Professional Documents

Culture Documents

Ansi

Uploaded by

Sonu SinghOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ansi

Uploaded by

Sonu SinghCopyright:

Available Formats

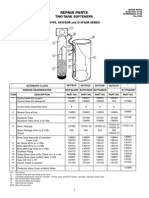

ANSI/FCI Leakage Classes

Page 1 of 2

ANSI/FCI Leakage Classes

ANSI/FCI leakage classes are defined in the following table.

Table 1. ANSI/FCI Leakage Classes

ANSI/FCI 702

(FGS 4L5)

II

Maximum

Leakage

0.5% of valve capacity at full travel

Test

Medium

Air

III

0.1% of valve capacity at full travel

Air

Service DP(3) or 50 psi, whichever is

lower

IV

0.01% of valve capacity at full travel

Air

Service DP(3) or 50 psi, whichever is

lower

V(1)

Standard Air Test

for Sliding Stem Valves

0.0005 mL/min/psid/inch port dia.

Water

Std 0.05 mL/min/psid/inch port dia

Air

(SATSSV)

VI

Test

Pressures

Service DP(3) or 50 psi, whichever is

lower

Service DP(3)

(3)

Service DP

Test

Procedure

A

or 50 psi, whichever is

lower

(2)

Nominal

Bubbles

mL

Air or N2

C

Service DP or 50 psid, whichever is

Port Dia.

per Min.

per Min.

lower

(Inch)

Up to 1

1

0.15

11/2

2

0.30

2

3

0.45

21/2

4

0.60

3

6

0.90

4

11

1.70

6

27

4.00

8

45

6.75

1.ANSI/FCI Class V seat leak water test is not available for oxygencleaned, cryogenic or any valves cleaned per Fishers Oxygen cleaning

guidelines. Any disassembly to dry and/or reclean the valve would invalidate the seat leak test. Contact your local Fisher sales representative

for optional seat leakage tests for oxygencleaned valves.

2.Fisher Controls leakage classes.

3.Specify service DP when ordering.

Special NonANSI/FCI Leakage Class

A special nonANSI/FCI leakage class is defined in the following table.

Table 2. TSO (Tight Shutoff) Leakage Class

Leakage Class

Maximum Leakage

TSO (Tight Shutoff) Valves with TSO trim are factory

tested to a more stringent Fisher

Controls test requirement of no

leakage at time of shipment.

1. Specify service DP when ordering.

Test Medium

Water

Test Pressure

Service DP(1)

Test Procedure

ANSI/FCI Class V test procedure B

Test Procedures

A brief description of the test procedures is given below.

Test Procedure A

The test is performed with clean air at room temperature pressurized to the lesser of 50 psig or the maximum

operating differential pressure specified on the order. Valve seats are wetted with tap water or demineralized

water. The actuator, adjusted to meet the operating conditions on the order, is then pressurized (airtoclose)

to the specified maximum plus 5 psi or vented (springtoclose) to atmosphere and leakage flow is allowed to

stabilize.

Test Procedure B

file:///C:/Program%20Files/Fisher%20Controls%20International%20LLC/HelpFiles/Shut... 10/13/2016

ANSI/FCI Leakage Classes

Page 2 of 2

The test is performed with clean tap water or demineralized water at room temperature pressurized to the

maximum service pressure drop across the valve. Prior to the actual test, the valve is opened to allow the

downstream valve cavity and piping to fill with water. The actuator, adjusted to meet the operating conditions

on the order, is then pressurized (airtoclose) to the specified maximum plus 5 psi or vented (springtoclose)

to atmosphere and leakage flow is allowed to stabilize.

Test Procedure C

The test is performed with clean air or nitrogen at room temperature pressurized to the lesser of 50 psi or the

operating differential pressure specified on the order. The actuator, adjusted to meet the operating conditions

on the order, is then pressurized (airtoclose) to the specified maximum plus 5 psi or vented (springtoclose)

to atmosphere and leakage flow is allowed to stabilize.

Test Procedure D

The test is performed with clean air at room temperature pressurized to the lesser of 50 psi or the maximum

operating differential pressure specified on the order.

Back to ANSI/FCI Leaksage class definitions

file:///C:/Program%20Files/Fisher%20Controls%20International%20LLC/HelpFiles/Shut... 10/13/2016

You might also like

- 5 3 17Document14 pages5 3 17Raymond de WeeverNo ratings yet

- Pump by BoseDocument26 pagesPump by BoseSonu SinghNo ratings yet

- Manufacturing Egg Trays from Waste PaperDocument17 pagesManufacturing Egg Trays from Waste Paperravibarora86% (7)

- Tank Baffles Design CalcDocument8 pagesTank Baffles Design CalcJorge Alberto Martinez Ortiz100% (1)

- Standpipes PDFDocument2 pagesStandpipes PDFAhmed Omar100% (1)

- OPERATING & SERVICE MANUAL AZ-1-107-NL SERIES PUMPDocument16 pagesOPERATING & SERVICE MANUAL AZ-1-107-NL SERIES PUMPREZA ASGARINo ratings yet

- 02-A Kinetico Owners Manual - Commercial Plus Softener SeriesDocument32 pages02-A Kinetico Owners Manual - Commercial Plus Softener SeriesCastoriadisNo ratings yet

- Lateral Tee: What Is The Difference Between Lateral Tee and True WYEDocument2 pagesLateral Tee: What Is The Difference Between Lateral Tee and True WYEAnonymous 6ZWS6IG2J9No ratings yet

- BQ Mechanical (Sirim)Document7 pagesBQ Mechanical (Sirim)mohd farhan ariff zaitonNo ratings yet

- C22-Yb60-M-4763 - 0 Sa3-Ps2, Butterfly Valve, Operating ManualsDocument173 pagesC22-Yb60-M-4763 - 0 Sa3-Ps2, Butterfly Valve, Operating ManualssartajNo ratings yet

- Glass Level GaugesDocument44 pagesGlass Level GaugespikethNo ratings yet

- ISO 10474 1992 Steel and Steel ProductsDocument9 pagesISO 10474 1992 Steel and Steel ProductsAjesh Kumar MuraleedharanNo ratings yet

- Automotive Control SystemsDocument406 pagesAutomotive Control SystemsDenis Martins Dantas100% (3)

- Product Brochure: Manufacturers and Stockists of High Pressure Pipeline and Drilling EquipmentDocument30 pagesProduct Brochure: Manufacturers and Stockists of High Pressure Pipeline and Drilling EquipmentSaravanan NatesanNo ratings yet

- Easy Control Valve SelectionDocument5 pagesEasy Control Valve SelectionhrtoroNo ratings yet

- Easy Control Valve SelectionDocument5 pagesEasy Control Valve SelectionhrtoroNo ratings yet

- Choke Specification - CCI PDFDocument4 pagesChoke Specification - CCI PDFAakashRanjan100% (1)

- Mathcad - Ampacity CalculationDocument76 pagesMathcad - Ampacity CalculationAlex Ribeiro100% (4)

- Generating Pump System Resistance CurveDocument4 pagesGenerating Pump System Resistance CurveKiran DasNo ratings yet

- ActuationDocument12 pagesActuationSrimp sasaNo ratings yet

- Rapid calculations of sediment settling ratesDocument74 pagesRapid calculations of sediment settling ratesSonu Singh100% (4)

- API 598, EN 12266-1 Leakage RatesDocument2 pagesAPI 598, EN 12266-1 Leakage RatesjshadwanNo ratings yet

- Neles Seat Leakage SpecDocument9 pagesNeles Seat Leakage SpecIkhsan Ly100% (1)

- Selecting The Proper Flare System PDFDocument6 pagesSelecting The Proper Flare System PDFjdgh1986100% (1)

- Pressure - Vacuum Relief Valve - Part 1Document10 pagesPressure - Vacuum Relief Valve - Part 1winarnobNo ratings yet

- SC/V - Valve Actuator Spring Return: Instruction Manual 5018Document49 pagesSC/V - Valve Actuator Spring Return: Instruction Manual 5018kaicyemNo ratings yet

- Use of Nitrogen Purge in Flare and Vent SystemsDocument8 pagesUse of Nitrogen Purge in Flare and Vent SystemsssnisharNo ratings yet

- MCQ in Services MarketingDocument83 pagesMCQ in Services Marketingbatuerem0% (1)

- Water SoftenersDocument11 pagesWater Softenersadel rihanaNo ratings yet

- Testing StandardDocument7 pagesTesting StandardDiego Fernando Pedroza UribeNo ratings yet

- Marine Emergency Diesel Generator SetDocument2 pagesMarine Emergency Diesel Generator SetVicky ZulfikarNo ratings yet

- 331-16-En Seat Tightness Test With HeliumDocument7 pages331-16-En Seat Tightness Test With HeliumSubkiAmatNo ratings yet

- Dual-Plate Lug Check Valves - Face To Face Dimensions - API Standard 594Document2 pagesDual-Plate Lug Check Valves - Face To Face Dimensions - API Standard 594unknownNo ratings yet

- Process Control Instrumentation PDFDocument2 pagesProcess Control Instrumentation PDFben mohamed SofianeNo ratings yet

- STG Lube Oil FlushingDocument21 pagesSTG Lube Oil FlushingAnthony DelarosaNo ratings yet

- Astm A923Document1 pageAstm A923rohitNo ratings yet

- KCDocument3 pagesKCSandheepKumarNo ratings yet

- ASME InterpretationDocument4 pagesASME Interpretationhrh_pogcNo ratings yet

- As 2360.1.5-2001 Measurement of Fluid Flow in Closed Conduits Pressure Differential Methods - Measurement UsiDocument8 pagesAs 2360.1.5-2001 Measurement of Fluid Flow in Closed Conduits Pressure Differential Methods - Measurement UsiSAI Global - APACNo ratings yet

- GE Energy Gas Engines Starting Systems Air Volume and Pressure Guidelines For 12V275GL GL+ and 12VAT27GLDocument2 pagesGE Energy Gas Engines Starting Systems Air Volume and Pressure Guidelines For 12V275GL GL+ and 12VAT27GLecavalinNo ratings yet

- Thrust and TorqueDocument41 pagesThrust and TorquevelusankarNo ratings yet

- FKQ640-5 BOP Control SystemDocument4 pagesFKQ640-5 BOP Control SystemGasim MohNo ratings yet

- 24 CalibrationDocument9 pages24 CalibrationAdhanom G.No ratings yet

- 49283991-DNV-OS-C401-2009-10 Fab and Testing Offshore Structure PDFDocument46 pages49283991-DNV-OS-C401-2009-10 Fab and Testing Offshore Structure PDFtriyuliantoNo ratings yet

- Choke Specification - CCIDocument4 pagesChoke Specification - CCIAakashRanjanNo ratings yet

- Hydrostatic Test ProcedureDocument7 pagesHydrostatic Test Procedurelaleye_olumideNo ratings yet

- Butterfly Valve Info PDFDocument14 pagesButterfly Valve Info PDFCS100% (1)

- Validation of Arc Welding Equipment - Revision of BS7570 (May 2001)Document2 pagesValidation of Arc Welding Equipment - Revision of BS7570 (May 2001)Elias KapaNo ratings yet

- TD107 Operation Manual PDFDocument42 pagesTD107 Operation Manual PDFshalabyahmedNo ratings yet

- Bv421 Pressure Reducing ValveDocument4 pagesBv421 Pressure Reducing ValveFAIYAZ AHMEDNo ratings yet

- 15no03-Ds-020-007 Electric Jockey Water Pump (3322-P-003)Document5 pages15no03-Ds-020-007 Electric Jockey Water Pump (3322-P-003)bagus handokoNo ratings yet

- New SSIV InstallationDocument12 pagesNew SSIV InstallationDidiNo ratings yet

- 4505 DiaphragmValves RWDocument49 pages4505 DiaphragmValves RWdbmingoNo ratings yet

- Instruction Manual Enardo 2000 2500 Series Emergency Pressure Relief Vents North America Only en 122600 3Document8 pagesInstruction Manual Enardo 2000 2500 Series Emergency Pressure Relief Vents North America Only en 122600 3Ramon GarciaNo ratings yet

- SV Pilot Crosby Type-93Document22 pagesSV Pilot Crosby Type-93MarcelocrossNo ratings yet

- Commissioning: of Stationary Nickel-Cadmium Batteries With FNC CellsDocument10 pagesCommissioning: of Stationary Nickel-Cadmium Batteries With FNC CellsVembi DwiNo ratings yet

- S 7517Document32 pagesS 7517JDavid NavaNo ratings yet

- Valve Cavity Relief 2Document2 pagesValve Cavity Relief 2Azar DeenNo ratings yet

- Bifold UpdatedDocument8 pagesBifold UpdatedGopinath GunasekaranNo ratings yet

- Manifold Burst Pressure TestDocument3 pagesManifold Burst Pressure TestrajeshNo ratings yet

- 2012 Ol1 1.7 UDocument14 pages2012 Ol1 1.7 UalexedamalaNo ratings yet

- Durco Plug Valve Dimensions PDFDocument28 pagesDurco Plug Valve Dimensions PDFjtai1983No ratings yet

- Atmospheric Relief Valve ManualDocument12 pagesAtmospheric Relief Valve ManualTarun ChandraNo ratings yet

- Instruction manual for 630 Series regulators and relief valvesDocument10 pagesInstruction manual for 630 Series regulators and relief valvesClemente Rafael Marval EscalonaNo ratings yet

- Tanktrader Bitutainer SpecDocument9 pagesTanktrader Bitutainer SpecNauman AliNo ratings yet

- Howto-Recommended Guidelines For Testing of Heat ExchangersDocument1 pageHowto-Recommended Guidelines For Testing of Heat ExchangersSam_1_No ratings yet

- Pipe Support Load Calculation SheetDocument3 pagesPipe Support Load Calculation SheetHassan Muhammad TundeNo ratings yet

- EnCal 3000 Gas Chromatograph Software ManualDocument83 pagesEnCal 3000 Gas Chromatograph Software ManualMostafa NabilNo ratings yet

- Lesson Learnt From SNC On Stress AnalysisDocument3 pagesLesson Learnt From SNC On Stress AnalysiszahoorNo ratings yet

- Spe 77 - 307Document5 pagesSpe 77 - 307Dunamis Joe100% (1)

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- ANSI/FCI Leakage Class DefinitionsDocument2 pagesANSI/FCI Leakage Class DefinitionsGusAriasNo ratings yet

- Deluge Valve ADocument14 pagesDeluge Valve APatel MehulkumarNo ratings yet

- Deluge Valve Technical Data SheetDocument14 pagesDeluge Valve Technical Data SheetSiddharth GupteNo ratings yet

- The Use of Control Valve Sizing Equations With Simulation Based Process DataDocument14 pagesThe Use of Control Valve Sizing Equations With Simulation Based Process DataJimmyNo ratings yet

- Process Engineering - Draw Insights On Distillation - Chemical ProcessingDocument6 pagesProcess Engineering - Draw Insights On Distillation - Chemical ProcessingSonu SinghNo ratings yet

- Impact of Downcomer Sizing Upon Column PDFDocument6 pagesImpact of Downcomer Sizing Upon Column PDFSonu SinghNo ratings yet

- TurboTutorial5 PDFDocument10 pagesTurboTutorial5 PDFSonu SinghNo ratings yet

- Comparison Table GDUDocument1 pageComparison Table GDUSonu SinghNo ratings yet

- Comparison Table GSUDocument1 pageComparison Table GSUSonu SinghNo ratings yet

- Control Valves: Types, Characteristics and EffectivenessDocument11 pagesControl Valves: Types, Characteristics and EffectivenessHitesh MittalNo ratings yet

- CEIL Engineering AnnexureADocument4 pagesCEIL Engineering AnnexureASonu SinghNo ratings yet

- Time To Empty Out Vessel No Dished EndsDocument2 pagesTime To Empty Out Vessel No Dished Endsbb.tiwari100% (1)

- Calculation of Actual Contaminated Firewater Volume: K T Q VDocument5 pagesCalculation of Actual Contaminated Firewater Volume: K T Q Vankur2061No ratings yet

- Steam Loss Calculations - Rev 0Document2 pagesSteam Loss Calculations - Rev 0Sonu SinghNo ratings yet

- TurboTutorial5 PDFDocument10 pagesTurboTutorial5 PDFSonu SinghNo ratings yet

- T07 PDFDocument16 pagesT07 PDFSonu Singh100% (1)

- T06Document15 pagesT06Sonu SinghNo ratings yet

- AzeotropicDocument4 pagesAzeotropicGoh Keng SiongNo ratings yet

- Pid Control TheoryDocument8 pagesPid Control TheorySonu SinghNo ratings yet

- Agitor Design Method & DataDocument11 pagesAgitor Design Method & DataSonu SinghNo ratings yet

- HP Flare Case 1 - Rev 1Document34 pagesHP Flare Case 1 - Rev 1Sonu SinghNo ratings yet

- Water Hammer SystemDocument38 pagesWater Hammer SystemKarennSoutoNo ratings yet

- Sizing A Valve From ScratchDocument30 pagesSizing A Valve From ScratchganeshdhageNo ratings yet

- Grant Park Platform Bedroom Set Furniture RowDocument1 pageGrant Park Platform Bedroom Set Furniture Rowjyzjz6sr65No ratings yet

- Presentation On BAJAJDocument19 pagesPresentation On BAJAJVaibhav AgarwalNo ratings yet

- Attachment To Division Memorandum No. - , S, 2020Document3 pagesAttachment To Division Memorandum No. - , S, 2020Jasmin Move-RamirezNo ratings yet

- Shipping Label GuideDocument41 pagesShipping Label GuidebriggantiiNo ratings yet

- Sample Style GuideDocument5 pagesSample Style Guideapi-282547722No ratings yet

- Christianity and Online Spirituality Cybertheology As A Contribution To Theology in IndonesiaDocument18 pagesChristianity and Online Spirituality Cybertheology As A Contribution To Theology in IndonesiaRein SiraitNo ratings yet

- حل جميع المعادلات الكهربائيةDocument60 pagesحل جميع المعادلات الكهربائيةGandhi HammoudNo ratings yet

- Rob Thomas Digital Booklet - Cradle SongDocument15 pagesRob Thomas Digital Booklet - Cradle SongAgnieszka ŁukowskaNo ratings yet

- Brigada Eskwela Activities With PicsDocument6 pagesBrigada Eskwela Activities With PicsCharisse TocmoNo ratings yet

- Allcargo Corporate BrochureDocument12 pagesAllcargo Corporate BrochureallinonecargologisticsNo ratings yet

- Direct Burial Optic Fiber Cable Specification - KSD2019 PDFDocument5 pagesDirect Burial Optic Fiber Cable Specification - KSD2019 PDFjerjyNo ratings yet

- Powerful Cooling and Easy Installation For Really Large SpacesDocument4 pagesPowerful Cooling and Easy Installation For Really Large Spacesalkaf08No ratings yet

- Pivot Part NumDocument2 pagesPivot Part Numrossini_danielNo ratings yet

- Project Hydraulics and HydrologyDocument17 pagesProject Hydraulics and HydrologyEiyra NadiaNo ratings yet

- Sample Cover Letter: No Work ExperienceDocument4 pagesSample Cover Letter: No Work ExperienceMaya ElvisaNo ratings yet

- Suparco+ KRL Test Ques For Electrical EngrzDocument5 pagesSuparco+ KRL Test Ques For Electrical Engrzمحمد فصیح آفتابNo ratings yet

- Grade 6 Science PuzzleDocument4 pagesGrade 6 Science Puzzlemargie riveraNo ratings yet

- Strategic Information Systems Planning: Course OverviewDocument18 pagesStrategic Information Systems Planning: Course OverviewEmmy W. RosyidiNo ratings yet

- Star S07FS32DR Water Softener Repair PartsDocument1 pageStar S07FS32DR Water Softener Repair PartsBillNo ratings yet

- Android Car Navigation User ManualDocument74 pagesAndroid Car Navigation User ManualРисте ПановNo ratings yet

- Ficha Tecnica 750 GPMDocument156 pagesFicha Tecnica 750 GPMByron Chele0% (2)

- RDSO - Specification No.M&C NDT 125 2004 Rev IDocument6 pagesRDSO - Specification No.M&C NDT 125 2004 Rev INiking ThomsanNo ratings yet

- Amptec Issue 7Document8 pagesAmptec Issue 7Linda Turner-BoothNo ratings yet

- VNX Power UP Down ProcedureDocument8 pagesVNX Power UP Down ProcedureShahulNo ratings yet