Professional Documents

Culture Documents

Douglas Twinjets

Uploaded by

jorge paezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Douglas Twinjets

Uploaded by

jorge paezCopyright:

Available Formats

__(C}l>tDY!L([J)Q '-',:....

--'_

Other titles in the Crowood Aviation Series

Aichi D3A 1/2 Val

Airco - The Aircr<lft Manuf<lcturing Company

Avro Lancaster

BAC One-Eleven

Bell P-39 Airacobra

Boeing 737

Boeing 747

Boeing 757 and 767

Boeing 13-17 Flying Fortress

onsolidated 13-24 Liberator

Douglas AD Skyraider

Engl ish Electric Canberra

Engl ish Electric Ligh tn ing

Fairchild Republic A-IO Thunderbolt II

Fokker Aircraft of World War One

Hawker Hunter

Hawker Hurricane

Junkers Ju 87 Stuka

Junkers Ju 88

Lockheed C-130 Hercules

Lockheed F-I 04 Starfighter

Luftwaffe - A Pictorial History

McDonnell Douglas A-4 Skyhawk

McDonnell Douglas F-IS Eagle

Messerschmitt Bf 110

Messerschmitt Me 262

Nieuport Aircraft of World Wm One

North American 13-25 Mitchell

North American F-86 Sabre

North American T-6

Panavia Tornado

The Turret Fighters - Defiant and Roc

Short Sunderland

V-Bombers

Vickers VC 10

Voughr F4U Corsair

Peter C. Smith

Mick Davis

Ken Delve

Malcolm L. Hill

Robert F. Dorr wirh Jerry C. Scum

Malcolm L. Hill

Martin W. Bowman

Thomas Becher

Marrin W. Bowman

Marrin W. Bowman

Peter C. Smirh

Barry Jones

Marrin W. Bowman

Peter C. Smith

Paul Leaman

Barry Jones

Peter Jacobs

Peter C. Smith

Ron Mackay

Marrin W. Bowman

Marrin W. Bowman

Eric Mombeek

Brad Elwmd

Perer E. Davies and Tony Thornborough

Ron Mackay

David Baker

Ray Sanger

Jerry Scum

Duncan Curtis

Perer C. Smirh

Andy Evans

Alec Brew

Ken Delve

Barry Jones

Lance Cole

Marrin W. Bowman

AVIATION ~ SERIES

Douglas Twinjets

DC-9 MD-BO MD-90 and Boeing 717

ThoIllas Becher

1)~CI

The Crowood Press

First published in 2002 by

The Crowood Press Ltd

Ramsbury, M'lrlborough

Wiltshire SN8 2HR

Thom'ls Becher 2002

Contents

Acknowledgements

This book would not havc been possiblc without thc support from Bocing's Long Beach

facility, the former McDonnell Douglas. I wish to thank Pat McGinnis, who opened up

its mesmcrizing archivcs for vital information and photographs, and John Thom and

Warren Lamb of Boeing's public relations office, for a tour of the facility, photographs

and othcr much-needed support. I also thank the retircd McDonnell Douglas enginccrs

interviewcd for this book for taking time to wax nostalgic. I also thank the many photographers who, sharing my similar passion for commcrcial aviation, were all too

willing to supply photographs from all over the world. Above all, I wish to thank my

wife, Amy, for her continual love, support and understanding.

1. DOUGLAS HISTORY

All rights reserved. No part of this publication

may be reproduced or transmitted in any form

or by any means, electronic or mechanical,

including photocopy, recording, or any

information storage and retrieval system,

without permission in writing from the

pub Iishers.

British Library Cataloguing-in-Publication

Data

A catalogue record for this book is available

from the British Library.

ISBN 186126446 I

Printed 'lnd bound in Grear Britain by

Bookcrafr, M idsomer Norton

2. DESIGN AND DEVELOPMENT

19

3. LAUNCH AND PRODUCTION

45

4. EVOLUTION OF THE FAMILY

52

5. THE FAMILY GROWS: THE MD-80 SERIES

68

6. MD-90

102

7. BOEING 717

106

8. POWERPLANTS

119

9. HOW THE BIRDS ARE BORN

127

10. IN SERVICE

Designed and typeset hy Focus Publishing,

Ila Sr Bowlph's Road, Sevenoaks, Kenr

TN 13 3AJ

In trod lIction

138

11. SAFETY

165

12. THE COMPETITION

168

13. MILITARY, CARGO AND OTHER USES

170

14. THE FUTURE OF THE FAMILY

180

Appendix I: Deliveries by Year

184

Appendix II: Operators

185

Appendix Ill: Accidents

186

Index

189

CHAPTER ONE

Douglas History

Introduction

Among

the

most

common

and

recognizable commercial aircraft, the

Douglas Aircraft Company DC-9 was

developed to accommodate the explosive

growth in air travel during the boom of

the jet age in the 1960s. Designed to be

rugged, reliable and easy to maintain, the

DC-9 introduced jet service to hundreds

of communities in North America,

Europe and elsewhere around the world,

making air travel accessible and affordable

for millions of air travellers and enabling

airlines to open new routes and increase

service.

Combining all models in the family

over nearly forty years of development,

the DC-9 and its successors - the

McDonnell Douglas MD-80 series, the

MD-90 and Boeing 717 - remain the

second-most popular commercial jet ever

built, after the Boeing 737.

No other airliner in history has

undergone

more

evolution

and

refinement than th is prol ific and

ubiquitous series, starting with the

seventy-seat DC-9-10 model in the 1960s.

Developed as a short-range twinjet

aircraft to complement Douglas's much

larger four-engine DC-8, the DC-9 was

launched on 8 April 1963. This all-new

design featured rear fuselage-mounted

engines, a T-shaped tail and moderately

swept wings. Although not the first twinengine commercial jet - that distinction

goes to the Sud-Est (later Aerospatiale)

Caravelle - or even the first twin-engine

jet with the horizontal stabilizer attached

to the top of the tail- the British Aircraft

Corporation BAC I-II has that honourthe DC-9 was much more successful, a

model that made money for airlines,

appealed to passengers, and established a

formidable safety record.

The DC-9, a small jetliner designed

specifically for short, frequent flights,

brought the Jet revolution to towns and

cities that had, until then, only been

served by piston-powered aircraft. The

DC-9 helped to spawn a steady growth in

air travel that, in turn, created giant

airlines out of one-time local operations.

At the same time, the DC-9 contributed

to the economic growth of communities

that were able to use the lure of jet service

to attract new industries or encourage

expansion of existing ones.

The DC-9 family consists of four

distinct types: the original DC-9 line,

entailing five separate models, starting

with the initial DC-9-10; the McDonnell

Douglas MD-80 series, also with five

unique models; the McDonnell Douglas

MD-90; and the Boeing 717. This volume

describes each in detail.

Although now out of production, the

DC-9/MD-80/MD-90

series

today

remains an industry workhorse, a

tradition its latest offshoot, the Boeing

717, hopes to continue for decades to

come as the only member of the aircraft

family still being produced.

With its sporty look, unusual two-bythree seating arrangement, and reputation

for ruggedness and dependability, the DC9, along with its successors, remains a

favouri te among operators, passengers,

pilots and airports. Even with strict

engine-noise regulations around the

world, hundreds of older DC-9s, including

some of the first off the assembly lines,

have been fitted with noise-reducing hush

kits, ensuring that even the first members

Chronology

1963: Decision made to build the DC-9

1965: 25 February - First flight of the DC-9-1 0: 8

December - DC-9-10 enters service

1966: 1August - First flight of the DC-9 Series 30

1967: 28 November - First flight of the DC-9 Series 40

1968: 31 May - First flight of C-9A: 10 August - First

C-9A accepted by US Air Force: 18 SeptemberFirst flight of DC-9 Series 20

1973: 7 February - First flight of C-9B July - DC-9

Series 50 launched.

1974: 17 December - First flight of DC-9 Series 50

1977 December - DC-9 Series 80 announced

1979: DC-9-81 enters flight testing

1980: 12 September- DC-9-81 delivered to Swissair

1982: 28 October - Last OC-9 (C-9B) delivered

1983: DC-9-80 renamed MD-80

1984: 17 December - First flight of MD-83

1986: 4 December - First flight of MD-87

1987: 15 August - First flight of MD-88

1989: November - MD-90 production go-ahead

1990: MD-80 series assembled in China

1991: MD-95 announced at Paris Air Show

1993: 22 February - First flight of MD-90

1994: 16 November - MD-90 certified

1995: 1April- MD-90 enters service; MD-95

launched

1996: MD-90 enters service in Europe with SAS

1997: Boeing acquires McDonnell Douglas; Boeing

announces end of MD-80 and MD-90 lines

1998: MD-95 renamed 717: 2 September- first flight

of 717

1999: 12 October-717 enters service: Final MD-80

series (MD-83 model) delivered to TWA

2000: Saudi Arabian Airlines takes delivery of final

MD-90

2001: Long Beach facility scaled back: 717 deliveries

reach 100

Early Pioneer

The DC-9 was the second-to-last member

of a proud American institution, the

Douglas Aircraft Company. From the tiny

DC-I to the widebody DC-tO, Douglas

huilt a heritage of quality aircraft until its

amalgamation with arch-rival Boeing in

1997. The story of the DC-9 cannot be

adequately told without exploring some of

the

history

that

made

Douglas

synonymous with both commercial and

military aviation.

Tired of cold winters and with a nagging

desi re to bu i1d h is own aeroplanes,

twenty-eight-year-old

Donald

Wills

Douglas arrived in sunny Los Angeles (for

good) in 1920. He brought with him his

family, a few personal belongings, $600

and a letter of introduction to some of

California's wealthy investors.

The one-time Navy cadet and graduate

engineer was convinced that Californiawith its mild climate, open spaces and

energetic immigrants from throughout the

United States - would be the next centre

of aviation. Born the second son to

William and Dorothy Douglas of

Brooklyn, New York, Donald Douglas was

raised in the comfort of the upper middle

class. He had always expressed an interest

in the sea, so it was no surprise to his

family when Donald followed his younger

brother to begin his university education

at the US Naval Academy. However, he

resigned from the academy after his

sophomore

year

to

enter

the

Massachusetts Institute of Technology.

With his love for the sea supplanted by

an affinity for flight, Douglas completed a

four-year aeronautical programme in only

two years. Upon graduation, he landed a

of this venerable family will continue to

soldier on around the world well into the

twenty-first century, continuing a storied

aviation tradition.

job at MIT as an aeronautical engineer. In

August 1915, just twelve years after the

Wright Brothers' first flight on the dunes

of the North Carolina shore, Douglas

travelled to Los Angeles to interview as

the chief engineer at the Glenn L. Martin

Company, one of California's leading

aircraft manufacturers. Indeed, at just

twenty-three years old, Douglas became

the company's youngest chief engineer.

A year later, with World War 1

spreading in Europe, Douglas was

summoned to Washington, D.C., where

he was offered the posi tion of ch ief

civilian aeronautical engineer for the

Army Signal Corps' aviation section.

Douglas left the Martin Company for the

post, but returned a few months later to be

assigned the task of designing an attack

MD aD-series aircraft silhouetted. Boeing

DOUGLAS HISTORY

DOUGLAS HISTORY

The DC-9 in silhouette. Boeing

hadn't become the First to span a

continent, Davis sold his interest in the

company - unaware that Douglas had

stumbled upon a recipe For success.

Within two months of the Cloudster's

First flight, Douglas received his First

contract From the US Navy For three

torpedo

bombers,

wh ich

Douglas

designated DT-ls. In the two years that

Followed, the Navy increased its order to

thirty-eight of the aircraFt manuFactured

under the designation DT-2. A total of

ninety-three of the aircraFt were built,

garnering the attention of the Post Office

and the Army.

Douglas used many of the design

principles in the Cloudster and DT-I to

build the Douglas World Cruiser

(DWC), a cargo version called the C-l,

III observation aircraFt called the 0-2

,lIld a mail plane, the M-l. The World

( ruiser was the First aeroplane to fly

Iround the world. On 17 March 1924,

"1m DWCs leFt Clover Field in Santa

Monica, CaliFornia, en route to Seattle,

Washington, to start the 27,553-mile

(4 ),452km) journey. With stops in such

lilies as Tokyo, Calcutta, Vienna and

New York, two of the original Four

[)WCs returned on 23 September. The

,uccess of the flight helped to propel

[)ouglas to the Forefront of the aviation

IIldustry. Orders For various DWC

\l'rsions poured in, and by 1925

[)ouglas was producing Four aircraFt a

week From a converted movie studio

plant in Los Angeles.

Breakthrough Aircraft

With additional designs that included an

amphibious aircraFt and more bombers,

Douglas later opened a Factory at Clover

Field in Santa Monica, CaliFornia,

manuFacturing bombers For the US

military, which included the B-7, B-18, B19 and B-23. In 1932, with a nation still

struggling through the Depression,

Douglas was actively seeking commercial

customers. H is efForts paid off when a

young airline, Transcontinental and

Western Air (TWA), expressed interest in

acquiring ten new tri-motor transports. It

was with this project that Douglas kicked

off the First of what would become a

hugely successFul line of commercial

The DC-9-10 was the first aircraft in a family that would go on to become the second-most popular series of

modern commercial airliners. Boeing

aircraFt For the US Army that would

outperform Foreign Fighters in the nascent

Fighter-aircraFt industry.

Martin's

new

Facility

in

From

leveland, Ohio, Douglas set out to work

on what would become one of the most

important military projects of the time the Martin Bomber (MB-I). AFter its First

flight on 17 August 1917, the Army

ordered nine of the bombers. With his

First aircraFt in service, Douglas decided to

try h is luck as a solo engi neer and

businessman. In March 1920, the

aeronautical entrepreneur packed up his

Family to return to Southern CaliFornia.

He set up an office in the back room of a

barbershop. Two months aFter searching

For his Fi rst customer, Douglas met a

wealthy businessman named David Davis.

Davis, with $40,000 to invest, wanted to

sponsor the First-ever non-stop, coast-tocoast flight. Douglas took on the

challenge by Forming the Davis-Douglas

ompany. The upstart moved into a 10Ft

above a planing mill, and staFFed the new

company with six associates Douglas had

worked with at Martin.

Six months later, the company unveiled

its First aircraFt - the Cloudster. Although

the model wasn't the First aircraFt to fly

across the continental United States nonstop, Douglas noted with pride that it was

the First aeropl::lIle in history to ::lirliFt a

useFul load exceeding its own empty

weight. Disappointed that their plane

Donald Douglas with his DT-1 in early 1920s.

Boeing

aircraFt

the

DC-I

(Douglas

ommercial, First). Production of the

twin-engine DC-l began in June 1933,

with delivery to TWA by December.

Though over-budget,

it became

immediately clear that the DC-I had set a

new standard For airline saFety and

comFort. The passenger cabin was

insulated From engine noise through

rubber-mounted seats and noise-absorbing

carpet. The plane also had a galley and

lavatory. Although only one was ever

produced, TWA was pleased with the

creation and awarded Douglas a contract

to build twenty-Five larger versions designated the DC-2 - beginning a

history between Douglas and TWA that

would continue until the very end of the

century.

Next, Douglas improved the DC-2 over

its prototype predecessor. It was two Feet

DOUGLAS HISTORY

DOUGLAS HISTORY

The DC-3, still in service around the world today, is

the most popular airliner ever made. Boeing

(6Icm) longer, to accommodate two

additional passengers. The DC-2 was a hit

with the flying public. TWA employed the

aeroplane

on

its

nineteen-hour

Newark-Los Angeles route, which made

coast-to-coast travel possible overnight for

the first time. The DC-2 soon became the

aircraft of choice for many of the world's

largest airlines, including Eastern, Braniff,

Western, American, Pan Am and KLM. A

total of 156 DC-2s were produced.

At the insistence of American Airlines,

which would become one of its biggest

customers, Douglas began work on a new

aircraft similar in appearance to the DC-2.

Called the Douglas Skysleeper Transport

(DST), the plane was divided into six

compartments, each with two large seats

that could sl ide together to form a bed. The

plane also featured a honeymoon suite

equipped with its own bathroom - an

unheard-of concept at the time. American

took delivery of the DST - later known as

the DC-3 -on 7 June 1936.

The DC-l was the first in a long line of Douglas models. Just one was produced for service with TWA, a long-time Douglas customer. Boeing

The DC-2 made coast-to-coast travel possible in the United States. Boeing

70

77

DOUGLAS HISTORY

DOUGLAS HISTORY

The DC-6 was a faster and longer-range version of the DC-4. Boeing

The DC-4 was Douglas's first four-engine model. Boeing

Just twelve of the DC-5 models were built. Boeing

Douglas's final propeller-driven airliner was the DC-7. which could easily fly non-stop across the United States. Boeing

72

73

DOUGLAS HISTORY

DOUGLAS HISTORY

'1,441 aeroplanes. At its peak the Long

I\l',llh facility was producing 108 aircraft

I'l'r week. Production dropped with the

llld of World War II in 1945. A total of$2

hillion in backorders vanished overnight,

IIld the company laid off 99,000

l'lllployees nationwide. But like Boeing,

I he Douglas company used the war effort

III further develop the technology needed

Illr future commercial aircraft that later

Il'lluld be bu iI tin Long Beach.

The next Douglas aircraft, the DC-4,

1l',1S a four-engine evolution of the DC-3

1hat could carry forty-four passengers.

Roughly three times the size of the DC-3,

It was used by the military during World

War II, delaying its use in commercial

service until 1946. More than 300 DC-4s

were built. The next aircraft in the line

was the DC-5, a twin-engine aircraft that

used many DC-3 systems, although only

twelve were built.

Derived as an enhanced version of the

DC-4, the DC-6 was a faster, longer-range

aircraft. The improved DC-6B offered

even more power, and increased passenger

capacity from fifty-eight to eighty-nine

with top speeds of 380mph (611ktn/h).

The final Douglas propeller-driven

transport was the DC-7, introduced in

May 1953. It was the first commercial

transport able to fly non-stop westbound

The DC-8-62 caught on film on its first flight. Boeing

Originally conceived as a DC-2

derivative, the DC-3 featured a wider

fuselage, larger wing and lower operating

costs. As it turned out, the DC-3

revolutionized the airline industry. As one

of the most successful aircraft ever built,

the DC-3 made everyday air transportation

possible. By 1939, more than 90 per cent of

US airlines were flying DC-2s or DC-3s.

The DC-3 also appealed to one of

Douglas's most reliable customers, the US

Army, which bought aircraft converted to

suit its transport needs, including the C-32,

-33 and C-39. Eventually 10,300 DC-3s

and its military equiv<llents were produced,

with dozens still operating around the

world even today.

With World War II approaching,

Douglas scouted additional locations to

expand his operations. The property

where the DC-9 f<lmily would be

produced two decades l<lter began as the

winds of war blew half a world away. On

22 November 1940, Douglas broke

ground on its newest assembly plant in

Long Beach, Californi<l. With existing

facilities in nearby Santa Monica and EI

Segundo, the 200-acre facility adjacent to

Daugherty Field, the city's municipal

airport, was built to produce aeroplanes

for the US war effort.

For its time, the new plant W<lS a

technological

marvel. The

first

completely air-conditioned factory also

featured full artificial lighting. The

factory was designed to accommodate

thousands of employees - up to 43,000

men and women worked there, twentyfour hours a day, between 1941 and 1944.

The windowless eleven-building rlant

was protected from be ing spotted by

enemy aircraft. Most of its entryways and

receiving bays were <lccessible only

through double, lightrroof doors. From

the outside, it was camouflaged. Below

ground it offered underground storage ~lIld

bombproof shelters. The rlant was funded

by Douglas Aircraft, but the US

government agreed to repay the company

over sixty months. Aircraft production

started on 5 June 1941, just seven months

after plant construction had begun.

During that time, Southern California

experienced explosive growth. Thousands

of potential workers settled into the area,

giving the commerci~d aircr<lft industry a

14

Above: The DC-8 was Douglas's first jet-powered

airliner. The DC-8-61 was an intercontinental

version. Note the same cockpit shape as the DC-9.

Boeing

broad supply of skilled workers. The first

aircraft produced in the new facility was

the C-47 Skytrain, a modified DC-3 that

would become the standard transport

during the war. The C-47 differed from

the DC-3 in that its carpeting and

soundproofing were removed, heavy

landing gear was added and its cargo door

was enlarged. The Royal Air Force

received a large number of C-47s under

the designation Dakota, and the Soviet

Union produced the aircraft under its

deSignation, the Li-2. C-47s, one of the

four most important pieces of Allied

military equipment, would go on to playa

critical initial role in the 1948 Berlin

Airlift, delivering food, medicine and fuel

to those blockaded in West Berlin.

From 1941 to 1945, the Long Beach

plant produced an amazing 4,285 C-47s,

3,000 B-l7 bombers (under license from

historic rival Boeing), 999 Douglas A-20

bombers, and other aircraft for a total of

15

across the United States

prevailing winds. The DC-7C

dubbed the 'Seven Seas,' could

passengers. Douglas built 338

delivering the last one in 1958.

against

version,

fly 110

DC-7s,

Jet Age

Thanks to the DC- 3, DC-4 and DC-6,

Douglas was, by the mid-1950s, the most

popular manufacturer with the world's

airlines. But with development of the first

widely used jet-powered airliner, the

Boeing 707, Douglas grew concerned. As

production in Long Beach focused

primarily on building military transports,

competition in the r<lridly growing post-

DOUGLAS HISTORY

DOUGLAS HISTORY

James Smith McDonnell merged his company with

Douglas in 1967. Boeing

war commercial aviation

industry

prompted Douglas to design a commercial

jet transport to succeed its DC-7.

Th is historic model, the DC-8,

launched Douglas into the jet age in the

late 1950s, transforming Long Beach into

a world centre for commercial aviation.

On 2 April 1956, the company broke

ground on a DC-8 assem bl y faci! ity

adjacent to its existing Long Beach plant.

The one-million-square foot (92,903

square metre) facility, completed in just

thirteen months, made it possible to

produce commercial and military planes

si mul taneousl y.

Douglas proceeded cautiously with the

DC-8. While the company was rressured

by the widespread appea I of the 707,

Douglas wanted to avoid costly and fatal

mistakes that had grounded Britain's de

Havilland Comet, the world's first

commercial jet transport, in 1954. Three

years after the DC-8 programme was

launched, the first version, the DC-8-10,

made its maiden flight from Long Beach

on 30 May 1958.

Having met the milestone of jet

technology, Donald Douglas announced

his retirement on 28 October 1957. His

son, Donald Douglas Jr, succeeded him as

president of the Douglas Aircraft

ompany. Douglas Senior remained as

chairman of the board, leaving his son

with day-to-day operations.

The first DC-8-tO entered service with

United Airlines and Delta Air Lines on

18 September 1959. It closed out the

decade with a multitude of orders from

some of the world's largest airlines, setting

the stage for a family of Douglas jet

aircraft. Soon thereafter, the DC-8 line

continued to evolve, with the faster Series

20, and two intercontinental versions, the

Series 30 and 40. In 1960, Douglas

introduced the DC-8 Series 50, which

used turbofan instead of turbojet engines

to reduce fuel consumption, giving the

aircraft greater rflnge than any of its

predecessors. It a Iso was the fi rst DC-8 to

be offered as a freigh ter. Soon after,

Douglas began a missile and space

business to take advantage of the space

race, and built a new headquarters

building in Long Beach.

It was during this time that a new

product line - the DC-9, which would go

on to become the most successful Douglas

transport since the DC-3 - was quietly

being developed and was soon launched.

By the mid- J960s, production in Long

Beach had risen to its highest level since

World War II. In addition to a handful of

military trainers, the plant also was

producing the latest DC-8 series, the

Super Sixty. The DC-8-61 had the same

nose and tail as earlier DC-8s, but its

fuselage was extended by nearly thirtyseven feet (I 1.3 m) . Two other versions,

the DC-8-62 and DC-8-63, followed. The

final version, the DC-8-70, debuted in the

early 1970s.

took effect on 28 April 1967, ensuring

that the DC-9 family would continue

with new funding and fresh marketing.

The new company, McDonnell Douglas

orporation, brought together the

aviation-pioneer spirit of Donald Douglas

and McDonnell, whose famous products

included the F-4 Phantom II fighter.

James McDonnell immediately assumed

the duties as the new corporation's

chairman and CEO. Donald Douglas Sr

was named honorary board chairman

while his son remained preSident of the

Douglas Aircraft unit until 1968. Douglas

Sen ior died on 1 February 1981, at the age

of eighty-eight.

The transfusion of McDonnell cash

saved Douglas from bankruptcy and

enabled it to continue a line of respected

aircraft. With the merger, Douglas

advanced into the widebody commercial

field with the DC-IO, a three-engine giant

that would compete with Boeing's 747

and Lockheed's LlOll in the long-range

market. The DC-tO's first flight, on 29

August 1970, helped to boost production

at the plant, which was experiencing the

effects of recession. The DC-l 0 succeeded

in bringing Douglas to parity with Boeing

in the commercial airliner industry.

McDonnell Douglas survived for two

decades, through economic downturns

that reduced demand for new airliners,

AIR

The DC-9 entered service after the Caravelle, the world's first twin-engine jet airliner. For a while Douglas offered to market the aircraft in the United States,

Ralph Olson, Flying Images Worldwide

Donald Douglas Sr's contribution to aviation

included the introduction of the DC-9 in 1965. Boeing

Mergers

Douglas quickly became the victim of its

own success. The company could not

produce stretched DC-8 and new DC-9

models fast enough to meet delivery

guarantees. Start-up and production costs

skyrocketed, and Douglas was unable to

secure additional working capital. Facing

bankruptcy at the end of 1966, Douglas

sought to merge with one of its rivals.

North American Aviation, General

Dynamics, Garrett

Industries and

McDonnell Aircraft Company were

invited to submit merger proposals. On 13

January 1967, James Smith McDonnell

agreed to pay $68.7 million for Douglas,

and Douglas reluctantly accepted the offer

from the McDonnell Company, which

had been rebuffed in a bid to merge with

Douglas four years earl ier. The merger

76

OCII:;

"-

OC_

The BAC 1-11, which made its debut before the similar-sized DC-9, was not nearly as successful as the Douglas model.

Ralph Olson, Flying Images Worldwide

77

DOUGLAS HISTORY

CHAPTER TWO

Design and DevelopDlent

Origins

fhe DC-9 was conceived and designed as

highly reliable, economical, short-range,

high-performance jet transport, with the

ilhility to operate from runways as short as

5,000ft (l,520m), to bring the speed,

Cllmfort

and

rei iabil ity

of

jet

transportation

to

hundreds

of

(ommunities previously served only by

propeller-driven airliners. Timed to meet

the needs of airlines for a small jet, the

DC-9 made its debut in 1965, just as the

market for jet travel was increasing

hetween 6 and 8 per cent a year.

Douglas initiated preliminary studies of

the DC-9 in the late 1950s. Unlike the

long-range DC-8, the DC-9 was

envisioned to operate on routes between

100 miles (l60km) and 1,500 miles

(2,400km) in length, and where traffic

was sometimes sparse. At the time, 60 per

cent of all air travel was over distances of

.1

500 miles (800km) or less, so the DC-9

was seen as an opportunity to bring new

standards of service to this segment of air

travel. One important consideration was

runway length. Most airports were still

adapted to the needs of the piston aircraft

and lacked the longer runways necessary

for jets. Short field performance was

therefore essential if the maximum

potential of this new aircraft was to be

rea Iized.

Perhaps Donald Douglas's vision for

such an aircraft was articulated as early as

] 955, when he told an audience in San

Francisco: 'I have great faith in aviation

and the future ... the aeroplane will come

into its own. It will transport most

everyone and everything from every place

to everywhere.' A decade later, the DC-9

would help to bring that vision to life.

Entering the marketplace after the

Douglas originally conceived the DC-9 as a four-engine stablemate to the larger DC-8. Boeing

A DC-8 (foreground) is assembled alongside a row of DC-9s. Boeing.

and cuts in defence spending that limited

production of its military models. All

manufacturing was consolidated to Long

Beach to save money, and layoffs were

common. The company continued to

flounder, despite building the very

successful MD-80 family, until a fierce

competitor it strove so much to match for

decades ultimately swallowed it up.

On I August 1997, Boeing merged with

McDonnell Douglas in a $16 billion deal

that created the world's largest aerospace

company, with customers in 145

countries. The acquisition turned Boeing,

the world's leading manufacturer of

commercial jets, into the biggest maker of

military aircraft as well. Boeing clearly

saw value in McDonnell Douglas's

lucrative military products, but the

Seattle company already had its own full

range of commercial aircraft. At the time

McDonnell Douglas was producing just

two DC-9 derivatives - the M D-80 family

and the MD-90 - as well as the MD-11, a

DC-10 successor. Few in the industry were

surprised, then, when Boeing announced

it would shut down production of all

McDonnell Douglas models.

78

larger Caravelle and similar-sized BAC Ill, but before the Boeing 737-100, the

DC-9 helped to define the short-range jet

market, one that would become, for many

airlines, the backbone of their business. 'It

was clear that shorter routes were needed

and that smaller airports really were

anxious to have jet service. We perceived

that,' says Roger Schaufele, the former

project director for the DC-9 who retired

as vice president of engineering for

Douglas Aircraft. 'While there were

competing designs, I think when our

marketing guys looked at it, there was an

opportunity to replace piston-powered

aircraft, and the traffic growth was

projected to sky-rocket.'

By the early 1960s, design studies in

Long Beach began to focus on a shortrange stablemate for the high-capacity

DC-8 known as Model 2011. The

The final jetliner with a Douglas

name, an M D-11

freighter, was

delivered to Lufthansa Cargo on 22

February 200 I. The last mem bel' of the

DC-9 line bearing the Douglas name,

an MD-90 for Saudi Arabian Airlines,

was delivered in February 2000, the

2,287th twinjet produced by Douglas

and McDonnell Douglas. While the

DC-9 family continues in the shape of

the 717-200, it now bears the Boeing

name, an attribute the company hopes

will enable the family to survive for

years to come.

79

DESIGN AND DEVELOPMENT

DESIGN AND DEVELOPMENT

Soecifications - DC-9

Powerplant:

OC-9-10 and OC-9-20: Two 12,250lb (5,500kgl Pratt & Whitney JT80 (various models)

OC-9-30 and OC-9-40: Two 14,500-15,OOOlb (6,500-6,800kg) Pratt & Whitney JT80 (various models)

OC-9-50: Two 15,500-16,OOOlb (7,OOO-7,250kg) Pratt & Whitney JT80 (various models)

Weights:

Empty 49,900lb (22,635 kg) (Series 1D); 52,880lb (23,985 kg) (Series 20); 57,190lb (25,940 kg) (Series 3D); 58,670lb (26,612 kgl (Series 40); 61,880lb (28,068 kgl {Series 501

Gross 90,7001b (41,177 kg) (Series 10); 98,OOOIb (44,450 kg) (Series 201; 11 O,OOOlb (49,940 kgl (Series 30); 114,OOOIb (51,756 kgllSeries 40); 121,OOOIb (54,885 kg) (Series 501

Maximum landing 93,4001b 142,365 kg) (Series 10 and 20); 11O,OOOIb (49,895 kg) ISeries 3D, 40,50)

Dimensions:

Length 104ft 5in (31.82m) ISeries 10 and 201; 119ft 3.5in 136.37m) (Series 30); 125ft 7in (3828m) (Series 401; 133ft 7in (40.72m) (Series 50): height 27ft 6in (8.38mlIAIl Series).

Wingspan 89ft 5in (27.25m) ISeries 10); 93ft 5in (28.47ml (Series 20, 3D, 40 and 50): wing area 934sq ft (86.8sq m) (Series 10); l,OOOsq ft 193sq m) (Series 20, 3D, 40 and 501

Performance:

Cruising speed 557 -570mph (898-917km/h); landing speed 155mph (250km/h)

Ceiling 35,OOOft (10,675m)

Range 1,265 miles (2,036 km) (Series 10); 1,848 miles (2,974 km) (Series 20); 1,635 miles (2,631 kml (Series 30); 1,685 miles (2)12 km) {Series 401; 1,635 miles (2,631 km) (Series

50)

Takeoff 5,1 OOft (l,555m) (Series 101; 5,1 OOft (l,555mllSeries 20); 5,530ft (l,685m) (Series 301; 6,850ft (2,088m) ISeries 40 and 501

Landing 4,450ft (1 ,355m) (Series 10); 4,450ft 11,355m) (Series 20); 4,680ft (1,425m) (Series 30;)4,720ft (1,440m) (Series 40); 4,880ft (1,485m) (Series 50)

Passenger capacity:

70-90 (Series 10 and 20); 105-115 (Series 30); 125 (Series 40); 139 (Series 50)

Cabin:

Width 10ft 1in (3.07m); height 6ft 9in (2.06m)

Fuel capacity:

3,693USgall13,9781) (Series 10); 3,679USga1113,9251) ISeries 20, 30 and 40); 4,259USgai (16,1221) ISeries 50)

company assigned a top management

team to direct DC-9 design, development

and production. Many employees who

worked

on

the

programme

had

backgrounds that spanned the entire

Douglas fam ily line, from the DC-3 to the

DC-8. Schaufele says Douglas's expenses

on the DC-8 programme took its toll on

company finances, and the DC-9 was

developed with a meagre budget. 'We had

a lot of experience. There was a lot of

knowing how to do things - keeping

everything simple, safe and reliable,' he

says. 'If we knew something worked, we

did it. We learned a lot of lessons from the

DC-8, and we even used hardware from

the DC-8 programme.'

Throughout its inception and early

design, the DC-9 evolved from four

strategic

fundamentals:

simplicity,

reliability,

maintainability

and

economics. Among the primary concerns

of Douglas engineers was to design and

build a reliable, rugged aircraft that was

easy to operate, one that could fly many

times every day, and one that would be

easier to maintain than the propellerdriven aircraft of the past or even the DC-

Model 2086 was close to the final DC-9 design. Boeing

20

H, whose new technology was a bear to

manage. This philosophy would lead to an

aircraft that could spend more time in the

air making money than idle on the

ground.

Before the DC-9's final design evolved,

Douglas stud ied a four-engi ne DC-9

concept, essentially a shortened version of

the DC-8 that was seen as being

compatible with existing DC-8 fleets. But

intensive market studies led Douglas to

extend the time-scale for the launch of

this new type, and to initiate a wholly

original design rather than attempt to use

DC-8 components. Engineers quickly

determined two engines would reduce

both operating costs and complexity - key

principles behind the ultimate success of

the model. 'The fewer engines you could

get away with the better,' Schaufele says.

With two engines instead of four, the

DC-9 could also be more competitive.

'The BAC I-II was the first to announce

an aircraft in this market size and was the

Douglas experimented with an underwing engine design before determining that a fuselage-mounted

design would be the most effective for the short-range DC-9. Boeing

first in service,' Schaufele recalls. 'The

people at Douglas felt there was enough

business for two competing types even

though we were after the same niche. It

was our intent to design a better

aeroplane.'

Before offering its own aircraft, Douglas

offered to market the Caravelle in the

United States as a way to enter the new

craze for short-range jets. Strapped for

cash to develop the DC-9, Douglas

formed an alliance with Sud Aviation,

promising to market the aircraft in the

United States and build it in Long Beach

if demand warranted. Douglas even

considered a new Caravelle design that

would offer a new fuselage, engines and

wing. But the partnership broke up when

demand for the Caravelle fell short.

Douglas managed to lease only a small

number of Caravelles to TWA under this

27

arrangement - and that contract was

cancelled after two years. The Caravelle

had limited success in the United States

despite its popularity in Europe. United

Airlines was the only major US operator,

taking delivery of twenty of the type,

beginning in 1961.

While the partnership may have fallen

through, the Caravelle, with its two rearmourned engines, greatly influenced the

DC-9's design. Another influence was the

DC-9's earliest competitor. British

Aerospace announced the sixty-fivepassenger BAC I-lIon 9 May 1961, two

years before the DC-9 programme was

officially announced. The BAC 1-11 was

the first twinJet aircraft designed

specifically for short-haul traffic, a niche

the DC-9 would later fill with

considerably more success. Except for the

Caravelle, there was little competition for

DESIGN AND DEVELOPMENT

DESIGN AND DEVELOPMENT

the BAC 1-11. Indeed, a wave of early US

orders for the type - including thirty

planes for American Airlines - convinced

BAC that it had a money-making

successor to the turboprop Viscount, the

only British transport with any wide-scale

success in the large and fast-growing US

market.

The Soviet Tupolev Tu-134, with

similar capacity to the DC-9-10, was also

influenced by the Caravelle. With aT-tail

and fuselage-mounted engines, the Tu134 made its first flight on 29 July 1963,

one month before the BAC I-II and a

full two years before the DC-9. But

because it never operated beyond Sovietbloc nations, it was never a competitive

threat to the DC-9.

Douglas had plans of its own in this

market. Headed by an engineering team

under the direction of John Brizendine,

who would go on to become Douglas's

president, the first tangible evidence of

the DC-9's final design dates back to

1962, when design study data was released

and a full-scale mock-up was built in Long

Beach named Model 2086. The aircraft's

specification was frozen in 1963. Now

named the DC-9, it quickly caught the

attention of Delta Air Lines, a DC-8

customer. With interest from a leading

airline - but without a single contract in

hand - Douglas formally announced the

DC-9 in April 1963, a bold step that,

because of the company's tenuous

financial position, likely made it possible

for Douglas to remain in the commercial

airliner business. Delta immediately

signed up for fifteen DC-9s, setting the

stage for a new model that would become

Douglas's second jet transport, the first

American-made commercial twinjet and,

most notably, the best-selling commercial

twinjet family for more than three

decades.

'We were behind BAC, so trying to get

a commitment from an airline was

tough,' Schaufele recalls. 'Airlines knew

BAC was committed to its aeroplane.

We had not committed.' But with Delta's

nod of approval, other airlines began to

sign up for the new model, including Air

Canada and two US regional carriers,

Allegheny and Bonanza. 'There was a lot

of interest from a couple of airlines, but

with any new model we had to be

patient,' he says. 'Still, we were off and

running.'

After maturing from a four-engine

design into a twinjet, production began

on 6 March 1964. The first prototype, a

DC-9-10 model, completed its inaugural

flight on 25 February 1965, and was

certified on 23 November 1965, entering

service with Delta on 8 December of that

year. Five DC-9s were flying by the end of

1965.

A total of 976 DC-9s were built, the

last one in 1982, over an eighteen-year

production run entailing five distinct

models: the DC-9-10, DC-9-20, DC-930, DC-9-40 and DC-9-50 - each

providing operators with maximum

efficiency for diverse combinations of

traffic density, cargo volume and route

distances. Succeeding models, the MD80 series and the MD-90, more than

doubled the production number of the

overall family.

Key Design Decisions

The DC-9's key design elements - a

moderately swept-back wing, two rearmounted engines, a T-shaped tail, and

two-by-three seating in the passenger

cabin - evolved over at least four years of

testing and modification involving nearly

1,000 engineers.

Because of the experience Douglas

brought to the programme, the company

hesitated to hire more than necessary.

Schaufele, the retired engineer says:

i.., t', ""

I ...

':l'.; .,',

It was a very low-cost programme. We didn't

lhrow droves of people on it. We all enjoyed

working on the DC-S, bur thm had a lor o(

prohlem, lO be resolved - it wa> our first jet

LnIl1SJXm.

TIle DC-9, though, wa, (un to work on

(rom the beginning. There was a great deal of

satisfaction from those who participated thar there

was a perceived need for an aeroplane thar we

were de,igning. We knew from our own (amilie,

lhal eight-hour automobile drives could hecome

one-hour jet flights. The market was just fanra,tic.

Timetable

1959-1962:

8 April 1963:

July 1963:

25 February 1965:

8 December 1965:

Initial design work

DC-9 announced, go-ahead

decision

Prototype construction started

First flight, DC-9-10

First airline service, DC-9-10

The DC-9-1D, shown in this company illustration,

was envisioned as opening jet service to

communities served only by propeller-driven

aircraft. Boeing

22

After rejecting a four-engine design and

even experimenting with a version

featu ri ng wi ng- mou n ted engi nes tha t

resembled the Boeing 737, then also

under design, Douglas focused on testing

and perfecting the final design of the

launch model, the DC-9-JO.

The aircraft had two engine choices:

the Rolls-Royce Spey, found on the BA

I II, or the Pratt & Whitney JT8D,

already flying on the Boeing 727, which

l'l1tered service in 1964. 'It was one of our

"oten tia I customers, A merican Ai rI ines,

that suggested we go wi th the JT8D,'

Schaufele says. 'The engine was already in

'l'rvice, and since we designed the DC-9

to fly many cycles per day, it was not a

good idea to start with a new, untested

l'ngine.' (The JT8D on the first DC-9-10

was actually a bit too powerful for the new

,rircraft. So the engine was derated for

lower th rust leve Is a nd opera ti ng

temperatures.)

The first step in the evolution of the

DC-9 was the definition of the size and

layout. With airlines ordering the larger

Boeing 727, Douglas felt there was a gap

111 the market for a smaller aircraft. Since

the desired size of the DC-9 and the

available engine types dictated a twoengine design, the first major design

decision was the wing. The DC-9's initial

cruising speed was to be Mach .80, or 80

per cent of the speed of sound. Since it

had to be fast and perform well on short

runways, various wing-sweep angles and

DC-9s on the assembly line. Boeing

wi ng th icknesses were stud ied to

determine the optimal combination - one

that would yield the lowest operating cost

for a given cruise speed, payload-range

ability, and field-length requirement. The

design chosen was 24 degrees of sweep at

the centre chord of the wing, in a manner

reminiscent of the Caravel Ie. The

resulting wing thickness allowed for

adequate fuel volume and sufficient

tra iI ing-edge angles over the wi ng's

control

surfaces.

The

thickness

distribution and the variation of the

aerofoil shape across the wingspan were

selected for optimum performance.

With the type of engine certain and the

wing design established, the next major

decision was engine location. One aspect

of the DC-9's design that differed

fundamentally from previous Douglas

practice was the location of engines.

Placing engines on the sides of the aft

fuselage, it was initially believed,

introduced the possibility of a drag

problem due to air separation formed by

the engine nacelle, the pylon separating

the nacelle and the adjacent part of the

23

fuselage. Another area of concern was the

possihility of engine operating difficulties

due to ingesting wakes from the wing,

spoilers and fuselage. These concerns

were proven to be unfounded during wind

tunnel testing.

The choice of fuselage-mounted

engines over wing-mounted ones was

carefully considered for the DC-9. One of

the arguments in favour of the aft engine

location was the higher maximum lift

capahility that comes from a clean wing

leading

edge

and

from

a

flap

uninterrupted by an opening for engine

exhaust or for nacelles. Another

important advantage engineers focused on

was the reduction of drag <lch ieved by

eliminating interference hetween the

wing and pylons. A third hencfit is the

reduction of asymmetric-thrust yawing

(drifting off course) in the event of one of

the two engines failing. With the nacelles

located close to the fuselage, the

asymmetric thrust is reduced and the

minimum control speed can he made

relatively low without having to increase

the size of the vertical tail. Another

DESIGN AND DEVELOPMENT

DESIGN AND DEVELOPM ENT

I'

t ,III length, provid ing the model wi th

IIlll"casing control and stability.

As the DC-9 was undergoing wind

tllnnel

tests

to

improve

stall

l haracteristics, a BAC l-ll crashed after

!.:lllJ1g into a deep stall. That crash shed

light on the stall characteristics of an

,lIrcraft with a Ttail design. The aircraft

that crashed went into a deep stall

(l,llIsed by low fl igh t speed) at angles of

,Iltack ranging from 25 to 50 degrees. For

,lIrcraft designs that use the Trail and aftIl1llunted engines, pitching motions

heyond normal stall can provoke such

Incidents. To ensure normal recovery

during stalls, the DC-9's horizontal tail

was enlarged by about 20 per cent over

thc original design.

The last major decision - the cabin

lllllfiguration

was also carefully

lllllsidered. 'The basic two-by-three

'cating on the DC-9 was directly related

III the capacity of aeroplane,' Schaufele

cxplains. 'A two-by-two configuration

would have given us a fuselage that's too

long and three-by-three would have

mcant an aeroplane that's too shorr. Itwas

87.4'

cs

.",0'

J

T

studied and decided that two-by-three was

the hest solution.'

Douglas intended to stretch the DC-9

from the beginning, just as the DC-S had

becn available in different models.

'Initially, we didn't think of stretches

beyond the first plane. We focused on

competi tion wi th the BA C l-ll,' he says.

'But as traffic grew, we had an

opportunity. We prided ourselves on

making various versions and lengths that

customers wanted.' To ensure future

development of the model, engineers

made sure the DC-9 had enough wing

area. Engine placement ensured that

higher-thrust engine models could be

accommodated. Arrangements also were

made so the DC-9 could carry more

passcngers and fly farther. 'The key was

not LO lock yourself in,' Schaufele says.

The cockpit, designed to be simple,

logical and efficient, was created using

mock-ups. Designcd from the start to be

operated by two pi lots, it provides for

maximum crew comfort and efficiency.

A mock-up of the DC-9. showing a two-class interior configuration. Boeing

27.4'

no'="<

\

.../

~~

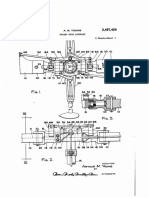

DOU GLAS DC9

Company diagrams showing the DC-9 design.

Boeing

significant gain with aft-mounted engines

is the reduction of drag during takeoff and

climb. Tests on the DC-S had shown a

substantial drag from the vortex arising

from the intersection of the pylon and

wing. Since performance in the takeoff

climb is especially important on a twoengine aeroplane, the beneficial effect of

eliminating the pylon from the wing was

probably the most dominant performance

factor in the decision to mount the

engines on the rear fuselage.

Several non-aerodynamic factors were

considered as wei!. Placing engines

beneath the wing tends to elevate the

entire aeroplane, increasing the length

and weight of the landing gear and builtin stairway. In an aeroplane the size of a

DC-9, maintainability and loadability

required an aircraft configuration that is

close to the ground, with minimum height

between the wing and tarmac. Another

advantage of having the engines mounted

on the rear fuselage is in case of landings

without landing gear deployed. Wingmounted engines would be severely

damaged in such a case, but the DC-9

engines would survive largely unscathed.

Schaufele, who served as the DC-9's

project aerodynamicist, cites another key

advantage. 'The design was accepted,' he

says. 'The BAC l-II and Caravelle

already were out there. So we went with

that arrangement, which was new for

Douglas. We figured if they could do it in

England and France, we can do it too.'

Placing the engines aft of the passenger

cabin also had implications for passenger

comfort: unless seated in the rear, next to

the

engines,

the

aft-mounted

arrangement was found to make for a

quieter cabin.

The next step was defining the design of

24

All essential controls and instruments can

be operated and viewed by either

crewmember.

The cockpit design was completed after

a long design cffort, and reviews and

critiques by more than 100 pilots from the

world's airlines and the US Federal

Aviation Administration. During two

years of development, Douglas thoroughly

analysed cockpits of both jet and non-jet

aircraft, taking into consideration such

factors as system analyses, flight crew time

and

motion

studies

to

ensure

compatibility

betwcen

cockpit

arrangement, crew work load and

operational reljuirements.

In addition, the DC-9 underwent a

laboratory developmclll and structural

testing process using principles and

systems thar were used to produce the

DC-S. Schaufele says testing showed the

DC-9 did everything engineers promised.

'Pcrformance-wise we were very satisfied

with the final product.'

The resul t - the DC-9-1 0 - was a sporty

the tai!' One of the DC-9's most

distinctive features is the high horizontal

stabilizer, mounted on top of the mil, <l

design also known as a 'Ttai!.' This

position accommodates engines on either

side of the aft fuselage and allows for a

clean wing design. The Ttail was

determined following an extensive study

that showed it was the most stable option

for the DC-9 - and was well-accepted in

the industry, as both the Boeing 727,

SAC I-I I and Caravelle had horizontal

stabilizers attached either at or toward the

top of the tail. During the DC-9's design,

the T-rail arrangement was the subject of

hoth analytical and wind tunnel studies.

No anomalies surfaced, and the design

proceeded without difficulty. The design

was shown to be the most efficielll

configuration, from a weight and drag

standpoint, to use with aft-mounted

engi nes. 1n add ition, the sweep of the

DC-9's tail resulted in greater horizontal

25

DESIGN AND DEVELOPMENT

DESIGN AND DEVELOPMENT

Wing

Jackson McGowen and John Brizendine look over

the DC-9 model. Boeing

aircraft, powered by two JT8D engines,

that measured 104ft 4in (31.8201) in

length, with a wingspan of 89ft 4in

(27.2501). Its cabin is 10ft J in (3.0701)

wide, carrying up to seventy passengers in

a two-class configurmion (fewer than

some versions of the DC-6) or ninety

passengers in one class. Standard fuel

capacity in the first DC-9 was

2,786USgal. (10,5461), providing for a

range of 1,265 miles (2,040km) at speeds

exceeding 500 mph (800 km/h) and

altitudes of more than 30,000 feet

(9,10001). The initial DC-9 has a wing

area less than that of a DC-3, a payload

capacity exceeding that of the DC-7 and

nearly the cruising speed of the DC-8.

Design in Detail

Much effort went into designing an

aircraft based on simplicity and durability.

All of the DC-9's systems and components

were carefully laid out to ensure the

aircraft would operate cost-effectively and

reliably, day in and day out.

The DC-9's ease of maintenance has set

high standards over the years for

airworthiness and low costs. This was

achieved, among other things, by

eliminating all unnecessary components,

since parts that are not installed to begin

with incur no maintenance costs. Douglas

engi neers actua II y el im ina ted some

subsystems required in larger jets without

forsaking safety. One example is the ability

to dump fuel, which is unnecessary because

the DC-9's maximum landing weight is 95

per cent of its maximum takeoff weight.

Systems and components that could not be

eliminated were designed and built to be

highly reliable, and only components with

a proven track record were considered.

Maintenance concepts never before

incorporated into an aeroplane contribute

to the DC-9's low operating costs, high

utilization rates and service longevity. To

simplify maintenance, systems and parts

on the aircraft were made as accessi ble as

possible to mechanics on the ground, from

engines and wings to the auxiliary power

unit (APU) and landing gear; providing

access for replacing components without having to disturb other systems or

components - was a predominant design

consideration. As result, the DC-9 was

among the world's first jet transports to

provide for easy servicing, inspecting and

troubleshooting capabilities to reduce and

simplify maintenance and to save time,

equipment and personnel. A prime

example of this is the engine installation,

designed for maximum commonality

between right- and left-hand units. The

only components that are not common

are the nose cowls and starter ducts.

Other than that, the engi nes are

interchangeable between right- and lefthand positions.

An overview of each of the DC-9's

major components follows:

The Pratt & Whitney JT8D engine was chosen

because of its existing marketplace success and

its ease of maintenance. Boeing

26

The DC-9 wing is highly efficient,

provides excellent performance on short

runways, and was, in its era, the simplest

design of any modern jet transport. One

reason the DC-9 is going strong even after

nearly forty years of service is its inherent

stability, provided in large part by the

wing.

The wing design was adapted from the

DC-8. Like its larger predecessor, the DC9 wing has a varying aerofoil shape and

thickness from the wingtip to the root of

the wing by the fuselage, providing

stabil ity and performance at both high

ami low speeds.

The DC-9's basic wing design was

determined from studies of the effect of

wing geometry on the overall project

design goals: the highest cruise speed

using available engines, economical

operations over short ranges, and the

ability to land and takeoff on short

runways. Various combinations of wing

area, sweep angle and thickness were

analysed.

Douglas relied heavily on data from

previous aircraft programmes and windtunnel tests to develop the final wing

deSign. These studies found that 934sq ft

(86.8sq m) of wing area (for the initial

DC-9-1O) with a 24-degree sweep angle,

resulting in a .80 Mach cruise speed, were

ideal. The wing on the first DC-9 model is

augmented by double-slotted flaps which

extend from the back of the wing over

two-thirds of the span. These flaps were

based on the deSign of earl ier Douglas

models, including the DC-8 and military

transports. The wing itself is a two-spar

structure with a leading edge that results

in a wing box with three shear webs. The

two half sections are joined at the

centreline of the aeroplane at the lower

fuselage.

Since the DC-9 was designed and

produced to provide a rei iable and sturdy

aeroplane structure - particularly crucial

for jets operating over short route

segments because frequent takeoffs and

landings put more stress on the airframe alloys used in the DC-9's all-metal wing

were carefully selected to achieve

maximum strength while maintaining

high fatigue and corrosion resistance.

Douglas used riveted skin and stringers in

the wing (as well as the empennage and

fuselage). Structural joints were kept to a

minimum to produce increased fatigue

resistance.

The wing itself incorporates the

ailerons, spoilers, tra iI ing-edge flaps, fuel

tanks, and supporting structure for the

main gear. Leading-edge slats were added

on the later DC-9-30 model.

Satisfactory stall characteristics have

always been one of the most important

design criteria for any aeroplane, particularly

passenger transports. Requirements for

adequate stall recovery and control were

established during the conceptual design of

the OC-9. Engineers were well versed with

initial stall problems that faced the BAC III, an earlier design with a Ttail. The OC-9

programme therefore underwent extensive

testing to ensure the chances of stall during

flight were remote.

To prevent stalls, the DC-9 has a

structure under the wing, known as a

vortilon, or vortex-generating pylon. This

fence-like device was developed during

wind-tunnel testing. Should the aircraft

approach a stall situation, the interference

of the vortilon with the cross flow of air

from the wing's leading edge creates a

strong vortex that goes over the top of the

wing. This creates an upwash of air that

helps the horizontal tail produce nosedown pitching during a stall. The vortilon

is installed on each wing's lower surface at

about one-third of the span. In addition to

the vortilon, a triangular strip of metal

extending spanwise from the fuselage is

Stall Testing

Flight testing would be incomplete if the stall programme - a test pilot's least favourite portion - were

not successfully completed. Aerodynamic stall speeds

and characteristics in various configurations and

power settings are the cornerstone upon which all

takeoff and landing performance is based, and is vital

to prove a new aircraft. This portion of testing is conducted when the pilot. at a safe altitude, pulls back

the power and lets the aeroplane decelerate, usually

at one knot per second. This is called the 1g stall, one

with neither positive nor negative g-force applied. At

a certain slow speed, buffeting of the aeroplane will

commence, followed by a series of gyrations until it

can no longer fly. At this point the nose will pitch

down, denoting the stall speed. The aeroplane must

be recoverable with forward pitch control and should

not exceed 20 degrees of roll during the recovery.

Stalls are induced over and over again to record the

exact airspeed at each stall.

located on the wing leading edge to

improve nose-down motion.

To further reduce stalls, the size of the

horizontal tail span was enlarged by 20 per

cent during the design process. The DC9's noted ability to avoid stalls and handle

well at low speeds were particularly

desirable for the short-haul market, where

much of the total flight time is devoted to

takeoff, approach and landing. The DC9's stability was demonstrated during

flight testing, when the model successfully

recovered from about 2,000 stalls.

Wind-Tunnel Testing

The DC-9's design was tried and finalized through

extensive wind-tunnel testing. Five primary miniature aircraft models were used in the process: a preliminary low-speed model to check basic aerodynamic characteristics; a high-speed model to check

high-speed stability, and control and drag characteristics; a third to obtain maximum-lift and stall characteristics data; the fourth with a relatively largescale aft-fuselage-empennage model to determine

horizontal and vertical tail lift: and the fifth was an

aft-fuselage-nacelle-pylon model for detailed drag

studies on the nacelle, pylon and fuselage. The

large-scale aft-fuselage-empennage model provided

extensive data on horizontal- and vertical-tail lift

characteristics and the effectiveness of the rudder,

stabilizer and elevator.

These tests involved six models and 1,500 hours of

operation in tunnels at four laboratories - the Douglas

Aerophysics Laboratory, the Guggenheim Aeronautical

Laboratory at the California Institute of Technology, the

Cornell Aeronautical Laboratory, and the NASA Ames

Research Centre. This was in addition to work conducted at the Douglas low-speed wind tunnel in Long

Beach. Results found that the DC-9's lift, drag, stability

and load measurement met or exceeded forecasts and

performance guarantees.

27

To further test the DC-9 design, in the days before

powerful desktop computers and virtual-reality sessions,

Douglas used analogue computer studies. Hundreds of

wind-tunnel runs with different configurations and various assumed pilot inputs were recorded. Later, the analogue computer served as an early-generation simUlator.

This set-up evaluated angle of attack, aeroplane attitude, flight-path angle, elevator angle, normal acceleration, air speed and altitude. These tests also showed the

DC-9's performance would exceed expectations once the

DC-9 finally flew.

Early development work on the low-speed model

generally verified the DC-9's estimated stability levels

and control capability. Yet further studies of air flow at

the intersection of the horizontal stabilizer and vertical

tail indicated a potential problem in the original design.

Design changes were subsequently made in the placement of the horizontal tail to ensure better stability.

Meanwhile, the high-speed model provided valuable

information on stability levels and control effectiveness

at high speeds, as well as an early check on the level of

drag during flight.

Results of the wind-tunnel tests showed the DC-9

could operate efficiently beyond its designed speed, and

in effect confirmed the decision by Douglas engineers to

use the T-tail design.

DESIGN AND DEVELOPMENT

DESIGN AND DEVELOPMENT

h<lwed the fatigue life should be 144,000

flight hours based on missions of 1 hour

\l~ minutes, and 120,000 flights based on

fllghls of 45 minutes each.

Unlike later aircraft, which had lighter

nllnposite material, the DC-9 is made of

.II metal

construction,

primarily

,tlllminium. To prevent corrosion during

fllghls in all kinds of weather, the DC-9 is

\Il~lIlated using paint coatings on steel

t.1~lenings installed in its aluminium

~l rllctures. In the fuselage, the size, spacing,

material and thickness of skins, stringers

.\Ild frames on the fuselage help to keep

Llllgue-induced cracks from extending.

The geometry of the DC-9 provides

~tructural integrity and safety from fire

h.1Zards in the event of a wheels-up

l'mergency landing. In several incidents

over the years, aircraft suffered so little

damage while landing without gear that

rcrairs were made and the aircraft flown

the following day. By contrast, an aircraft

with wing-mounted engines usually suffers

~cvere damage to the exrensive engines,

~lructural damage to the wing, and faces

the risk of fire hazard if the fuel lines arc

ruptured. Both the engine mounting pylon

and the fuselage arc protected from fire

damage by titanium shields and a specially

developed 3,000F (I ,650C) fire barrier

installed in the engine burner area.

Tail

The DC-9 tail consists of a vertical

stabilizer, a horizontal stabilizer, two

elevators and a rudder. The vertical

stabilizer is mounted on the aft fuselage,

and the horizontal stabilizer is mounted on

top of the vertical stabil izer to form the Tshaped tail. The rudder and elevators arc

mounted on the vertical and horizontal

stabilizers, respectively. A hole for the airconditioning system is located on the lower

leading-edge section. The rudder, which

heirs to control the direction of the

aircraft, is operated hydraulically with a

manual backup. Mechanically controlled

tabs aerodynamically

position

the

elevators, which control longitudinal

direction during normal flight.

The DC-9's basic cockpit was enhanced throughout the family's development. Shown is the DC-9-50. Boeing

Wings, nose sections and fuselages share the floor space during production in the 1960s. Boeing

The DC-9 wing evolved following the

original DC-9-10. Later models had a

larger wing (I ,000sq ft or 93sq m) and an

increase in wingspan of 4ft (1.2 I m) to

accommodate higher gross weights and

rassenger capacity. In addition, full-span

leading-edge slats, devices that improve

lift, were added as the result of customer

requests, and a reshaped leading edge was

introduced. These changes helped to

lower stall speeds and improve cruise

performance. Adding leading-edge slats

was the primary way to improve lift,

permit slower takeoff and landing speeds,

and improve performance on short

runways - all to better compete against

the Boeing 737, which debuted with the

devices. The slats, Iike the flaps, arc

extended and retracted by completely

separate, dual hydraulic-power systems.

The DC-9 series incorporates dual rearfacing navigation lights located in the

wingtip, along with the primary

retractable wing landing light. Extended

wingtips on the DC-9-30 and later models

did not leave sufficient depth to include

the retractable wing landing lights. A

compromise installation features the light

some 14in (35.5cm) inboard of I' he actual

tip, resulting in a bump on both the upper

and lower surfaces of the wing.

Fuselage

The DC-9's fuselage is composed of the

nose section, centre section and tail

section. The nose section is structu ra II y

identical

to

the

DC-8.

Entirely

pressurized, it contains the cockpit, the

accessory

compartment

and

the

electronics compartment. The centre

section is composed of the passenger

cabin, two cargo compartments and the

wheel wells. The tail section includes the

28

aft cahin rressure bulkhead, engine

support structure, auxiliary power unit,

empennage and the tail cone. Customer

options located in the tail include a

venn'al stairway and an emergency exit.

The type's rugged fuselage has been

thoroughly substantiated by analysis,

extensive testing, and by millions of miles

of DC-9 service over the years.

From the beginning, Douglas chose

materials for tear-resistant strength. The

fuselage shell is designed for a dependable

operating pressure of 7.46psi, which means

that, while flying at 35,000 feet ( 10, 700m),

inside the cabin it feels like the altitude

equivalent of 8,000 feet (2,500m).

The DC-9 fuselage was designed to

withstand 50,000 flights, although many

DC-9s in service today boast more than

100,000 cycles (one takeoff and landing is

a cycle). During testing, a pressurized

fuselage was pressure-tested for 120,000

cycles, and the empennage was fatiguetested for 360,000 cycles. Testing also

29

Cockpit

The DC-9 cockpit was designed to

accommodate two pilots. It incorporates

many conveniences that simplify the

crew's tasks. Lighted checklists, folding

writing tables and fixed chart-holders

help to reduce the workload, while

footrests, ample storage areas and general

roominess contribute to general comfort.

Essential displays and controls arc

dupl icated to provide redundancy and to

accommodate both pilots. The central

caution-and-warning presentation is

visible to both as well, within the pilot's

straight-ahead field of vision, so the crew

has a continuous advisory on the

cond ition of the aircraft. The fl igh I' deck

provides stations (or the captain and first

officer. The scats arc track-mounted and

arc fully adjustable. A folding scat is

available for a flight observer.

All flight, engine and other instruments

in the early DC-9s have white dialmarkings on black faces and are readable

during daylight without lighting. Mode

selectors in the DC-9 are rotary switches,

which provide vertical-speed control,

altitude control, pitch hold, coordinated

DESIGN AND DEVELOPMENT

DESIGN AND DEVELOPMENT

Inertial and Omega Navigation Systems

to provide long-range navigation, even

over water. High Frequency (H F) and

Very Iligh Frequency (VHF) with

optional Ultra High Frequency (UHF)

provide the aeroplane with short- and

long-range communications.

To alert the flight crew of any potential

stall, the DC-9 was equipped with two

completely

redundant stall-warning

systems.

Flight-Control Systems

The home of the DC-9 was a busy place during the height of production. Boeing

bank/turn/heading

hold,

heading

selection, and VOR (VHF Omnidirectional Radio)/Iocalizer.

The cockpit contains four different

types of windows: a centre windshield and

two side-windshields, a clear-view

window on either side, an aft window on

either side and two windows above. The

centre windshield and two sidewindshields are electrically heated to

remove ice and eliminate fogging. Electric

wipers and liquid rain-repellent aid in