Professional Documents

Culture Documents

The Effects of Neat Biodiesel and Biodiesel and HVO Blends in Diesel Fuel On Exhaust Emissions From A Light Duty Vehicle With Diesel Engine PDF

Uploaded by

patikavalcoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Effects of Neat Biodiesel and Biodiesel and HVO Blends in Diesel Fuel On Exhaust Emissions From A Light Duty Vehicle With Diesel Engine PDF

Uploaded by

patikavalcoCopyright:

Available Formats

Article

pubs.acs.org/est

The Eects of Neat Biodiesel and Biodiesel and HVO Blends in Diesel

Fuel on Exhaust Emissions from a Light Duty Vehicle with a Diesel

Engine

Adam Prokopowicz,*, Marzena Zaciera, Andrzej Sobczak,, Piotr Bielaczyc, and Joseph Woodburn

Institute of Occupational Medicine and Environmental Health, Koscielna 13, 41-200 Sosnowiec, Poland

School of Pharmacy with Division of Laboratory Medicine in Sosnowiec, Medical University of Silesia, Poniatowskiego 15, 40-055

Katowice, Poland

BOSMAL Automotive Research and Development Institute Ltd, Sarni Stok 93, 43-300 Bielsko-Biala, Poland

S Supporting Information

*

ABSTRACT: The inuence of fatty acid methyl esters (FAME) and

hydrotreated vegetable oil (HVO) diesel blends on the exhaust emissions

from a passenger car was examined. The impact of FAME for the cold

urban phase (UDC) was increased CO and HC emissions, probably due

to blend physical properties promoting incomplete combustion. The

HVO blend caused the lowest CO and HC emissions for the UDC. NOx

emissions did not change signicantly with the fuel used, however the

UDC was characterized by lower NOx emission for FAME blends.

Particle emissions were highest with standard diesel. Emissions of

carbonyl compounds increased as fuel biodiesel content increased,

especially during the UDC. HVO in diesel fuel decreased carbonyl

emissions. Formaldehyde and acetaldehyde were the most abundant

carbonyl compounds in the exhaust gas. Total particle-bound PAH

emissions were variable, the emission of heavier PAHs increased with

blend biodiesel content. The HVO blend increased emission of lighter PAHs. Nitro-PAHs were identied only during the UDC

and not for all blends; the highest emissions were measured for pure diesel. The results showed that emission of nitro-PAHs may

be decreased to a greater extent by using biodiesel than using a HVO blend.

consumption needs.4,5 The transesterication process decreases

the viscosity and increases the cetane number and heating value

in comparison to the feedstock, so FAMEs properties do not

dier signicantly from petroleum diesel fuel, and may be used

in unmodied diesel engines. However, the high percentage of

unsaturated bonds in the fatty acids structure causes biodiesel

to be more prone to oxidation compared to diesel, which

decreases its long-term stability properties. Much research has

indicated that their addition to diesel fuel reduces the toxicity of

exhaust emissions by lowering the emission of particulate

matter, carbon monoxide, and total hydrocarbons, although

some increase in emission of nitrogen oxides is observed.69

Hydrotreated vegetable oil (HVO) is another renewable fuel

for diesel engines, which is produced from vegetable oils and

composed mainly of liquid paranic hydrocarbons. A pathway

to their production is conventional hydrotreating catalysis, in

which hydrogen is used to remove oxygen atoms and double

bonds from the structure of triglicerides. The physical and

INTRODUCTION

In the past decade interest in usage of renewable fuels has

increased sharply, due to limited fossil fuel resources and the

opportunity to reduce greenhouse gas emissions. This also

involves transport fuels, which for example, in the EU, have the

highest contribution to general energy consumption (about

40%) and of which 56% originate from renewable sources.1 In

the case of diesel engines, commonly used both in heavy

transportation vehicles and passenger cars, fatty acid methyl

esters (FAMEs), known as biodiesel, are the main biocomponents which are blended and used with conventional petroleum

diesel fuel.2 FAMEs are produced mainly by transestrication of

vegetable oils such as soybean, rapeseed, and palm oils with

glycerol as a byproduct in an alkali-catalyzed process.3 Although

methanol and ethanol are most frequently used as a alcohol, the

former is mainly employed because of its low cost and

physicochemical advantages but, in contrast to ethanol,

methanol originates mostly from fossil feedstock. Production

may lead to the presence of some catalyst poisons in biodiesel,

like Na, K, or P. The fats for FAME production also may

originate from postfrying oils, waste animal fats, or microalgae

oil, which fulll the greenhouse gas emission criteria better than

edible vegetable oils and do not compete with food

2015 American Chemical Society

Received:

Revised:

Accepted:

Published:

7473

February 5, 2015

April 30, 2015

May 20, 2015

May 20, 2015

DOI: 10.1021/acs.est.5b00648

Environ. Sci. Technol. 2015, 49, 74737482

Article

Environmental Science & Technology

Table 1. Main Physicochemical Properties of the Test Fuelsa

fuel parameter

density at 15 C (kg/dm3)

viscosity at 40 C (mm2s)

ash point (C)

sulfur content (ppm)

cetane number

water content (ppm)

CFPP C

E250 (evaporated at 250 C)

[% v/v]

E350 (evaporated at 350 C)

(% v/v)

T95(95% vol. evaporated at)

(C)

LHV (MJ/kg)

PAHs (% m/m)

a

B0 (100%

DF)

B7 (93.1% DF + 6.9%

FAME)

B15 (85% DF + 15%

FAME)

B30 (70% DF + 30%

FAME)

B100(100%

FAME)

HVO30 (70% DF +

30% HVO)

0.836

2.632

59.5

8.0

55.2

70

28

38.7

0.838

2.637

61.0

7.1

52.5

82

27

41.1

0.842

0.847

0.816

2.737

25

17

0.875

4.64

178

6.0

56.1

350

8

98.8

95.7

339.8

347.5

42.6

3.0

37.0

42.9

2.2

17

DF, diesel fuel; FAME, fatty acid methyl esters; HVO, hydrotreated vegetable oil.

condition, which may change the emission prole of most

harmful pollutants, probably due to the higher viscosity and

lower volatility of biodiesel in comparison to conventional

diesel fuel. Concerning paranic fuels, it was observed that

emission of formaldehyde and PAHs can decrease with this

fuel.16,19

Diesel engine operation is very sensitive to fuel properties;

crucially, a number of physical properties change when

biodiesel or paranic fuel are added to diesel fuel. Thus,

changes in emissions may not be just due to the change in

chemical composition, but also to changes in other properties

such as density, volatility, and cetane number.20

The purpose of the present study was a comparison of

regulated and unregulated (carbonyl, PAH and nitro-PAH

compounds) emissions in relation to fuels containing dierent

proportions of FAMEs and HVO in diesel fuel. The European

legislative NEDC test cycle (Supporting Information page S3),

introduced in Directive 98/69/EC, was selected as a

representative test for this study. The emission tests were

performed on a chassis dynamometer and conducted on a

passenger car equipped with a modern direct injection

turbocharged diesel engine meeting Euro 4 emission standards.

functional properties of this fuel are very comparable to

petroleum diesel fuel so their importance increases, including

the possibility of usage as aviation fuel.10 However, aside from

cold ow properties, which may be improved by alkane

isomerization, due to its low lubricity and high cetane number it

is not recommend to use HVO blends with concentrations

above 50% in diesel fuel.11 The sooting reduction tendency

observed in the same study indicated potential reductions in

particulate matter (PM) emissions in most recent model year

vehicles.

The toxicity of exhaust emission and changes in the prole of

emitted pollutants when using renewable fuels is a very

important issue, due to the inuence on air pollution and the

attending possible health eects. Diesel engine exhaust consists

of many toxic compounds and has been classied in group 1,

according to IARC, as carcinogenic to humans.12 Despite many

studies which concern the emissions prole using biodiesel,

most of them were conducted with test engines under steady

state driving condition, and not on in-use cars, operating with

exhaust after treatment devices over transient cycles, for

example the New European Driving Cycle (NEDC). A recent

investigation indicated a marginal increase in HC, CO, and PM

emission under these conditions, due to certain physical

properties of biodiesel blends and cold-start occurring in the

cycle.13 However, previous studies showed signicant increases

in CO, HC, and even PM when using biodiesel blends and pure

biodiesel, which was explained by higher viscosity and lower

volatility of these fuels in comparison to conventional diesel

fuel.14,15 In turn, usage of paranic biofuels caused reductions

of emissions of these pollutants under similar test conditions.16

There are, however, growing concerns regarding unregulated

pollutants emitted from diesel engines, which mostly include

carbonyl compounds, polycyclic aromatic hydrocarbons

(PAHs), and their nitrated derivatives (nitro-PAHs). Recent

studies have reported increasing carbonyl compound emissions

with increased biodiesel content in the diesel fuel, which is in

agreement with the majority of investigations conducted in

engine test cells.17,18 In turn, the emission of PAHs was shifted

toward lighter PAH compounds and was clearly dependent on

the feedstock origin for FAME production, showing that

oxidized fuel increased emissions of some PAHs and nitroPAHs compared to when using standard diesel fuel.13

Moreover, these emissions were aected by the cold-start

MATERIAL AND METHODS

The experiment was carried out on midsize passenger car of

European manufacture, produced in 2009 and with a

compression ignition engine of displacement 1920 cm3. The

vehicles engine also featured typical technology for a Euro 4

diesel passenger car: a turbocharger, cooled exhaust gas

recirculation controlled by an air ow meter, and a commonrail fuel injection system with high-pressure injectors. A diesel

particulate lter was not present, but an oxidation catalyst was

tted, again, typical for a Diesel car meeting the Euro 4

standard. The emission tests were carried out in BOSMALs

Emission Testing Laboratory using an AVL48 single roll

chassis dynamometer. This chassis dynamometer is situated

within a climatic chamber (Supporting Information Figure S1).

As per the European legislative test method, the test

commenced from a cold start at a temperature of 20 C to

30 C (24 C was targeted) with the oil, coolant and all

elements of the engine at ambient temperature (24 C 2 C).

The vehicle speed versus time plot for the NEDC is presented

in the Supporting Information in Figure S2. Each test on each

7474

DOI: 10.1021/acs.est.5b00648

Environ. Sci. Technol. 2015, 49, 74737482

Article

Environmental Science & Technology

Figure 1. Relative emissions of CO, HC, NOx, PM, CO2, and absolute values of fuel consumption for the fuels tested. * p < 0.05.

A HORIBA CVS 7400S system with a full-ow dilution

tunnel and DLS 7100EPM sampling system, a set of HORIBA

MEXA HTRLE and the HORIBA VETS7000NT management

system were all used to measure exhaust emission levels.21 An

average dilution ratio of 1:20 and 1:10 was used during UDC

and EUDC phases, respectively. Fuel consumption was

calculated by the carbon balance method.

blend was performed in triplicate. Six dierent fuels were used,

whose general compositions and densities with some others

parameters are listed in Table 1. Pure petroleum diesel fuel,

neat rapeseed methyl ester (RME) and B7 were purchased

from PKN ORLEN. Pure HVO produced using NExBTL

technology was obtained from Neste Oil Oyj. In addition,

conventional diesel was blended to obtain the remaining fuels

(B15, B30, HVO30).

7475

DOI: 10.1021/acs.est.5b00648

Environ. Sci. Technol. 2015, 49, 74737482

Article

Environmental Science & Technology

Table 2. Regulated emissions over the NEDC (UDC + EUDC)a

emissions (mg/km)

NEDC

CO2 emission (g/km)

UDC

EUDC

fuel

CO

NOx

HC

PM

CO

NOx

HC

PM

CO

NOx

HC

PM

NEDC

UDC

EUDC

B0

B7

B15

B30

B100

HVO30

121

159

145

167

426

59

221

211

219

220

211

224

30

36

40

45

97

25

33

29

29

26

16

30

323

428

391

448

1152

154

257

234

241

249

206

266

69

83

90

103

246

51

34

32

27

25

31

30

4

4

4

4

4

5

201

197

207

204

213

200

8

8

11

12

10

10

33

27

31

26

8

31

162.8

164.3

161.4

163.4

169.7

161.9

214.0

212.1

207.9

211.3

226.9

207.3

133.4

136.7

134.6

135.7

136.6

135.6

Euro 4 limits (mg/km): CO 500; NOx 250; (NOx+HC) 300; PM 25.

a near-linear relationship between this reduction and the

increase in the H/C ratio of the fuel. However, the main reason

for the observed reduction is probably the lower boiling point,

which has a benecial impact on complete vaporization of the

fuel in the combustion chamber at low load and cold start

conditions.11In turn, Lim et al. indentied the increased cetane

number with HVO addition to diesel fuel as an important factor

for reducing the CO emission level.30During the EUDC phase,

emissions of CO were at a very low level, due to the high

eectiveness of the vehicles diesel oxidation catalyst at

removing CO, and comparable for all tested fuels. No

reductions in CO emissions during the EUDC phase were

observed for any of the fuels containing FAME, nor for HVO

blend.

A similar tendency as for CO emission was observed for total

HC emissions, which were also the highest in the case of B100

in the UDC phase. In reference to conventional diesel fuel, a

signicant increase occurred also for B30, but for the other

biodiesel blends, the increase in HC emissions was only

marginally signicant. As reported previously, benzene was the

most abundant among the light aromatic hydrocarbons, and

benzene emissions showed a similar trend to that of total HC.31

This trend was especially visible during the UDC phase and it is

undoubtedly the result of the cold start conditions and the

physicochemical parameters of fuels containing FAME. Diesel

engine cold start is aected by many interacting processes

during mixture formation inside the cylinder that lead to

autoignition and combustion. Emissions during DI diesel

engine cold-start and warm up are signicant for overall

emissions, (however not as signicant as in a spark-ignition

engine), since the conditions for fuel atomization, mixture

formation and combustion are poor.32 Moreover, aftertreatment devices (e.g., an oxidizing catalyst) do not work eectively

under these conditions. A previous investigation concerning

HC emissions when using standard diesel fuel indicated that

during the rst of the four elementary phases of the UDC, this

emission is 100150% higher than during the last elementary

phase of the UDC.33 Poorer atomization and vaporization due

to the higher density, viscosity and boiling point of FAME and

its blends than for pure petroleum diesel fuel lead to an increase

in HC emissions during the UDC, which during the following

EUDC phase did not show such a signicant dierentiation

(only for B30, marginally). As discussed by Giacoumis and coworkers,9 a diesel oxidation catalyst may seem to operate less

eciently with biodiesel and biodiesel blends not only under

cold conditions, but also throughout the whole cycle. The

reason for this behavior is the lower biodiesel exhaust gas

temperature causing lower available exhaust gas thermal energy.

It was evident that HC emissions decreased for the HVO30

Carbonyl compounds in the engine exhaust gas were

determined using 2,4-dinitrophenylhydrazine (2,4-DNPH)

method after collection of diluted exhaust in Tedlar bags.

Particle bound PAHs and nitro-PAHs collected onto Pallex

(T60A20) lters were determined by HPLC with uorescence

detection and GC-MS method, respectively.14,15

Methodological details and QA/QC data including recoveries, precision and accuracy for carbonyl, PAH and nitro-PAH

compounds are presented in the Supporting Information,

(pages S3S4 and Table S1).

t test analyses were used to assess dierences in emission

results. P values <0.05 were considered statistically signicant.

RESULTS AND DISCUSSION

The emission results of three biodiesel blends, as well as neat

biodiesel and the HVO blend were related to petroleum diesel

fuel and presented in Figure 1 as mean values with standard

errors. The gures show the results for both phases, that is, the

UDC and the EUDC, as well as for the complete NEDC cycle

(UDC+EUDC). Additionally, Figure 1 shows the fuel

consumption during all cycles. Measured emission values are

listed in Table 2.

For the vehicle under test, the addition of FAMEs to the fuel

lead to an increase in CO emissions during the UDC phase.

The increase was particularly evident for neat biodiesel, for

which the level was over three times that of conventional diesel

fuel. This was probably the result of poor atomization and

vaporization of fuels containing FAMEs during cold-start and

engine warm up, due to their higher viscosity and density in

comparison to diesel fuel. This trend is in contrast to most

investigations, which used steady-state conditions,2428

although the opposite trend has also been observed.29

Reduction of CO emission was explained mainly by the oxygen

content of ester molecules and the more complete combustion

that results. Nevertheless, results similar to those presented

here were obtained during the UDC by Fontaras et al.14 and

Macor et al.,18 who also attributed this result to higher blend

viscosity and poor atomization during cold start conditions.

Karavalakis et al.13 investigated the inuence of cold start on

CO emission and noted only a marginal increase within the

uncertainty range of the measurement method, and even a

signicant decrease in the case of some biodiesel blends. In this

study, only the HVO30 blend was characterized by lower CO

emissions, which were reduced by more than half in

comparison to emissions from diesel fuel. The HVO30 fuel

had the lowest density, which would conrm the inuence of

the physical properties of this fuel on the combustion processes.

Zervas16 investigated pure aliphatic fuels and also obtained

signicantly lower CO emissions during the NEDC, indicating

7476

DOI: 10.1021/acs.est.5b00648

Environ. Sci. Technol. 2015, 49, 74737482

Article

Environmental Science & Technology

vehicle speed increases.13,14,18 No signicant dierences in NOx

emission were observed for HVO30 fuel. Nevertheless, a slight

increase in NOx emission was observed during the UDC phase

in comparison to diesel fuel. This could indicate a tendency

toward some increase in NOx emissions, as shown in a previous

study using pure paranic fuels.16

PM emissions for each the biofuels, both FAME and HVO

blends, decreased in comparison to emissions when using

conventional diesel fuel. The highest reduction was observed

for pure biodiesel during the EUDC phase. Specically, PM

emissions during the UDC phase decreased by 8.7% for B7, by

20.6% for B15, by 27.5% for B30, by 9.9% for B100 and by

11.8% for HVO30. However, due to the high variability of the

PM emission results for some fuels, these reductions were only

statistically signicant for the B15 and B30 blends over this test

cycle. PM emissions during the EUDC phase decreased by

16.5% for B7, by 5.2% for B15, by 18.6% for B30, by 76.3% for

B100, and by 5.2% for HVO30. These results are consistent

with the majority of comparable observations, where signicant

reductions in PM emissions were obtained for fuel with FAME

content and pure paranic fuel.19,34 This reduction is

attributed to the presence of oxygen in biodiesel as well as

the absence of aromatic hydrocarbons and sulfur in this fuel.38

HVOs sulfur content is also very low since, (similarly to

FAME) it is produced from raw vegetable material. Additionally, it was observed that all aromatics have a higher PM

formation tendency than parans.40 This may explain the PM

reduction in the case of HVO blend, however, the opposite

tendency was also obtained and was attributed to the improved

cetane number in comparison to diesel fuel, resulting in a

reduction of the premixed combustion region, while diusion

combustion increases.30 As shown by Happonen and coworkers39 even higher PM emissions reductions are possible by

blending HVO fuel with a suitable oxygenate. The relatively

small reduction in PM emission for B100 during the UDC

phase was probably caused by cold start and the physical

properties of FAME. Substantial CO and HC emission using

neat biodiesel indicates poor combustion under cold start

conditions and hence an increase in PM emission is to be

expected. This could lead to nearly 10 times higher PM

emission using B100 in comparison to base diesel or low

biodiesel blend, as observed in previous studies over the UDC

phase.41,42

The CO2 emissions were comparable in most of the

emissions tests performed. For all test fuels (excluding B100),

a slight decrease in CO2 emission was observed in relation to

diesel fuel during the UDC phase; however, this decrease was

statistically signicant only for the B15 and HVO30 blends. In

turn, CO2 emission signicantly increased (by 6%) for B100

during this phase, which indicated that high contents of

biodiesel may lead to evident increases in CO2 emissions,

similar to those for B50 and B100 in the study by Fontaras et

al.,14 where CO2 emissions for those blends increased by 9 and

14%, respectively over the same driving cycle. In the EUDC

phase a statistically insignicant increase (12%) was found

regarding CO2 emissions for fuel with biodiesel and HVO

content. No increases in the variability of the CO2 emission

measurements with increasing biodiesel content in fuel were

observed, as reported by Karavalakis et al.,13 who observed less

repeatable engine operation using biodiesel blends. Fuel

consumption showed similar trends as CO2 emissions, with

the highest values noted for B100. In the UDC phase fuel

consumption was very comparable for all fuels tested excluding

blend, by over 50% in comparison to the value for diesel fuel

during the UDC, which indicates very good atomization and

vaporization of this fuel, even during cold start and warmup.

This fuel had the lowest density among all test fuels, which

suggests an impact of certain physical parameters on the HC

emission level. Similarly as for CO, Karavalakis et al.13 analyzed

the inuence of cold-start condition on HC emission and in

fact found a lack of any relationship between the amount of

FAMEs in the fuel (up to 30%) and HC emissions.

Nevertheless, as with CO emissions, most published studies

report reductions in HC emissions using biodiesel, which has

been attributed to the higher oxygen content of fuels blended

with biodiesel, resulting in more complete combustion. A

similar eect was obtained by the addition of other oxygenated

blending components and compared to rapeseed methyl estersdiesel blends containing the same oxygen concentration.34 In

turn, Balesteros et al.35 did not observe any dierences in HC

emissions during urban driving conditions, whereas during

extra-urban conditions emissions decreased with increasing fuel

FAME content. Reductions in HC emissions in comparison to

diesel fuel ranging from over 20 to over 40% using B5, B20, and

B30 were observed in other studies during the EUDC.15Our

results did not show any signicant reductions in HC

emissions, even during the EUDC, which is consistent with

previous studies performed by Macor et al.18 and Fontaras et

al.14 using a Euro 3 diesel engine.

Formation of NOx is inuenced by the fuel oxygen content

and the local gas temperature. Pure biodiesel (B100) contains

approximately 10% oxygen by weight. However, for the vehicle

under test a slight decrease of NOx emission in the complete

NEDC cycle was observed (ranging from 15% for all fuels

containing FAME) and was caused by the decreased emission

of NOx during the UDC phase. During the EUDC slight and

statistically insignicant increases were observed for the biofuel

blends, excluding the B7 blend (for which NOx emission

decreased negligibly). Unexpectedly, the highest reduction

during the UDC phase was obtained for neat biodiesel. It is

interesting why such a large decrease in NOx emission

occurred, considering the fact that in the literature mainly

increases in NO x emission using biodiesel are reported.13,14,26,27,36 This unexpected trend indicates that it is

also likely that NOx formation is caused, at least in part, by the

physical properties of fuels which can inuence the performance of the fuel injection system. These properties are

especially important during cold start, inuencing the formation

of airfuel mixture and its combustion, as suggested by

Fontraras et al.14 Hotter and higher engine load tests than the

NEDC are usually characterized by higher emissions of NOx at

which point biodiesel and its blends increase this emission in

comparison to conventional diesel. It was also reported that

during idle and acceleration modes the NOx emissions for the

vehicle fuelled with B20 and B30 were much higher than those

using the base diesel fuel and B5 fuel.15 Hence, it is possible

that that the many changes in vehicle speed during the UDC

lead to lower NOx emissions over this cycle. Bergthorson and

Thomson summarize that the so-called biodiesel NOx eect,

which manifests itself in dierent eects on NOx emissions, is

the result not so much of basic fuel chemistry issues, but rather

the physical and chemical properties of the fuel on the

performance of an individual diesel engine.37 Excluding B100,

the UDC phases of all tests were characterized by higher

emissions of NOx than the EUDC phases, which is consistent

with most studies indicating a decrease in NOx emissions when

7477

DOI: 10.1021/acs.est.5b00648

Environ. Sci. Technol. 2015, 49, 74737482

Article

Environmental Science & Technology

precursors participating in photochemical smog formation.

Among the 15 carbonyl compounds determined, only 2,5dimethylbenzaldehyde was not identied in any of the exhaust

samples. Individual results are presented in the Supporting

Information (Table S2). Formaldehyde and acetaldehyde were

the most abundant for each fuel used, with a prevalence of

formaldehyde over acetaldehyde observed. The highest

emissions were observed over the UDC cycle, which may be

attributed to the cold-start condition at the beginning of that

cycle, during which fuel combustion is incomplete and the

oxidation catalyst has not reached its light-o temperature.

Similar observations were reported by Macor et al.18 with Euro

3 diesel engines, whereas Karavalakiset al.17and Fontaraset al.14

probably did not observe such high emission during the UDC

cycle; however, only emissions for the complete NEDC were

shown, which were at levels comparable to those observed over

the other (Artemis) hot driving cycle. A Similar level of

formaldehyde and acetaldehyde emission rates were presented

by Nelson et al. for an older type of vehicle produced before

2000.47 In this study, total carbonyl emissions increased with

increasing biodiesel content in the fuel under every driving

condition, as shown in Figure 2. Such an increase has been

B100, for which it increased signicantly (on average 14%).

The values for the EUDC phase were more varied and showed

a global trend toward higher fuel consumption for all test fuels

in comparison with diesel fuel. Nevertheless, a signicant

dierence was found only for B100 which showed 10% higher

value compared with diesel. However, for the entire NEDC

cycle a signicant increase in fuel consumption appeared not

only for B100, but also for B30 and HVO30, increasing by 2.4%

in both cases. These results are in agreement with the

observations found in most previous studies, which explained

this phenomenon in terms of the lower heating value of FAME

compared with pure diesel fuel.36 However, there are studies

which support the opposite trend, linking it to an improvement

in volumetric combustion eciency due to the structural

oxygen content in FAME,4345 which is rather surprising, given

the much lower energy density of such a fuel. The signicant

increase in fuel consumption over the entire NEDC with using

HVO30 blend can be attributed to the lower heating value on a

volumetric basis. Although HVO fuel has a greater heating

value on a mass basis, its presence in fuel decreases the energy

content on a volumetric basis due to its lower density. As a

consequence, higher volumetric consumption may be expected

for HVO blends because both diesel injection systems and fuel

dispensing systems deliver fuel by volume, not by mass.11

However, this may be partly compensated by higher mass-based

energy content due to the higher hydrogen to carbon ratio of

HVO in comparison with diesel fuel.

The results indicate that changes in fuel physical properties

due to the addition biodiesel or paran may aect substantially

diesel emission levels. Parameters such as density and viscosity

play a signicant role in diesel emissions due to the inuence

on air-fuel mixture formation. Especially density has been

studied extensively and it was shown that higher fuel density

increased emissions of HC, CO, NOx, and PM.20 Since FAME

addition increased the density and viscosity of the base diesel

fuel, it may cause emissions to deteriorate, particularly during

cold start and engine warm-up. A similar inuence may be

exerted by the higher boiling point or back-end volatility, which

is highly correlated with fuel density. However, the eect of

increased density and viscosity on diesel engine emissions are

probably compensated to a great extent by the higher cetane

number of FAME and its oxygen content, which are

traditionally factors improving the combustion process. This

leads to the reductions in HC, CO, and PM emissions observed

in many studies, but mostly during hot engine operation. HVO

fuel as a blending component decreased the density of diesel

fuel and only slightly increased the fuel viscosity, so that the

values are close to those of conventional diesel fuel. HVO is

characterized by a very high cetane number in comparaison to

pure diesel fuel, reecting its propensity for autoignition. In

conjunction with the lower boiling points of the HVO blend, its

nal properties lead to more complete combustion, also during

cold engine condition and despite the lack of oxygen atoms in

the fuel.

Carbonyl Emissions. Carbonyl emissions when using

biodiesel remain an important issue due to many observations

that biodiesel use could signicantly increase emission of both

aldehydes and ketones with established toxic properties such as

formaldehyde, acetaldehyde, acrolein, and acetone. Formaldehyde is classied by the International Agency for Research

of Cancer (IARC) as a human carcinogen (Group 1);

acetaldehyde as possibly carcinogenic to humans (Group

2B).46Additionally, carbonyl compounds are important ozone

Figure 2. Total carbonyl emissions for the test fuels over the UDC,

EUDC, and complete NEDC cycles. * p < 0.05.

observed in the majority of studies performed and was usually

linked to the presence of oxygen in the ester group of FAME.

However, the opposite trend has also been found and was

explained by more complete combustion of biodiesel than

diesel, due to the need to combust more reduced substances

with diesel fuel.48 Nelson et al.47 studied emissions from

dierent conventional diesel fuels and concluded that formaldehyde and acetaldehyde are largely formed in the

combustion process from fuel fragments produced in the initial

oxidative pyrolysis of the fuel, and this fragments are largely

derived from the major constituents of the fuels. Hence,

combustion conditions such as local stoichiometry and

temperature may largely determine their formation. The

highest emission was found for B100 in the case of all carbonyl

compounds except acetone, for which the highest value was

obtained when pure diesel fuel was used. This upward trend

was observed for most of the carbonyl compounds, but only

during the UDC cycle. The EUDC was characterized by much

lower emissions, which was the result of eective combustion

and full catalyst eciency.49 However, even during the EUDC

7478

DOI: 10.1021/acs.est.5b00648

Environ. Sci. Technol. 2015, 49, 74737482

Article

Environmental Science & Technology

PAHs originate mainly from incomplete combustion of fuel and

lubricating oil, and also from pyrosynthesis of lower molecular

mass hydrocarbons. PAH molecules containing 45 benzene

rings are the most harmful PAH compounds, and are

exclusively bonded to exhaust particles. Nitro-PAH are direct

or indirect products of incomplete fuel combustion. The

majority of these compounds are formed by reactions of parent

PAH with NOx in the gas phase and rapidly adsorbed onto

particulate matter. Some nitro-PAH are characterized by higher

mutagenicity and carcinogenicity in comparison to unsubstituted PAH molecules. A number of studies have conrmed the

presence of nitro-PAH in extracts of diesel particulate matter,

among which 1-nitropyrene, 2-nitrouorene, and 3-nitrouoranthene are the most commonly detected compounds.51

During the tests, the highest emission was measured for light

PAHs such as acenaphthene and uorene, which emission was

determined as a sum of these compounds, and subsequently for

uoranthene, pyrene, benzo(a)anthracene and chrysene.

Individual results are presented in Supporting Information

Table S3. Acenaphthene and uorine were the most abundant

compounds among the PAH emitted, and emissions were lower

when using fuels containing biodiesel compared to diesel fuel,

with a single exception: a slight increase for B30 during the

EUDC cycle. Emission of lower and medium molecular weight

PAHs such as phenanthrene, which dominated in some

previous studies,52,53 anthracene, uoranthene, and pyrene

decreased for B7 and increased for the higher biodiesel blends,

compared to diesel fuel. In turn, emissions of benzo(a)anthracene and chrysene, after decreasing for both B7 and B15,

increased slightly for the B30 blend. However, the emission of

heavier PAHs was usually higher for biodiesel blends than for

pure diesel fuel. Unexpectedly, use of B100 led to lower

emissions of the lighter PAHs and usually the highest emission

of heavier and most toxic PAH molecules such as bezeno(k)uoranthene, benzo(a)pyrene, benzo(g,h,i)perylene, and

indeno(1,2,3-c,d)pyrene. This is in contrast to most previous

studies, which found a decrease in emission of heavier PAH

molecules with biodiesel,13,17,18,52,5456 although the opposite

tendency- or lack of response - has also been observed.53,57 The

increased toxicity of particulate from pure biodiesel use was also

shown by Kooter et al.s58 in a mutagenicity test, despite the

strong decrease in the weight and number of particles emitted.

The prole of emitted PAH was similar for the UDC and the

EUDC with acenaphthene and uoranthene dominant, but

emission during the EUDC was signicantly lower than during

the UDC phase, as reported by Ballesteros and co-workers.56

Similar to Kooter and co-workers work,58 a gradual increase in

most PAH emission was observed with an increase in biodiesel

content in the blends. This observation is especially reected by

the total PAH emissions shown in Figure 3. Work by

Karavalakis et al.13 indicated the opposite trend, with the

exception of oxidized biodiesel blends, whose use resulted in

substantial increases in PAH emissions compared to diesel fuel.

Nevertheless, the amount of PAH emitted was much lower in

our study in comparison to the aforementioned study. For the

B30 blend the total PAH emission exceeded emission from

pure diesel fuel and was the highest among all biodiesel

containing test fuels. Macor and co-workers18 also obtained

higher emission of total PAH with B30 compared to diesel fuel,

but a substantial decrease was observed in the case of emission

of heavier PAHs with this blend. The results indicate that

physical and chemical fuel properties probably inuence the

combustion process and consequently the formation of

cycle, formaldehyde emission increased with increased biodiesel

content in the fuel. Emissions of other carbonyl compounds

increased or decreased with biodiesel blends during the EUDC,

but were still highest using B100 fuel. In none of the tests

performed in this study was it found that emission of heavier

carbonyls increased with use of pure diesel fuel, as reported

elsewhere.14,17 Benzaldehyde emission, which could be

expected to be the highest when using pure diesel fuel, due

to its high level of aromatic compounds, was also the highest

for B100 fuel. Similar results were obtained for other aromatic

aldehydes such as o-tolualdehyde, p-tolualdehyde, and particularly for m-tolualdehyde. The latter was the most abundant,

which indicated that it was the prevalent product of incomplete

fuel combustion among all aromatic carbonyl compounds. In

contrast, in all tests the HVO30 blend caused the lowest

carbonyl compound emissions among the test fuels in both the

UDC and EUDC. In relation to pure diesel fuel, emission of the

most abundant formaldehyde and acetaldehyde decreased by

49.2 and 46.5%, respectively, whereas total carbonyls decreased

by 47.4% for the complete NEDC cycle. Such a substantial

reduction in carbonyl emissions may be attributed to the high

eectiveness of combustion in respect to this fuel. Pure HVO is

a mix of liquid paranic hydrocarbons, whose addition

improves combustion even during cold-start and engine

warm-up. This is probably a result of improved properties for

atomization and volatilization of the HVO blend due to the

lower density and boiling temperature of this fuel. As shown in

the literature, lower fuel density and back-end volatility have a

great impact on decreasing CO and total hydrocarbons

emissions, which indicates higher combustion eciency during

diesel engine operation. Moreover, pure HVO has a very high

cetane number (>70) and its addition to diesel fuel increases

the cetane number linearly. It was found that increased cetane

number also reduced emissions of HC and CO, probably due

to improvement of ignition performance.30Another cause for

the observed reduction may be a decrease in concentration of

precursors for carbonyl compound formation and the degree of

molecular unsaturation. The ability of paranic fuel to reduce

emission of carbonyl compounds was also found in some earlier

studies. Yuan et al.50 evaluated emissions from a heavy-duty

diesel engine in a transient test using a paranic and biodiesel

blend and they obtained a signicant reduction of carbonyls in

exhaust gases, equaling 24% and 30% for 20% and 5% biodiesel

paranic blend, respectively. Zervas et al.16tested two types of

paranic fuel and also obtained signicant reductions of

formaldehyde, acetaldehyde and total carbonyl compounds,

which reached 69% and 89% in comparison to when using

conventional diesel fuel.

PAH Emissions. PAH emissions in vehicular diesel exhaust

are the focus of much attention because many of these

compounds have been identied as potential cancer causing

compounds. According to IARC, there is sucient evidence of

the carcinogenicity of benzo(a)pyrene in humans (group 1A).

Additionally, dibenzo(a,h)anthracene, benzo(a)anthracene,

benzo(b)uorantene, benzo(k)uorantene, chrysene, and

indeno(1,2,3-c,d)pyrene are recognized as animal carcinogens

(IARC groups 2A and 2B). Regarding diesel exhaust emissions,

there are especially suitable conditions for adsorption of these

compounds on simultaneously emitted particulate matter. Very

ne particulate matter containing particles <2.5 m in diameter

plays a particular role in this process. The particles contain

mainly soot, which formed carbon complexes with products of

incomplete combustion, which are adsorbed onto the surface.

7479

DOI: 10.1021/acs.est.5b00648

Environ. Sci. Technol. 2015, 49, 74737482

Article

Environmental Science & Technology

formation of nitro-PAHs when biodiesel is present in the fuel,

although Huang et al.59 observed increasing emission of one

nitro-PAH species (5-nitroacenaphthene) with biodiesel, but

only during idling. In spite of the similar quantity of total PAH

emitted using the B30 and HVO30 blends, conditions for

formation of nitro-PAHs were better in the case of HVO30

than for B30. This might be because HVO is more similar in

terms of structure to pure diesel fuel than biodiesel is.

ASSOCIATED CONTENT

S Supporting Information

*

The methodological details (pages S3S4). Recoveries,

precision and accuracy of analytical methods (Table S1).

Carbonyl compound and PAH emissions for the test fuels over

the UDC, EUDC and complete NEDC cycles (Tables S2S3),

Nitro-PAH emissions for the test fuels over the UDC cycle

(Table S4). The chassis dynamometer used in this study, within

its climate chamber (Figure S1). The New European Driving

Cycle NEDC (UDC + EUDC) (Figure S2). The Supporting

Information is available free of charge on the ACS Publications

website at DOI: 10.1021/acs.est.5b00648.

Figure 3. Total PAH emissions for the test fuels over the UDC,

EUDC, and complete NEDC cycles.

individual PAHs, because despite the fact that biodiesel does

not contain PAH compounds, the addition of biodiesel to diesel

resulted in increased emission of most PAHs.

Using the HVO30 blend the total PAH emission was the

highest among all tested fuels, slightly exceeding emission using

B30 biodiesel blend. This was a consequence of the highest

emissions of lower molecular weight PAHs such as

acenaphthene, uorene, phenanthrene, and anthracene. In

contrast, the emission of the heaviest PAHs was usually at

the lowest level compared to the use of other tested fuels. Thus,

HVO30 fuel parameters such as lower density and boiling point

resulted in decreased formation of the most toxic PAHs

containing more than four rings, but increased emissions of

lighter PAH, which is dicult to explain. Perhaps if HVO

increases the cetane number and the diusion combustion

phase is longer, this may be a favorable condition to form more

stable polyaromatic compounds, particularly at low engine load.

Lim and colleagues30 also showed that the level of total PAH

was higher with HVO-blended diesel when compared to diesel

blended with an additive to produce a fuel with an equivalent

cetane number. In turn, Youn and co-workers19 found a

substantial potential for reducing PAH emission using paranic

fuel, which, when blended with biodiesel, signicantly

decreased exhaust PAH emissions and their toxicity equivalent

in comparison to diesel fuel.

Emissions of nitro-PAHs were not detectable during most

tests. These compounds were identied in exhaust particles

emitted during the UDC phase only, when using pure diesel

fuel, B7, B100 and HVO30 blends (Supporting Information

Table S4). The highest emission was found using pure diesel

fuel. Total nitro-PAH emissions for the test fuels decreased in

the following order: B0 > B7 > HVO30 > B100 and with B15

and B30 all of the 6 nitro-PAHs analyzed were below the limit

of detection. These decreasing nitro-PAH emissions with

biodiesel and biodiesel blends in comparison to diesel fuel is in

agreement with previous studies.13,17,58,59 The main reason for

this reduction was attributed to lower emission of nitro-PAH

precursors, that is, parent PAHs, which therefore resulted in the

higher emission of nitro-PAHs measured with oxidized

biodiesel blends, whose use were related to higher PAH

emissions than with diesel fuel. In this study a reduction was

found in most cases, despite the increase in emission of parent

PAHs. This may suggest less favorable conditions for the

AUTHOR INFORMATION

Corresponding Author

*Phone: +48326341195; e-mail: a.prokopowicz@imp.

sosnowiec.pl.

Author Contributions

The manuscript was written through contributions of all

authors. All authors have given approval to the nal version of

the manuscript.

Funding

This work was supported by the Polish Ministry of Science and

Higher Education, grant number N N404 311540.

Notes

The authors declare no competing nancial interest.

ABBREVIATIONS

CVS

constant volume sampling

EUDC Extra Urban Driving Cycle

NEDC New European Driving Cycle

UDC Urban Driving Cycle

REFERENCES

(1) Roszkowski, A. Biodiesel in the EU and in Poland present

conditions and the prospects for the future. Prob. Agric. Eng. 2012, 77

(3), 6578 (in Polish)..

(2) Demibras, A. Competitive liquid biofuels from biomass. Appl.

Energy 2011, 88, 1728.

(3) Aransiola, E. F.; Ojumu, T. V.; Oyekola, O. O.; Madzimbamuto,

T. F.; Ikhu-Omoregbe, D. I. O. A review of current technology for

biodiesel production: State of art. Biomass Bioenergy 2014, 61, 122.

(4) Directive 2009/28/EC. On the promotion of the use of energy

from renewable sources and amending and subsequently repealing

Directives 2001/77/EC and 2003/30/EC.2009.04.23.O J EU 2009. L

140:1662.

(5) Dutta, K.; Davarey, A.; Lin, J. G. Evolution retrospective for

alternative fuels: First to fourth generation. Renewable Energy 2014, 69,

114122.

(6) Demirbas, A. Biofuels sources, biofuel policy, biofuel economy

and global biofuel projections. Energy Convers Manage 2008, 49,

210616.

(7) McCormick, R. L. The Impact of Biodiesel on Pollutant

Emissions and Public Health. Inhalation Toxicol. 2007, 19, 10331039.

7480

DOI: 10.1021/acs.est.5b00648

Environ. Sci. Technol. 2015, 49, 74737482

Article

Environmental Science & Technology

(28) Di, Y.; Cheung, C. S.; Huang, Z. Experimental investigation on

regulated and unregulated emissions of diesel engine fueled with ultralow sulfur diesel fuel blended with biodiesel from waste cooking oil.

Sci. Total Environ. 2009, 407, 835846.

(29) Jeong, G. T.; Oh, Y. T.; Park, D. H. Emission profile of rapeseed

methyl ester and its blend in diesel engine. Appl. Biochem. Biotechnol.

2006, 129, 165178.

(30) Lim, Y.; Seo, C.; Lee, J.; Kang, D.; Kim, J. S.; Kim, H. J. The

effect of diesel cetane number on exhaust emissions characteristics by

various additives. J. Therm. Sci. Technol. (Tokyo, Jpn.) 2012, 7 (1), 90

103.

(31) Prokopowicz, A.; Zaciera, M.; Szczotka, A.; Sobczak, A. The

effects of biodiesel and its blends with diesel oil on the emission of

volatile aromatic hydrocarbons. Med. Srod./ Environ. Med. 2013, 16

(4), 5763 (in Polish)..

(32) Bielaczyc, P.;Merkisz, J.;Pielecha, J. Exhaust Emission from Diesel

Engine during Cold Start in Ambient Temperature Conditions, SAE Paper

2000-05-0316.

(33) Bielaczyc, P.; Pajdowski, P. Investigation of cold start emissions

from passanger car with DI diesel engine using the modal analysis

method. J. Kones Combust. Engines 2001, 8 (12), 100108.

(34) Gill, S. S.; Tsolakis, A.; Herreros, J. M.; York, A. P. E. Diesel

emissions improvements through the use of biodiesel or oxygenated

blending components. Fuel 2012, 95, 578586.

(35) Ballesteros, R.; Hernandez, J. J.; Lyons, L. L.; Cabanas, B.;

Tapia, A. Speciation of semivolatile hydrocarbon engine emissions

from sunflower biodiesel. Fuel 2008, 87, 18351843.

(36) Bakeas, E.; Karavalakis, G.; Stournas, S. Biodiesel emissionprofile in modern dieselvehicles. Part 1: Effects of biodiesel origin on the

criteria emissions. Sci. Total Environ. 2011, 409, 16701676.

(37) Bergthorson, J. M.; Thomson, M. J. A review of the combustion

and emissions properties of advanced transportation biofuels and their

impact on existing and future engines. Renew. Sustainable Energy Rev.

2015, 42, 13931417.

(38) Karjalainen, P.; Ronkko, T.; Pirjola, L.; Hekkila, J.; Happonen,

M.; Arnold, F.; Rothe, D.; Bielaczyc, P.; Keskinen, J. Sulfur driven

nucleation mode formation in diesel exhaust under transient driving

conditions. Environ. Sci. Technol. 2014, 48, 23362343.

(39) Happonen, M.; Heikkila, J.; Aakko-Saksa, P.; Murtonen, T.;

Lehto, K.; Rostedt, A.; Sarjovaara, T.; Larmi, M.; Keskinen, J.;

Virtanen, A. Diesel exhaust emissions and particle hygroscopicity with

HVO fuel-oxygenate blend. Fuel 2013, 103, 380386.

(40) Nakakita, K.; Ban, H.;Takasu, S.;Hotta, Y.; Inagaki,

K.;Weissman, W.; Farrell, J. T. Eect of Hydrocarbon Molecular

Structure in Diesel Fuel on In-Cylinder Soot Formation and Exhaust

Emissions, SAE Paper 2003-01-1914.

(41) Bielaczyc, P.;Szczotka, A.;Gizynski, P.;Bedyk, I. The Eect of Pure

Rme and Biodiesel Blends with High Rme Content on Exhaust Emissions

from a Light Duty Diesel Engine, SAE Technological Paper 2009-012653, 2009; DOI: 10.4271/2009-01-2653.

(42) Bielaczyc, P.;Szczotka, A. The eect of pure RME and biodiesel

blends with dierent RME content on exhaust emissions from a light

duty vehicle with diesel engine, FISITA Conference, paper F2010A134,

2010.

(43) Reyes, J. F.; Sepulveda, M. A. PM-10 emissions and power of

the diesel engine fueled with crude and refined biodiesel from salmon

oil. Fuel 2006, 85, 17141719.

(44) Ozgunay, H.; Colak, S.; Zengin, G.; Sari, O.; Sarikahya, H.;

Yuceer, L. Performance and emission study of biodiesel from leather

industry pre-fleshings. Waste Manage. 2007, 27, 18971901.

(45) Pal, A.; Verma, A.; Kachhwaha, S. S.; Maji, S. Biodiesel

production from through hydrodynamic cavitation and performance

testing. Renewable Energy 2010, 35, 619624.

(46) International Agency for Research on Cancer (IARC). Agents

classied by the IARC (Monographs, Vols. 1105); International Agency

for Research on Cancer: Geneva, Switzerland, 2012; http://

monographs.iarc.fr/ENG/Classication/index.php.

(8) Xue, J.; Grift, T. E.; Hansen, A. C. Effect of biodiesel on engine

performances and emissions. Renewable Sustainable Energy Rev. 2011,

15, 10981116.

(9) Giakoumis, E. G.; Rakopoulos, C. D.; Dimaratos, A. M.;

Rakopoulos, D. C. Exhaust emissions of diesel engines operating under

transient conditions with biodiesel fuel blends. Prog. Energy Combust.

Sci. 2012, 38 (5), 691715.

(10) Kulczycki, A.; Dziegielewski, W. Biofuels for turbine aviation

engines based on biohydrocarbons and other biocomponents. J.

KONBiN 2011, 1 (17), 165178 (in Polish)..

(11) Lapuerta, M.; Villajos, M.; Agudelo, J. R.; Boehman, A. Key

properties and blending strategies of hydrotreated vegetable oil as

biofuel for diesel engines. Fuel Process. Technol. 2011, 92, 24062411.

(12) Benbrahim-Tallaa, L.; Baan, R. A.; Grosse, Y.; Lauby-Secretan,

B.; Ghissassi, F. E.; Bouvard, V.; Guha, N.; Loomis, D.; Straif, K.

Carcinogenicity of diesel-engine and gasoline-engine exhausts and

some nitroarenes. Lancet Oncol. 2012, 13 (7), 663664.

(13) Karavalakis, G.; Bakeas, E.; Fontaras, G.; Stournas, S. Effect of

biodiesel origin on regulated and particle-bound PAH (polycyclic

aromatic hydrocarbon) emissions from a Euro 4 passenger car. Energy

2011, 36, 53285337.

(14) Fontaras, G.; Karavalakis, G.; Kousoulidou, M.; Tzamkiozis, T.;

Ntziachristos, L.; Bakeas, E.; Stournas, S.; Samaras, Z. Effects of

biodiesel on passenger car fuel consumption, regulated and nonregulated pollutant emissions over legislated and real work driving

cycles. Fuel 2009, 88, 16081617.

(15) Bielaczyc, P.; Szczotka, A. A study of RME-based biodiesel blend

inuence on performance, reliability and emissions from Modern

Light-Duty Diesel Engine. SAE Int. 2008011398.

(16) Zervas, E. Regulated and non-regulated pollutants emitted from

two aliphatic and commercial diesel fuel. Fuel 2008, 87, 11411147.

(17) Karavalakis, G.; Boutsika, V.; Stournas, S.; Bakeas, E. Biodiesel

emissions profile in modern diesel vehicles. Part 2: Effect of biodiesel

origin on carbonyl, PAH, nitro-PAH and oxy-PAH emissions. Sci.

Total Environ. 2011, 409, 738747.

(18) Macor, A.; Avella, F.; Faedo, D. Effects of 30% v/v biodiesel/

diesel fuel blend on regulated and unregulated pollutant emissions

from diesel engines. Appl. Energy 2011, 88, 49895001.

(19) Yuan, C. S.; Lin, Y. C.; Lee, W. J.; Lin, Y. C.; Wu, T. S.; Chen, K.

F. A new alternative fuel for reduction of polycyclic aromatic

hydrocarbon and particulate matter emissions from diesel engines.

Air Waste Manage. Assoc. 2007, 57, 465471.

(20) Hochhauser, A. Review of Prior Studies of Fuel Effects on

Vehicle Emissions. SAE Int. J. Fuels Lubr. 2009, 2 (1), 541567

DOI: 10.4271/2009-01-1181.

(21) Bielaczyc, P.;Szczotka, A. Analysis of Uncertainty of the Emission

Measurement of Gaseous Pollutants on Chassis Dynamometer, SAE

Technological Paper 2007-01-1324, 2007; DOI: 10.4271/2007-011324.

(22) Zaciera, M.; Mniszek, W.; Kurek, J. Environmental levels of

nitro-PAHs in total suspended particulate matter in Upper Silesia

(Poland). Arch. Environ. Prot. 2009, 35 (4), 3543.

(23) Zaciera, M.; Kurek, J.; Dzwonek, L.; Feist, B.; Jdrzejczak, A.

Seasonal variability of PAHs and nitro-PAHs concentrations in total

suspended particulate matter in ambient air of cities of Silesian

voivodeship. Environ. Prot. Eng. 2012, 38 (1), 4550.

(24) Buyukkaya, E. Effects of biodiesel on a DI diesel engine

performance, emission and combustion characteristics. Fuel 2010, 89,

30993105.

(25) Ozener, O.; Yuksek, L.; Ergenc, A. T.; Ozkan, M. Effects of

soybean biodiesel on a DI diesel engine performance, emission and

combustion characteristics. Fuel 2014, 115, 875883.

(26) Lapuerta, M.; Armas, O.; RodriguezFernandez, J. Effect of

biodiesel fuels on diesel engine emissions. Prog. Energy Combust. Sci.

2008, 34, 198223.

(27) Krahl, J.; Knothe, G.; Munack, A.; Ruschel, Y.; Schroder, O.;

Hallier, E.; Westphal, G.; Bunger, J. Comparison of exhaust emissions

and their mutagenicity from the combustion of biodiesel, vegetable oil,

gas-to-liquid and petrodiesel fuels. Fuel 2009, 88, 10641069.

7481

DOI: 10.1021/acs.est.5b00648

Environ. Sci. Technol. 2015, 49, 74737482

Article

Environmental Science & Technology

(47) Nelson, P. F.; Tibbett, A. R.; Day, S. J. Effects of vehicle type

and fuel quality on real world toxic emissions from diesel vehicles.

Atmos. Environ. 2008, 42, 52915303.

(48) Guariero, L. L. N.; Pereria, P. A. P.; Torres, E. A.; Rocha, G. O.;

Andrade, J. B. Carbonyl compounds emitted by a diesel engine fuelled

with diesel and biodiesel-diesel blends: Sampling optimization and

emissions profile. Atmos. Environ. 2008, 42, 82118218.

(49) Ballesteros, R.; Hernandez, J. J.; Guillen-Flores, J. Carbonyl

speciation in a typical European automotive diesel engine using

bioethanol-diesel blends. Fuel 2012, 95, 136145.

(50) Yuan, C. S.; Lin, Y. C.; Tsai, C. H.; Wu, C. C.; Lin, Y. S.

Reducing carbonyl emissions from a heavy-duty diesel engine at US

transient cycle test by use of paraffinic/biodiesel blends. Atmos.

Environ. 2009, 43, 61756181.

(51) Selected Nitro- and Nitro-Oxy-Polycyclic Aromatic Hydrocarbons,

Environmental Health Criteria 229; World Health Organization:

Geneva, 2003.

(52) He, C.; Ge, Y.; Tan, Y.; You, K.; Han, X.; Wang, J.

Characteristics of polycyclic aromatic hydrocarbons of diesel engine

fueled with biodiesel and diesel. Fuel 2010, 89, 20402046.

(53) Casal, C. S.; Arbilla, G.; Correa, S. M. Alkyl polycyclic aromatic

hydrocarbons emissions in diesel/biodiesel exhaust. Atmos. Environ.

2014, 96, 107116.

(54) Correa, S. M.; Arbilla, G. Aromatic hydrocarbons emissions in

diesel and biodiesel exhaust. Atmos. Environ. 2006, 40, 68216826.

(55) Turrio-Baldassarri, L.; Battistelli, C. L.; Conti, L.; Crebelli, R.;

De Berardis, B.; Iamiceli, A. L.; Gambio, M.; Iannaccone, S. Emission

comparison of urban bus engine fueled with diesel oil and biodiesel

blend. Sci. Total Environ. 2004, 327, 147162.

(56) Ballesteros, R.; Hernandez, J. J.; Lyons, L. An experimental

study of the influence of biofuel origin on particle-associated PAH

emissions. Atmos. Environ. 2010, 44, 930938.

(57) Szewczynska, M.; Posniak, M. Polycyclic aromatic hydrocarbons

and soluble organic fraction in fine particles from solid fraction of

biodiesel exhaust fumes. Med. Pr. 2012, 63, 659666 (in Polish)..

(58) Kooter, I. M.; Vugt, M.A.T. M.; Jedynska, A. D.; Tromp, P. C.;

Houtzager, M. M. G.; Verbeek, R. P.; Kadijk, G.; Mulderij, M.; Krul, C.

A. M. Toxicological characterization of diesel engine emissions using

biodiesel and closed soot filter. Atmos. Environ. 2011, 45, 15741580.

(59) Huang, L.; Bohac, S. V.; Chernyak, S. M.; Batterman, S. A.

Effects of fuels, engine load and exhaust after-treatment on diesel

engine SVOC emissions and development of SVOC profiles for

receptor modeling. Atmos. Environ. 2015, 102, 228238.

7482

DOI: 10.1021/acs.est.5b00648

Environ. Sci. Technol. 2015, 49, 74737482

You might also like

- A Statistical Investigation of Biodiesel Effects On Regulated Exhaust Emissions During Transient CyclesDocument19 pagesA Statistical Investigation of Biodiesel Effects On Regulated Exhaust Emissions During Transient CyclespatikavalcoNo ratings yet

- Combustion and Emission Characteristics of Diesel Engine Fueled With Diesel Biodiesel Pentanol Fuel BlendsDocument8 pagesCombustion and Emission Characteristics of Diesel Engine Fueled With Diesel Biodiesel Pentanol Fuel BlendspatikavalcoNo ratings yet

- Extensive Analyses of Diesel-Vegetable Oil-n-Butanol Ternary Blends in A Diesel EngineDocument8 pagesExtensive Analyses of Diesel-Vegetable Oil-n-Butanol Ternary Blends in A Diesel EnginepatikavalcoNo ratings yet

- Effects of Using Renewable Fuels On Vehicle EmissionsDocument11 pagesEffects of Using Renewable Fuels On Vehicle EmissionspatikavalcoNo ratings yet

- Battle in The Amazon: Arapaima Versus PiranhaDocument10 pagesBattle in The Amazon: Arapaima Versus PiranhapatikavalcoNo ratings yet

- The Effects of Neat Biodiesel and Biodiesel and HVO Blends in Diesel Fuel On Exhaust Emissions From A Light Duty Vehicle With Diesel Engine PDFDocument10 pagesThe Effects of Neat Biodiesel and Biodiesel and HVO Blends in Diesel Fuel On Exhaust Emissions From A Light Duty Vehicle With Diesel Engine PDFpatikavalcoNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Underground Mining Blast TechniquesDocument15 pagesUnderground Mining Blast TechniquesJose RojasNo ratings yet

- Comparative Evaluation of The Nutritional Quality of Corn, Sorghum and Millet Ogi Prepared by A Modified Traditional TechniqueDocument6 pagesComparative Evaluation of The Nutritional Quality of Corn, Sorghum and Millet Ogi Prepared by A Modified Traditional TechniqueFaldy LeimenaNo ratings yet

- TelleriumDocument35 pagesTelleriumAbishekh SekharNo ratings yet

- Pipelines Design CriteriaDocument16 pagesPipelines Design CriteriaAnonymous 3kDy7eNo ratings yet

- Textile TechnologyDocument5 pagesTextile TechnologyKaye NicolasNo ratings yet

- Library SearchDocument18 pagesLibrary SearchRathod Chandra SekharNo ratings yet

- FDS Verification GuideDocument338 pagesFDS Verification GuideDarkoNo ratings yet

- Effects of Ultrasound and Microwave Pretreatments of Carrot Slices Before Drying On The Color Indexes and Drying RateDocument9 pagesEffects of Ultrasound and Microwave Pretreatments of Carrot Slices Before Drying On The Color Indexes and Drying RateAbhishek ChandraNo ratings yet

- Acticide MbsDocument10 pagesActicide MbsBogdan MuresanNo ratings yet

- Dequest 2040, 2050 and 2060 Product SeriesDocument9 pagesDequest 2040, 2050 and 2060 Product SeriesLê CôngNo ratings yet

- 0050 Goldenseal ApplicationNote PW PDFDocument5 pages0050 Goldenseal ApplicationNote PW PDFFábio Teixeira da SilvaNo ratings yet

- Dura Profile Technical SpecificationDocument4 pagesDura Profile Technical Specificationec04017No ratings yet

- USEPA, Wet Scrubber Inspection and Evaluation Manual (Sep. 1983) PDFDocument164 pagesUSEPA, Wet Scrubber Inspection and Evaluation Manual (Sep. 1983) PDFChristopher Brown100% (1)

- Datasheet AVEVA PROII-Simulation 06-20.pdf - Coredownload.inline PDFDocument8 pagesDatasheet AVEVA PROII-Simulation 06-20.pdf - Coredownload.inline PDFMariah AnjelikaNo ratings yet

- ASTM-A519.pdf - Scribd: Rating: 5 - 1 VoteDocument3 pagesASTM-A519.pdf - Scribd: Rating: 5 - 1 VoteInfoNo ratings yet

- Advancement in Internal Field Joint Coating SystemsDocument5 pagesAdvancement in Internal Field Joint Coating SystemsKnight rider100% (1)

- The Leaf MCQDocument5 pagesThe Leaf MCQSanjay Ku AgrawalNo ratings yet

- Fisher 1975 VTM DepositsDocument18 pagesFisher 1975 VTM DepositsEdm SanNo ratings yet

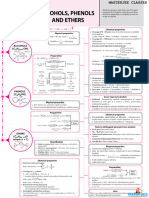

- Alcohols Phenols and EthersDocument1 pageAlcohols Phenols and EthersNitisha GuptaNo ratings yet

- Problems and Remedies in Bottle WashingDocument13 pagesProblems and Remedies in Bottle WashingSmiley Dimple100% (2)

- Tetrahedron Letters Volume 40 Issue 5 1999 (Doi 10.1016/s0040-4039 (98) 02540-4) Francisco JoséRomero-Salguero Jean-Marie Lehn - Synthesis of Multitopic Bidentate Ligands Based On Alternating PyDocument4 pagesTetrahedron Letters Volume 40 Issue 5 1999 (Doi 10.1016/s0040-4039 (98) 02540-4) Francisco JoséRomero-Salguero Jean-Marie Lehn - Synthesis of Multitopic Bidentate Ligands Based On Alternating PyJoakin BahamondesNo ratings yet

- Semiconductor polishing compound for cerium oxide slurry stabilityDocument13 pagesSemiconductor polishing compound for cerium oxide slurry stabilityrat0708No ratings yet

- Synthesis and Characterization of Expandable GraphiteDocument66 pagesSynthesis and Characterization of Expandable GraphitequiqueNo ratings yet

- Pozzolanic CementsDocument30 pagesPozzolanic CementsJoko Dewoto100% (1)

- Kingdom of Saudi Arabia: Ministry of Interior High Commission For Industrial Security Secretariat GeneralDocument2 pagesKingdom of Saudi Arabia: Ministry of Interior High Commission For Industrial Security Secretariat GeneralVishnudasNo ratings yet

- B.pharm. Class NotesDocument817 pagesB.pharm. Class NotesMukesh TiwariNo ratings yet

- Multiple Choice Competition: SolutionsDocument11 pagesMultiple Choice Competition: SolutionsAadityaNo ratings yet

- Laterolog-3 (LL3) : Well LoggingDocument5 pagesLaterolog-3 (LL3) : Well LoggingNarjes WalidNo ratings yet

- Growing Crystal PTDocument3 pagesGrowing Crystal PTClarizze Jade Magno AlananoNo ratings yet

- Liquid Soap ProcessDocument3 pagesLiquid Soap ProcessAnnette40% (5)