Professional Documents

Culture Documents

Design Plastic Bottle Crusher

Uploaded by

agungCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design Plastic Bottle Crusher

Uploaded by

agungCopyright:

Available Formats

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 10, October- 2014

Design and Development of a Plastic Bottle

Crusher

Yeshwant M. Sonkhaskar

Anurag Sahu, Amit Choubey, Amritpal Singh

and Raghav Singhal,

Asst. Professor, Department of Mechanical Engineering.

Shri Ramdeobaba College of Engineering & Management,

Katol Road, Nagpur, Maharashtra, India

bottle and make an exit path for the fluid trapped inside a

closed bottle without which the closed bottle cannot be

crushed. Also an escape path for the crushed bottle was made.

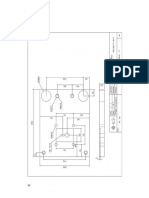

A 3-D model of the final design is as shown in fig.1

The various components were designed based on the

principles of design. Various calculations were done and the

dimensions of all the components were calculated. The force

required for crushing a Plastic Bottle was calculated and the

force that can ergonomically applied by an average human

was also obtained from the ergonomic table. Based on these,

the gear ratio was calculated. Further, the Forces and Stress

on each element were analyzed and thereafter the safe

dimensions for all the components were calculated.

IJE

RT

AbstractA crusher is a machine designed to reduce large

solid material objects into a smaller volume, or smaller pieces.

Crushers may be used to reduce the size, or change the form, of

materials so they can be more easily and efficiently used in the

purpose intended to. Crushing is the process of transferring a

force amplified by mechanical advantage through a material

made of molecules that bond together more strongly, and resist

deformation more, than those in the material being crushed do.

The aim of this work as the title suggests is to design and

manufacture a crusher which will minimize the volume of

commercially used mineral water plastic bottles. This project

would help the people to crush commercially used plastic Bottles

conveniently. This project aims to design and manufacture a

plastic bottle crusher that is portable and can be installed at

multiple public places, which will aid in crushing of used bottles.

KeywordsCrusher, Bottle Crusher, Can Crusher, Crusher

Design, Jaw Crusher

Students, Department of Mechanical Engineering,

Shri Ramdeobaba College of Engineering &

Management, Katol Road, Nagpur, Maharashtra, India

I.

INTRODUCTION

A. Tentative Design of the Mechanism

The design process was accomplished in many

stages. At first, we chalked out the objectives of the design

and the basic mechanism of the machine. The ideas and

innovations about the working of project were implemented

in this stage of the Project.

The Portability and compactness of the machine

were the major objectives of design, so that the designed

machine could be stationed easily at multiple public place.

Also the machine had to be simple in design and construction

such that its maintenance and repair could be convenient. The

bottle crushing machine is a hand operated machine and thus

it is important to have an optimum usage of effort.

Accordingly, the mechanism was designed. This

conceptualized machine should also have the agility to crush

bottles of different dimensions and hence the dimensions and

other design aspects were chosen accordingly.

B. Final Design

Once the objectives and basic mechanisms of the

machine were decided, the process of design of various

components was initiated. In the process of design, various

configurations of the components were analyzed and the

almost compact and efficient were chosen. This design has a

gear train housed in between the two flywheels. The Gear

train transmits the power from the hand driven wheel to the

flywheel and cutter. The flywheel then transfers the rotary

motion to the reciprocating mechanism which will crush the

bottle. The Cutter mechanism was incorporated to cut the

IJERTV3IS100320

Fig. 1. Final Design

II.

STEPS IN FABRICATION

Fabrication of the bottle crusher was divided into 4

stages. It consists of the fabrication of base structure, its

components, transmission system and the reciprocating

system. The different processes followed in the fabrication of

these components is elaborated under the following heads

A. Fabrication of Base Structure

The steel structural bar that has an L-shaped

cross section of 2*2 inches were taken and were cut into 4

pieces as per the dimensions of the structure plate, out of

which 2 steel bars were of longer length and 2 were of shorter

length. These steel bars were welded to form the base plate of

the machine.

www.ijert.org

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

297

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 10, October- 2014

Four more bars were cut and were welded to support

the frame to bring it to a particular height i.e. which acted as

the legs of the frame as shown in fig.2

Fig. 4. Cutter

Fig. 2. Base Structure

IJE

RT

B. Fabrication of Various Components

A long MS shaft was cut into 4 pieces of appropriate

dimensions with the help of acetylene gas cutter, after which

the edges were made round by grinding. Then the shafts were

turned on the lathe machine for its proper fitting into the

pedestal.

For the spur gears, the bushes were manufactured on

the lathe machine. The bushes were faced from both sides

and then turned so that it matches the inner diameter of the

gear. These bushes were then press fitted into the gear and a

hole of the diameter same as that of the shaft was drilled.

Then a vertical hole was drilled in the bush for the grub

screw. The grub screw was tightened over the flat notch. The

same procedure was followed for the rest of the gears. The

gear assembly is shown in fig. 3

For flywheels, two square plates were taken having

size larger than the flywheel dimension after which they were

cut into the required circular shape by acetylene-arc cutter.

Flywheels were then machined over the lathe machine. A

bush was welded at the center of a flywheel and a hole was

drilled. After that, a shaft was attached to the flywheel with

the help of a grub screw. One more hole was drilled near the

outer edge of both the flywheels for the insertion of pin.

Now, a bolt was inserted into the hole. To provide an offset to

the link, we had introduced a nut between the flywheel and

link and then an outer nut for locking the links. Fig. 5 shows

flywheel arrangement.

Fig. 5. Flywheel Arrangement

C. Fabrication of Transmission System

The gears were fitted over the shaft and were locked

in their respective position with the help of grub screws. On

the first shaft, a cutter was fixed in its appropriate position.

Pedestals were attached on both the sides of the shaft. All the

pedestals were placed at their respective location in

accordance with proper meshing of gears. Marking was done

for holes to be drilled over the base for fitting the pedestal.

Fig. 3. Gear Assembly

For the cutter, a bolt was welded to the side of the

cutter and then the drilling was done in the perpendicular

direction to its axis of rotation for same locking arrangement

as that in gears. Fig 4 shows the position of cutter on the shaft

IJERTV3IS100320

The pedestals were bolted over the base and all the

shafts were place at their respective locations in accordance

with proper meshing of gears. The flywheels were attached

outside the frame over the second shaft, which were then

tightened with the help of grub screws. Both the flywheels

were aligned such that both the pins were in a same line. The

power transmission system is as shown in fig.6

www.ijert.org

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

298

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 10, October- 2014

Fig. 8. Reciprocating System

Fig. 6. Transmission System

IJE

RT

For the driving handle, a long plate was cut with the

help of acetylene cutter, after which grinding was done to

make its edges smooth. After that,a nut was welded on one

side of the plate and a hole was drilled on the other side. The

handle was then attached with the help of nut and bolt. The

handle was then attached to fourth shaft on its outer side as

shown in Fig. 7.

The second plate was supported with the help of two

ribs. After that, the slider was kept between the two bright

bars and were inserted into the holes passing through the first

plate, then through the slider and finally through the second

plate as shown in Fig.8

A small circular support was attached to the slider

plate so that the bottle does not slip. Below the cutter, a plate

was welded which acts as a support to the bottle during the

crushing mechanism. Two bolts were welded on the slider

plate over the holes through which the bright bars was

passing, which acted as a support to the slider plate during

reciprocating motion.

III. EXPERIMENTATION AND TESTING

The experimentation was conducted after the

manufacturing process was completed. In this phase, the

components of Machine were checked for smooth operation

and movement. Then the experimentation on crushing was

performed. The objective of design was to manufacture a

Plastic bottle crushing machine to crush plastic bottles of

different dimensions. Experimentation was also conducted to

test the agility of machine. Thus Plastic Bottles of different

dimensions and quality were collected and an experiment was

conducted. The Experimentation data for Crushed Plastic

Bottles is mentioned below in Table-I

Fig. 7. Driving Handle

D. Fabrication of Reciprocating System

In this part, a C.I. flat plate was cut into three parts

of required dimensions by arc cutter, out of which, two were

used as fixed plates which will act as the support and one is

the moving slider plate which crushes the bottle.

On all the flat plates, marking was done with the

help of punch and two holes were drilled on each plate with

the help of drilling machine, whose diameter was same as

that of the bright bars to be inserted. These bright bars acted

as a guide for the moving plate. The second fixed plate was

welded at a calculated distance. The rectangular slot was cut

in the first plate by arc-cutter so that the cutter can cut the

bottle.

IJERTV3IS100320

Table

Head

TABLE I.

EXPERIMENTATION DATA

Table Column Head in millimeters

Brand of Bottle

Length

Width

Length after

Crushing

Bisleri

275

80

140

Aquafina

275

86

140

Kinley

270

85

140

Oxyrich

270

84

140

The length of all the bottles were reduced to 140 mm

for any input length and quality of material. Thus, it can be

said that the Plastic Bottle Crushing Machine can crush

bottles of different dimension. After that, the percentage of

crushed volume was calculated. In the Crushing process, it

was found that the circular cross section bulges out at some

sections and deforms inwards at some. Thus the mean area of

the circular cross section of the bottle will remain the same as

before.

www.ijert.org

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

299

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 10, October- 2014

The percentage of reduction in length was

calculated. For all the input dimensions and quality of plastic

bottle, the length of crushed bottle obtained was 140 mm. In

the subsequent stage the percentage reduction in volume was

calculated for all the crushed bottles. Reduction in volume

was calculated with the help of the following formula.

=

Thus, the initial and Final Volume was found out by the

dimensions of the Bottles that were measured. The Following

table-II shows percentage reduction in volume.

TABLE II.

PERCENTAGE REDUCTION IN VOLUME

Table Column Head

Table

Head

Brand of

Bottle

Initial

Length

(mm)

Final

Length

(mm)

Percentage Reduction

in Volume

Bisleri

275

140

49.09 %

Aquafina

275

140

49.09%

Kinley

270

140

48.14 %

Oxyrich

270

140

48.14 %

Thus, from the above calculations we can say that

the Plastic Bottle Crushing Machine has the ability to reduce

the volume of the plastic bottle up to 49%.

On an average the Machine reduces the volume of

bottle to 49% of the initial volume. It was found that the

machine is capable of crushing Cans as well with some

appropriate positioning of Can.

REFERENCES

[1]

Yeshwant M. Sonkhaskar, Amit Choubey, Amritpal Bhamra, Raghav

Singhal, Anurag Sahu. New Design of a Plastic Bottle Crusher

International Journal of Scientific & Technology Research (IJSTR)

ISSN 2277-8616, volume 3, issue 7, Page 61-63, July 2014.

[2] La-la ZHAQ, Zhong-binWANG and Feng ZANG, Multi-object

optimization design for differential and grading toothed roll crusher

using a genetic algorithm, Journal of China University of mining and

technology, Volume 18, Issue 2, June, Page 316-320, 2008.

[3] A. Gupta and D. S. Yan, Gyratory and Cone Crusher, Mineral

Processing Design and Operation, Volume 2, Pages 128

[4] M. Moshgbar, R. A. Bearmant, R. Parkin, Optimum control of cone

crusher utilising an adaptive strategy for wear compensation, Journal

of Minerals Engineering, Volume 8, Issues 4

[5] Patent by Warren R. Heiser, 934 N. Mildred, Dearborn, Mich. 48128,

Can Crusher Appl. No.: 450,422, Mar. 12, 1974.

[6] Patent by Larry M. Belfils, 12670 San Pablo Ave., Richmond, Calif.

94803, Can Crusher Appl. No.: 810,526, Jun. 27, 1977.

[7] Patent by Constantino J. Balbo, 116 France St.; Leonard F. Bruhn;

Clements E. Bruhn, both of P.O. Box 153, all of Sonoma, Calif. 95476,

Can Crusher Appl. No.: 198,522, Oct. 20, 1980.

[8] Patent by George F. Wittmeier Can Crusher for reducing cans or

similar containers to a compact form Appl. No.: 679,577, Apr. 23,

1976.

[9] Joseph Edward Shigley, Shigleys Mechanical Engineering Design,

Mc. Graw Hill Publishers, 8th Edition, Pg. Nos.: 33- 145, 209- 260

[10] Design Data Book by Dr. B.D. Shivalkar, Revised Edition 2011

Published by Denett & Co.

[11] Theory of Machine and Mechanism by John J. Uicker, Joseph E.

Shigley, Gordon R Pennock, 3rd Edition

IJE

RT

The next stage of Experimentation was performed to

test the agility of Machine to crush cans. A Can of Mirinda

Cold Drink was taken for the experiment. The can was placed

on the Base and Piston was moved forward to press the can

against the Cutter. The crushing stroke of Machine was then

completed and Can was Crushed.

In the next stage of process testing was carried out

on the Machine. The Machine thus designed has the agility to

crush Bottles of different dimensions as observed in the

Testing and Experimentation phase. Experiments were also

conducted on crushing of Cans.

There were no abnormal vibrations nor wear of

cutter observed in the crushing process of can. Thus we can

conclude that the machines can also crush Cans.

IV. RESULTS AND CONCLUSIONS

The plastic Bottle Crusher thus designed and

fabricated is a unique, compact and portable Plastic Bottle

Crushing Machine. The final machine is an outcome of a

series of processes, in which the first was analysis and study

of requirements and conceptualization of machine, then the

Design and Fabrication and finally the Testing of Machine.

Thus all the mentioned processes were successfully executed

for the Plastic Bottle Crusher.

The Plastic Bottle Crusher thus manufactured is

portable and compact. The crushing force that is required to

crush a plastic bottle as found experimentally, is well within

the range of the force that can ergonomically be applied by an

average human. The machine was then designed on the basis

of the load required to crush the bottle. The tentative design

and dimensions of machine components was then taken for

fabrications. The Manufacturing difficulties brought further

changes in the design. The model thus designed was

fabricated and assembled.

IJERTV3IS100320

www.ijert.org

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

300

You might also like

- Design and Fabrication of Plastic Bottle and Can Crusher For Recycling PurposeDocument3 pagesDesign and Fabrication of Plastic Bottle and Can Crusher For Recycling PurposeInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Design and Fabrication of Ginger Juice Extracting MachineDocument33 pagesDesign and Fabrication of Ginger Juice Extracting MachineSanman SawantNo ratings yet

- Programmable Logic Controller Hardware and Software ArchitectureDocument10 pagesProgrammable Logic Controller Hardware and Software ArchitectureKantharaj ChinnappaNo ratings yet

- Automatic Plaster MachineDocument4 pagesAutomatic Plaster MachineIJMTST-Online JournalNo ratings yet

- Automatic Rice Transplantation Machine PDFDocument4 pagesAutomatic Rice Transplantation Machine PDFHidden Face01No ratings yet

- Chapter 10Document78 pagesChapter 10Si Thu AungNo ratings yet

- Lemon Grass HarvesterDocument61 pagesLemon Grass HarvesterKok HuanNo ratings yet

- Coconut Dehusking MachineDocument16 pagesCoconut Dehusking MachineArjuncv100% (4)

- Fabrication of Portable Noodle Making Ma Fd82a2eeDocument4 pagesFabrication of Portable Noodle Making Ma Fd82a2eeankush belkarNo ratings yet

- Advanced Pepper Separator Machine: A Project ReportDocument42 pagesAdvanced Pepper Separator Machine: A Project ReportSports GalleryNo ratings yet

- Can CrusherDocument11 pagesCan CrusherElakkiya KarthicNo ratings yet

- Portable Electric Power Tilling Machine Project ReviewDocument8 pagesPortable Electric Power Tilling Machine Project ReviewP KalaivaniNo ratings yet

- FS 244 ManualDocument23 pagesFS 244 Manualonkarvaidya89100% (1)

- MD E-Note 22092018 125841PM PDFDocument175 pagesMD E-Note 22092018 125841PM PDFPramod DhaigudeNo ratings yet

- Design and Fabrication of Multipurpose Agricultural Mini Farm Vehicle Using Scooter EngineDocument10 pagesDesign and Fabrication of Multipurpose Agricultural Mini Farm Vehicle Using Scooter Enginenagaraju b 334No ratings yet

- Machinery TextDocument25 pagesMachinery TextMd Firoz Alam Khan100% (1)

- Final Thesis - 2Document48 pagesFinal Thesis - 2pratik giradkarNo ratings yet

- Compressed Air VehicleDocument21 pagesCompressed Air VehicleHarshit Dhawan100% (1)

- Analysis of Tool Geometry for Screw Extrusion MachinesDocument12 pagesAnalysis of Tool Geometry for Screw Extrusion MachinesdjklikaNo ratings yet

- Mchine Onion22Document78 pagesMchine Onion22Siraj Mohammed100% (1)

- What Are Different Types of Brakes?Document9 pagesWhat Are Different Types of Brakes?Japhet Charles Japhet Munnah100% (1)

- Design and Fabrication of Pedal Powered Lawn Mower CycleDocument2 pagesDesign and Fabrication of Pedal Powered Lawn Mower CycleVinayaga ProjectinstituteNo ratings yet

- Fabrication of An Aluminium Can Crusher MachineDocument33 pagesFabrication of An Aluminium Can Crusher MachineVincent MartinezNo ratings yet

- 08 CH-6, Fluid Motion Within Combustion ChamberDocument24 pages08 CH-6, Fluid Motion Within Combustion ChamberAhsan AliNo ratings yet

- Fabrication of Bevel Gear Drive Screw Jack for Automobile GaragesDocument5 pagesFabrication of Bevel Gear Drive Screw Jack for Automobile GaragesANAND KRISHNAN100% (1)

- Design of A Bicycle Powered Rope PumpDocument46 pagesDesign of A Bicycle Powered Rope PumpOrtega Ian67% (3)

- PS Chapter 3Document2 pagesPS Chapter 3Barlo Yñigo AlcantaraNo ratings yet

- Design and Fabrication of Waste Paper Recycling Machine For Laboratory and Medium Scale OperationDocument7 pagesDesign and Fabrication of Waste Paper Recycling Machine For Laboratory and Medium Scale OperationKenn MendozaNo ratings yet

- Design and Fabrication of Ginger Harvesting MachineDocument19 pagesDesign and Fabrication of Ginger Harvesting MachineNarender YadavNo ratings yet

- Design and Testing of Mechanical Juice Extraction Especially For Sugar Cane - 24 PagesDocument24 pagesDesign and Testing of Mechanical Juice Extraction Especially For Sugar Cane - 24 PagesMoHaMMeD HaLaBy50% (6)

- Multi Type ForkliftDocument46 pagesMulti Type ForkliftlokeshNo ratings yet

- Vegetable Cutting MachineDocument48 pagesVegetable Cutting MachineOo PoutNo ratings yet

- Working Model of a Hydroelectric Power PlantDocument25 pagesWorking Model of a Hydroelectric Power PlantAshwani SahuNo ratings yet

- (Estrera Final Papers) YAHOODocument95 pages(Estrera Final Papers) YAHOOJohn Mark CarpioNo ratings yet

- Multipurpose Air Flow Duct PDFDocument11 pagesMultipurpose Air Flow Duct PDFHabtie GetinetNo ratings yet

- BoardDocument8 pagesBoardJerald ManlangitNo ratings yet

- Identification of The Diesel Engine ComponentsDocument13 pagesIdentification of The Diesel Engine Componentsguswerino240% (1)

- Fabrication of Automatic Pneumatic Clamping IgnovDocument7 pagesFabrication of Automatic Pneumatic Clamping IgnovChockalingam AthilingamNo ratings yet

- Salient Features Sunkoshi 3 HEP-2 PagerDocument2 pagesSalient Features Sunkoshi 3 HEP-2 PagerBidur GautamNo ratings yet

- Automatic Tapping Drilling MachineDocument76 pagesAutomatic Tapping Drilling MachineChandramanikandanNo ratings yet

- Design of An Innovative Coconut Grating Machine Using TinkercadDocument5 pagesDesign of An Innovative Coconut Grating Machine Using TinkercadChristopher Ysit100% (1)

- Adigrat University: Pedal Operated Water Pump (Concrete Pedal Pump)Document50 pagesAdigrat University: Pedal Operated Water Pump (Concrete Pedal Pump)Melese HaileNo ratings yet

- Designof Power Driven Dough Mixing MachineDocument5 pagesDesignof Power Driven Dough Mixing MachineTewodros B.No ratings yet

- Machine DrawingDocument15 pagesMachine Drawingganesh916No ratings yet

- Design of Seed Sowing MachineDocument7 pagesDesign of Seed Sowing MachinePranshu GuptaNo ratings yet

- Triangle Multi Drill HolderDocument43 pagesTriangle Multi Drill HolderSendhilNathan100% (1)

- Virtual Manufacturing: ColloquiumDocument37 pagesVirtual Manufacturing: ColloquiumSum Sumne SumanthNo ratings yet

- Debre Tabor University Designs Solar Water HeaterDocument72 pagesDebre Tabor University Designs Solar Water Heateryoseph GetnetNo ratings yet

- Multi Spindle Drilling MachineDocument4 pagesMulti Spindle Drilling Machinejohn2292No ratings yet

- BioDocument5 pagesBioAnnie MasakalNo ratings yet

- Pnumatic Ramming and Punching Machine ReportDocument28 pagesPnumatic Ramming and Punching Machine ReportSun SriNo ratings yet

- A Review On Revolution of Flat Plate Collector For Solar Water HeaterDocument17 pagesA Review On Revolution of Flat Plate Collector For Solar Water HeaterIJRASETPublications100% (1)

- Design and Fabrication of Onion Seed Sowing Machine 1433826027 PDFDocument10 pagesDesign and Fabrication of Onion Seed Sowing Machine 1433826027 PDFGuiiNo ratings yet

- Upto 2010 KomDocument36 pagesUpto 2010 KomRajueswarNo ratings yet

- Fabrication of Multipurpose 4 in 1 Agriculture Robotic VehicleDocument33 pagesFabrication of Multipurpose 4 in 1 Agriculture Robotic Vehicleanne valiaNo ratings yet

- Development of Plastic Bottle Shredding Machine 2252 5211 1000336Document4 pagesDevelopment of Plastic Bottle Shredding Machine 2252 5211 1000336salfm08100% (1)

- Pneumatic Bike: A Step To Future: V. Lohit A. Imran MohideenDocument3 pagesPneumatic Bike: A Step To Future: V. Lohit A. Imran MohideenTanviNo ratings yet

- MV harmonic motion problemsDocument1 pageMV harmonic motion problemsNeeraj Goyal100% (1)

- Design & Development of Three Roller Sheet Bending MachineDocument4 pagesDesign & Development of Three Roller Sheet Bending MachineEditor IJRITCCNo ratings yet

- Fabrication of Automatic Drilling & Tapping MachineDocument5 pagesFabrication of Automatic Drilling & Tapping MachineIJRASETPublicationsNo ratings yet

- ReadmeDocument1 pageReadmeagungNo ratings yet

- Kartu Hasil StudiDocument1 pageKartu Hasil StudiagungNo ratings yet

- Perpindahan Panas QuisDocument1 pagePerpindahan Panas QuisagungNo ratings yet

- Electronic Learning Inspires CreativityDocument11 pagesElectronic Learning Inspires CreativityagungNo ratings yet

- Electronic Learning Inspires CreativityDocument11 pagesElectronic Learning Inspires CreativityagungNo ratings yet

- Revisi Kalender Elearning Reguler II Genap 14.15 PDFDocument1 pageRevisi Kalender Elearning Reguler II Genap 14.15 PDFSiti NurjanahNo ratings yet

- Lampiran BDocument6 pagesLampiran BagungNo ratings yet

- TA On ClassDocument1 pageTA On ClassagungNo ratings yet

- Materials 2015Document28 pagesMaterials 2015agungNo ratings yet

- Project XDocument1 pageProject XagungNo ratings yet

- Diketahu 1Document3 pagesDiketahu 1agungNo ratings yet

- Springbacks Metal On RollformingDocument10 pagesSpringbacks Metal On RollformingagungNo ratings yet

- ValuGrind 2015Document23 pagesValuGrind 2015agungNo ratings yet

- Seminar - UMB Pengertian API, Ledakan & Risk Assessment (Share)Document120 pagesSeminar - UMB Pengertian API, Ledakan & Risk Assessment (Share)agungNo ratings yet

- Poster Workshop Renewable Energy V2Document1 pagePoster Workshop Renewable Energy V2agungNo ratings yet

- ValuGrind 2015Document23 pagesValuGrind 2015agungNo ratings yet

- Project XDocument1 pageProject XagungNo ratings yet

- Auto Indexing Gear Cutter PDFDocument7 pagesAuto Indexing Gear Cutter PDFagungNo ratings yet

- Y. H. P. Manurung, M. A. Mohamed, D. Andud, A. Z. Abidin, S. Saidin, K. Kasim, D. P. IshakDocument15 pagesY. H. P. Manurung, M. A. Mohamed, D. Andud, A. Z. Abidin, S. Saidin, K. Kasim, D. P. IshakFatman Fatin FaudiNo ratings yet

- Sanding PowerPointDocument8 pagesSanding PowerPointagungNo ratings yet

- Desain Otomatis KonveyorDocument8 pagesDesain Otomatis KonveyoragungNo ratings yet

- Modeling and Design of Wave Spring WashersDocument7 pagesModeling and Design of Wave Spring WashersagungNo ratings yet

- Auto Indexing Gear Cutter PDFDocument7 pagesAuto Indexing Gear Cutter PDFagungNo ratings yet

- Transmission Line and Substation ComponentsDocument72 pagesTransmission Line and Substation ComponentsVictor CiprianNo ratings yet

- GEIER SDGE TestimonyDocument10 pagesGEIER SDGE Testimonyonell.soto653No ratings yet

- GDTP Flyer PDFDocument2 pagesGDTP Flyer PDFAliefNo ratings yet

- MassMin 2004 PDFDocument740 pagesMassMin 2004 PDFFelipe Espinoza Cortés100% (2)

- Docslide Us Jet Blue Airways Managing Growth Case SolutionDocument12 pagesDocslide Us Jet Blue Airways Managing Growth Case SolutionprateekNo ratings yet

- Overseas Job Visa Consulting in GhanaDocument9 pagesOverseas Job Visa Consulting in GhanadevrajnNo ratings yet

- Quality Plus Company ProfileDocument36 pagesQuality Plus Company ProfileMartin Carlo Martinez0% (1)

- Te Mecanica U-BoltDocument2 pagesTe Mecanica U-BoltJuan carlos santos jimenezNo ratings yet

- Birdair Tensotherm Brochure - 2014Document4 pagesBirdair Tensotherm Brochure - 2014Angel ReyesNo ratings yet

- Technical Explanation of Corrugated Board Structure and PropertiesDocument2 pagesTechnical Explanation of Corrugated Board Structure and PropertiesCraig DaughertyNo ratings yet

- Man, Machine, Material, Method, EnvironmentDocument3 pagesMan, Machine, Material, Method, Environmentanua9496No ratings yet

- HL78Document2 pagesHL78Renato WatanabeNo ratings yet

- Exposre in Weblogic Server 11g and Experience in Integration Ebs With Sso/oamDocument6 pagesExposre in Weblogic Server 11g and Experience in Integration Ebs With Sso/oamMohammad ZaheerNo ratings yet

- Penerapan Value Engineering Untuk Menghemat Biaya Produksi Sapu Ijuk Pada Ud. Maju JayaDocument5 pagesPenerapan Value Engineering Untuk Menghemat Biaya Produksi Sapu Ijuk Pada Ud. Maju JayaSagita Aulia IndriyaniNo ratings yet

- Maintenance Score CardDocument24 pagesMaintenance Score Cardrkan71268186% (14)

- ProjectCalcs KEYDocument72 pagesProjectCalcs KEYHaider Shadfan100% (1)

- Boeing 767 - Wikipedia, The Free EncyclopediaDocument22 pagesBoeing 767 - Wikipedia, The Free EncyclopediaSherlock HólmesNo ratings yet

- Understanding and Selecting Data Masking Solutions: Creating Secure and Useful DataDocument33 pagesUnderstanding and Selecting Data Masking Solutions: Creating Secure and Useful DataEntoni_104No ratings yet

- Sujit ResumeDocument3 pagesSujit ResumeRahul Singh PariharNo ratings yet

- Fehr Bros Garage Door CatalogDocument52 pagesFehr Bros Garage Door CatalogMauricio J. GongoraNo ratings yet

- Hempedur 85671Document2 pagesHempedur 85671Shanoor ASNo ratings yet

- Library 1Document7 pagesLibrary 1Dayakar RanaNo ratings yet

- EMS User ManualDocument20 pagesEMS User ManualKhurram shahzadNo ratings yet

- Structural Eurocode Timber Bd2405Document262 pagesStructural Eurocode Timber Bd2405Joe Howard50% (2)

- BOMA 1 Introduction AIADocument70 pagesBOMA 1 Introduction AIAConstantin FlorescuNo ratings yet

- Numerical, Wind Tunnel, and On Track Study of Monash 2002 Aero PackageDocument13 pagesNumerical, Wind Tunnel, and On Track Study of Monash 2002 Aero PackageZizo StarkNo ratings yet

- Adstock Rate - Deriving With Analytical Methods - BlogDocument2 pagesAdstock Rate - Deriving With Analytical Methods - BlogbashdeepNo ratings yet

- ARP4761 - WikipediaDocument3 pagesARP4761 - Wikipediagowtham raju buttiNo ratings yet

- Godrej Product MixDocument10 pagesGodrej Product MixAritra SilNo ratings yet

- API 6D Overview - Pipeline & Piping ValvesDocument3 pagesAPI 6D Overview - Pipeline & Piping ValvesNilesh MistryNo ratings yet