Professional Documents

Culture Documents

Safety Inspection Checklist For Shipboard Operations

Uploaded by

Ionescu EdaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Safety Inspection Checklist For Shipboard Operations

Uploaded by

Ionescu EdaCopyright:

Available Formats

Safety inspection checklist for shipboard operations

http://shipsbusiness.com/safety-inspection-checklist.html

Home page|| Tanker Notes || Container Ship Operations || Ocean Navigation ||

Safety inspection checklist for shipboard operations

Modern shipping industry recognizes safety is the prime concern for all shipboard activities. Summarized below are some basic check items

ensuring safe working environment onboard vessel.

These procedures are only indicative, not exhaustive in nature and one must always be guided by practices of good seamanship .

Accommodation -Safety checklist

1. All emergency lights operational, color coded and marked with "E"

2. Internal and external lighting in accommodation ok

3. Escape routes unobstructed; exits clearly marked

4. Safety signs and placards posted and clearly readable

5. All portable fire extinguishers & stowage locations numbered, in place & inspection dated

6. Life jackets, immersion suits & EEBDs correctly stowed & marked

7. Adequate number of ashtrays provided and correctly placed. (On Tankers-Safety ash trays)

8. For safety reasons, fire station not locked but only sealed

9. Internal communications equipment tested and operating correctly

10. Muster list signed and properly displayed at appropriate locations

Accommodation - Housekeeping/General checklist

11. Is the cleanliness of common rooms satisfactory

Mess rooms & smoking rooms

Gymnasium

Laundry

Ship's Office & Cargo control room

Changing rooms

Common toilets and showers

12. Cleanliness of all cabins, alleyways and staircases satisfactory

13. All garbage bins & lids in common spaces, color coded, labeled and made of non-combustible material. In cabins, 2 bins available (1 for

plastic)

14. Area free of overloaded, unauthorised or jury-rigged electrical items

15. Galley and food storage areas:

Cold chambers set at correct temperatures

1 of 4

10/17/2016 7:00 PM

Safety inspection checklist for shipboard operations

http://shipsbusiness.com/safety-inspection-checklist.html

Pots, knives, cooking utensils are clean

Provision chambers are clean

Any signs of cockroaches or other

Infestation in the galley or storage areas

Reefer chamber alarm tested and working

Food products are within expiry dates

16. Catering personnel comply with the following:

Any wound, cut or illness reported to master

Wounds, cuts are appropriately covered

No smoking in galley/mess rooms (tankers)

Washing hands with soap prior handling food

17. Quality of fresh water is good

18. Stores are neatly stowed in lockers

19. Approved First Aid supplies are readily available, accessible and clearly marked

20. Hospital is clean, unoccupied and ready for use

21. Garbage properly stowed, segregated & disposed

Machinery spaces -Safety checklist

22. Escape routes, ladders and emergency exits unobstructed and clearly marked

23. All handrails, guard-rails and safety guards correctly fitted and secured to protect against fall

24. Spare life-jackets marked and in good order, emergency equipment accessible and operational

25. All lights operational, stairways and work areas adequately lit, emergency lighting in E/R checked

26. No Hot Work stenciled on all fuel and lub oil tanks in E/R

27. Safety signs and placards posted and clearly readable

28. Switchboard area clear and free of obstructions and rubber mats in position

29. All portable fire extinguishers correctly stowed, accessible and inspection dated

30. All fixed fire-fighting equipment unobstructed and in good condition

31. All personnel wear correct personal protective gear

32. High voltage areas clearly marked

33. Muster lists displayed

34. Protective guards for rotating machinery properly secured in place

35. Steering gear space free from oil, gratings or non-slip surfaces in place around the steering gear

36. Shielding of high pressure fuel pipes in place, steam pipes properly insulated

37. Self-closing device on sounding pipes and glass level gauges functional & not tied in open posn

38. Steam, water or oil leaks anywhere in the machinery space

39. Area free of spilt oil, grease, combustible rubbish, tools and equipment not in use

2 of 4

10/17/2016 7:00 PM

Safety inspection checklist for shipboard operations

http://shipsbusiness.com/safety-inspection-checklist.html

40. Area free of combustible liquids in open containers

41. Pipe Insulations are oil free

42. Walkways, stairways and ladders clear of obstructions

43. Walkways, stairways and ladders are clean, dry and have non-skid surfaces where appropriate

44. Low clearance limits stripe marked

45. Oil soaked rags and other flammable materials kept in covered non-combustible bins

46. Supplies and materials properly stored

47. Chemicals properly labelled and stored, acids & alkalis segregated, MSDS & PPE available at site

48. Approved First Aid supplies readily available, accessible and clearly marked

49. Bilges free of oil

50. Is the engine room workshop tidy with equipment protected as required & safety instructions posted

Deck area - Safety checklist

51. Escape routes and embarking areas marked, unobstructed and no slipping and tripping hazards

52. Danger-Enclosed Space marked outside all such spaces having access other than via manholes

53. All deck lights operational and in sound enclosures

54. All hand-rails and guard-rails correctly fitted and secure, all ladderways guarded by railings

55. All safety & hazard zone identification signs posted & readable, fire plan wallets updated

56. HRU's for life rafts and EPIRB's correctly fitted (incl. weak link) and within expiry date

57. All lifebuoys correctly stowed, life buoy lights and smoke markers valid & in good condition

58. Lifeboats in good condition

59. All personnel wearing correct personal protective gear

60. Decks and walkways free form oil / grease and is there anti-slip paint at mooring areas

61. Piping systems on deck are properly clamped

62. W/T doors closing properly with packing in good condition

63. All weather tight hatches closing properly with packing in good condition

64. Is the oil pollution clean-up equipment in good condition and are the storage locations clearly marked?

65. Deck cranes, mooring winches & windlasses are free from oil leakages

66. Area free of combustible rubbish and tools and equipment which are not in use

67. Area free of leaking pipes and fittings

68. Supplies and materials are properly stored

69. All cans in paint store are closed, cargo & bunker samples on tankers are stowed in paint store

70. MSDS provided and readily accessible. (Paints, chemicals & Tanker Cargos)

71. Drip trays are in good condition empty and clean with capacity clearly marked

72. All sounding caps in place & properly tightened?

Other areas (Tankers) -Safety & house keeping checklist

3 of 4

10/17/2016 7:00 PM

Safety inspection checklist for shipboard operations

http://shipsbusiness.com/safety-inspection-checklist.html

73. Cargo pump rooms are marked with entry requirements

74. Pump room rescue equipment ready for use

75. Pump room- Internal communications equipment tested and operating correctly

76. Pump room-Cargo pump glands visually inspected for leaks and marked

77. Pump room- Area free of leaking pipes and fittings, bilges free of oil & water

78. Pump room lighting in good order

79. Emergency towing arrangements forward and aft ready for use

80. No unsafe camera, cell phones, torch, walky-talkie or other electronic equipment in use on deck

81. Electrical conductivity arrangement at flanges of cargo,COW & electric cable pipes in good order

Related articles

How to ensure safe working atmosphere in the engine room

Ships crew familiarization training onboard

Job specific training onboard

Other info pages !

Ships Charterparties Related terms & guideline

Stevedores injury How to prevent injury onboard

Environmental issues How to prevent marine pollution

Cargo & Ballast Handling Safety Guideline

Reefer cargo handling Troubleshoot and countermeasures

DG cargo handling Procedures & Guidelines

Safety in engine room Standard procedures

Questions from user and feedback Read our knowledgebase

Home page

ShipsBusiness.com is merely an informational site about various aspects of ships operation,maintenance procedure, prevention of pollution

and many safety guideline. The procedures explained here are only indicative, not exhaustive in nature and one must always be guided by

practices of good seamanship.

User feedback is important to update our database. For any comment or suggestions please Contact us

Site Use and Privacy - Read our privacy policy and site use information.

//Home //Terms and conditions of use

Copyright 2015 www.shipsbusiness.com All rights reserved.

4 of 4

10/17/2016 7:00 PM

You might also like

- Manual - UpdatareDocument44 pagesManual - UpdatareIonescu EdaNo ratings yet

- Informatii SoftDocument165 pagesInformatii SoftIonescu EdaNo ratings yet

- Risk of Gas Freeing Operation & Precautions For Oil TankersDocument3 pagesRisk of Gas Freeing Operation & Precautions For Oil TankersIonescu Eda100% (1)

- Atlas of Maritime HistoryDocument152 pagesAtlas of Maritime Historyshz600100% (11)

- Disposal For Spilled Oil and Prevention For Secondary DisasterDocument4 pagesDisposal For Spilled Oil and Prevention For Secondary DisasterIonescu EdaNo ratings yet

- How To Prevent Damage To Ship & Machinery Prior Entering Freezing AreasDocument4 pagesHow To Prevent Damage To Ship & Machinery Prior Entering Freezing AreasIonescu EdaNo ratings yet

- A Master's Guide To Berthing 2nd EditionDocument40 pagesA Master's Guide To Berthing 2nd Editionanil.rai67% (3)

- Advanced Shiphandling - 2012Document106 pagesAdvanced Shiphandling - 2012Ionescu Eda100% (3)

- Nitrate and NitriteDocument3 pagesNitrate and NitriteIonescu EdaNo ratings yet

- Nitrate and NitriteDocument3 pagesNitrate and NitriteIonescu EdaNo ratings yet

- Nitrate and NitriteDocument3 pagesNitrate and NitriteIonescu EdaNo ratings yet

- Nitrate and NitriteDocument3 pagesNitrate and NitriteIonescu EdaNo ratings yet

- Knitting-Techniques:Short Row TurnDocument11 pagesKnitting-Techniques:Short Row TurnAnonymous Y2qwEuA100% (2)

- Functioning of The Ministry of Health, There Is One Directorate With Responsibilities inDocument12 pagesFunctioning of The Ministry of Health, There Is One Directorate With Responsibilities inIonescu EdaNo ratings yet

- Nitrate and NitriteDocument3 pagesNitrate and NitriteIonescu EdaNo ratings yet

- GUIDE Dec 2009Document81 pagesGUIDE Dec 2009Ionescu EdaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Bioversal QF: Material Safety Data SheetDocument24 pagesBioversal QF: Material Safety Data Sheetfareedee50% (2)

- Helizarin TOW Liq C - MSDSDocument12 pagesHelizarin TOW Liq C - MSDSVictorian Groups FaisalabadNo ratings yet

- Material Safety Data Sheet: 1. Product and Company IdentificationDocument11 pagesMaterial Safety Data Sheet: 1. Product and Company IdentificationdrikaapiresNo ratings yet

- Safety Data Sheet: TetrahydrofuranDocument13 pagesSafety Data Sheet: TetrahydrofuranMuh. Thaufik UmarNo ratings yet

- Orica Kurri ANE Safety-Management-System Rev01Document48 pagesOrica Kurri ANE Safety-Management-System Rev01Larry AbarcaNo ratings yet

- Identification of Preparation and Company: Safety Data Sheet Avesta Pickling Gel 122 EU - EngDocument10 pagesIdentification of Preparation and Company: Safety Data Sheet Avesta Pickling Gel 122 EU - EngDanialNufailAfandiNo ratings yet

- MSDS 447 BulkDocument3 pagesMSDS 447 BulkEliasNo ratings yet

- Scotchgard MSDSDocument12 pagesScotchgard MSDStsj9205No ratings yet

- Tankguard 412: Technical Data Sheet Application GuideDocument9 pagesTankguard 412: Technical Data Sheet Application GuideEngTamerNo ratings yet

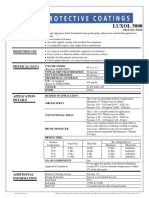

- Pds Luxol 5000 VocDocument2 pagesPds Luxol 5000 VocmuthukumarNo ratings yet

- Super StopDocument1 pageSuper StopReyna Mari Espinoza AguilarNo ratings yet

- Chemical Purchase PolicyDocument2 pagesChemical Purchase PolicyRafiqul Alam100% (3)

- 1-10 Phenanthroline MonohydrateDocument5 pages1-10 Phenanthroline Monohydratewongpengchiong7205No ratings yet

- Safety Data Sheet: Oxalyl Chloride, Reagentplus®, 99%Document9 pagesSafety Data Sheet: Oxalyl Chloride, Reagentplus®, 99%anubhav krNo ratings yet

- Safety Information: en 197-1 Common CementsDocument12 pagesSafety Information: en 197-1 Common CementsDaphne Lianne DegayNo ratings yet

- MSDS Bagazo de CañaDocument5 pagesMSDS Bagazo de CañaYovany Padilla100% (2)

- Safety Data Sheet: 1 Identification of The SubstanceDocument6 pagesSafety Data Sheet: 1 Identification of The SubstancePedro Jesús Navarrete SegadoNo ratings yet

- Material Safety Data Sheet: Section 1 - Chemical Product and Company IdentificationDocument7 pagesMaterial Safety Data Sheet: Section 1 - Chemical Product and Company IdentificationAlejandro MoralesNo ratings yet

- Student Name Student ID Qualification Code and Name Trainer NameDocument56 pagesStudent Name Student ID Qualification Code and Name Trainer Namejoe joyNo ratings yet

- MSDS COUWELD Exhothermic Weld MainDocument3 pagesMSDS COUWELD Exhothermic Weld MainSameer Shaikh100% (1)

- 8430 TractorDocument5,645 pages8430 TractorJohnathan LarkanNo ratings yet

- Haz Com Manual OriginalDocument19 pagesHaz Com Manual OriginalJoko YanNo ratings yet

- Albumin Reagent SDS Safety Data SheetDocument5 pagesAlbumin Reagent SDS Safety Data SheetDorisjuarsa SmsNo ratings yet

- MSD MB Series InkDocument14 pagesMSD MB Series InkrogelenaNo ratings yet

- Product Safety Data Sheet: Document Code: Description: Status: Revision Reason: Issue DateDocument6 pagesProduct Safety Data Sheet: Document Code: Description: Status: Revision Reason: Issue Datejayand_netNo ratings yet

- Risk Assessment For Installation of Drainage Pipes and FittingsDocument8 pagesRisk Assessment For Installation of Drainage Pipes and Fittingsfaizan khan100% (1)

- SDS for ZI-CHEM 1630 boiler blend chemicalDocument4 pagesSDS for ZI-CHEM 1630 boiler blend chemicalwaskito_agusNo ratings yet

- Material Safety Data Sheet: 1. IdentificationDocument10 pagesMaterial Safety Data Sheet: 1. IdentificationMai PhuongNo ratings yet

- MSDS Dalsorb 3000MDocument7 pagesMSDS Dalsorb 3000Mfransiska ariNo ratings yet

- Mergal K14-30268-Apc Sds English (Us) - 160829Document11 pagesMergal K14-30268-Apc Sds English (Us) - 160829winsonecNo ratings yet