Professional Documents

Culture Documents

Morhs Circle Construction

Uploaded by

Marty DelimaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Morhs Circle Construction

Uploaded by

Marty DelimaCopyright:

Available Formats

Diploma of Mechanical Engineering

Mohr's Circle

This is a graphical method of establishing the state of stress within a material. Once the circle

has been constructed, the values of direct and shear stress occurring at any angle in the material

can be measured for the circle.

Construction of Mohr's circle

1

Draw the element with all the applied stresses on the top right corner of the page. This

is used as the reference for angles and stresses.

Draw the axes for Mohr's circle. Normal stress () Horizontal and Shear stress () on

the vertical.

Plot and label the X point (using the values of x and x ) and Y points (using the values

of Y and Y ) on the graph.

Join the X and Y points and draw a circle to pass through these two points. The centre

must be on the axis.

Note -- Any angle measured on the element are drawn on the circle as TWICE the angle.

Maximum

Shear

Shear

x

x

x

y

x-axis

2

Principle

stress

y-axis

Normal

stress

Principle

stress

Y

X

Principle

stress

Morhs circle construction.doc

S. E. Tomsett.

Version 13-Feb-06

Christchurch Polytechnic

Institute of Technology

Page 1

Printed 16-Feb-09

Diploma of Mechanical Engineering

EXAMPLE PART A

A material is subjected to a stress of 100

MPa in the X direction and a compressive

stress of 30 MPa in the Y direction. A

shear stress of 30 MPa is also applied on

the X axis.

A complementary shear stress of -30 MPa

must exist on the Y axis to prevent the

element from spinning.

This element is now shown in figure 1.

The X Stresses shown in fig 1 are +100

MPa Normal stress (+ being tensile)

and a shear of +30 MPa (+ meaning the

shear arrow is trying to turn the

element clockwise).

The Y Stresses and -30 MPa and -30

MPa.

Note that the two X stresses act on the

same face of the element with the

direct stress acting in the direction of

the x axis.

The X and Y points are plotted and labelled (fig 1). And a circle drawn through the two points

(fig 2).

The X axis labelled in the circle shows the direction of the X stress. The direction of the

maximum stress is also shown (these arrows are

only draw to assist in the explanation of the

method and are not normally drawn). The

direction of the max principal stress lies

clockwise from the direction of the X stress by an

angle of 2. Thus, draw this axis on the element

at an angle of clockwise from the X axis and

state the value of stress given on the circle, 106.6

MPa (show in fig 2). This is the maximum

principal stress.

Draw the principal element aligned at this angle

of . The stresses on the other face of the

element are 90 from the ones above on the

element, so their values are obtained from the circle 180 from the first point. (fig 3). These are

the minimum principal stresses.

Note there is no shear stress on the principal element.

Morhs circle construction.doc

S. E. Tomsett.

Version 13-Feb-06

Christchurch Polytechnic

Institute of Technology

Page 2

Printed 16-Feb-09

Diploma of Mechanical Engineering

PART B

If the stresses on an element at an angle of

30 clockwise from the X axis are

required, (top right hand of fig 4), then

this axis is plotted on the circle at an angle

of 2 x 30 = 60 clockwise from the X axis

shown on the circle. (figure 4).

This axis touches the circle at a point

giving the stresses of = 93.5 MPa and

= -41.3 MPa. (figure 5) Note -ve shear

means the shear arrow for this axis will

turn the element ACW.

These stress act on the axis at 30.

The stresses on the other face of the element are

90 from these on the element, so their values

are obtained from the circle 180 from the first

point.

Morhs circle construction.doc

S. E. Tomsett.

Version 13-Feb-06

Christchurch Polytechnic

Institute of Technology

Page 3

Printed 16-Feb-09

You might also like

- Combined Stresses MOHRS CIRCLEDocument15 pagesCombined Stresses MOHRS CIRCLEMarlNo ratings yet

- Mohr's Circle: Academic Resource CenterDocument23 pagesMohr's Circle: Academic Resource CentersyedamiriqbalNo ratings yet

- Section III: Load and Stress AnalysisDocument29 pagesSection III: Load and Stress Analysisrameshaarya99No ratings yet

- MANE-4030: Elements of Mechanical Design: Worksheet #4: ( 986.4j 469.1k) N ( 563.6j 1250.9k) NDocument4 pagesMANE-4030: Elements of Mechanical Design: Worksheet #4: ( 986.4j 469.1k) N ( 563.6j 1250.9k) Nazizieh5701No ratings yet

- Stress and Strain Relationships of Elastic BehaviorDocument26 pagesStress and Strain Relationships of Elastic Behaviorhsy5478No ratings yet

- Resistencia de MaterialesDocument141 pagesResistencia de MaterialesOscar GutierrezNo ratings yet

- Mohrs Circle Construction ExampleDocument2 pagesMohrs Circle Construction ExampleCarlos Alquinta PNo ratings yet

- Combined Stresses 1Document19 pagesCombined Stresses 1Mae Belle AngayNo ratings yet

- Mohrs Circle Construction ExampleDocument2 pagesMohrs Circle Construction ExampleTesaiNo ratings yet

- Assignment 2Document5 pagesAssignment 2Hamlity SaintataNo ratings yet

- X y Xy: of Plane Stress at A Point (Normal StressesDocument11 pagesX y Xy: of Plane Stress at A Point (Normal Stressesİlker ÇirkinNo ratings yet

- College of Engineering, Architecture and Technology:: Course Title: Course Number: Course DescriptionDocument13 pagesCollege of Engineering, Architecture and Technology:: Course Title: Course Number: Course DescriptionEdmil Jhon AriquesNo ratings yet

- Chapter 6 - COMPLEX STRESSDocument33 pagesChapter 6 - COMPLEX STRESSNurul Raihan Shahizan100% (1)

- Chapter 05 Compound StressesDocument7 pagesChapter 05 Compound StressesAshish KumarNo ratings yet

- Mohr's Circle. It Is So Named in Honor of The German Professor in Civil Engineering Otto Christian Mohr (1835-1918)Document11 pagesMohr's Circle. It Is So Named in Honor of The German Professor in Civil Engineering Otto Christian Mohr (1835-1918)gayatripatil8905No ratings yet

- Exercises On Stress StateDocument4 pagesExercises On Stress StatecusanhNo ratings yet

- Mechanical Aspects Stress at A PointDocument44 pagesMechanical Aspects Stress at A PointAkash SavaliyaNo ratings yet

- Solid Mechanics: Stress Mohr's Circle For Plane StressDocument22 pagesSolid Mechanics: Stress Mohr's Circle For Plane Stressindula123No ratings yet

- Mohr's CircleDocument13 pagesMohr's Circleaap1No ratings yet

- Strength of Materials by S K Mondal 2 PDFDocument31 pagesStrength of Materials by S K Mondal 2 PDFajaykrishna_99No ratings yet

- Chapter Problems (Ed 5)Document167 pagesChapter Problems (Ed 5)ابو النمرNo ratings yet

- Met 1Document46 pagesMet 1Ahmed AbdelhamedNo ratings yet

- GEOENG2 Mohr's CircleDocument28 pagesGEOENG2 Mohr's CirclejbenedictangNo ratings yet

- StressDocument42 pagesStressNauman SuriaNo ratings yet

- Principal Strain: Linear Strains: Extension - PositiveDocument9 pagesPrincipal Strain: Linear Strains: Extension - PositiveMechanical ZombieNo ratings yet

- Chapter 3-Load and Stress AnalysisDocument60 pagesChapter 3-Load and Stress AnalysisNguyễnBảoKhánh100% (1)

- Emg 2309 - 3Document18 pagesEmg 2309 - 3VictoriaNo ratings yet

- Bending of Open & Closed Cross Section BeamsDocument57 pagesBending of Open & Closed Cross Section BeamsSebastian Carter100% (1)

- Theme 2: Mohr Diagram: Exercise 2 - Mathematical Demonstration of The Existence of Principal StressesDocument8 pagesTheme 2: Mohr Diagram: Exercise 2 - Mathematical Demonstration of The Existence of Principal StressesNAFISSA BOURQUIANo ratings yet

- Intro Lecture Stresses in Solid Body OVERVIEWDocument34 pagesIntro Lecture Stresses in Solid Body OVERVIEWhurairabaig37No ratings yet

- Chapter Nine (Autosaved)Document8 pagesChapter Nine (Autosaved)haymanotNo ratings yet

- Chapter 7 - Mohr's CircleDocument28 pagesChapter 7 - Mohr's CircleCho Wing SoNo ratings yet

- Chapter Two Compund StressDocument72 pagesChapter Two Compund StressYalem MesfinNo ratings yet

- Background Notes: Xy Yx X y Xy XyDocument6 pagesBackground Notes: Xy Yx X y Xy Xybridge14No ratings yet

- Two Dimensional Stress TransformationDocument3 pagesTwo Dimensional Stress TransformationKishan MadhooNo ratings yet

- Load and Stress Analysis: 3.1 Equilibrium and Free-Body DiagramsDocument35 pagesLoad and Stress Analysis: 3.1 Equilibrium and Free-Body DiagramsAditya DandekarNo ratings yet

- Mohr Circle ProblemsDocument17 pagesMohr Circle Problems21je0444No ratings yet

- Exam 04032021Document2 pagesExam 04032021Giannis MamalakisNo ratings yet

- Mechanics of Materials: Chapter 7: Transformation of StressDocument39 pagesMechanics of Materials: Chapter 7: Transformation of Stressاحمد يوسفNo ratings yet

- SEISMOLOGY, Lecture 2Document38 pagesSEISMOLOGY, Lecture 2Singgih Satrio WibowoNo ratings yet

- Lecture-4 Moher CircleDocument37 pagesLecture-4 Moher CircleAbhishek BhardwajNo ratings yet

- Lecture 8: Principal StrainDocument8 pagesLecture 8: Principal StrainDavid SilvaNo ratings yet

- Pure Bending PDFDocument8 pagesPure Bending PDFAlvin SmithNo ratings yet

- Assignment 1Document4 pagesAssignment 1MikeyNo ratings yet

- CBE2027 Structural Analysis I Chapter 7 - Mohr's CircleDocument28 pagesCBE2027 Structural Analysis I Chapter 7 - Mohr's CircleManuelDarioFranciscoNo ratings yet

- Chapter NineDocument12 pagesChapter NinehaymanotNo ratings yet

- Stress TransformationDocument10 pagesStress TransformationdocsdownforfreeNo ratings yet

- Essay U4Document5 pagesEssay U4marianacarmonargzNo ratings yet

- Plane Stress Model: Transforming Stress Components and DirectionsDocument7 pagesPlane Stress Model: Transforming Stress Components and DirectionsEngr Aizaz AhmadNo ratings yet

- Mohr's Circle For 2-D Stress AnalysisDocument11 pagesMohr's Circle For 2-D Stress AnalysisabimanaNo ratings yet

- Lec 1 Stresses in Solid BodyDocument36 pagesLec 1 Stresses in Solid Bodyumair100% (1)

- Tutorial 1Document2 pagesTutorial 1Mani BhaiNo ratings yet

- MECH2610 - S2 - Unit 1 - Lecture NotesDocument14 pagesMECH2610 - S2 - Unit 1 - Lecture NotesAatif shaikhNo ratings yet

- 1 Review Stresses Pages2Document16 pages1 Review Stresses Pages2quockhanh310No ratings yet

- Problemas MdsolidDocument11 pagesProblemas MdsolidCristian ReyesNo ratings yet

- All of MeDocument3 pagesAll of MeMarty DelimaNo ratings yet

- Let There Be Peace in EarthDocument1 pageLet There Be Peace in EarthMarty DelimaNo ratings yet

- Go Tell EveryoneDocument2 pagesGo Tell EveryoneMarty Delima100% (2)

- After The Lovin ChordsDocument3 pagesAfter The Lovin ChordsMarty Delima100% (1)

- Go Tell EveryoneDocument2 pagesGo Tell EveryoneMarty Delima100% (2)

- Twist and Shout: (Intro) D - G - A - A7 D-G - A (Verse)Document2 pagesTwist and Shout: (Intro) D - G - A - A7 D-G - A (Verse)Marty DelimaNo ratings yet

- Bridges: G A/C# - CDocument3 pagesBridges: G A/C# - CMarty DelimaNo ratings yet

- The Holy Rosary: Prayer GuideDocument17 pagesThe Holy Rosary: Prayer GuideMarty DelimaNo ratings yet

- Acronis True Image 2016 WD Edition - Knownissues - Build33Document2 pagesAcronis True Image 2016 WD Edition - Knownissues - Build33Marty DelimaNo ratings yet

- 1 Superposition Beam DeflectionDocument2 pages1 Superposition Beam DeflectionMarty DelimaNo ratings yet

- Bolted Joints Twisting ProblemsDocument1 pageBolted Joints Twisting ProblemsMarty DelimaNo ratings yet

- Lord Have Mercy CantorSATBDocument1 pageLord Have Mercy CantorSATBMarty DelimaNo ratings yet

- One Note SambaDocument3 pagesOne Note SambaMarty DelimaNo ratings yet

- Pba Legends 2015 Voting ResultsDocument2 pagesPba Legends 2015 Voting ResultsMarty DelimaNo ratings yet

- Set 1 SongsDocument13 pagesSet 1 SongsMarty DelimaNo ratings yet

- Competitions Training Affiliations Event Coordination Games Venue Physical Arrangements Sponsorship Membership FeesDocument1 pageCompetitions Training Affiliations Event Coordination Games Venue Physical Arrangements Sponsorship Membership FeesMarty DelimaNo ratings yet

- Strain (And Stress) in Two DirectionsDocument1 pageStrain (And Stress) in Two DirectionsMarty DelimaNo ratings yet

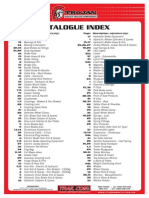

- Trojan Trailer ComponentsDocument44 pagesTrojan Trailer ComponentsMarty DelimaNo ratings yet

- 1 Superposition Beam DeflectionDocument2 pages1 Superposition Beam DeflectionMarty DelimaNo ratings yet

- Battle of The Bands PDFDocument4 pagesBattle of The Bands PDFMarty DelimaNo ratings yet

- Operations Management: Location StrategyDocument21 pagesOperations Management: Location StrategyMarty DelimaNo ratings yet

- CAEfatigue 2021.4 Technical FAQDocument13 pagesCAEfatigue 2021.4 Technical FAQOliver RailaNo ratings yet

- Physical Science Module 4 EditedDocument13 pagesPhysical Science Module 4 EditedLj kim100% (2)

- Lab-Pdf hvt12-05 281115081236Document7 pagesLab-Pdf hvt12-05 281115081236Jai Kumar Sharma MENo ratings yet

- Motion in A PlaneDocument7 pagesMotion in A PlaneDheeraj Kumar SharmaNo ratings yet

- ElectroMagnetic InductionDocument8 pagesElectroMagnetic InductionRobin Singh100% (1)

- A Vortex Model of The Darrieus Turbine: An Analytical and Experimental StudyDocument6 pagesA Vortex Model of The Darrieus Turbine: An Analytical and Experimental Studyjohn arbuckleNo ratings yet

- A Critical Reappraisal of Preconsolidation Pressure Interpretations Using The Oedometer TestDocument3 pagesA Critical Reappraisal of Preconsolidation Pressure Interpretations Using The Oedometer TestUsman HasanNo ratings yet

- Full Download Ebook Ebook PDF Orbital Mechanics For Engineering Students Aerospace Engineering 4th Edition PDFDocument42 pagesFull Download Ebook Ebook PDF Orbital Mechanics For Engineering Students Aerospace Engineering 4th Edition PDFjanet.martino412100% (40)

- Nueva Vizcaya State University College of Engineering: Transport Mechanism For Variable LoadsDocument59 pagesNueva Vizcaya State University College of Engineering: Transport Mechanism For Variable LoadsIvy Joy UbinaNo ratings yet

- Beata J. Dąbrowska-Wüster Et Al - Multicomponent Gap Solitons in Spinor Bose-Einstein CondensatesDocument11 pagesBeata J. Dąbrowska-Wüster Et Al - Multicomponent Gap Solitons in Spinor Bose-Einstein CondensatesPomac232No ratings yet

- Class2 Moment of InertiaDocument45 pagesClass2 Moment of Inertiadccadar100% (1)

- Huth Equation TateDocument69 pagesHuth Equation TatewingsmithNo ratings yet

- (English) Gibbs Phase RuleDocument2 pages(English) Gibbs Phase RuleSahand ShafeeiNo ratings yet

- Worksheet 3 - AMDocument5 pagesWorksheet 3 - AMHydeki RyugaNo ratings yet

- PREDICTION OF TEMPERATURE PROFILE IN OIL WELLS, A. Laderian, 1999, 14 PGDocument14 pagesPREDICTION OF TEMPERATURE PROFILE IN OIL WELLS, A. Laderian, 1999, 14 PGjoselosse desantosNo ratings yet

- Bearing Capacity SPT Graphs ReportDocument90 pagesBearing Capacity SPT Graphs ReportDusan Katic100% (1)

- Phys 3106Document8 pagesPhys 3106myo htetNo ratings yet

- Similarity and Modelling - 2Document7 pagesSimilarity and Modelling - 2Alexander MugabeNo ratings yet

- 9709 w15 QP 42Document4 pages9709 w15 QP 42yuke kristinaNo ratings yet

- Advanced Survey MethodsDocument83 pagesAdvanced Survey MethodsMaxine MukokiNo ratings yet

- 3 Transfer Function PDFDocument4 pages3 Transfer Function PDFisteboiNo ratings yet

- Dynamics - Chapter 1.0Document12 pagesDynamics - Chapter 1.0soraNo ratings yet

- Design of Built Up Plate Girders - p1 - 2perDocument56 pagesDesign of Built Up Plate Girders - p1 - 2perLuis CortesNo ratings yet

- Door and Window Seal Impact On Acoustic and Vi-Brational Behavior of Aerodynamic NoiseDocument8 pagesDoor and Window Seal Impact On Acoustic and Vi-Brational Behavior of Aerodynamic NoiseNivedita SahooNo ratings yet

- Rigid Pavement Design PDFDocument14 pagesRigid Pavement Design PDFvikashNo ratings yet

- Engineering Mechanics Question BankDocument59 pagesEngineering Mechanics Question BankvelavansuNo ratings yet

- Fluid Mechanics-1Document6 pagesFluid Mechanics-1Athar SajjadNo ratings yet

- Sheet 2-Pressure DropDocument2 pagesSheet 2-Pressure Dropmohelg83No ratings yet

- Multiple Choice Questions (MODULE 4 & 5) Mechanics of SolidsDocument67 pagesMultiple Choice Questions (MODULE 4 & 5) Mechanics of SolidsA22 Tekale AdityaNo ratings yet

- Preboard 1 Struct Nov 2017 Without AnswersDocument4 pagesPreboard 1 Struct Nov 2017 Without AnswersEngr. HLDCNo ratings yet