Professional Documents

Culture Documents

Making A Flynn Motor - Circuit Diagram Attached: Parallel Path Magnetic Theory

Uploaded by

dewidewi76Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Making A Flynn Motor - Circuit Diagram Attached: Parallel Path Magnetic Theory

Uploaded by

dewidewi76Copyright:

Available Formats

Making a Flynn Motor - Circuit Diagram Attached

http://homemadecircuitsandschematics.blogspot.com/2014/02/making-flynn-motorcircuit-diagram.html

The post provides an in-depth description of the Flynn motor concept and furnishes the

rough replication details for the same.

In one of my previous posts we got a comprehensive view regarding what's populary

known as the parallel path magnetic theory

In this theory a relatively weaker electromagnetic assistance is used for manipulating a

massive force obtained from a few enclosed permanent magnets.

The same theory when implemented for acquiring a rotational movement, is able to

create to a force which could not be achieved through the conventional motor concepts.

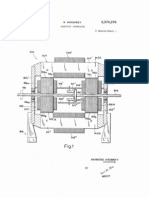

Also called the Flynn motor, the figure below is the basic or the classic representation

which shows how the parallel path technology could be implemented for building motors

with outstanding efficiency.

Understanding the Flynn Motor

The concept used in Flynn motor is no rocket science rather a very straightforward

magnetic theory where the magnetic attraction of permanent magnets is enforced for

the generating massive amounts of free energy.

The images below show the basic design of the Fynns motor, which just like an ordinary

motor has an outer stator and an inner rotor.

The stator is a stationery structure made out of two ferromagnetic sections specially

dimensioned for facilitating the proposed parallel path actions.

Fundamentally these are two "C" shaped ferromagnetic structures possessing a central

block space for accommodating a coil winding, while the ends are chiseled flat for

clutching a couple of permanent magnets in between the two "C" structures.

The above structures form the stator.

A circular structure also made up of ferromagnetic material can be seen positioned

exactly at the center of the two "C" shaped stator. This forms the rotor of the proposed

Flynn motor design.

The above rotor circular structure encloses five projected convex arms at its

circumference with a specific cut-out shape which makes a calculated angle with the

complimentary concave edges enclosed with the two"C" shaped stator.

The relative angle between the rotor/stator surfaces are configured such that all the

surfaces never come face to face at any given instant.

Now let's understand how the wire coil and the permanent magnets interact to generate

the proposed extraordinary amount of force over the rotor movement.

As long as the winding over the stator is not connected to the specified electrical input,

all the four stator's inner concave surfaces exhibit an equal amount of magnetic

attraction over the rotor arms keeping the rotor movement uninfluenced.

The above magnetic pull is caused due to the two permanent magnets stationed at the

shown locations.

Now as soon as an electrical input is fed across the winding (which must alternate across

the two coils at any specified frequency) the rotor experiences the parallel path effect

and responds with a high torque rotation with an RPM determined by the frequency

applied between the coils by the electrical input .

The rotational influence generated by the parallel effect can be understood by referring

to the diagram below.

Now suppose, the initial instantaneous frequency polarity of the coil input pulls the rotor

and aligns the A and B arms of the rotor with the 1 and 2 surfaces of the stator, inducing

a clockwise movement.... the next instant as soon as the coil polarity is reversed, the

above clockwise movement is reinforced as the "parallel path" magnetic pull tries to

align the rotor C and D arms with the 3/4 surfaces of the stator....the next polarity

change repeats the previous alignment procedure.

The above explained continuous magnetic influence (supported by the outstanding

parallel path technology) forces the rotor to undergo a strong rotational motion featured

with efficiency exceeding the 100% mark.

The referred exceptional torque is generated due to the parallel path effect through

which a relatively weaker electrical input causes the magnetic fields of the enclosed

permanent magnets to concentrate on either sides alternately making sure the opposite

side is subjected with a zero force simultaneously.

The speed of above flipping action is determined by the frequency of the electrical input

across the two winding.

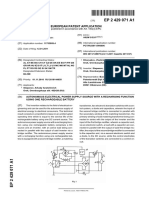

How to Make the Flip Flop Circuit

The flip flop or the alternate switching of the stator coils can be implemented simply by

using the circuit shown below.

The circuit is not complicated at all, the entire configuration is built around the IC 4047

and the switching is done with the help of two mosfets.

The center tap of the coil can be seen terminated to the positive while the ends of the

coils wires are connected with the mosfet drain.

The RPM can be controlled with the aid of the shown pot.

A few things that must be taken into account while building the above explained Flynn

motor.

The dimensions of the test prototype must not exceed that of a normal fan motor.

The magnets should not be too strong, a rule of thumb is to select a cross sectional area

that may be 50% less than the enclosing surface of the stator.

The RPM must not be made too rapid, the Flynn motor is said to work the best at lower

RPMs where it is able to generate exceptional amounts of torque compared to the fed

electrical input.

The gap between the rotor and stator surfaces must not exceed the 0.5mm mark.

Image Courtesy: http://peswiki.com/index.php/Directory:Flynn_patent_images

A more graphical representation of the discussed Flynn motor layout ca be seen below.

You might also like

- Parallel Magnetic Path TechnologyDocument16 pagesParallel Magnetic Path TechnologyMohammed FaizanNo ratings yet

- Power Generation by Foot Step Method - Rack and PinionDocument13 pagesPower Generation by Foot Step Method - Rack and Pinionprem53100% (2)

- Prentice Earth Energy TapDocument7 pagesPrentice Earth Energy TapGeorggeNo ratings yet

- Build Your Own DIY QuadcopterDocument23 pagesBuild Your Own DIY QuadcopterHoàngCôngAnhNo ratings yet

- Stepper Motors 1Document4 pagesStepper Motors 1ngt881No ratings yet

- Ni Sbrio-9651: Getting Started With The Sbrio-9651 Som Development KitDocument2 pagesNi Sbrio-9651: Getting Started With The Sbrio-9651 Som Development Kitkhin600No ratings yet

- LJ Create: Analog and Digital Motor ControlDocument7 pagesLJ Create: Analog and Digital Motor ControlMahmud Hasan SumonNo ratings yet

- EMS Lab Manual Ver 1.0 (Fall 2016)Document69 pagesEMS Lab Manual Ver 1.0 (Fall 2016)Fahad MahmoodNo ratings yet

- 0102 - Forever Flasher PDFDocument3 pages0102 - Forever Flasher PDFMuhammadAsifNo ratings yet

- Micro Drive Processor Based Mosfet AC InverterDocument131 pagesMicro Drive Processor Based Mosfet AC InverterMugunthan SVNo ratings yet

- Automatic Solar Tracking SystemDocument82 pagesAutomatic Solar Tracking SystemDebashishParidaNo ratings yet

- 220V DC To 220V AC: DIY Inverter Part 2: InstructablesDocument10 pages220V DC To 220V AC: DIY Inverter Part 2: InstructablesTnT ElektricNo ratings yet

- Electric Motor: Your Activity MaterialDocument6 pagesElectric Motor: Your Activity MaterialJoel Varghese ThomasNo ratings yet

- Antenna Add On 2 12 18 Pdfmate MergeDocument946 pagesAntenna Add On 2 12 18 Pdfmate MergepowerinfiniteNo ratings yet

- Generating electric power from ferromagnet magnetic fieldsDocument12 pagesGenerating electric power from ferromagnet magnetic fieldsMihai DanielNo ratings yet

- Permanent Magnet Motor GuideDocument36 pagesPermanent Magnet Motor GuidekkarthiksNo ratings yet

- Bedini Monopole 3 Group ExperimentDocument5 pagesBedini Monopole 3 Group Experimentnadirma66No ratings yet

- Fan Charger Relay ChargerDocument4 pagesFan Charger Relay ChargerluzenskiNo ratings yet

- No. 390,721, Patented 00 T. 9, 1888.: Best Avalable Cop N, TeslaDocument4 pagesNo. 390,721, Patented 00 T. 9, 1888.: Best Avalable Cop N, TeslaAtharva Deshpande100% (1)

- PhysicsDocument16 pagesPhysicslordbravorious100% (1)

- Andrey Melnichenko 19 AugDocument3 pagesAndrey Melnichenko 19 AugJaroslav KnopNo ratings yet

- Roto Verter - Rv-9Document38 pagesRoto Verter - Rv-9chigoNo ratings yet

- Bsse Knowledge How - The - Stan - Meyer - Tech - Works 2 July 2018Document120 pagesBsse Knowledge How - The - Stan - Meyer - Tech - Works 2 July 2018Jumpman OutletNo ratings yet

- March 19, 1968 - R, Kromrey I 3,374,376: Electric GeneratorDocument8 pagesMarch 19, 1968 - R, Kromrey I 3,374,376: Electric GeneratorVlad AdrianNo ratings yet

- How Parallel Path Magnetic Technology Achieves Over-Unity EfficiencyDocument62 pagesHow Parallel Path Magnetic Technology Achieves Over-Unity EfficiencyrockrainNo ratings yet

- Homopolar Motor With Liquid Metal BrushesDocument7 pagesHomopolar Motor With Liquid Metal Brushestheodorakis017781No ratings yet

- MelnichenkoDocument5 pagesMelnichenkomitza22No ratings yet

- Stepper MotorDocument59 pagesStepper Motorya zool / يا زولNo ratings yet

- Tesla Coil Project: V1 Cprobe 15p CP 9.3p L1 19.5m R1 1megDocument9 pagesTesla Coil Project: V1 Cprobe 15p CP 9.3p L1 19.5m R1 1megNISHANT KumarNo ratings yet

- VHDL Implementation of Floating Point Multiplier Based On Vedic Multiplication TechniqueDocument8 pagesVHDL Implementation of Floating Point Multiplier Based On Vedic Multiplication Techniqueganga_chNo ratings yet

- WWW Youtube Com Watch V HyTplvO4i9UDocument2 pagesWWW Youtube Com Watch V HyTplvO4i9UJohnnyLarsonNo ratings yet

- Free Energy GenerationDocument3 pagesFree Energy Generationjohn peterNo ratings yet

- Bedini Monopole 3 Group ExperimentDocument5 pagesBedini Monopole 3 Group Experimentfrankmiller1480% (1)

- Lic Eec-501 Notes Unit5 Iftm UniversityDocument14 pagesLic Eec-501 Notes Unit5 Iftm UniversitySougata GhoshNo ratings yet

- Sony DXC 3000aDocument14 pagesSony DXC 3000aOnceUponAThing100% (1)

- Slip Ring and Split RingDocument5 pagesSlip Ring and Split RingboltuNo ratings yet

- Samsung CL29K3W Chassis KS3ADocument92 pagesSamsung CL29K3W Chassis KS3AHernan Ortiz EnamoradoNo ratings yet

- Design Analysis and Simulation of Magnetic Biased Inductors With Saturation-Gap - EPE2014Document8 pagesDesign Analysis and Simulation of Magnetic Biased Inductors With Saturation-Gap - EPE2014andresNo ratings yet

- Ultrasonic Motor AbstractDocument2 pagesUltrasonic Motor AbstractVishal Singh Rahangdale100% (2)

- Significance of Back EmfDocument1 pageSignificance of Back Emfntrimurthulu100% (1)

- Particle Accelerator TorDocument12 pagesParticle Accelerator Tormonica pradhanNo ratings yet

- Joule Thief CircuitDocument8 pagesJoule Thief CircuitTariq PatelNo ratings yet

- How To Build Johann BesslerDocument13 pagesHow To Build Johann BesslerixCxlNo ratings yet

- Solid State Relay Backemf - Recoil Recovery Circuit - AlternativeWorld EnergyDocument2 pagesSolid State Relay Backemf - Recoil Recovery Circuit - AlternativeWorld Energyfsilassie8012No ratings yet

- The Marinov Generator1Document7 pagesThe Marinov Generator1Ioan CozmaNo ratings yet

- Step Recovery DIODEDocument9 pagesStep Recovery DIODEwoyaoxiaxiaNo ratings yet

- Permanent Magnet Linear Generator DesignDocument5 pagesPermanent Magnet Linear Generator DesignIOSRjournalNo ratings yet

- Edge-Triggered Driver Circuit For Ultra-WidebandDocument4 pagesEdge-Triggered Driver Circuit For Ultra-WidebandTeeNo ratings yet

- Andrei Melnichenko InventionsDocument7 pagesAndrei Melnichenko InventionsPopescu George BogdanNo ratings yet

- Make A High Voltage Supply in 5 MinutesDocument11 pagesMake A High Voltage Supply in 5 MinutesfabaummNo ratings yet

- 555 Oscillator ApplicationsDocument17 pages555 Oscillator Applicationsgopir28No ratings yet

- Autonomous Power Supply with Increased Operation Time Using a Single BatteryDocument6 pagesAutonomous Power Supply with Increased Operation Time Using a Single BatteryPopescu George BogdanNo ratings yet

- Thermodynamics 2Document7 pagesThermodynamics 2riez24No ratings yet

- HPT (Ieee, 2005)Document7 pagesHPT (Ieee, 2005)Muhammad Hadi MustajabNo ratings yet

- LV Steho enDocument7 pagesLV Steho enKeresztúri FerencNo ratings yet

- Laser spectroscopy IXFrom EverandLaser spectroscopy IXMichael FeldNo ratings yet

- Magneto-Resistive and Spin Valve Heads: Fundamentals and ApplicationsFrom EverandMagneto-Resistive and Spin Valve Heads: Fundamentals and ApplicationsNo ratings yet

- For The Detection of LP Gas: Applications: FeaturesDocument2 pagesFor The Detection of LP Gas: Applications: Featuresdewidewi76No ratings yet

- Technical Information Sheet NAP-66A Catalytic Gas Sensor, Optimised For The Detection of LPG, Butane, Propane NemotoDocument2 pagesTechnical Information Sheet NAP-66A Catalytic Gas Sensor, Optimised For The Detection of LPG, Butane, Propane Nemotodewidewi76No ratings yet

- 0 60V LM317 Variable Power Supply CircuitDocument6 pages0 60V LM317 Variable Power Supply Circuitdewidewi76No ratings yet

- Contoh Rumus Daya Pada Resistor Dan Ic Lm317Document1 pageContoh Rumus Daya Pada Resistor Dan Ic Lm317dewidewi76No ratings yet

- Amplifier Protection CircuitDocument2 pagesAmplifier Protection Circuitdewidewi76No ratings yet

- Inductance Measuring Adapter For MultimeterDocument7 pagesInductance Measuring Adapter For Multimeterdewidewi76No ratings yet

- Amplifier Protection CircuitDocument2 pagesAmplifier Protection Circuitdewidewi76No ratings yet

- Samonasavaci Cerpadlo CEHDocument19 pagesSamonasavaci Cerpadlo CEHdewidewi76No ratings yet

- Simple Motor MonopolarDocument9 pagesSimple Motor Monopolardewidewi76No ratings yet

- The Design and Formula of DC To DC Converter SmpsDocument9 pagesThe Design and Formula of DC To DC Converter Smpsdewidewi76No ratings yet

- Experimental Research of Magnetic-Gravity EffectsDocument0 pagesExperimental Research of Magnetic-Gravity Effectsdewidewi76No ratings yet

- Visual Ac Mains Voltage IndicatorDocument2 pagesVisual Ac Mains Voltage IndicatorIlle Antoniu NicolaeNo ratings yet

- I O Controller Designed For IP Surveillance SystemsDocument6 pagesI O Controller Designed For IP Surveillance Systemsdewidewi76No ratings yet

- Brushless Alternators: © 2000 Graig PearenDocument3 pagesBrushless Alternators: © 2000 Graig PearenAboalfotoh Mahmoud100% (2)

- Motor Direction ControllerDocument1 pageMotor Direction Controllerdewidewi76No ratings yet

- L14F1 Infrared DetectorDocument4 pagesL14F1 Infrared Detectordewidewi76No ratings yet

- Andrew Craig Caravan Fridge ThermostatDocument1 pageAndrew Craig Caravan Fridge Thermostatdewidewi76No ratings yet

- Design of Small Photovoltaic (PV) Solar-Powered Water PumpDocument71 pagesDesign of Small Photovoltaic (PV) Solar-Powered Water Pumpdewidewi76No ratings yet

- Opa132, Opa2132, Opa4132Document8 pagesOpa132, Opa2132, Opa4132dewidewi76No ratings yet

- Add This Short Circuit Protection To Your Power SupplyDocument2 pagesAdd This Short Circuit Protection To Your Power Supplydewidewi76No ratings yet

- Temp Sensor Manual Update 1Document4 pagesTemp Sensor Manual Update 1dewidewi76No ratings yet

- Use Magnetic Energy To Heal The WorldDocument230 pagesUse Magnetic Energy To Heal The WorldyakyyakyNo ratings yet

- Pulse Width Modulator With NE555 Timer OscillatorDocument1 pagePulse Width Modulator With NE555 Timer Oscillatordewidewi76No ratings yet

- 60Hz Noise Fillers Adjustable Circuit and PCB Parts AssemblyDocument1 page60Hz Noise Fillers Adjustable Circuit and PCB Parts Assemblydewidewi76No ratings yet

- Electric motor with increased torqueDocument8 pagesElectric motor with increased torqueAngel CoteraNo ratings yet

- Manual Oper Manut Gerador KATO - 350 01001 00Document48 pagesManual Oper Manut Gerador KATO - 350 01001 00Damiao PereiraNo ratings yet

- ABB-Motors and Generators TrainingDocument130 pagesABB-Motors and Generators TrainingElafan100% (1)

- 5 MCE Test Data PDFDocument60 pages5 MCE Test Data PDFLuis GonzalezNo ratings yet

- Basic Electricity ReviewerDocument3 pagesBasic Electricity Reviewercircuitor201283% (6)

- Usco PD V1 A1 22Document12 pagesUsco PD V1 A1 22baywatch80No ratings yet

- 3-Phase Induction Motor FundamentalsDocument26 pages3-Phase Induction Motor Fundamentalsravin singhNo ratings yet

- Ger 3954c Generator in Situ InspectionsDocument16 pagesGer 3954c Generator in Situ InspectionsAnonymous veyW4YWjkNo ratings yet

- PhdThesis Weizhong FeiDocument284 pagesPhdThesis Weizhong FeiHuynh Thanh AnhNo ratings yet

- Binder 1Document18 pagesBinder 1tj82npdh9cNo ratings yet

- Online Monitoring of Inter-Turn Short Circuit Fault of Field Winding in Large Turbo-GeneratorDocument5 pagesOnline Monitoring of Inter-Turn Short Circuit Fault of Field Winding in Large Turbo-GeneratorhamidrezaNo ratings yet

- Axial Flux Motors Radial Flux MotorsDocument5 pagesAxial Flux Motors Radial Flux Motors123456No ratings yet

- BobiSoft Short Description 2017Document12 pagesBobiSoft Short Description 2017Masum uddin mondolNo ratings yet

- Intorq Bfk457: Setting The StandardDocument40 pagesIntorq Bfk457: Setting The StandardElton Rodrigues de BritoNo ratings yet

- BacksTab 03Document155 pagesBacksTab 03VaishnaviRaviNo ratings yet

- Conference Paper Gvpi Rewind Geno 02082018externalforweb LegallyDocument21 pagesConference Paper Gvpi Rewind Geno 02082018externalforweb LegallySISWANTONo ratings yet

- Three Phase Induction Motor Torque-Slip CharacteristicsDocument22 pagesThree Phase Induction Motor Torque-Slip Characteristicskarthikeyan249No ratings yet

- Webdoc Dax 2 Pole SM0000247E A3 5.10Document4 pagesWebdoc Dax 2 Pole SM0000247E A3 5.10tonwalaNo ratings yet

- 18EES101J Basic Electrical Engineering EeeDocument122 pages18EES101J Basic Electrical Engineering EeeShaik RazaqNo ratings yet

- Motor Manufacturing Process FlowDocument8 pagesMotor Manufacturing Process FlowcmashtamoorthyNo ratings yet

- HTB12 AC Drilling Motor User ManualDocument15 pagesHTB12 AC Drilling Motor User ManualJohn SimancaNo ratings yet

- Solar Hacksaw Project ReportDocument55 pagesSolar Hacksaw Project Reportramesh218482% (11)

- Tim Lab ManualDocument66 pagesTim Lab ManualDEVAKREDDY ChNo ratings yet

- Generato RS: Prepared By: Ms. Clydine Jethna O. SigueDocument33 pagesGenerato RS: Prepared By: Ms. Clydine Jethna O. SigueChamain MarreroNo ratings yet

- VR6 Voltage Regulator - Pruebas y Ajustes - CATERPILLARDocument30 pagesVR6 Voltage Regulator - Pruebas y Ajustes - CATERPILLARCesar Alfonso Saldivar MontoyaNo ratings yet

- Grr-Monthly Progress Report April 2014Document52 pagesGrr-Monthly Progress Report April 2014TigistuNo ratings yet

- Thermal Power Station ReportDocument51 pagesThermal Power Station ReportChinni BandaruNo ratings yet

- Aruna Biomass Company ProfileDocument9 pagesAruna Biomass Company ProfileAdhavan ThamizhanNo ratings yet

- Automatic Magnetic Motor Free Energy Generator: PG Scholar, EEE, PRIST UniversityDocument11 pagesAutomatic Magnetic Motor Free Energy Generator: PG Scholar, EEE, PRIST UniversityCris VillarNo ratings yet

- Kirloskar Electric Ltd. Internship ReportDocument41 pagesKirloskar Electric Ltd. Internship ReportPranit Patil100% (5)