifshapeiscomplex:

F1

subdivideintosimpleshapes,

A

B

Principle:

STEP2:DecidefeederH/D,

F1

calculatemodulusforeach.

Metal

k (min)

CalculateitsHandDbasedon

A

B

Example:

Vol.

(cm3)

250

100

60

Mf=Vf /Af =0.38Df

Area

(cm2)

225

95

94

Df =3.5cmHf =1.5Df =5.3cm

Mod.

(cm)

1.11

1.05

0.64

Feedersolidifiesaftercasting

GreyIron

1.2

Initial:

f >c Mf >Mc Mf =kMc

Ductile Iron

1.2

Mf =kMA=1.2x1.11=1.33cm

Steel

1.3

Aluminum

1.2

Copper

1.3

M=V /A

V =volumeofshape

A =heattransferarea

(c)B.Ravi,IITBombay

modulusvalue.

CastingDesignandSimulation

2012

FeederSize

Prof.B.Ravi,I.I.T.Bombay

FeederSizeEvaluation

Prof.B.Ravi,I.I.T.Bombay

STEP3:Revisefeederdesign

F2

NegativeGradient=>PoorFeeding

consideringenhancedmodulus

A

B

ofconnectedpart

Vol.

(cm3)

250

100

60

Mf=Vf /Af =0.38Df

Area

(cm2)

175

95

94

Df =4.5cmHf =1.5Df =6.8cm

Mod.

(cm)

1.43

1.05

0.64

Revised:

Mf =kMA=1.2x1.43 =1.71cm

CoolingSurfaceArea

Prof.B.Ravi,I.I.T.Bombay

Lowheattransferfrominnerfaces

Effectivemodulus

offeederneckis

1020%higher

d>0.7D

100%coolingfromcore

Layout1

Layout2

FeederNeckDesign

Prof.B.Ravi,I.I.T.Bombay

Feedermodulus>adjacentcastingsectionmodulus

Mfeeder >Mneck

1Mneck >Mhotspot

2 Mneck =Mhotspot

3 Mneck <Mhotspot

11

0.7D>d>0.5D

50%coolingfromcore

d

d <0.5D

0%coolingfromcore

Notchneck

FeederNeckDesign:Exceptions

Prof.B.Ravi,I.I.T.Bombay

Greyandductileirons:graphitisationatendofsolidification:

volumetricexpansioninhardmoldsreducesfeedrequirement.

Idealdesign:feedersuppliesfeedmetalinthebeginning,

thenshutsoff(byfreezingofneckattheappropriatetime).

Mfeeder /Mhotspot =1.1(forGI),1.2(forDI)

Mfdneck /Mhotspot =0.8(forGI),0.9(forDI)

Effectivemodulusofneck

isgreaterthancalculatedvalue

duetoheatingaroundneck.

FeedingDistance

Prof.B.Ravi,I.I.T.Bombay

Platetypecastings,thicknesst,shortfreezingrangemetal

Maximumdistanceincastingfreeofshrinkagedefect:

4.5t

Max.Dist.

Max.Dist.

4.5t

4t

t

Max.Dist.

4.5t+50mm

Max.Dist.

9t+100mm

t

Chill

(c)B.Ravi,IITBombay

Chill

CastingDesignandSimulation

2012

FeedingPressure

Prof.B.Ravi,I.I.T.Bombay

SectionfedbyFeederF1 andF2

SectionfedbyFeederF3

F1

ReversedPr.Gradientcausing

flowfromcastingtofeeder

FeedingPressure

Prof.B.Ravi,I.I.T.Bombay

F2 IscorrectlyventedandeffectsonsectionS3 andS4.

F3 Isnotvented=>buildupofgas =>lowpressure infeeder=>

causingmetalflowsfromS 8toF8=>causingrupture at

weakpointinS8, thuscausingamassivecavityatS8.

F1

CorrectlyVented

S9

S1

S3

F2

S4

F3

S9

NotVented

S1

S3

F2

S4

Surface

Rupture

F3

S8

S8

S2

S2

S5

S6

Summary

Prof.B.Ravi,I.I.T.Bombay

Directionalsolidificationleadstoperfectfeeding

Mfeeder >MNeck >Mcasting toensure feeding

VolumetricexpansioninFGironreducesfeedrequirements

S6

S5

S7

[Adaptedfrom:Castings,J.Campbell]

S7

[Adaptedfrom:Castings,J.Campbell]

Exercise

Prof.B.Ravi,I.I.T.Bombay

Thefollowingfourfeedershaveequalvolume.Arrange

theminincreasingorderofmodulus(solidificationtime).

A

D=10

H=15

D=10.4

H=15.6

D=10.6,L=7

H=15.9

D=11.25

B=3.75,H=16.8

Highest

modulus

Allunitsincm

Metalflowcanbeundergravity,pressureorvacuum

Suitableforintricatepartswithinternalfeatures

(significantcostsavingcomparedtomachining).

Least

modulus

(c)B.Ravi,IITBombay

You might also like

- Control of Ovality in Pipe Bending-A New ApproachDocument5 pagesControl of Ovality in Pipe Bending-A New ApproachJuan AlmeidaNo ratings yet

- Directional DrillingDocument32 pagesDirectional DrillingDante SchneiderNo ratings yet

- Directional DrillingDocument12 pagesDirectional DrillingAsif IqbalNo ratings yet

- Design For Manufacturability: Casting Design and Simulation 2012Document3 pagesDesign For Manufacturability: Casting Design and Simulation 2012Pranjal JainNo ratings yet

- 04 Hybrid RotaryDocument9 pages04 Hybrid RotaryElizabethMnsgNo ratings yet

- Casting Software Lab: Part, Core, Mold: Casting Design and Simulation 2012Document4 pagesCasting Software Lab: Part, Core, Mold: Casting Design and Simulation 2012Pranjal JainNo ratings yet

- Directional DrillingDocument102 pagesDirectional DrillingmatiasNo ratings yet

- (PDF) Machining Operations and Machine ToolsDocument31 pages(PDF) Machining Operations and Machine ToolsKishwatNo ratings yet

- 2010 Model Year Technical ForumDocument89 pages2010 Model Year Technical Forumpablo_sag18100% (3)

- Gear Hobbing FeedingDocument2 pagesGear Hobbing Feedingwalmir.f.navarroNo ratings yet

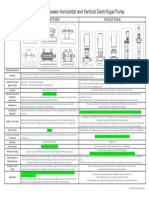

- API 610 Centrifugal Pump Types - OH, BB & VSDocument17 pagesAPI 610 Centrifugal Pump Types - OH, BB & VSDANISH ALINo ratings yet

- Assignment in Subsea Engineering Technology: Villarino, Ray Jason A. Bspe 5ADocument2 pagesAssignment in Subsea Engineering Technology: Villarino, Ray Jason A. Bspe 5AXaviery Keith NoconNo ratings yet

- Rotational Part Example - Capproductions: David Legge / Engineering Design GroupDocument2 pagesRotational Part Example - Capproductions: David Legge / Engineering Design GroupKnvpavankalyan SunnyNo ratings yet

- Asif Ullah,: Me-418 Cad/Cam Laboratory - CreoDocument43 pagesAsif Ullah,: Me-418 Cad/Cam Laboratory - CreoTalhaNo ratings yet

- Asif Ullah,: Me-418 Cad/Cam Laboratory - CreoDocument43 pagesAsif Ullah,: Me-418 Cad/Cam Laboratory - CreoTalhaNo ratings yet

- Asif Ullah,: Me-418 Cad/Cam Laboratory - CreoDocument43 pagesAsif Ullah,: Me-418 Cad/Cam Laboratory - CreoTalhaNo ratings yet

- Design and Fabrication of Vertical AxisDocument4 pagesDesign and Fabrication of Vertical AxisAdibo FostinNo ratings yet

- Directional Well ProfilesDocument4 pagesDirectional Well Profilesmadonnite3781No ratings yet

- Comparison Between Horizontal and Vertical PumpDocument1 pageComparison Between Horizontal and Vertical PumpWilmer GarcíaNo ratings yet

- Brecher2013 Article InfluenceOfTheManufacturingMetDocument10 pagesBrecher2013 Article InfluenceOfTheManufacturingMetranim najibNo ratings yet

- 3.well Profile DesignDocument37 pages3.well Profile Designbruno100% (2)

- G) Fasteners, Bolts and JointsDocument64 pagesG) Fasteners, Bolts and JointsUser 9853No ratings yet

- 2017 Test02 (Non Vib, DFA)Document12 pages2017 Test02 (Non Vib, DFA)deepakNo ratings yet

- Himanish Mehra (Mini Project Report)Document31 pagesHimanish Mehra (Mini Project Report)himanish mehraNo ratings yet

- Presentation SlidesDocument24 pagesPresentation SlidesYidenek NgussieNo ratings yet

- Design and Analysis of Centralizer Used in WellboreDocument6 pagesDesign and Analysis of Centralizer Used in WellboresatyendraNo ratings yet

- Mechanical Engineering Drawing: MECH 211Document98 pagesMechanical Engineering Drawing: MECH 211SaumyaNo ratings yet

- CulvertDesign - Design in Easy Manner1 - 20 - 15Document24 pagesCulvertDesign - Design in Easy Manner1 - 20 - 15Subash KathiresanNo ratings yet

- Ijciet 09 13 153Document8 pagesIjciet 09 13 153Prasun BanikNo ratings yet

- Gear TechnologyDocument31 pagesGear TechnologyRishabh GawriNo ratings yet

- Bini 1Document64 pagesBini 1Mikias TewachewNo ratings yet

- BHA FundamentalsDocument30 pagesBHA FundamentalsAnkit Goyal100% (1)

- 2006 Turner BikesDocument16 pages2006 Turner BikesRichard Quito SeguraNo ratings yet

- Drilling Engineering Overview: Project ManagementDocument24 pagesDrilling Engineering Overview: Project ManagementcricameNo ratings yet

- Power Point Presentation For Foot Driven Centrifugal PumpabebawDocument30 pagesPower Point Presentation For Foot Driven Centrifugal PumpabebawKirubel MogesNo ratings yet

- BHEF Section B - HandoutDocument23 pagesBHEF Section B - HandoutadrianstydNo ratings yet

- Face Hobbing Design & DevelopmentDocument14 pagesFace Hobbing Design & DevelopmentMassimiliano TurciNo ratings yet

- HobbsDocument41 pagesHobbsganeshanNo ratings yet

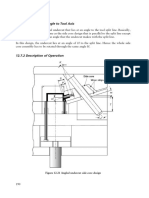

- 2undercuts at Angle To Tool Axis PDFDocument2 pages2undercuts at Angle To Tool Axis PDFnamNo ratings yet

- Please Find The Attached Resume) PDFDocument13 pagesPlease Find The Attached Resume) PDFMUHAMMED FUADNo ratings yet

- Introduction of Manufacturing ProcessesDocument44 pagesIntroduction of Manufacturing Processesdhruvmistry300No ratings yet

- Part SolutionDocument5 pagesPart SolutionCherrydhelNo ratings yet

- Finite Element Study On Chain-Die Forming of An AHSS Channel With Variable DepthDocument24 pagesFinite Element Study On Chain-Die Forming of An AHSS Channel With Variable DepthFRANCK MOREL BENE FANKEMNo ratings yet

- Lecture 6Document25 pagesLecture 6liaqat37_763886179No ratings yet

- Master in Fabrication Layout Development PDFDocument299 pagesMaster in Fabrication Layout Development PDFNicolae Arhire33% (3)

- uPVC Ball Valves: For Water Supply and Irrigation Application..Document2 pagesuPVC Ball Valves: For Water Supply and Irrigation Application..shehanNo ratings yet

- Materi 4 Machining IIDocument51 pagesMateri 4 Machining IIASDI MUNANDAR.FNo ratings yet

- An Example in Steel Casting The One Person Hitch Housing For The 2 and 5 Ton TrucksDocument26 pagesAn Example in Steel Casting The One Person Hitch Housing For The 2 and 5 Ton Trucksram3106No ratings yet

- 80 - Sharma - THESIS - Design of Inlet For Boundary Layer Ingestion in A BWBDocument143 pages80 - Sharma - THESIS - Design of Inlet For Boundary Layer Ingestion in A BWBKevin SánchezNo ratings yet

- Laurence C. Fabiala: Prepared byDocument11 pagesLaurence C. Fabiala: Prepared byLaurenceFabialaNo ratings yet

- S4-Innovative Intersection SolutionDocument44 pagesS4-Innovative Intersection Solutionmuktjemal41No ratings yet

- Suction Bowl DesignDocument3 pagesSuction Bowl DesignSouvik SingharoyNo ratings yet

- PtrE 521 - Lecture 6 - Horizontal and Multilateral WellsDocument116 pagesPtrE 521 - Lecture 6 - Horizontal and Multilateral WellsGhoulemEllah Haithem IfreneNo ratings yet

- Detaliu Nod Pod Integral 3Document56 pagesDetaliu Nod Pod Integral 3Bogdan HritcuNo ratings yet

- The Best of Both Worlds-A Hybrid Rotary Steerable System: Oklahoma City, Oklahoma, USADocument9 pagesThe Best of Both Worlds-A Hybrid Rotary Steerable System: Oklahoma City, Oklahoma, USAStefany Jimenez MendozaNo ratings yet

- Types of Directional Well ProfileDocument6 pagesTypes of Directional Well Profileamol modakNo ratings yet

- Technical Data Sheet: Board Type in Line With EN 622-5Document2 pagesTechnical Data Sheet: Board Type in Line With EN 622-5JulioG.CamposCadenaNo ratings yet

- Features and Benefits: Model CB 15-100 HP BoilersDocument5 pagesFeatures and Benefits: Model CB 15-100 HP BoilerssebaversaNo ratings yet

- 600MW Training Manual of Boiler 20110326Document94 pages600MW Training Manual of Boiler 20110326chandhramohan100% (5)

- MicROLOGIC SETTINGDocument6 pagesMicROLOGIC SETTINGiqkhanukNo ratings yet

- CE 551 NonlinearDocument84 pagesCE 551 NonlinearDeepak ChachraNo ratings yet

- Ciht Industrial Training FileDocument48 pagesCiht Industrial Training FileRishabNo ratings yet

- J. Ross Publishing All Rights Reserved: Foundation-Soil InteractionDocument1 pageJ. Ross Publishing All Rights Reserved: Foundation-Soil InteractionBuliga MarianNo ratings yet

- Bridge EngineeringDocument16 pagesBridge EngineeringJoson Anquillano Villegas100% (1)

- Part HF Requirements For Boilers Constructed of Wrought MaterialsDocument21 pagesPart HF Requirements For Boilers Constructed of Wrought MaterialsKarthikeyan ParthasarathyNo ratings yet

- Pelaksanaan Pekerjaan Contiguous Bored Pile Pada Proyek Margocity Mall, DepokDocument9 pagesPelaksanaan Pekerjaan Contiguous Bored Pile Pada Proyek Margocity Mall, DepokTama PutraNo ratings yet

- 3,000 Psi Weld-On & Threaded Adapters: Industries LTDDocument6 pages3,000 Psi Weld-On & Threaded Adapters: Industries LTDJose Alberto Gamiño GarciaNo ratings yet

- Direct Expansion Air ConditioningDocument1 pageDirect Expansion Air ConditioningPrabhat Kumar100% (1)

- 224700, Drinking Fountains and Water CoolersDocument4 pages224700, Drinking Fountains and Water Coolerssrp. mohammedNo ratings yet

- Quaker Passive House' School Is First of Its Kind in Maine: Heating BillDocument10 pagesQuaker Passive House' School Is First of Its Kind in Maine: Heating BillEss AarNo ratings yet

- Astm d7234Document9 pagesAstm d7234chankawai28100% (9)

- Coat Defects PDFDocument72 pagesCoat Defects PDFkirubha_karan2000100% (1)

- DNJ Energy SavingDocument62 pagesDNJ Energy Savingsantoshkumar777No ratings yet

- Downloadmela Com ST7006 Design of BridgesDocument14 pagesDownloadmela Com ST7006 Design of BridgesSuman.SNo ratings yet

- MCT D ManualDocument25 pagesMCT D ManualAmit KumarNo ratings yet

- Cost Comparison Between Foundry ProcessesDocument14 pagesCost Comparison Between Foundry ProcessesSUNDARRAJAN BNo ratings yet

- A 826 - A826m - 95 Qtgyni05nqDocument5 pagesA 826 - A826m - 95 Qtgyni05nqsachinguptachdNo ratings yet

- How Does Heat Affect MagnetsDocument1 pageHow Does Heat Affect MagnetsMmdNo ratings yet

- 257 - Trelleborg Bending StiffenersDocument8 pages257 - Trelleborg Bending StiffenersantidemosNo ratings yet

- تصميم الكمرات الخرسانيةDocument33 pagesتصميم الكمرات الخرسانيةtvsofianNo ratings yet

- Introduction To The ASTM Designation SystemDocument6 pagesIntroduction To The ASTM Designation Systemmajor_duanNo ratings yet

- Shaftwall PD and UL DesignsDocument57 pagesShaftwall PD and UL DesignsBlake FicklingNo ratings yet

- Lecture 2 Sanitary Pipe SizingDocument52 pagesLecture 2 Sanitary Pipe SizingAlchea Aldeguer100% (1)

- Installation Chapter OneDocument16 pagesInstallation Chapter Oneassefa0% (1)

- Temperature Rise Test On SwitchgearDocument4 pagesTemperature Rise Test On SwitchgearBalusamyNo ratings yet

- Shell and Tube Heat Exchangers FormulaDocument3 pagesShell and Tube Heat Exchangers FormulayuvionfireNo ratings yet