Professional Documents

Culture Documents

PT Qualita Utama Radiographic Testing Procedure Specification

Uploaded by

papathsheilaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PT Qualita Utama Radiographic Testing Procedure Specification

Uploaded by

papathsheilaCopyright:

Available Formats

PT.

QUALITA UTAMA

DATE

18-12-2014

PAGE

1 of 20

RADIOGRAPHIC TESTING

PROCEDURE SPECIFICATION

DOC. NO.

QU/RT/003

REV

02

PT. QUALITA UTAMA

RADIOGRAPHIC TESTING

PROCEDURE SPECIFICATION

In Accordance With ASME BPV Section V Article 2, 2007 and

ASME B31.3, 2004 As Acceptance Criteria

QU/RT/003

THIS AND ALL STANDARD PRACTICE INSTRUCTIONS / OPERATING PROCEDURES

CONTAINED IN THE COMPANY QUALITY ASSURANCE SYSTEM ARE CONTROLLED BY

THE QUALITY ASSURANCE REPRESENTATIVE AND MAY NOT BE AMENDED, REVISED

OR IN ANY ALTERED WITHOUT HIS AUTHORITY.

The signatures below indicate, Review and Authorization of all the numbered pages in this Operating

Procedures up to and including the date of Authorization. This Procedure is invalid without page 1.

PT. QUALITA UTAMA

DATE

18-12-2014

PAGE

2 of 20

RADIOGRAPHIC TESTING

PROCEDURE SPECIFICATION

DOC. NO.

QU/RT/003

REV

02

TABLE OF CONTENTS

SECTION NO

TITLE

1.0.

SCOPE

2.0.

REFERENCES AND APPLICABLE CODES

3.0.

PERSONNEL QUALIFICATION & RESPONSIBILITY

4.0.

SAFETY

5.0.

EQUIPMENTS

6.0.

FILM, PROCESSING AND LEAD INTENSIFYING SCREENS

7.0.

SURFACE PREPARATION

8.0.

DETECTION AND PREVENTION OF BACK SCATTERED RADIATION

9.0.

SYSTEM RADIOGRAPHS IDENTIFICATION

10.0.

FILM AND SOURCE PLACEMENT

11.0.

IMAGE QUALITY INDICATOR (IQI) & PLACEMENT

12.0.

SHARPNESS OF RADIOGRAPHIC IMAGE AND SOURCE

TO FILM DISTANCE

13.0.

QUALITY AND INTERPRETATION OF RADIOGRAPHS

14.0.

QUALIFICATION OF TESTING PROCEDURE / TECHNIQUE SHEETS

15.0.

EXTENT OF EXAMINATION

16.0.

REPORTING

17.0.

RE EXAMINATION

18.0.

ACCEPTENCE CRITERIA

Appendix 1

SINGLE WALL RADIOGRAPHIC TECHNIQUE

Appendix 2

EXPOSURE TECHNIQUE FOR FLAT COMPONENTS

Appendix 3

PLACEMENT OF LOCATION MARKERS

Appendix 4

IQI DESIGNATION AND SELECTION

Appendix 5

ASTM WIRE TYPE PENETRAMETER

Appendix 6

HOLE TYPE IQI PENETRAMETER

Appendix 7

PERIODIC VERIFICATION CERTIFICATE

1.0

PT. QUALITA UTAMA

DATE

18-12-2014

PAGE

3 of 20

RADIOGRAPHIC TESTING

PROCEDURE SPECIFICATION

DOC. NO.

QU/RT/003

REV

02

SCOPE

1.1. This testing procedure describes the requirements, technique evaluation and

interpretation of radiographic testing on boilers and pressure vessels.

1.2. Specific testing parameter are detailed in the technique sheet.

2.0

3.0

4.0

REFERENCES AND APPLICABLE CODES

2.1

ASME BPV Section V Article 2, 2007

2.2

ASME BPV Section VIII Div 1 and 2, 2007

2.3

ASME BPV B31.3, 2004 Edition

2.4

SHELL DEP 31.38.01.31-GEN

2.5

PT. Qualita Utamas Company Written Practice No. QU-WP-0 Rev. 0 for NDT

Personnel Qualification and Certification.

PERSONNEL QUALIFICATION AND RESPONSIBILITY

3.1

The ASNT NDT RT Level III examiner shall be responsible for the initiation of this

procedure.

3.2

Radiographers and interpreters shall be qualified in accordance with the latest edition of

PT. Qualita Utamas written practice No. QU-WP-0 Rev. 0, NDT Personnel

Qualification and Certification.

3.3

Radiographers qualified to ASNT NDT RT Level I and under the supervision of the

ASNT NDT RT Level II and radiographers qualified to RT Level II may perform

radiographic testing

3.4

Minimum ASNT RT Level II may interpret testing under approval of client.

SAFETY

All radiographers and assistants shall abide to the safety requirements and rules at all times

when performing radiographic work or handling of radio isotopes.

This manual formed part of the employment condition for the employees. Client safety

procedure shall be followed in addition to the in-house safety manual.

5.0

EQUIPMENT

5.1

Generally the X-ray unit, Ir-192 and Se-75 Gamma ray system shall be used.

5.2

Gamma source unit shall be of the remote (wind-out) type

Example Tech-ops model 660 gamma camera. The cameras shall be tested and certified

by the manufacturer prior to shipment to the end user.

In addition, it is mandatory requirement that these cameras be inspected periodically by

the National Atomic Energy (BATAN).

5.3

Small Control Area Radiography ( S.C.A.R ) system with Sentinel model 959 projector

including controls, pipe mounting jigs and shield Se-75 source with a maximum of 30

PT. QUALITA UTAMA

DATE

18-12-2014

PAGE

4 of 20

RADIOGRAPHIC TESTING

PROCEDURE SPECIFICATION

DOC. NO.

QU/RT/003

REV

02

curie strength.

5.4

Source strength of Ir-192 will be 100 curies maximum.

5.5

All personnel radiation safety devices shall be calibrated and in good working

condition. Record of dosage and calibration of devices shall be maintained and

available for inspection at all times.

5.6

The recommended thickness range (testing limit) for Ir-192 is as follow :

Isotope

Steel

Aluminum

Copper or Nickel Alloy

Ir-192

6.0 to 65 mm

3.5 mm and above

5.0 mm and above

Other thickness may be radiographed upon received approval of procedure

demonstration by the Authorized Inspector or the Client.

6.0

FILM PROCESSING AND LEAD INTENSIFYING SCREENS.

6.1

Radiographs shall be made using type AGFA D7 or equivalent films or as per Clients

specification..

6.2

All films shall be stored in a clean, dry place where they will not be subjected to :

6.2.1

Chemical vapors

6.2.2

Radiation and light

6.2.3

Excess heat

6.2.4

Undue pressure

If there is any doubt regarding the condition of unexposed film, a film from each box

without exposure to light or radiation, shall be processed in the manner used to

production radiographs. If this processed films show a density of more than 0.3 H & D

the entire box shall be discarded.

6.3 The film processing dark room and all accessories shall be kept the manufacturer.

Processing details are stated in the technique sheets attached. Chemical preparation and

change out shall follow manufacturers recommendations.

6.4 Lead foil intensifying screens of thickness 0.005 (0.13 mm) shall be used to sandwich

the film, front and back and placed in leak proof cassettes for exposure.

Lead screens to be free of scratches, dust , dirt and moisture which may impair the

sensitivity of the film or induced false indication/image on processed films.

7.0

SURFACE PREPARATION

Surface of components to be radiographer shall satisfy the requirements of the applicable

material and fabrication specification, with additional conditioning, if necessary, by any

suitable process to a degree that surface irregularities cannot mask or be confused with

discontinuities. All loose foreign particles on the test surface shall be removed.

8.0

9.0

10.0

PT. QUALITA UTAMA

DATE

18-12-2014

PAGE

5 of 20

RADIOGRAPHIC TESTING

PROCEDURE SPECIFICATION

DOC. NO.

QU/RT/003

REV

02

DETECTION AND PREVENTION OF EXCESSIVE BACK SCATTERED

RADIATION

8.1

To check for back scattered radiation, a (13 mm) high lead symbol B of thickness

1/16 (1.6 mm) is attached to the back of the film cassette.

If a light image of the B appears on a darker background of the radiograph, protection

from back scattered is insufficient and the radiograph shall be considered unacceptable.

A dark image of the B on a lighter background is not cause of rejection. (ASME VArt.2-T-284)

8.2

Whenever back scattered is evident, a 2 or 3 mm lead sheet or additional layer of

intensifying screens will be placed at the back of the film cassette during exposure to

shield the film from back scattered radiation.

SYSTEM OF RADIOGRAPHS IDENTIFICATION

9.1

As a minimum, client/contract/project name, component identification , weld seam

number, welder number, date and location marker shall be clearly identified on the

radiographs by using lead alphabets and lettering.

9.2

The image of these data shall not appear in the image of the area of interest.

For flat component or weldment with reinforcement flush to the parent metal, lead

arrows or other suitable markers will be used to indicate the area of interest.

FILM AND SOURCE PLACEMENT

10.1 Cassettes with films loaded (sandwiched) shall be securely positioned and intimately

close to the surface of the component being radiographer.

10.2 Film overlap of at both ends of the films is required when more than one film are

used during single exposure.

The effective film length when testing component in flat position can be determined

by :

L = 0.8 x source to film distance

where L is the effective film length

10.3 The main radiation beam to the object and the film shall be as perpendicular as possible

to minimize geometric distortion of the radiographic image.

11.0

IMAGE QUALITY INDICATOR (IQI) AND PLACEMENT

11.1 Materials of IQIs

IQIs shall be selected from the same alloy material group or grade as identified in

ASME SE-1025 or from an alloy material group or grade with less radiation absorption

than the material being radiographed.

11.2 Shims under Hole IQIs

Shims is applied when use IQI hole type to accommodate weld reinforcement. The

material is made similar to the weld metal. It shall be place between the part and the

PT. QUALITA UTAMA

DATE

18-12-2014

PAGE

6 of 20

RADIOGRAPHIC TESTING

PROCEDURE SPECIFICATION

DOC. NO.

QU/RT/003

REV

02

IQI. The Shim dimensions shall exceed the IQI dimensions and outline of at least three

sides of the IQI image shall be visible.

11.3 IQIs / penetrameters shall meet the requirements of ASME V, i.e. wire type (SE-747) or

hole type (SE-1025) see T233 Valid for Appendix 2

11.4 One IQI shall be used for 10 x 4 film and two IQI shall be used for 15 x 4 or larger

films.

11.5 IQI shall be placed at the least advantage position across the area of interest with

thinnest wire facing outward except when using panoramic technique).

The identification of the IQI shall not obscure the image of the area of interest.

11.6 Placement of IQIs

IQI shall be on the source side of the component being radiographed. If the source side

is inaccessible, the IQI may be placed on the film side for which letters F shall appear,

provided the radiographs sensitivity as stipulated in section 13.0 can be achieved. If

necessary, procedure qualification can be carried out on a test weld (having same

dimensions as the production weld) on which IQI s can be placed on both source and

film sides. When the source side IQI achieved the required sensitivity , the smallest

corresponding wire discernible on the film used for production radiography.

12.0

SHARPNESS OF RADIOGRAPHIC IMAGE AND SOURCE TO FILM DISTANCE

12.1 Geometric unsharpness (Ug) of radiographs shall not exceed the following :

Material Thickness

Ug. Maximum

Under 2 ( 50.8 mm)

0.02 ( 0.51 mm)

2 through 3 ( 50.8 mm to 76.2 mm)

0.03 ( 0.76 mm)

Over 3 through 4 (76.2 mm to 101.6 mm)

0.04 ( 1.02 mm)

Greater than 4 (101.6 mm)

0.07 ( 1.78 mm)

12.2 The geometric unhappiness (Ug) can be determined by :

Ft

Ug = ------D

Where :

F

= Source size , the maximum projected dimension of the radiating source (or

focal spot) in the plane perpendicular to the distance D from the component

being radiographer.

D = Source to object distance.

13.0

PT. QUALITA UTAMA

DATE

18-12-2014

PAGE

7 of 20

RADIOGRAPHIC TESTING

PROCEDURE SPECIFICATION

DOC. NO.

QU/RT/003

REV

02

= Thickness of component, assuming the film is intact with the component, plus

the space between the film and component. In double wall double image

technique on piping, the outside diameter shall be considered as it.

QUALITY AND INTERPRETATION OF RADIOGRAPHS

13.1 The transmitted film density through the radiographic image of the IQI and the area

of interest shall be 1.8 minimum for single film viewing for radiographs made with an

x-ray unit and 2.0 minimum for radiographs made with gamma-ray source.

For composite viewing of multiple film exposures, each film of the composite

set shall have a minimum density of 1.3 H&D. The maximum density shall be

4.0 H&D for either single or composite viewing. The tolerance for variations in

density reading shall be 0.05 H&D.

13.2 If the density of the radiograph anywhere through the area of interest varies by

more than minus 15% and plus 30% from the density through the body of the

hole type penetrameter and adjacent to the designated wire of a wire type

penetrameter, within the required minimum/ maximum density ranges, then an

additional penetrameter shall be used.

13.3 The film density shall be determined by calibrated densitometer or stepwedge

comparison film verified with a calibrated stepwedge film traceable to a national

standard.

Calibration of densitometer and Stepwedge comparison strip shall be as described in

section T-262 of ASME BPV Section V, Article 2, 2007.

13.4 The required IQI sensitivity for various thickness is stated in the radiographic testing

technique sheets attached in this procedure specification.

IQI sensitivity shall be calculated base on thinnest visible wire :

i.

ii.

Diameter of Thinnest Wire Visible

IQI sensitivity = ------------------------------------------ x 100%

Thickness of Component below

The diameter of the smallest discernible wire image of the IQI on the parent metal

adjacent to the weld-toe-shall be considered.

iii. For double wall double image exposure, that IQI sensitivity shall be computed

based on double wall thickness . The IQI sensitivity shall be 3% or better.

13.5 Viewing room for radiographs shall be provided with subdued background lighting of

an intensity that will not cause shadow or glare on the radiographs. The viewer shall

have minimum 30,000 Lux of Light Intensity to properly illuminate radiographs with H

& D density of up 3.5 and adjustment of intensity will be incorporated.

13.6 All radiographs shall be free from mechanical, chemical or other blemishes to the extent

that they cannot mask or be confused with the image of any discontinuity in the area of

interest in the radiograph, such blemishes include but are not limited to :

14.0

PT. QUALITA UTAMA

DATE

18-12-2014

PAGE

8 of 20

RADIOGRAPHIC TESTING

PROCEDURE SPECIFICATION

DOC. NO.

QU/RT/003

REV

02

i.

Fogging

ii.

Processing defects such as streaks, water marks or chemical stains.

iii.

Scratches , finger marks, crimps, dirt, static marks, smudges or tears.

iv.

False indications due to defective screens or internal faults.

QUALIFICATION OF TESTING PROCEDURE / TECHNIQUE SHEETS.

14.1 Testing techniques shall be established in a standard format / technique sheets- see

attached.

14.2 Each testing technique shall be individually qualified and its parameters recorded.

However, qualification test may be waived if the testing techniques have been

previously qualified and approved by client.

14.3 Radiographs and testing procedure qualification record sheets shall be maintained and

kept on file.

15.0

EXTENT OF EXAMINATION

The extent of radiographic examination shall be as per Client or Authorized Inspector

request.

16.0

REPORTING

16.1 Interpretation of radiographs shall be reported on the standard radiographic report

format (see attached).

16.2 Accompanying the reports, radiographs of each component shall be presented to the

client in film folders with all the necessary information including result of

interpretation, printed name and signature, recorded on the outside for easy reference.

16.3 A copy of the radiographic report shall be keep and maintained by PT. Qualita Utama

for filing and record.

16.4 Client is responsible for maintaining and safekeeping of the reports and radiographs.

K

17.0

RE-EXAMINATION

17.1 An item showing unacceptable defects ,when repaired, shall be re-examined using the

same RT technique as originally used.

18.0

ACCEPTANCE CRITERIA

18.1 ASME B31.1 Power Piping 2007 Paragraph 136.4.5

Welds that are shown by radiography to have any of the following types of discontinuities are

unacceptable :

a.

Any type of crack or zone of incomplete fusion or penetration

b.

Any other elongated indication which has a length greater than

b.1 (6.0 mm) for t up to (19.0 mm)

b.2 1/3t for t from (19.0 mm) to 2 (57 mm), inclusive

PT. QUALITA UTAMA

DATE

18-12-2014

PAGE

9 of 20

RADIOGRAPHIC TESTING

PROCEDURE SPECIFICATION

DOC. NO.

QU/RT/003

REV

02

b.3 (19.0 mm) for t over 2 (57 mm) where t is the thickness of

the thinner portion of the weld

c.

Any group of indications in line that have an aggregate length greater than t in a length of

12t, except where the distance between the successive indications exceed 6L where L is

the longest indication in the group

d.

Porosity in excess of that shown as acceptable in Appendix A-250 of ASME BPV Section

I, 2007 Edition and Addenda 2009

e.

Root concavity when there is an abrupt change in density, as indicated on the radiograph.

PT. QUALITA UTAMA

DATE

18-12-2014

PAGE

10 of 20

RADIOGRAPHIC TESTING

PROCEDURE SPECIFICATION

DOC. NO.

QU/RT/003

REV

02

APPENDIX 1

Single Wall Radiographic Techniques

Pipe

O.D.

Exposure

Technique

Radiograph

Viewing

Source-Weld-Film Arrangement

End View

Side View

IQI

Selection

Placement

Location

Marker

Placement

Exposure Arrangement A

FILM

Single

Wall

T-271.1

Any

Single

Wall

Source

Side

T-277.1(a)

T-276

and

Table

T-276

Source centrally placed within circumference.

Film(s) wrapped around outside surface.

Film

Side

T-277.1(b)

Either

Side

T-275.3

T-275.1(c)

Exposure Arrangement B

Single

Wall

T-271.1

Any

Source

Side

T-277.1(a)

X

T-276

and

Table

T-276

Single

Wall

Film

Side

T-275.1

(b)(1)

Film

Side

T-277.1(b)

Source offset internally.

FILM

Film on opposite outside surface.

Exposure Arrangement C

Source

Side

T-277.1(a)

Single

Wall

T-271.1

Any

Single

Wall

FILM

T-276

and

Table

T-276

Source

Side

T-275.1

(a)(3)

FILM

Source outside pipe. Film inside on near wall.

Film

Side

T-277.1(b)

PT. QUALITA UTAMA

DATE

18-12-2014

PAGE

11 of 20

RADIOGRAPHIC TESTING

PROCEDURE SPECIFICATION

DOC. NO.

QU/RT/003

REV

02

APPENDIX 1

Double Wall Radiographic Techniques (Continued)

Pipe

O.D.

Exposure

Technique

Radiograph

Viewing

Source-Weld-Film Arrangement

End View

IQI

Side View

Selection

Placement

Location

Marker

Placement

Exposure Arrangement D

Any

Double

Wall

T271.2(a)

at Least 3

Exposures

120 to Each

Other

for

Complete

Coverage

X

X

X

X

Single

Wall

Source

Side

T-277.1(a)

T-276

and

Table

T-276

Film

Side

T-275.1

(b)(1)

Film

Side

T-277.1(b)

Double Wall Single Image

Film and source both outside pipe.

X-X Optional Source Location

Exposure Arrangement E

Any

Double

Wall

T271.2(a)

at Least 3

Exposures

120 to Each

Other

for

Complete

Coverage

X

X

X

X

Source

Side

T-277.1(a)

T-276

and

Table

T-276

Single

Wall

Film

Side

T-275.1

(b)(1)

Film

Side

T-277.1(b)

Double Wall Single Image

Source and film both outside pipe

X-X Optional Source Location

Exposure Arrangement F

X

Double

Wall

T-271.2

3 in.

(b)(1)

(88.9mm) at Least 2

or

Exposures

Less

at 90 to

Each Other

for

Complete

Coverage

Double

Wall

(Ellipse):

Read

Offset

Source

Side

and

Film

Side

Images

Source

Side

T-277.1(a)

T-276

and

Table

T-276

Double Wall Double Image

Source and film both outside pipe. Beam offset

Either

Side

T-275.2

PT. QUALITA UTAMA

DATE

18-12-2014

PAGE

12 of 20

RADIOGRAPHIC TESTING

PROCEDURE SPECIFICATION

DOC. NO.

QU/RT/003

REV

02

APPENDIX 1

Double Wall Radiographic Techniques (Continued)

Pipe

O.D.

Exposure

Technique

RadioGraph

Viewing

Source-Weld-Film Arrangement

End View

Side View

IQI

Selection

Placement

Location

Marker

Placement

Exposure Arrangement G

X

Double

Wall

T-271.2

3 in.

(b)(2)

(88.9mm) at Least 3

or

Exposures

Less

at 60 or

120 to

Each Other

for

Complete

Coverage

Double

Wall

Read

SuperImposed

Source

Side and

Film Side

Images

Source

Side

T-277.1(a)

T-276

and

Table

T-276

Double Wall Double Image

Source and film both outside pipe

Beam perpendicular to weld and film.

Either

Side

T-275.2

PT. QUALITA UTAMA

DATE

18-12-2014

PAGE

13 of 20

RADIOGRAPHIC TESTING

PROCEDURE SPECIFICATION

DOC. NO.

QU/RT/003

REV

02

APPENDIX 2

EXPOSURE TECHNIQUE FOR FLAT COMPONENTS

RADIATION SOURCE

RADIATION SOURCE

FILM

PT. QUALITA UTAMA

DATE

18-12-2014

PAGE

14 of 20

RADIOGRAPHIC TESTING

PROCEDURE SPECIFICATION

DOC. NO.

QU/RT/003

REV

02

APPENDIX 3

PLACEMENT OF LOCATION MARKERS

PT. QUALITA UTAMA

DATE

18-12-2014

PAGE

15 of 20

RADIOGRAPHIC TESTING

PROCEDURE SPECIFICATION

DOC. NO.

QU/RT/003

REV

02

APPENDIX 4

IQI DESIGNATION AND SELECTION

IQI

Designation

Table T-233.1 Hole-Type IQI Designation, Thickness,

and Hole Diameters, in.( mm )

IQI

1T Hole

2T Hole

Thickness

Diameter

Diameter

4T Hole

Diameter

0.005 ( 0.13 )

0.010 ( 0.25 )

0.020 ( 0.51 )

0.040 (1.02 )

0.0075 ( 0.19 )

0.010 ( 0.25 )

0.020 ( 0.51 )

0.040 ( 1.02 )

10

0.010 ( 0.25 )

0.010 ( 0.25 )

0.020 ( 0.51 )

0.040 ( 10.2 )

12

0.0125 ( 0.32 )

0.0125 ( 0.32 )

0.025 ( 0.64 )

0.050 ( 1.27 )

15

0.015 ( 0.38 )

0.015

( 0.38 )

0.030 ( 0.76 )

0.060 ( 1.52 )

17

0.0175 ( 0.4 )

0.0175 ( 0.44 )

0.035 ( 0.89 )

0.070 ( 1.70 )

20

0.020 ( 0.51 )

0.020

( 0.51 )

0.040 ( 1.02 )

0.080 ( 2.03 )

25

0.025 ( 0.64 )

0.025

( 0.64 )

0.050 ( 1.27 )

0.100 ( 2.54 )

30

0.030 ( 0.67 )

0.030

( 0.76 )

0.060 ( 1.52 )

0.120 ( 3.05 )

35

0.035 ( 0.89 )

0.035

( 0.89 )

0.070 ( 1.78 )

0.140 ( 3.56 )

40

0.040 ( 1.02 )

0.040

( 1.02 )

0.080 ( 2.03 )

0.160 ( 4.06 )

45

0.045 ( 1.14 )

0.045

( 1.14 )

0.090 ( 2.29 )

0.180 ( 4.57 )

50

0.050 ( 1.27 )

0.050

( 1.27 )

0.100 ( 2.54 )

0.200 ( 5.08 )

60

0.060 ( 1.52 )

0.060

( 1.52 )

0.120 ( 3.05 )

0.240 ( 6.10 )

70

0.070 ( 1.78 )

0.070

( 1.78 )

0.140 ( 3.56 )

0.280 ( 7.11 )

80

0.080 ( 2.03 )

0.080

( 2.03 )

0.160 ( 4.06 )

0.320 ( 8.13 )

100

0.100 ( 2.54 )

0.100

( 2.54 )

0.200 ( 5.08 )

0.400 ( 10.1 )

120

0.120 ( 3.05 )

0.120

( 3.05 )

0.240 ( 6.10 )

0.480 ( 12.19 )

140

0.140 ( 3.56 )

0.140

( 3.56 )

0.280 ( 7.11 )

0.560 ( 14.22 )

160

0.160 ( 4.06 )

0.160

( 4.06 )

0.320 ( 8.13 )

0.640 ( 16.26 )

200

0.200 ( 5.08 )

0.200

( 5.08 )

0.400 (10.16 )

240

0.240 ( 6.10 )

0.240

( 6.10 )

0.480 ( 12.19 )

280

0.280 ( 7.11 )

0.280

( 7.11 )

0.560 ( 14.22 )

PT. QUALITA UTAMA

DATE

18-12-2014

PAGE

16 of 20

RADIOGRAPHIC TESTING

PROCEDURE SPECIFICATION

DOC. NO.

QU/RT/003

REV

02

APPENDIX 4

IQI DESIGNATION AND SELECTION (Continued)

Table T-276 IQI Selection

IQI

Nominal Single-Wall Material Thickness

Range, in. ( mm )

Source Side

Hole-Type

Wire-Type

Designation

Essential

Wire

Film Side

Hole-Type

Wire-Type

Designation

Essential

Wire

Up to 0.25 (6.4), incl.

12

10

Over 0.25 (6.4) through 0.375 (9.5)

15

12

Over 0.375 (9.5) through 0.50 (12.7)

17

15

Over 0.50 (12.7) through 0.75 (19.0)

20

17

Over 0.75 (19.0) through 1.00 (25.4)

25

20

Over 1.00 (25.4) through 1.50 (38.1)

30

10

25

Over 1.50 (38.1) through 2.00 (50.8)

35

11

30

10

Over 2.00 (50.8) through 2.50 (63.5)

40

12

35

11

Over 2.50 (63.5) through 4.00 (101.6)

50

13

40

12

Over 4.00 (101.6) through 6.00 (152.4)

60

14

50

13

Over 6.00 (152.4) through 8.00 (203.2)

80

16

60

14

Over 8.00 (203.2) through 10.00 (254.0)

100

17

80

16

Over 10.00 (254.0) through 12.00( 304.8)

120

18

100

17

Over 12.00 ( 304.8) through 16.00(406.4)

160

20

120

18

Over 16.00 (406.4) through 20.00 (508.0)

200

21

160

20

PT. QUALITA UTAMA

DATE

18-12-2014

PAGE

17 of 20

RADIOGRAPHIC TESTING

PROCEDURE SPECIFICATION

DOC. NO.

QU/RT/003

REV

02

APPENDIX 5

ASTM WIRE-TYPE PENETRAMETER

PT. QUALITA UTAMA

DATE

18-12-2014

PAGE

18 of 20

RADIOGRAPHIC TESTING

PROCEDURE SPECIFICATION

DOC. NO.

QU/RT/003

REV

02

APPENDIX 6

HOLE-TYPE IQI PENETRAMETER

PT. QUALITA UTAMA

DATE

18-12-2014

PAGE

19 of 20

RADIOGRAPHIC TESTING

PROCEDURE SPECIFICATION

DOC. NO.

QU/RT/003

REV

02

APPENDIX 7

PERIODIC VERIFICATION CERTIFICATE

Step tablet No.

:

Date of Verification :

Densitometer and No. Series :

Date of Expiration

:

The density values reported are traceable to NIST and have been verified in accordance with ASME BPV

Section V, Article 2 Paragraph T-262, 2007 requirements with results as follow :

Step No.

Density Recorded

Actual Density

Deviation

Result

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

The step wedge comparison films is acceptable if the density readings do not vary by more than + 0.05 density

units from the density stated on the step wedge comparison films.

Verified By,

Name______________

ASNT NDT RT. Level II

PT. QUALITA UTAMA

DATE

18-12-2014

PAGE

20 of 20

RADIOGRAPHIC TESTING

PROCEDURE SPECIFICATION

DOC. NO.

QU/RT/003

REV

02

APPENDIX 8

RADIOGRAPHY TEST REPORT FORM

You might also like

- RT Procedure Rev01EDocument20 pagesRT Procedure Rev01ETrương Ngọc SơnNo ratings yet

- Radiographic Test ProcedureDocument10 pagesRadiographic Test ProcedureNoor A AlamNo ratings yet

- Internal RT Procedure Spread IIDocument4 pagesInternal RT Procedure Spread IIravi00098100% (1)

- BIX - RT ProcedureDocument36 pagesBIX - RT ProcedureEduard Abastillas100% (1)

- RT Procedure 10.09.16Document9 pagesRT Procedure 10.09.16mukeshsingh6No ratings yet

- Radiography Test ProcedureDocument12 pagesRadiography Test Procedurehasan_676489616100% (4)

- Muksyn Engineering Radiographic Testing ProcedureDocument24 pagesMuksyn Engineering Radiographic Testing Procedurecloud23100% (1)

- Radio Graphic ExaminationDocument33 pagesRadio Graphic ExaminationSakthi PanneerSelvam Tanjai100% (6)

- Radiography Testing - NDT Inspection - TWIDocument5 pagesRadiography Testing - NDT Inspection - TWIKolusu SivakumarNo ratings yet

- RT ProcedureDocument33 pagesRT Procedurenathgsurendra100% (2)

- Digital Radiography ReportDocument7 pagesDigital Radiography ReportadityaromasNo ratings yet

- Assessing linearity of phased array instrumentsDocument20 pagesAssessing linearity of phased array instrumentsKevin HuangNo ratings yet

- Reviewed UT Procedure 10-12-2016Document18 pagesReviewed UT Procedure 10-12-2016Muhammad Maulana100% (1)

- RADIOGRAPHIC TEST PROCEDURE (RT Procedure)Document17 pagesRADIOGRAPHIC TEST PROCEDURE (RT Procedure)Senthil Kumaran100% (1)

- CA-40-19-TOFD-UT Procedure-AWS D1.1Document27 pagesCA-40-19-TOFD-UT Procedure-AWS D1.1Luong Ho VuNo ratings yet

- Dye Penetrant Testing ProcedureDocument5 pagesDye Penetrant Testing ProcedureTabish Shaikh50% (2)

- Carbon Steel Paut Setup SummaryDocument20 pagesCarbon Steel Paut Setup Summaryprabhu_trichyNo ratings yet

- Inspection of Unusual Pipe Types With Eddy Current TechnologiesDocument25 pagesInspection of Unusual Pipe Types With Eddy Current Technologiesmaz234100% (1)

- Hardness Testing Rev 00Document8 pagesHardness Testing Rev 00muslim100% (1)

- 013 NDT-UT TSE API 1104 - Rev 00-2-21Document21 pages013 NDT-UT TSE API 1104 - Rev 00-2-21zainalNo ratings yet

- Procedure For The Dye Penetrant Testing of Steel Forgings To BS EN 10228-2:2016Document4 pagesProcedure For The Dye Penetrant Testing of Steel Forgings To BS EN 10228-2:2016Mark BrailsfordNo ratings yet

- Positive Material Identification (Pmi)Document2 pagesPositive Material Identification (Pmi)MurugadossRajendranNo ratings yet

- Liquid Penetrant Examination Procedure For Asme CodeDocument15 pagesLiquid Penetrant Examination Procedure For Asme Codeshabbir626No ratings yet

- Tofd 2022Document28 pagesTofd 2022ahmed elezabyNo ratings yet

- Radiography Procedure for PipelinesDocument12 pagesRadiography Procedure for PipelinesMecon HyderabadNo ratings yet

- UT Procedure Rev.0Document32 pagesUT Procedure Rev.0Goutam Kumar Deb100% (2)

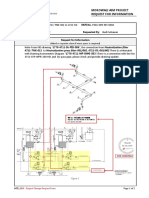

- Paut Inspection Report: Client Rfi NoDocument6 pagesPaut Inspection Report: Client Rfi NoThiru Maran MasterscanNo ratings yet

- Euro NDT PresentationDocument9 pagesEuro NDT PresentationBetoCordeiroNo ratings yet

- Student Training Notes Floormap 3diDocument86 pagesStudent Training Notes Floormap 3diTechnical A-Star Testing & Inspection MalaysiaNo ratings yet

- Computer Radiography Wall ThicknessDocument36 pagesComputer Radiography Wall ThicknessTonyo Ayshiyu100% (3)

- Procedure of UT-TestDocument2 pagesProcedure of UT-TestJohn ShermanNo ratings yet

- 1101 - 1 Procedure For Radiography Rev 1 Dt.19!04!2017 ZORDocument72 pages1101 - 1 Procedure For Radiography Rev 1 Dt.19!04!2017 ZORnathgsurendraNo ratings yet

- AWSD1.1 Procedure UtDocument19 pagesAWSD1.1 Procedure Utkevin desai50% (2)

- Ultrasonic Test Report SummaryDocument6 pagesUltrasonic Test Report SummaryGibson FisherNo ratings yet

- TOFD CV PDFDocument19 pagesTOFD CV PDFKarna2504No ratings yet

- Manual Ultrasonic Testing Procedure for 26Document12 pagesManual Ultrasonic Testing Procedure for 26Rohit Kumar Mishra100% (1)

- ACFM Applications1Document12 pagesACFM Applications1naoufel1706No ratings yet

- Airlines NDT Conf Digital-RadiographyDocument26 pagesAirlines NDT Conf Digital-RadiographyRamakrishnan AmbiSubbiah100% (1)

- Eddy Current Array TutorialDocument13 pagesEddy Current Array TutorialsameerNo ratings yet

- Isq-O&G Manual Ultrasonic Thickness & Corrosion Examination: ASNT Document UT-PTP7 Revision 2Document14 pagesIsq-O&G Manual Ultrasonic Thickness & Corrosion Examination: ASNT Document UT-PTP7 Revision 2muhammadazhanudinNo ratings yet

- MEENA Internation NDT TrainingDocument45 pagesMEENA Internation NDT Trainingahmzahid100% (1)

- RT Report FormatDocument1 pageRT Report FormatRonanki RaviNo ratings yet

- Ultrasonic Testing ProcedureDocument15 pagesUltrasonic Testing ProcedureZulaiha Abdul Rahman100% (1)

- NDE Procedure - Radiographic TestingDocument43 pagesNDE Procedure - Radiographic TestingJeganeswaranNo ratings yet

- ACFM OverviewDocument40 pagesACFM OverviewSooraj RajanNo ratings yet

- Jha-195 To Carry Out Mpi, PT TestDocument12 pagesJha-195 To Carry Out Mpi, PT Testhammadgull100% (1)

- RT-Technique Sheet Items Level IIDocument3 pagesRT-Technique Sheet Items Level IISugianto TanNo ratings yet

- RT ProcedureDocument18 pagesRT Procedure1339979No ratings yet

- D-p5-Bv-pd-002 - MT, Issue 01, Rev 00 - Magnetic Particle ExaminationDocument54 pagesD-p5-Bv-pd-002 - MT, Issue 01, Rev 00 - Magnetic Particle ExaminationThinh Nguyen100% (1)

- Corrosion Mapping Solutions EddyfiDocument4 pagesCorrosion Mapping Solutions EddyfiTHIRU.SNo ratings yet

- RT Safe Work Area CalculationDocument10 pagesRT Safe Work Area CalculationMuhammed Hisham H100% (1)

- Hardness Test ProcedureDocument5 pagesHardness Test Procedurefebinjohns87100% (1)

- All NDE ProcedureDocument35 pagesAll NDE ProcedureArun Karthikeyan100% (2)

- TSC - Technical Info, ACFM and Tank Floor Weld InspectionDocument2 pagesTSC - Technical Info, ACFM and Tank Floor Weld InspectionhcmcrlhoNo ratings yet

- Weld UTDocument6 pagesWeld UTSri Inavolu100% (1)

- JP For Radiography TestDocument16 pagesJP For Radiography Testsubudhiprasanna100% (1)

- Impact of Non-Destructive Testing: Proceedings of the 28th Annual British Conference on Non-Destructive Testing, Sheffield, UK, 18-21 September 1989From EverandImpact of Non-Destructive Testing: Proceedings of the 28th Annual British Conference on Non-Destructive Testing, Sheffield, UK, 18-21 September 1989C. BrookNo ratings yet

- RT Asme B31 3 2014Document20 pagesRT Asme B31 3 2014Shanmuga Navaneethan0% (1)

- Basics of FlangesDocument9 pagesBasics of FlangesChandra PratamaNo ratings yet

- Calc Acid Loading Filling Time - Rev 1Document2 pagesCalc Acid Loading Filling Time - Rev 1papathsheilaNo ratings yet

- China Standards and Foreign Standards Comparison Table 1.0Document14 pagesChina Standards and Foreign Standards Comparison Table 1.0papathsheilaNo ratings yet

- PEP-00-A0SP-0001 Civil and Structural Design BasisDocument43 pagesPEP-00-A0SP-0001 Civil and Structural Design BasispapathsheilaNo ratings yet

- Universe Series Catalogu - TSURUMI PUMPDocument11 pagesUniverse Series Catalogu - TSURUMI PUMPpapathsheilaNo ratings yet

- Tmbp-01-Pi-std-102 Rev.0 - Piping Support Standard DrawingDocument46 pagesTmbp-01-Pi-std-102 Rev.0 - Piping Support Standard DrawingpapathsheilaNo ratings yet

- PEP-10-J9-SP-0004 Specification For Instrument InstallationDocument30 pagesPEP-10-J9-SP-0004 Specification For Instrument InstallationpapathsheilaNo ratings yet

- PEP-20-E1-SP-0004 Specification For Portable Standby Generator SetsDocument14 pagesPEP-20-E1-SP-0004 Specification For Portable Standby Generator SetspapathsheilaNo ratings yet

- PEP-10-R1-SP-0004 Specification For Diaphragm Pumps, Air OperatedDocument7 pagesPEP-10-R1-SP-0004 Specification For Diaphragm Pumps, Air Operatedpapathsheila100% (1)

- PEP-00-L9-SP-0007 Specification For Line PipeDocument19 pagesPEP-00-L9-SP-0007 Specification For Line PipepapathsheilaNo ratings yet

- P501-Mti-Rfi-00xx Drawing 1778-4711-MP-DWG-032Document2 pagesP501-Mti-Rfi-00xx Drawing 1778-4711-MP-DWG-032papathsheilaNo ratings yet

- 506-CFA.00-PFD-009 Pond To CreekDocument1 page506-CFA.00-PFD-009 Pond To CreekpapathsheilaNo ratings yet

- Cooling Tower. Merkel Theory - TreybalDocument29 pagesCooling Tower. Merkel Theory - TreybalTech ManagerNo ratings yet

- Roasting Solutions: BenefitsDocument8 pagesRoasting Solutions: BenefitspapathsheilaNo ratings yet

- Gas Air Thermal PropertiesDocument22 pagesGas Air Thermal PropertiesSurjit DuttaNo ratings yet

- Notes: How To Complete The Project Status Report WorkbookDocument6 pagesNotes: How To Complete The Project Status Report WorkbookcabeaureyNo ratings yet

- Bernoulli and Piezometric LineDocument7 pagesBernoulli and Piezometric LineJMVNo ratings yet

- AdhamandLee CIMpaperonNiDocument7 pagesAdhamandLee CIMpaperonNiKokay QosarNo ratings yet

- Inspection and Test Plan for Piping Fabrication and InstallationDocument16 pagesInspection and Test Plan for Piping Fabrication and InstallationEyoh EffiongNo ratings yet

- Wet Air Volume Composition Dry Air Volume Composition: Volda (1) Volda (2) Volda (3) Volda (4) Volda (5)Document32 pagesWet Air Volume Composition Dry Air Volume Composition: Volda (1) Volda (2) Volda (3) Volda (4) Volda (5)papathsheilaNo ratings yet

- Contraction, Velocity and Discharge Coefficients of A Rectangular Sharp Edeged SlotDocument49 pagesContraction, Velocity and Discharge Coefficients of A Rectangular Sharp Edeged SlotpapathsheilaNo ratings yet

- Basic Pump Knowledge 2Document26 pagesBasic Pump Knowledge 2papathsheilaNo ratings yet

- Material EquilentDocument16 pagesMaterial EquilentShoaib JadoonNo ratings yet

- Piping KnowledgeDocument106 pagesPiping KnowledgeYo100% (1)

- Channels 1. Channel Functions Resume and Applications - Constant Manning's Coefficient - Comparison With Hcanales - DeductionsDocument50 pagesChannels 1. Channel Functions Resume and Applications - Constant Manning's Coefficient - Comparison With Hcanales - Deductionsr4mms3sNo ratings yet

- AS4035 - Conveyor and Elevator BeltingDocument11 pagesAS4035 - Conveyor and Elevator BeltingpapathsheilaNo ratings yet

- Abs-Equipment Condition Monitoring PDFDocument101 pagesAbs-Equipment Condition Monitoring PDFShubhodeep SarkarNo ratings yet

- Standard - Pipe - Supports (GDF SUEZ) PDFDocument63 pagesStandard - Pipe - Supports (GDF SUEZ) PDF이우견No ratings yet

- Steel pipe pressure ratings and flow ratesDocument2 pagesSteel pipe pressure ratings and flow ratesNarendra ChavdaNo ratings yet

- Learner's Activity Sheet Assessment Checklist: Contemporary Philippine Arts From The Regions Quarter 2 - Week 7Document17 pagesLearner's Activity Sheet Assessment Checklist: Contemporary Philippine Arts From The Regions Quarter 2 - Week 7Ken KenNo ratings yet

- CM 422 Lecture Plan 2023Document3 pagesCM 422 Lecture Plan 2023Donald SelmartinNo ratings yet

- General Math 1st Quarter Exam PDF FreeDocument4 pagesGeneral Math 1st Quarter Exam PDF FreeJayVince DelgadoNo ratings yet

- Bigbang TheoryDocument2 pagesBigbang TheoryElfina M. LintotNo ratings yet

- Integrity monitoring and inspection toolsDocument1 pageIntegrity monitoring and inspection toolsKailash UpretiNo ratings yet

- Block Syllabus S. St Grade 5 FIRST TERM 2024Document4 pagesBlock Syllabus S. St Grade 5 FIRST TERM 2024fatimaijaz928No ratings yet

- StstisticsDocument5 pagesStstisticsAhmed EssamNo ratings yet

- Zero To One by Peter ThielDocument1 pageZero To One by Peter ThielAbusufian SajibNo ratings yet

- Timothy Adès - Robert Desnos - Siren-Anemone - and Other Poems (2005)Document29 pagesTimothy Adès - Robert Desnos - Siren-Anemone - and Other Poems (2005)HamidNo ratings yet

- Motivation and PerformanceDocument15 pagesMotivation and PerformanceRizqina AwliyaNo ratings yet

- Math10 Q3 Ver4 Mod10 ProbabilityOfCompoundEventsDocument65 pagesMath10 Q3 Ver4 Mod10 ProbabilityOfCompoundEventserra100% (2)

- Activity Sheets - UCSPDocument24 pagesActivity Sheets - UCSPJashmin Corz100% (2)

- Sample Test 1.2022Document2 pagesSample Test 1.2022Phạm ToànNo ratings yet

- Google Chrome sqnzN6Document4 pagesGoogle Chrome sqnzN6Sachin AnandNo ratings yet

- GiroudHan 0212GS Part1and2 UnlockedDocument20 pagesGiroudHan 0212GS Part1and2 UnlockedEmerson Valentin ValverdeNo ratings yet

- LAB 09 Cell DivisionDocument9 pagesLAB 09 Cell DivisionGlaiza Nicole CuarteronNo ratings yet

- X Mid TermDocument13 pagesX Mid TermPM Rajeev Raj sahuNo ratings yet

- Result HSSC A 2022 Part-IIDocument794 pagesResult HSSC A 2022 Part-IIMusab AhmedNo ratings yet

- Void Empires v6Document342 pagesVoid Empires v6SamWissaNo ratings yet

- ADOR Booklet F Web FDocument132 pagesADOR Booklet F Web FbadesharamkNo ratings yet

- Seismic 4D AttributeDocument20 pagesSeismic 4D AttributeAndrianto WibowoNo ratings yet

- Manual of Forever Living ProductsDocument105 pagesManual of Forever Living Productsspiritualbeing100% (20)

- Emile Durkheim'in Pragmati̇zm Üzerine Fi̇ki̇rleri̇Document304 pagesEmile Durkheim'in Pragmati̇zm Üzerine Fi̇ki̇rleri̇İlayda ilaydasaglamhotmail.comNo ratings yet

- RetestsDocument21 pagesRetestsNnogge LovisNo ratings yet

- Understanding Microscopes with Virtual Lab SimulationsDocument3 pagesUnderstanding Microscopes with Virtual Lab SimulationsangelynNo ratings yet

- ML B 200 Bkasr183Document34 pagesML B 200 Bkasr183Marco Antonio PrietoNo ratings yet

- TB 291 Keystone Colorants For Wood Coatings (2!16!12)Document9 pagesTB 291 Keystone Colorants For Wood Coatings (2!16!12)Locer2011No ratings yet

- English - Grade 1Document16 pagesEnglish - Grade 1Michael Jorge Bernales100% (1)

- Syntax:: Familiarization of Infinite Impulse Response (IIR) and Pole-Zero Response FiltersDocument13 pagesSyntax:: Familiarization of Infinite Impulse Response (IIR) and Pole-Zero Response FiltersNico LomaNo ratings yet

- The Alchemist Study GuideDocument5 pagesThe Alchemist Study GuideSK ElangovanNo ratings yet