Professional Documents

Culture Documents

1ZVN460100-D Maintenance Manual

Uploaded by

nabil160874Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1ZVN460100-D Maintenance Manual

Uploaded by

nabil160874Copyright:

Available Formats

1ZVN460100 D

Maintenance Manuals

1ZVN460100 D

2/3

Table of contents

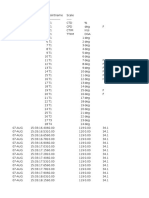

1 Maintenance ............................................................................................................... 3

2 Trouble Shooting ....................................................................................................... 5

1ZVN460100-D

1. Maintenance:

Subject

Insulating oil

Oil tightness

Oil level

Venting devices

Earthing devices

Shut-off devices

Buchholz relay

Dial-type thermometers

Current transformers

Check

Dielectric strength

Moisture content

Neutralisation value

Interfacial surface tension

Water content

Sludge content

Gas analysis

Tank

Conservator

Cooling equipment

Piping

Bushings

Cable sealing ends

Cable boxes

Buchholz relay

Gate valves

Valves

Tank

Conservator

Bushings

Cable sealing ends

Cable boxes

Thermometer pockets

Tank

Cooling equipment

Intermediate piping

Bushings

Piping

Buchholz relay

Cable sealing ends

All metal parts

Tank

Motors

Star points

Surge arresters

Control cabinet

Steal armoured cabling

In position service

Direction of oil flow

Float

Contacts

Gas sampling device

Functional test

Contact setting

Position of maximum pointer

Functional test

Polarity

Ratio

Short-circuit connection

1

1

1

1

1

1

Time period

Year

Month

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

As required

1

1

1

1

1

1

1

1

3

3

3

3

3

3

3

3

3

3

Remarks

If applicable

If applicable

If applicable

If applicable

Release vent screws until

Oil emerges. Afterwards

screw plugs tight

If applicable

If applicable

If applicable

See plan Position of shut off

devices (if provided)

At erection

If applicable

See the Technical data

At errection

At errection

1ZVN460100-D

Subject

Oil level indicator

Breather

Internal wiring

Corrosion protection

Cleanness

Control cabinet

On-load tap changer

Off-circuit tap changer

4/9

Check

Contact setting

Float

Functional test

Silicagel

Oil level

Venting pipes

Insulation resistance

Correct wiring connection

Paint

Blank steal parts

Bushings

Fittings

Indicating devices

Tank cover

Fans

Connection

1

1

1

3

3

3

3

3

3

3

3

3

3

3

3

With 1000V Megger Tester,

Values 50 M

Touch-up

Grease

Remove loose parts,

If applicable

1

See instruction of the

manufacture

N/A

1

3

test

Functional test

Functional test

Remarks

At errection

Switching over all positions

(at least 25 x) to clean

contacts that may be oxidated

and to prevent gas formation

that may result in flash-over

Cooling equipment

Supervisory equipment for

cooling equipment

Protective relay for OLTC

Thermostat Functional

Resistance thermometer

Pressure relief device

Time period

Year

Month

See instruction of the

manufacturer

See instruction of

manufacturer

3

3

3

1ZVN460100-D

5/9

2. Trouble shooting

Protective

and

supervisory

instruments

Various

Fault

Remedial measure

Possible cause

Detailed

description

components

Buchholz relay Alarm at

Buchholz

relay

- Oil loss

- Accumulation

of air

- Gas generation

due to inside

failure

- Violant

vibration

- Fault tripping

Operation can be continued

The following tests and examinations for fault analysis

Should be made as soon as possible

1. Check oil level, pipes, position of valves

2. Check the electrical connections

3. Check the tripping mechanism of the Buchholz relay

4. Put part of the gas into a glass container within five

hours and analyze it.

5. Evaluate the gas analysis

6. Take oil sample (1 litre) from tank top and make and

make a gas analysis

7. Take oil sample (1 litre) from tank bottom and check

for dielectric strength (VDE)

8. Undo all bushing connections and make the

following measurements:

8..1 Measure the insulation resistance between the

windings themselves.

Rough guide value: 1M per kV rated voltage

8.2 Ratio measurement either with measuring kit or by

applying low voltage to the HV side

8.3 Measure the winding resistance with DC

8.4 Measure the no-load current by applying low voltage

9. Compare the result with the test certificates of the

operating instructions

Vent the transformer and put it back into operation

when faults cannot be found or faults have been

eliminated. If the fault occurs frequently, contact

ABB.

Buchholz relay Buchholz

- Oil loss

- Violent oil

surge due to

inside flashover

- Violent gas

generation due

to inside failure

- Violent vibratio

- Fault tripping

relay

tripping

Protective

device for

OLTC

Tripping

due to

strong oil

surge

Maintain the shutdown status.

Carry out tests and measurements as described under

points 1 to 9

Vent the transformer and put in back into operation

when faults can not be found or faults have been

eliminated

Maintain the shutdown status

Check the tripping mechanism

Remove and check the diverter switch

Reset the tripping mechanism and put the

transformer into operation

Instruction of

OLTC

6/9

1ZV460100-D

Protective

and

supervisory

instruments

Various

Fault

Possible cause

Remedial measure

Detailed

description

Oil temp.

too high

- Transformer

overloaded or

inadequate

cooling

- Incorrect temp.

adjustment

Operation

Instruction of

thermometer

manufacture

components

- Resistance

thermometer

- Thermostat

- Dial type

thermometer

for oil or wdg

temperature

indicators

Wdg or

oil temp.

too high

Oil level

indicator

Oil level

too low

Oil flow

monitor

Water flow

monitor

No oil

flow

No water

flow

Pressure relief

device

Motor drive

for OLTC

Moto drive for

OLTC

Redused

water

flow

Internal

tank

pressure

too high

Drive

can not

be

operated

electrical

Drive

keeps on

running

Not enough oil

(low temperature

or oil loss)

Reduce load of the transformer

Put fans or cooling equipment in service

Clean the cooling equipment

Check the position of butterfly valves

Adjust incorrect temperature setting

Check the thermometer by comparative

measurements

Check the electrical connections and the tripping

mechanism

Check control devices for cooling equipment

Check current transformers and thermometers

Check for tightness

Top-up oil

Operation

instruction of

manufacturer

N/A

- Conservator

pipe shut-off or

clogged.

- Electric

flashover inside

the tank

- No voltage

supply at motor

protective

switch (MPS)

- MPS not in

oper. Position

- Motor

contactor K1 or

K2 does not

Pick up

- Motor

contactor K1 or

K2 stuck

- Brake contactor

- K3 does not

pick up

- Open circuit on

one or more

motor phases

- Brake contactor

- K3 stuck

Check the pipes and shut-off devices

Check the transformer as described in Buchholz

relay (point 1-8)

Operation

instruction of

manufacturer

Check supply feeders

Operation

instruction of

OLTC

Close motor protective switch

Check supply feeders and contactors and replace

If necessary

Check contactor, clean or replace if necessary

Correct it

Clean or replace

1ZVN460100-D

Protective

and

supervisory

instruments

Various

7/9

Fault

Possible cause

Remedial measure

components

Motor drive

for OLTC

Motor

protectiv

switch

trips

during

operatio

of motor

drive

Off-circuit tap

changer

Operatio

not

possible

Dehydrating

breather

The

drying

cristals

turn from

blue to

pink and

then to

white

from

below,

- Emergency

stop

button is on or

stuck

- Motor current

excessive due

to overload or

phase failure

Repair or replace emergency stop button

Check drive for stiffness with cran handle. Request a

factory engineer, if a mechanical fault in the tapchanger is suspected

N/A

- High atmosph.

humidity, glass

cylinder leaky

- Moisture in

conservator,

pipe leaky,

glass cylinder

leaky.

- Glass cylinder

burst,

maintenace

interval

Replace dehydrating agent

Replace glass cylinder or seal properly

Seal pipe leaks, check the oil for moisture content.

Flush the conservator with dry air

Breakd.

voltage

too low.

- Breather

inoperable or

trafo in service

very low

Put breather into operation

Water

content

too high

- Leaks in water

cool. System

- Water pressure

reducer

inoperable.

Seal or repair coolers

Contact manufacturer; dry the oil, if necessary

from top,

in

general

Electrical

breakdown

voltage of the

oil

Protective

spark gap on

bushings

Terminal lugs

on bushing

Frequent

operatio

N/A

Discoloration of

connecting parts

Check surface contact

Detailed

description

1ZVN460100-D

8/9

Protective

Fault

and

supervisory

instruments

Various

components

Control cabinet El. App.

does not

operate

properly

Contacts

corroded

or contaminated

Earthing

connection

Pressure gauge

for HV

bushing

Pressure

monitor for

HV bushing

Air flow

monitor

Oil sightpot

App.

housing

bent

Earthing

line

innterupt

-ted

Oil

pressure

in HV

bushing

too high

Oil

pressure

in HV

bushing

too high

No air

flow or

reduced

air flow

Traces of

oil on the

water

surface

Possible cause

Remedial measure

- Excessive

humidity in

control cabinet

Set the cabinet heater to a higher temperature

Seal the cabinet door, fit a dust filter if necessary

Protect the cabinet against solar irradiation; provide

for better ventilation

Clean the contacts, tighten the screws and check the

Electrical distances. Open up current loops. Only

one earthing with a sufficient cross section.

Correct the contact adjustment

Check the reading

Check the bushing; reduce the transformer load,

increase the cooling effect

Correct the contact adjustment

Check the pressure monitor and reset the auxiliary

switch

Check the bushings; reduce the transformer load;

increase the cooling

- Water or dust

inside the

cabin.

- Excessive high

temp. in the

cabinet

- Excessive

current due to

external flash

- Impermissible

current loops

through

multiple earthig

- Incorrect

contacts adjust.

- Bushing

overloaded, oil

temp. too high

due to solar

irradiation

- Incorrect

contact adjustm

- Bushing

overloaded, oil

temp. too high

due to solar

irradiation.

- Violent vibratio

on transformer

Detailed

description

Copyright 2007 ABB, All rights reserved

Document Title

Maintenance Manual

Document No.

Date & Rev. Ind.

No. of Pages

Page

1ZVN460100-D

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Customer Course CatalogDocument102 pagesCustomer Course Catalognabil160874No ratings yet

- MCT Mkvie OmDocument4 pagesMCT Mkvie Omnabil160874No ratings yet

- AbreviationDocument2 pagesAbreviationnabil160874No ratings yet

- AbreviationDocument2 pagesAbreviationnabil160874No ratings yet

- How Moog servo valves operate and differences between simplex and TMR controllersDocument5 pagesHow Moog servo valves operate and differences between simplex and TMR controllersMikoto Rifky100% (1)

- ABB Protection CurvesDocument60 pagesABB Protection Curvesnabil160874No ratings yet

- 389b3172ae B PDFDocument31 pages389b3172ae B PDFnabil160874No ratings yet

- Contacts and permissions for a field breaker switchDocument3 pagesContacts and permissions for a field breaker switchnabil160874No ratings yet

- 109T7219 - E - Network Topology PDFDocument12 pages109T7219 - E - Network Topology PDFnabil160874No ratings yet

- CS18214 Orbit - Q32019 - R1Document8 pagesCS18214 Orbit - Q32019 - R1nabil160874No ratings yet

- GE Frame 9E Gas TurbinesDocument8 pagesGE Frame 9E Gas TurbinesbananosnetNo ratings yet

- Geh 6811 - 2Document30 pagesGeh 6811 - 2nabil160874No ratings yet

- 109T7219 - E - Network Topology PDFDocument12 pages109T7219 - E - Network Topology PDFnabil160874100% (1)

- Med Riad: Sponsored by Control Technology Corp. ..Document8 pagesMed Riad: Sponsored by Control Technology Corp. ..nabil160874No ratings yet

- I To Hmi Upgrades Product Overview EnglishDocument2 pagesI To Hmi Upgrades Product Overview Englishnabil160874No ratings yet

- 635345136746345000Document28 pages635345136746345000nabil160874No ratings yet

- Voltage Protection and Control REU615: Standard ConfigurationsDocument4 pagesVoltage Protection and Control REU615: Standard Configurationsnabil160874No ratings yet

- 09 IGV SystemDocument5 pages09 IGV Systemnabil160874100% (1)

- Newtb 141Document7 pagesNewtb 141proxywarNo ratings yet

- Spectra RMS Molded Case Circuit Breakers: GEH-702 Users ManualDocument52 pagesSpectra RMS Molded Case Circuit Breakers: GEH-702 Users Manualnabil160874100% (1)

- Abb Ref615-2Document186 pagesAbb Ref615-2frajaprNo ratings yet

- Feeder Protection and Control REF620: Application ManualDocument164 pagesFeeder Protection and Control REF620: Application Manualnabil160874No ratings yet

- REF620 Product Guide 1MAC506635-PG Rev BDocument64 pagesREF620 Product Guide 1MAC506635-PG Rev Bnabil160874No ratings yet

- MCT Mkvie OmDocument4 pagesMCT Mkvie Omnabil160874No ratings yet

- 7fatripoildualfuel 140301161154 Phpapp01Document28 pages7fatripoildualfuel 140301161154 Phpapp01Jeya PrakashNo ratings yet

- Classeur 1Document345 pagesClasseur 1nabil160874No ratings yet

- Frame 9a5 DifinitionDocument2 pagesFrame 9a5 Difinitionnabil160874No ratings yet

- Example Diagnostic Report - UsDocument72 pagesExample Diagnostic Report - UsQuick sickNo ratings yet

- Exhaust Temperature Spread 2Document5 pagesExhaust Temperature Spread 2nabil160874No ratings yet

- EM5367Document17 pagesEM5367nabil160874No ratings yet

- CA2 Group-5Document5 pagesCA2 Group-5Lakshya KaushikNo ratings yet

- Primary Assignment 1 Science 1Document15 pagesPrimary Assignment 1 Science 1IslamBachaMkdNo ratings yet

- Zapi H2B ManualDocument67 pagesZapi H2B ManualEvans100% (3)

- LHD Specification R1Document32 pagesLHD Specification R1Roobens SC LaraNo ratings yet

- 3 - Electrical System PDFDocument39 pages3 - Electrical System PDFnamduong3680% (1)

- Maspro SRE-90R User ManualDocument11 pagesMaspro SRE-90R User ManualbacteriaaaNo ratings yet

- Data SheetDocument37 pagesData Sheetczds6594No ratings yet

- Ni 9213Document38 pagesNi 9213Milan DjordjevicNo ratings yet

- Verification of Superposition Theorem.Document6 pagesVerification of Superposition Theorem.Apu SarkarNo ratings yet

- ETSI TetraDocument142 pagesETSI TetramnnoriNo ratings yet

- Automatic Transfer Switch Trans-ATS - D - Manual - EN V03Document54 pagesAutomatic Transfer Switch Trans-ATS - D - Manual - EN V03POTÊNCIA ATIVA GERADORESNo ratings yet

- sjzl20083076-ZXMBW B9100 (V3.20) Installation Manual PDFDocument91 pagessjzl20083076-ZXMBW B9100 (V3.20) Installation Manual PDFRamiz3zNo ratings yet

- Low Loss Coaxial Cable For Radio Communications: CharacteristicsDocument2 pagesLow Loss Coaxial Cable For Radio Communications: CharacteristicsAntonio CorreiaNo ratings yet

- Book 1to9Document495 pagesBook 1to9sanssansshilthNo ratings yet

- Analog Circuits II Lab ManualDocument47 pagesAnalog Circuits II Lab ManualParesh SawantNo ratings yet

- Line of 2Nd Floor: 1St Floor Electrical Lighting and Wiring Plan E 1Document1 pageLine of 2Nd Floor: 1St Floor Electrical Lighting and Wiring Plan E 1Atienza ArjayNo ratings yet

- Current ElectricityDocument35 pagesCurrent ElectricityAdarshNo ratings yet

- Christie RF80 K Specification SheetDocument6 pagesChristie RF80 K Specification SheetJuan MartinezNo ratings yet

- R20ut2905eg0100 RSK TFT App Board SchematicDocument4 pagesR20ut2905eg0100 RSK TFT App Board SchematicZeeshan AslamNo ratings yet

- Distributed Generation JenkinsDocument9 pagesDistributed Generation JenkinsSandeep KumarkjNo ratings yet

- EHV Catalogue PDFDocument29 pagesEHV Catalogue PDFvineets058No ratings yet

- Schedule of Loads and Computation: General NotesDocument1 pageSchedule of Loads and Computation: General NotesRommel DollenteNo ratings yet

- Technical Information-Cables PDFDocument5 pagesTechnical Information-Cables PDFAlvin Smith100% (1)

- Brosur Line Post InsulatorDocument2 pagesBrosur Line Post InsulatorHizbul MaulanaNo ratings yet

- ANSI IEEE C63.5 ( (Electromagnetic CompatibilitDocument73 pagesANSI IEEE C63.5 ( (Electromagnetic Compatibilitoyavuz38No ratings yet

- IEC-E04-S02 Rev 3 Sep 2020 Dry Type Transformers up to 500 kVADocument9 pagesIEC-E04-S02 Rev 3 Sep 2020 Dry Type Transformers up to 500 kVA15150515715No ratings yet

- Two Resistor Model For Thermal Simulation-EDocument5 pagesTwo Resistor Model For Thermal Simulation-EILikeScribd5050No ratings yet

- IJCRT1803270Document13 pagesIJCRT1803270Chandra Shekhar SahuNo ratings yet

- Eps 123 Electric CircuitDocument2 pagesEps 123 Electric Circuiteuge sylNo ratings yet

- Enhancement Mode Power MOSFET: NCE N-ChannelDocument7 pagesEnhancement Mode Power MOSFET: NCE N-ChannelErroz RosadiNo ratings yet