Professional Documents

Culture Documents

Mack Planking Pre-Installation Faqs

Uploaded by

Mohd FadliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mack Planking Pre-Installation Faqs

Uploaded by

Mohd FadliCopyright:

Available Formats

Mack Industries, Inc.

201 Columbia Road

Valley City, Ohio 44280

PHONE: (800) 483-3161

FAX:

(330) 483-2990

Mack Planking Pre-Installation FAQs

Q1: How should rebar be positioned in a masonry wall for the planks ?

A1: Mack recommends that the rebar be placed at the spacing as designated on Macks

approved shop drawings. Most often, rebar size and spacing is designated as #4 bar, 4-foot on

center for plank-to-wall rebar and #5, 4-foot on center for rebar that is continuous up through

the wall. Mack is typically not responsible for rebar that must be grouted into the wall before

the plank is set. Refer to Macks approved shop drawings, as we will designate on those

drawings what rebar that we are responsible for providing and installing.

It is very important that the rebar be positioned in such a way that it does not interfere with the

bearing of the planks (see Fig. 1). This also means that grouted masonry cores should be

struck off level with the top of the block.

BEARING AREA

BEARING AREA

HOLLOW

CORE

PLANK

HOLLOW

CORE

PLANK

CORRECT

INCORRECT

Figure 1.

Q2: How should the steel be prepared for the plank ?

A2: Mack insists that all steel be properly secured, braced and welded (as applicable) prior

to setting. Free-standing columns that support or run past the plank should be temporarily

secured with guy wires or braced to prevent them from becoming out of plumb during the plank

erection.

Q3: How soon before you can set the plank ?

A3: Mack recommends at least two days of cure on grout-filled masonry walls before plank

erection. Plank can be set on steel immediately after the steel is secured properly.

1 of 5

Mack Industries, Inc.

201 Columbia Road

Valley City, Ohio 44280

PHONE: (800) 483-3161

FAX:

(330) 483-2990

Q4: How should the planks be lifted / handled ?

A4: Planks are most commonly set utilizing a four-point top pick with a suitably sized 4-leg

chains or cables due to the large width of plank that Mack manufactures. Typically, 3/8 hooks

and chains are used for the 8 hollow core (HC) product, and hooks and chains are used for

the 10 HC product. Extremely small pieces of HC may have only 1, 2, or 3 pick points,

dependent upon size.

Planks are sometimes also provided without lifters when provided in 50 widths or less.

In this case, the plank must be slung properly to be lifted and set. Chain, cable or nylon slings

may be used as chokers. Chokers placed around the planks should be a minimum of 16 feet in

length, with one choker at each end of the plank approximately 2-4 feet in from the end of the

plank. On planks ranging in lengths from 0 to 25 feet in length, spreader cables from the crane

hook to the chokers a minimum of 20 feet in length. On planks 25 feet to 45 feet use spreaders

a minimum of 30 feet in length. Where headroom is an issue, a spreader beam can be used.

DO NOT pick up any planks with just one choker around the middle of the plank. The

plank will break, as they are not designed to be loaded in that manner.

2 of 5

Mack Industries, Inc.

201 Columbia Road

Valley City, Ohio 44280

PHONE: (800) 483-3161

FAX:

(330) 483-2990

The erector is responsible for determining size and load capacity of any spreaders,

chokers, cables or any devices used in the erection of precast. Any precast planks broken due

to improper handling not recommended by Mack Industries, Inc. will be replaced at cost to the

erector or purchaser of the plank.

Planks 0 to 12 feet in length may be picked up with a forklift or telescoping loader.

Ensure the forks are set a minimum of 4-0 apart and the set of forks is centered on the plank.

Q5: How should the planks be stored on site ?

A5: If planks are to be stacked on the ground, the boards must be kept in a straight vertical

line on each end of the plank. Boards should be placed no further than 2 feet in from each end.

If stacking planks on soft ground, ensure bottom boards do not sink and the bottom plank does

not touch the ground. The bottom boards must rest under load parallel with each other to

prevent twisting or torsion of the planks. Stack planks no more than 5 slabs high. Do not flip

units over or on side for any reason.

Hollowcore Plank

Hollowcore Plank

2

2

3 of 5

Mack Industries, Inc.

201 Columbia Road

Valley City, Ohio 44280

PHONE: (800) 483-3161

FAX:

(330) 483-2990

Q6: What / How will you grout ?

A6: The erector (Mack or otherwise) is typically responsible for grouting all precast-toprecast seams and any lifting device pockets. This includes end-to-end and keyway grout

seams as well. If coordinated with the Mack, we may help you by grouting the perimeter of a

floor or area if a pour stop or soldier course of block is provided for us by the GC. We will grout

by hand, pouring bucket or concrete pump depending upon the size of the set, amount of

grouting, elevation, conditions, etc. Seams will be filled and excess will be removed by a either

a shovel or a stiff broom. We will leave the grout level with the top of the plank unless

instructed otherwise.

Q7: What kind of grout will you use ?

A7: Macks standard mix design is a 3500 psi strength cement and sand/fines grout mix (no

course aggregate). A 6% air-entraining admixture is also added for outdoor or unprotected

applications. It is provided at approximately a 6 slump to properly grout. Superplasticizer (not

water) may be added on-site to improve workability/flowability. We recommend and use this

mix unless specifications state differently.

Q8: How long will it take ?

A8: If Mack is erecting your job, we can set 6,000 to 10,000 SF per day. This is dependent

upon weather and site conditions, set start time, plank elevation, and the type of structure.

Grouting usually requires an additional day per 24,000 SF of planking, weather permitting.

Welding, if required, will be done as the setting, conditions, and weather permits. Often,

welding can be done after the job is complete and will not interfere with other trades working in

the area.

Q9: Is there anything I should be concerned about in winter conditions ?

A9: Yes. Mack can set plank in almost any weather except for thunderstorms and conditions

that would prevent a crane or tractor-trailer from pulling onto site. However we cannot erect

plank onto beams or walls that have large amounts of snow or ice on them. It must be

removed prior to setting. We must also grout the planking when conditions are favorable. This

usually means temperatures must be above 25F and climbing. Also, grouting should not be

conducted when it is steadily raining, as the addition of water will be detrimental to the grout.

4 of 5

Mack Industries, Inc.

201 Columbia Road

Valley City, Ohio 44280

PHONE: (800) 483-3161

FAX:

(330) 483-2990

Q10: Is there anything else I should do to prepare for the plank set ?

A10: Yes. Please note the following:

Mack is typically not responsible for providing safety measures for anyone but

ourselves. Mack practices either 100% tie-off or leading edge erection utilizing

controlled access areas and a safety monitor, depending upon the situation. Be

prepared to cover openings/penetrations, provide safety railings or other means of

fall protection as may be required after we leave site.

Ensure a stable, level area is provided for access for the mobile crane and tractortrailers delivering the planking.

Please inform your other trades of the days we will be setting plank. They must stay

out of the swing radius of the crane and the setting area. Also, no work should occur

two floors directly below the floor we are currently setting.

5 of 5

Mack Industries, Inc.

201 Columbia Road

Valley City, Ohio 44280

PHONE: (800) 483-3161

FAX:

(330) 483-2990

Mack Planking Post-Installation FAQs

Q1: How soon before I can put any substantial weight on the planks?

A1: Mack recommends that the planks not be loaded until the grout has cured to the

required strength of the project, typically 3500-4000 psi. This usually means 1-3 days

depending upon time of grouting, local temperatures and conditions. If planks are loaded

before the grout key has cured, deformation of the key can occur; therefore a loaded plank will

not share the load with neighboring plank. In addition, it may deflect under load independently.

Q2: How much weight can I put on the deck / can I put a scissor lift or skid steer on it ?

A2: Mack recommends that you confer with the project engineer of record as to the

permissible loading. The planking (as well as the supporting structures) are engineered and

manufactured to conform to the established loading specifications.

Q3: Is there any special preparation required before I add a topping ?

A3: Mack recommends that before applying a topping, the surface of the plank be swept

clear of any and all debris, especially any residual sand left on the surface from the grouting

process. Pressure washing the deck is best. Check with your topping contractor for any

adhesion modifiers they may recommend for your selected product.

Q4: Why is there water in the planks / leaking from the planks down the wall ?

A4: A hollowcore deck system is a structural system, not a waterproof system. Plank

exposed to the elements (snow, rain, etc.) will have water eventually infiltrate the grout joints

and may collect at the bearing ends of the planks at the core locations. Mack recommends that

once the deck is installed, that weep holes be drilled up into the ends of the planks before

water has a chance to collect. Weep holes are ~ holes located at the core locations, drilled

closely to the bearing ends of the plank (see Fig. 1 for core locations). A firred-out wall or drop

ceiling easily hides this location. In the case of an exposed plank ceiling, where the weep holes

are visible, the holes can be eventually caulked prior to painting.

Q5: Do I need to fire-proof caulk the plank seams ?

A5: No. Fully grouted seams, in conjunction with the planking, provide a 2-hour UL fire rated

system.

1 of 4

Mack Industries, Inc.

201 Columbia Road

Valley City, Ohio 44280

PHONE: (800) 483-3161

FAX:

(330) 483-2990

Q6: The plans call for a specific topping thickness; but where does that apply because the

planks are higher at the middle due to the camber ?

A6: PCI (the Precast/Prestressed Concrete Institute) recommends that the specified topping

thickness be uniform across the member. If this is not feasible (which is typically the case

because it does not leave a level surface), then the specified topping thickness is measured at

the highest point of the plank or location of maximum camber which is typically at midspan

(see Fig. 2), thus creating a thicker topping at the bearing ends of the plank.

SPECIFIED TOPPING

THICKNESS

NOTE: CAMBER

EXAGGERATED FOR CLARITY

HOLLOW

CORE

PLANK

Figure 2.

Q7: Is there anything I should be concerned about in winter conditions ?

A7: Yes. In conditions where temperatures are consistently below freezing, some special

precautions need to be taken. If wet conditions also exist as explained in Answer #4 and weep

holes are not provided; over a period of time, ice may build up inside the cores. This

occurrence, if left unchecked, can damage the underside of the plank due to ices expansive

nature. Although not typically a structural issue, if this occurs, spalling exposing the cores can

be seen. Mack recommends the following to prevent damage to the planking:

Tarp or otherwise cover the planking to prevent the infiltration of water.

- or Drill weep holes as explained in Answer #4.

- and Provide heat on the underside of the planking by means of gas-fired heaters or

similar to prevent freezing of moisture inside the cores.

2 of 4

Mack Industries, Inc.

201 Columbia Road

Valley City, Ohio 44280

PHONE: (800) 483-3161

FAX:

(330) 483-2990

CORED HOLE

WEEP HOLE

13 SPC. @ 6 = 7-0

7

Figure 1.

CORE

STRAND

Q8: Where should trades core drill / is it OK / should I try to miss the strand ?

A8: Hollowcore planking is designed to permit core drilling. Typically holes over 10 in

diameter are coordinated prior to manufacture and, if so, are provided by the precaster. Fieldcored holes over 10 should be verified with and approved by the engineer before proceeding.

In general, all core drilling should:

Make an attempt to miss the strand in the planking if possible.

Be located as close to the bearing end as possible.

Be centered at a core location for holes 6 and less (see Fig. 1 for core locations)

such that strand is missed entirely.

Be centered over a strand (between core centerlines) for holes over 6 such that

only one strand is encountered.

This is because:

Drilling through strand reduces the load carrying capacity of the plank.

Strand at the end of a plank is not at full prestress; therefore it less critically

affects the load carrying capacity of the member.

Drilling through strand is more difficult and time consuming, as the strand is

located between cores in the middle of the web where there is substantially more

concrete. Off-center engagement of a strand and core drill can also cause

binding of the core bit, making core drilling even more difficult.

3 of 4

Mack Industries, Inc.

201 Columbia Road

Valley City, Ohio 44280

PHONE: (800) 483-3161

FAX:

(330) 483-2990

Q9: How do I prepare or finish an exposed plank ceiling?

A9: The ceiling should be primed with an appropriate product before painting. If the primer is

sprayed on, the painting contractor should back roll after application to ensure all small voids

and pinholes are filled. Plank seams and pin holes in the plank may be caulked if desired prior

to priming. The most common finish is popcorn spray-applied texture paint. The finish of the

plank is such that a light popcorn finish may be used if properly primed.

Q10: How do I hang mechanical or electrical systems from the underside of the plank?

A10: Options for hanging systems from the underside of the planks include shallow

expansion anchors, toggle bolts, thru-bolts with a top-mounted plate, and light straps (see Fig.

3). The anchor type is to be chosen based on the direction of the loads (i.e. vertical only or

vertical and horizontal) and the magnitude of the loads. The anchors are to be installed

according to the manufacturers written installation instructions and must not exceed the

written allowable design loads.

4 of 4

You might also like

- PJE CFA Piling PortfolioDocument46 pagesPJE CFA Piling Portfolioprasad perkaNo ratings yet

- ROCLAcrossing InstallationDocument6 pagesROCLAcrossing InstallationByoungchul LeeNo ratings yet

- Strip Foudation ExcavationsDocument8 pagesStrip Foudation ExcavationsImperial OneNo ratings yet

- TL 5 X 10Document10 pagesTL 5 X 10number_25No ratings yet

- D8.1 Box Culvert SystemDocument4 pagesD8.1 Box Culvert SystemOby RobiniNo ratings yet

- Masonry Swimming Pools June - 05Document9 pagesMasonry Swimming Pools June - 05Jeffery RoweNo ratings yet

- Method of Statement Column and Access With Water MarkDocument11 pagesMethod of Statement Column and Access With Water MarkManu MohanNo ratings yet

- Method Statements InterLock WorksDocument3 pagesMethod Statements InterLock WorksNino Celso AstilleroNo ratings yet

- Contractors HandbookDocument33 pagesContractors HandbookJamil AlhamatyNo ratings yet

- Plug-And Abandonment BasicsDocument37 pagesPlug-And Abandonment Basicsakonuche100% (2)

- ACRYLIC INSTALLATION GUIDEDocument5 pagesACRYLIC INSTALLATION GUIDEMario J SoaresNo ratings yet

- StripDocument8 pagesStripnawidrasoolyNo ratings yet

- Log Homes Construction Manual1Document15 pagesLog Homes Construction Manual1duga11No ratings yet

- 10 Concrete PlacementDocument10 pages10 Concrete PlacementprsjimzNo ratings yet

- Hollow Core Slab DetailsDocument19 pagesHollow Core Slab DetailsMediks Ferrer100% (1)

- Hollow Core HandlingDocument4 pagesHollow Core HandlingSulaiman Mohsin AbdulAzizNo ratings yet

- Cost-effective helical pier foundations for steep sites and expansive soilsDocument6 pagesCost-effective helical pier foundations for steep sites and expansive soilsIza BlajovanNo ratings yet

- Spun PileDocument7 pagesSpun Pileمحمد فيذول100% (2)

- Method Statement For Interlocking BlocksDocument3 pagesMethod Statement For Interlocking BlocksJaime Manalili LandinginNo ratings yet

- Studliner Installation GuidelinesDocument10 pagesStudliner Installation GuidelinesJULIONo ratings yet

- Method Statement CMC HotakenaDocument7 pagesMethod Statement CMC HotakenaroshanNo ratings yet

- Tank Manual2 Of2Document195 pagesTank Manual2 Of2AlbertNo ratings yet

- Block Works & Plastering DraftDocument4 pagesBlock Works & Plastering DraftEljo AndsNo ratings yet

- Methodology For Pile Foundation 08-09Document4 pagesMethodology For Pile Foundation 08-09Jeremy Jenkins86% (7)

- Method Statement - DEMOLITION BUILDING - FENCINGDocument7 pagesMethod Statement - DEMOLITION BUILDING - FENCINGprisma integratedNo ratings yet

- Install GuideDocument24 pagesInstall Guidecubedog100% (1)

- Beany Block: Kerb Drainage at Its Most EfficientDocument2 pagesBeany Block: Kerb Drainage at Its Most EfficientMihaela TodiricaNo ratings yet

- Anchorage Snow Removal Notice 3-8-24Document4 pagesAnchorage Snow Removal Notice 3-8-24Alaska's News SourceNo ratings yet

- Permanent Packer Removal TechniquesDocument35 pagesPermanent Packer Removal Techniquesmahimoh18No ratings yet

- Shower Tile - Over Tray Installation Guide Wet Area Solutions (Aust) Pty LTDDocument4 pagesShower Tile - Over Tray Installation Guide Wet Area Solutions (Aust) Pty LTDpaulnidNo ratings yet

- Casting Box Girder Segments - tcm45-342871Document3 pagesCasting Box Girder Segments - tcm45-342871AuYongTheanSengNo ratings yet

- Inspection Concrete SlabDocument3 pagesInspection Concrete Slabmudy_vayneNo ratings yet

- The TermDocument29 pagesThe TermAngelica CatungalNo ratings yet

- O-PIle 2022Document18 pagesO-PIle 2022Rubén CunoNo ratings yet

- Proposed 2-Storey Restaurant Building SpecsDocument9 pagesProposed 2-Storey Restaurant Building SpecsDAP Ysabelle Marie FuentesNo ratings yet

- Hollow Core Planks Application and Design GuideDocument46 pagesHollow Core Planks Application and Design Guidemixi1978100% (1)

- Fixing Bracing Guidelines - Timber Roof TrussesDocument20 pagesFixing Bracing Guidelines - Timber Roof TrussesjaffnaNo ratings yet

- Supreme Beam and Block FloorDocument8 pagesSupreme Beam and Block FloorDoralba V NolanNo ratings yet

- Box Jacking Paper PDFDocument5 pagesBox Jacking Paper PDFFerdi Aparat100% (1)

- Atlantic Wire Walls: We Support YouDocument6 pagesAtlantic Wire Walls: We Support Youmatt_friendNo ratings yet

- Box Culverts HumesDocument12 pagesBox Culverts Humespete0980No ratings yet

- L9 - Construction Methodology - 1Document20 pagesL9 - Construction Methodology - 1J. Kumar Infraprojects LtdNo ratings yet

- Method Statement For Interlock WorksDocument3 pagesMethod Statement For Interlock Worksqoci5ko75% (4)

- Installation - Pot Bearings: Typical Bearing Installation Details Based On Aashto/Bs & Din RegulationsDocument5 pagesInstallation - Pot Bearings: Typical Bearing Installation Details Based On Aashto/Bs & Din Regulationsksm99No ratings yet

- A Paper Written To Assist Those Who May Be Concerned in The Finishing of Concrete Swimming Pool'sDocument18 pagesA Paper Written To Assist Those Who May Be Concerned in The Finishing of Concrete Swimming Pool'sDavid Coulson100% (1)

- Anchorage Snow Removal GuidanceDocument3 pagesAnchorage Snow Removal GuidanceAlaska's News SourceNo ratings yet

- Precast Driven R.C.C PileDocument3 pagesPrecast Driven R.C.C PilePriodeep ChowdhuryNo ratings yet

- Installing A Clark-Drain Recess Tray CoverDocument2 pagesInstalling A Clark-Drain Recess Tray CoverFace sheNo ratings yet

- Slabstress Freyssinet 713 PDFDocument16 pagesSlabstress Freyssinet 713 PDFkom1984No ratings yet

- Anchoring ArticleDocument4 pagesAnchoring ArticleVan LLiNo ratings yet

- Epoxy Grout Handbook - MasterFlowDocument17 pagesEpoxy Grout Handbook - MasterFlowaruncg2No ratings yet

- When Good Floors Go BadDocument4 pagesWhen Good Floors Go BadSergio DominguezNo ratings yet

- Installation Guidance For Cable Troughs and Service Ducts PD84Document7 pagesInstallation Guidance For Cable Troughs and Service Ducts PD84sosi2020No ratings yet

- Installation Guidance For Cable Troughs and Service Ducts PD84Document7 pagesInstallation Guidance For Cable Troughs and Service Ducts PD84sosi2020No ratings yet

- Install cable troughs and ductsDocument7 pagesInstall cable troughs and ductssosi2020No ratings yet

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionFrom EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNo ratings yet

- How to Build a Global Model Earthship Operation II: Concrete WorkFrom EverandHow to Build a Global Model Earthship Operation II: Concrete WorkNo ratings yet

- Cabins & Cottages, Revised & Expanded Edition: The Basics of Building a Getaway Retreat for Hunting, Camping, and Rustic LivingFrom EverandCabins & Cottages, Revised & Expanded Edition: The Basics of Building a Getaway Retreat for Hunting, Camping, and Rustic LivingNo ratings yet

- How to Build a Simple Three Bedroom Shipping Container HouseFrom EverandHow to Build a Simple Three Bedroom Shipping Container HouseRating: 4 out of 5 stars4/5 (2)

- Demag CC 1800 Crawler Crane Specifications and PerformanceDocument45 pagesDemag CC 1800 Crawler Crane Specifications and PerformanceMohd FadliNo ratings yet

- Straight Foward Lifting-ModelDocument2 pagesStraight Foward Lifting-ModelMohd Fadli100% (1)

- aaac32c291cb346be27f496586018bd7Document16 pagesaaac32c291cb346be27f496586018bd7Mohd FadliNo ratings yet

- 45t Grove Rt600e PGDocument16 pages45t Grove Rt600e PGMohd FadliNo ratings yet

- Kobelco 7150 PDFDocument11 pagesKobelco 7150 PDFSaktiawan Arief ChandraDwi Panusantara100% (2)

- CD6125Document33 pagesCD6125Mohd FadliNo ratings yet

- 2 - HirarcDocument4 pages2 - HirarcMohd Fadli100% (3)

- (21 Oct 18) Equipment IndexDocument1 page(21 Oct 18) Equipment IndexMohd FadliNo ratings yet

- End Cap Drawing PacketDocument4 pagesEnd Cap Drawing PacketMohd FadliNo ratings yet

- Lift Safely with Proper Hoist RingsDocument1 pageLift Safely with Proper Hoist RingsMohd FadliNo ratings yet

- (21 Oct 18) Equipment IndexDocument1 page(21 Oct 18) Equipment IndexMohd FadliNo ratings yet

- PI 05 03 en Additional Stamping On Green Pin ShacklesDocument2 pagesPI 05 03 en Additional Stamping On Green Pin ShacklesMohd FadliNo ratings yet

- Support Stand Product Information SheetDocument1 pageSupport Stand Product Information SheetMohd FadliNo ratings yet

- GBP Gorek LegDocument1 pageGBP Gorek LegMohd FadliNo ratings yet

- PI 05 03 en Additional Stamping On Green Pin ShacklesDocument2 pagesPI 05 03 en Additional Stamping On Green Pin ShacklesMohd FadliNo ratings yet

- Hse Car 2Document3 pagesHse Car 2Mohd Fadli100% (1)

- Instruction Manual for Hilman Roller SystemsDocument22 pagesInstruction Manual for Hilman Roller SystemsMohd Fadli0% (1)

- Graduate Engineer GuidelinesDocument6 pagesGraduate Engineer GuidelinesMohd FadliNo ratings yet

- Knowledge Test For The Understanding of Load Chart For Crane Operators and Lifting SupervisorsDocument2 pagesKnowledge Test For The Understanding of Load Chart For Crane Operators and Lifting SupervisorsMohd FadliNo ratings yet

- Cks 900 SpecDocument28 pagesCks 900 SpecMohd Fadli100% (1)

- SFSB-P27-L&R-0003-1 - A (3215-V-231) Confirm by SarensDocument1 pageSFSB-P27-L&R-0003-1 - A (3215-V-231) Confirm by SarensMohd FadliNo ratings yet

- Rigging Calculation Lifting Plan: B OO MDocument1 pageRigging Calculation Lifting Plan: B OO MMohd FadliNo ratings yet

- Manitowoc 8500 1Document24 pagesManitowoc 8500 1Mohd FadliNo ratings yet

- SFSB-P27-L&R-0003-2 - A (3215-V-231) Confirm by SarensDocument1 pageSFSB-P27-L&R-0003-2 - A (3215-V-231) Confirm by SarensMohd FadliNo ratings yet

- Knowledge Test For The Understanding of Load Chart For Crane Operators and Lifting SupervisorsDocument2 pagesKnowledge Test For The Understanding of Load Chart For Crane Operators and Lifting SupervisorsMohd FadliNo ratings yet

- Cks 900 SpecDocument28 pagesCks 900 SpecMohd Fadli100% (1)

- Lifting Steering Commitee Action PlanDocument21 pagesLifting Steering Commitee Action PlanMohd FadliNo ratings yet

- Rigging Calculation Lifting Plan: B OO MDocument1 pageRigging Calculation Lifting Plan: B OO MMohd FadliNo ratings yet

- Insurance BLQ 2040Document1 pageInsurance BLQ 2040Mohd FadliNo ratings yet

- Rigging Caculation Lifting Plan: B OO MDocument1 pageRigging Caculation Lifting Plan: B OO MMohd FadliNo ratings yet

- Hypothermia's central and peripheral effects on elbow flexor performanceDocument11 pagesHypothermia's central and peripheral effects on elbow flexor performanceCristopher Castro RdNo ratings yet

- Work at Height - ScaffoldingDocument46 pagesWork at Height - ScaffoldingajayjanardhankasleNo ratings yet

- Unofficial FAQ and Clarifications Based On The French Edition of King of TokyoDocument2 pagesUnofficial FAQ and Clarifications Based On The French Edition of King of TokyoOlga G. CabezasNo ratings yet

- P.E. 7 - Q1 - Module1bDocument17 pagesP.E. 7 - Q1 - Module1breymilyn zuluetaNo ratings yet

- Evil Overlord Instruction BookletDocument40 pagesEvil Overlord Instruction Bookleticoolkidgamer136iNo ratings yet

- Possessive Pronouns: Possessive Pronouns Show Ownership. They Tell The Reader That SomethingDocument8 pagesPossessive Pronouns: Possessive Pronouns Show Ownership. They Tell The Reader That SomethingGan Zi XiNo ratings yet

- Unifirst CatalogDocument8 pagesUnifirst CatalogMark Izsm AmersonNo ratings yet

- SneakersDocument9 pagesSneakersapi-253689397No ratings yet

- 2011 Cannondale Flash F1Document67 pages2011 Cannondale Flash F1MarcoBastosNo ratings yet

- Y3 Ujian SumatifDocument8 pagesY3 Ujian SumatifAhmad Suhaimi Mohd NasirNo ratings yet

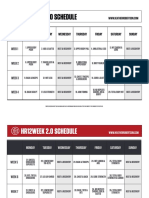

- HR 12 Week ProgramDocument4 pagesHR 12 Week ProgramMarcela GarciaNo ratings yet

- 03-04 l4 Engine Vibration in Gear 04-024Document4 pages03-04 l4 Engine Vibration in Gear 04-024Vincent HardyNo ratings yet

- USNEWS Ranking 2022Document16 pagesUSNEWS Ranking 2022Amaka AbatuluNo ratings yet

- By Pendekar Scott Mcquaid: 'Excellence Is The Mastery of The Basics.'Document4 pagesBy Pendekar Scott Mcquaid: 'Excellence Is The Mastery of The Basics.'diamond68No ratings yet

- Summary of key points from an Indonesian language articleDocument2 pagesSummary of key points from an Indonesian language articleAfifah HassanNo ratings yet

- This Is My WorldDocument3 pagesThis Is My Worldmadeinengland2No ratings yet

- Cheerdance Competition: A. EligibilityDocument2 pagesCheerdance Competition: A. EligibilityPianista KoNo ratings yet

- Future Heroes (2023)Document4 pagesFuture Heroes (2023)The Livingston County NewsNo ratings yet

- RMAX Instruction ManualDocument40 pagesRMAX Instruction ManualGuille Gimeno100% (1)

- Mayhem Entry 2015Document1 pageMayhem Entry 2015thedietdocNo ratings yet

- Present Simple vs Present ContinuousDocument4 pagesPresent Simple vs Present ContinuousaticemalikNo ratings yet

- D&D5e - Ravenloft RulesetDocument10 pagesD&D5e - Ravenloft RulesetMICHAEL BASTIANELLINo ratings yet

- W20 - Character SheetDocument4 pagesW20 - Character SheetWilliam PenroseNo ratings yet

- Manual de Internacional 7600Document492 pagesManual de Internacional 7600Felipe Marquez50% (2)

- Pan Am Sports Women's 100m RankingsDocument68 pagesPan Am Sports Women's 100m RankingsAna MattioNo ratings yet

- Air StarterDocument6 pagesAir StarterParvizNo ratings yet

- Physical Therapy Intervention For Individuals With Osteoporosis (W)Document2 pagesPhysical Therapy Intervention For Individuals With Osteoporosis (W)Tahsinur RahmanNo ratings yet

- MISSION WS 600 Pump Spec SheetDocument2 pagesMISSION WS 600 Pump Spec SheetFaroukNo ratings yet

- CV Ed Dela Cruz CivilDocument15 pagesCV Ed Dela Cruz CivilWilliam CabreraNo ratings yet

- O I LONG TO FEEL YOUR ARMS AROUND ME by Father John MistyDocument5 pagesO I LONG TO FEEL YOUR ARMS AROUND ME by Father John MistyStratis SgourellisNo ratings yet