Professional Documents

Culture Documents

Sustained Release Breath Freshener Wafer

Uploaded by

balaji19745Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sustained Release Breath Freshener Wafer

Uploaded by

balaji19745Copyright:

Available Formats

United States Patent [191

[11]

[45]

Barr

[54]

SUSTAINED RELEASE BREATH

FRESHENER, MOUTH AND PALATE

COOLANT WAFER COMPOSITION AND

METHOD OF USE

[76] Inventor:

[*1

Notice:

Arthur Barr, 2942 Shore Dr.,

Merrick, NY. 11566

The portion of the term of this patent

subsequent to Sep. 29, 1998 has been

disclaimed.

[21] Appl. No.: 373,342

Apr. 30, 1982

[22] Filed:

[5 1] Int. Cl.4 ........................ .. A61K 9/26; A61K 9/50

[52] US. Cl. ...................................... .. 424/ 19; 424/20;

424/22; 424/49

[58]

[56]

Field of Search ...................... .. 424/ 19, 20, 22, 49

References Cited

U.S. PATENT DOCUMENTS

3,911,099 10/1975

DeFoney et a1. ................... .. 424/49

3,957,964

5/1976

Grumm ....... ..

4,292,028

4,329,333

4,071,614

9/1981

5/1982

l/l978 Barr

Grumm

..................................... .. 424/19

Patent Number:

Date of Patent:

4,597,959 '

* Jul. 1, 1986 a

OTHER PUBLICATIONS

Fed. Register, Dec. 13, 1968, CA. 46240(b); vol. 70,

1969.

Suzuki et a1., C.A. 126l90(x); vol. 88, 1978.

Primary ExaminerD0nald B. Moyer

Assistant Examiner-C. Joseph Faraci

Attorney, Agent, or Firm-Roberts, Spiecens & Cohen

[57]

ABSTRACT

A cosmetic breath freshener composition, in wafer

form, having slow release comprising a multiplicity of

microencapsulated liquid droplets of ?avoring materials

contained in a base or carrier. The microcapsules are

soluble in the saliva in the mouth to release the ?avoring

material at sustained rate. The base has an adhesive

therein so that the formed wafer can be placed on the

lower or upper gums of the user, thus being activated by

the saliva in the mouth causing the capsules to release

the ?avoring material at a sustained rate for long peri

ods of time in the mouth to mask bad breath and also

offering a cool feel effect in the mouth of the user.

10 Claims, No Drawings

4,597,959

SUSTAINED RELEASE BREATH FRESHENER,

MOUTH AND PALATE COOLANT WAFER

COMPOSITION AND METHOD OF USE

lated liquid droplets of ?avoring materials the microen

capsulated droplets being soluble in the saliva of the

mouth to slowly release the ?avoring materials when

FIELD OF THE INVENTION

The invention relates to a breath and mouth freshener

composition capable of slow release, at a sustained rate,

of a microencapsulated liquid ?avoring material and to

methods of use thereof.

The invention is particularly applicable to the use of

such a breath freshener composition in a wafer form, for

the general public but is also applicable for use by full or

partial denture wearers.

The invention further relates to a method of delivery

of breath and mouth freshener materials, medications,

and caries retardants, at a sustained rate, of microencap

sulated material and to methods of use thereof.

The invention is particularly applicable to the use of

such materials in a self adhesive wafer form.

BACKGROUND

One of the major problems encountered by the gen

eral public is offensive breath, or bad breath due to

food and beverage residues retained in the oral cavity

producing this offensive cosmetic problem; in addition

natural food odors, such as onions, garlic, etc. and the

like add to bad breath.

Up to this time no satisfactory compositions or meth

ods have been obtained which will overcome these

problems for long periods of time, and despite the wide

spread use of varying ?avoring materials, there has been

no effective long-lasting solution to overcome the prob

refreshlng taste and feel in the mouth; the feeling of the

user being that of just having brushed the teeth.

In accordance with the invention, there is provided a

breath freshener composition, in a wafer. form, having

slow release comprising a multiplicity of microencapsu

entering into contact with the saliva. As a consequence

10

the microencapsulates can slowly release the liquid

?avoring materials at a sustained rate. The microencap

sulates are present in a wafer form which comprises a

base of gelatin, gum arabic and/or Carrageenen with an

adhesive distributed throughout. In this way the wafer

can be applied to the gums and palate or the wafer can

be directly applied to the inner or outer surfaces of full

or partial dentures.

A further object of the invention is to provide a wafer

containing a germicide having slow release in the oral

cavity which will retard the growth of harmful bac

teria, particularly after oral surgery when the risk of

oral infection is high.

In a further aspect of the invention, the formation of

caries, particularly in children is retarded by including

stannous ?uoride in the wafer in an amount of l5% by

weight of the ?avoring material.

In accordance with a specific embodiment of the

invention, the encapsulated ?avoring materials are pres

ent in an amount of 35-45% by weight of the composi

tion. The base is present as a remainder of 55-65% and

comprises a gum such as Gum Arabic (Acacia)and/or

Carrageenan. The gum can be present in an amount of

10-40% by weight of the composition.

According to a further aspect of the invention, the

lem of offensive breath (bad breath) with its accompa

nying bad mouth feel. Flavorings, such as spray breath

.base or carrier which may serve as an adhesive and/or

fresheners, mouthwashes, chewing gum, lozenges, liq

itself encapsulated and mixed with the microencapsu

lates of ?avoring materials, in conjunction with the base

uid drops and toothpaste as presently employed have

only a limited life of very short duration and rapidly

lose their ability to mask bad breath or offer long-lasting

fresh, cool feel in the mouth.

SUMMARY OF THE INVENTION

binding agent for attachment to the gums of the user, is

material.

PRIOR ART

U.S. Pat. No. 2,701,212 relates to germicidal deodor

izing powder adhesives and methods of manufacture

An object of the invention is to provide a breath and

thereof. The patent discloses powdered adhesives con-.

mouth freshener composition and mouth coolant in a 45 taining varlous amounts of ?nely divided karaya gum

wafer form, having a slow release in the mouth, capable

and borax with an without water-soluble chlorophyllin.

of eliminating offensive breath, and cooling the mouth.

A further object of the invention is to provide a wafer

composition of minimum size, i.e. thickness and diame

This patent lacks any teaching concerning encapsulated

minute droplets of ?avoring material having slow re

lease at a sustained rate.

ter so that placement of the wafer anywhere in the oral 50 U.S. Pat. No. 3,440,065 relates to an improved den

cavity would be comfortable while remaining in one

ture adhesive containing various additives, such as

position.

wood, ?our, cellulose or other wood pulp derivatives

Yet another object of the invention is to provide a

which are added to a gum-petrolatum base. The patent

wafer composition which is self-dissolving in the mouth

discloses an adhesive composition of a topically accept

of the user so that when placed in the mouth the wafer

able hydrocolloid, powdered insoluble adsorptive cellu

will dissolve and there will not be any residue remaining

lose material and petrolatum. The purpose of the cellu

for the user to discard.

lose material is to effect a greater hydration of the gum

A further object of the invention is to provide such a

particles, not only on the surface, but throughout the

breath freshener composition, in a wafer form for use

paste and thereby effect a much stronger cohesive bond

with full or partial dentures by compatability thereof 60 between the denture and the gingiva and palate. In

with or without the use of a denture adhesive.

addition, a ?avoring oil is blended into the composition,

but lacking is any teaching regarding sustained time

According to a feature of the invention, the breath

release based on the use of encapsulated ?avoring mate

rials.

U.S. Pat. No. 3,886,265 discloses a mouth cleansing

for continuous adherent contact with the palate or gums 65

and mouth freshener can be in the form of a wafer of

minimum size, having an adhesive distributed therein

of the user.

The invention also meets the oral grati?cation needs

of the consumer by offering the additional bene?ts of a

preparation containing at least one ene-diol compound

having at most 6 carbon atoms and an oxidizing agent in

the form of a water soluble peroxide. The composition

4,597,959

is intended to eliminate bad breath and is employed in

the form of a chewable tablet. The composition can

contain ?avoring agents, but these are not in the form of

encapsulated droplets adapted for slow sustained re

lease in the mouth.

U.S. Pat. No. 3,969,499 discloses dental adhesive

materials in the form of plastic ?lms or membranes

which are implanted in or adhered to tissue, bone or

tooth substrate in which a medicament such as a ?uo

ride compound is imbedded. The medicament is re

leased from the plastic over a period of time. Speci?

cally, the composition is intended for use as a dental

?ssure sealant. There is no teaching in this reference of

a sustained release of ?avoring material.

over a period of time, of the order of several hours,

when the encapsulated droplets come into contact with

saliva in the mouth. The encapsulating material must

satisfy the purposes of the invention of being saliva

soluble and providing sustained release of the encapsu

lated ?avoring material while being not soluble in water

and thus capable of long shelf life without weight loss to

the ambient atmosphere. Furthermore, because of this

property, breakdown of capsules will not be speeded up

by the intake of drinking water or other water contain

ing beverages.

The multiplicity of microencapsulated liquid droplets

of ?avoring materials is incorporated into a base formed

as a wafer having adhesive therein wherein the wafer

US. Pat. No. 4,029,759 discloses a method for impart 5 can be af?xed to the palate or gums of the wearer and

ing a cooling property to a composition for use in the

slowly release the ?avoring material. The wafer can

oral cavity. Speci?cally, the patent discloses the use of

thus be utilized whether the user wears dentures or not

para-menthane derivatives to various substances used in

and will provide protection against bad breath for

the mouth, such as toothpaste, mouthwash, tooth pow

several hours.

der, food stuffs and the like. The para-menthane deriva

The microencapsulated liquid droplets are composed

tives can also be employed in combination with ?avor

ing materials. Lacking in this disclosure is any teaching

concerning sustained slow release of ?avoring material

in the mouth.

US. Pat. No. 4,071,614 discloses a dentifrice which

contains encapsulated ?avoring materials. The denti

frice contains two different ?avoring materials in which

one ?avor is encapsulated in a thin walled capsule and

~ the other is encapsulated in a thick walled capsule. The

thin walled capsules rupture when the toothpaste is

squeezed from the container and the thick walled cap

sules rupture in the course of brushing the teeth. The

encapsulated material is not water-soluble and is in

tended for being broken by a mechanical action to re

lease bursts of the ?avoring material. There is thus no

disclosure in respect of a slow sustained release of ?a

voring material, particularly, in conjunction with a

static situation, such as, installation of dentures.

DESCRIPTION OF PREFERRED

of liquid ?avoring material constituting 85-95% by

weight of the microcapsules and 5-15% by weight of

encapsulating wall material consisting essentially of

cross-linked gelatin. The wall material comprises gela

tin, an adhesive binder such as gum arabic, a gelatin

cross-linking agent such as glutaraldehyde and sodium

silicate. The gelatin and binder are present in equal

amounts of between 2.25 and 7.25% and the cross-link

ing agent and sodium silicate are present in equal

amounts of 0.25%.

The ?avoring material can be of wide range and by

way of example, it may be a mint ?avor such as spear

mint, peppermint, oil of Wintergreen, etc. Also usable

are fruit ?avors or other ?avorings such as vanillin,

menthol, eucalyputus oil or combinations of ?avorings.

The microeapsules containing the ?avoring material are

present in an amount of 35-45% by weight of the com

position.

The base which represents the remainder of the com

EMBODIMENTS

position is present in an amount of 55-65% by weight

In order to confer a slow sustained release of ?avor

ing materials into the mouth of the user there is em

and serves as the vehicle for containing the encapsu

lated material distributed therethroughout to form the

wafers.

ployed a multiplicity of microencapsulated liquid drop

The base or carrier and the encapsulated ?avoring

lets of ?avoring material in a prepared base composi 45

material are formed as a slurry and are utilized to pro

tion. The encapsulated droplets are soluble in the saliva

in the mouth of the user so as to dissolve the microen

duce wafers or tablets in conventional manner in a tab

capsulation material and release the ?avoring material

letting machine extruder, spray or mold apparatus. The

slurry may contain various thickening agents, such as

when entering into contact with the saliva in the mouth.

It is noted that the entire wafer composition is dissolved

without any remaining residue to be extracted by the

user.

10% by weight Klucil, or 10% by weight Carrageenan,

or 40% by weight Gum Arabic. The viscosity range of

the slurry is 2200-3000cps Brook?eld at 20 C.

The formation of microencapsulated liquid droplets

The base or carrier can contain additional substances

of material is well known in the art and does not form

any part of the present invention. Hence, it will not be

and these include a small percentage of the order of 0.3

to 1% of methyl and propyl parabens as an antifungi

cide, 0.3-1% Benzocaine as an analgesic and a small

percentage of the order of 05-01% of a natural liquid

described at length herein. However, for the purpose of

brief explanation, reference is made to the publication

Microencapsulation by Herbig as presented in the

sweetener such as Pharma-Sweet.

Encyclopedia of Chemical Technology of Kirk

EXAMPLE I

Othmer, Volume 13, 2nd Edition, pp. 436-456. As dis 60

closed herein, minute particles or liquid droplets of

Microencapsulated droplets were prepared by encap

material can be encased by an impervious capsule wall

sulating peppermint ?avoring in liquid droplet form in

and isolated from the surrounding atmosphere.

an encapsulating material which is substantially not

In the circumstances of the present invention, the

soluble in water but is soluble in saliva in the mouth of

encapsulate liquid ?avoring material can be spray dried 65 the user.

or encapsulated in a non-water soluble coating and the

coating may be of varying wall thicknesses in order to

according to the invention includes the following com

provide for sustained release of the ?avoring material

ponents in % by weight.

A microencapsulated droplet composition prepared

4,597,959

5

liquid peppennint

gelatin

85%

7.25%

gum arabic (acacia)

7.25%

glutaraldhyde

with the addition of 1.4% by weight of phenol to the

?avoring material. Similar germicides such as Hyamin

No. 10X, may be used without the flavoring material,

.25%

(gelatin a cross

linking agent)

sodium silicate

but they must be non-soluble in water or blended with

a carrier that is non-soluble in water. Clove oil may be

25%

(Aerosil 972)

The microencapsulated droplets have a size of be 10

tween l0 and 400 microns and a wall thickness of less

than 5 microns and generally between 2 and 3 microns.

The droplets were found to have a maximum weight

loss in air of about 10% which was achieved within 9

days whereafter there was no further weight loss. The

microencapsulated droplets were not soluble in water

but were slowly soluble in the saliva in the mouth of the

is allergic to certain antibiotics or has developed an ~

The same procedure as in Example I l was carried out

with the addition of stannous ?uoride to the ?avoring

material of amounts between 1 and 5%. This provided

sustained release in the mouth of a proven retardant of

caries, over a longer duration of time than that con

sumed by brushing the teeth with conventional tooth

PERCENT BY WEIGHT

2O

25

39.4

40

Propylparaben

Benzocaine (Ethyl aminobenzoate)

paste containing stannous ?uoride, sodium ?uoride,

sodium mono?uororphosphate. The combination of a

sustained release breath freshener and caries retardant

was deemed to be unique and highly bene?cial to the

droplets (as prepared above)

Water

Gum Arabic

It was found that the sustained release of a germicide

in the oral cavity greatly reduces the pathogens in the

mouth and greatly reduces the risk of infection immedi

ately after extractions and for periods up to 5 to 6 hours.

immunity to them.

The following composition of the invention was pre

pared in wafer form by the method to be described

hereafter.

INGREDIENTS

used because of its germicidal and ?avoring properties.

This may preclude the necessity of the patient taking an >

antibiotic for the same purpose, particularly if a patient

user.

Microencapsulated peppermint

?avoring material tends to suppress the desire to smoke

and to inhibit the desire for snacks.

The same procedure in Example II was carried out

0.3

0.3

public at large.

30

The same composition as described above was pre

pared without the presence of the ethyl aminobenzoate

in one case and without the propylparaben in another

case. In each case the amount of water was increased by

0.3% by weight to make up the absence of the respec

tive ingredient.

EXAMPLE II

Although the invention has been described in con

junction with the speci?c embodiments thereof it will

be apparent to those skilled in the art that numerous

modi?cations and variations can be undertaken without

departing from the scope and spirit of the invention as

de?ned in the attached claims.

What is claimed is:

1. A method of releasing a ?avoring material and

providing effective protection against bad breath in the

The same procedure in Example I was carried out

mouth of a user, said method comprising forming a

using Carrageenan and Klucel in amounts of 10% by

weight instead of Gum Arabic in an amount of 40% by

wafer composition consisting of microencapsulated

weight (the balance being made up by the addition of

30% by weight of water) with substantially the same

said microencapsulated droplets having a coating which

droplets of liquid ?avoring material in a base or carrier,

is substantially non-soluble in water but which is soluble

results.

in the saliva of the mouth, said wafer having adhesive

The composition was prepared by adding irradiated 45 therein such that when the wafer is placed at any conve

tap water to a stainless steel kettle and then adding the

nient place on the palate or on the upper or lower gums,

propylparaben and Benzocaine. The mixture was then

adjacent to the cheek of the user, thereafter the saliva in

heated to a temperature of 20 C.

the mouth causes the adhesive therein to adhere to the

The gum Arabic was then added and mixing was

gum and at the same time the ?avoring material is

continued until a uniform mixture was obtained. The 50 slowly released, at a sustained rate, in situ in the mouth

encapsulated ?avoring was then added and mixing was

as the droplets of material are slowly dissolved, thereby

continued making sure that the viscosity is between

to offer effective relief against bad breath, for periods of

2200 to 3000 centipoises and that the mixer clearances

time in the order of 4-6 hours, said microencapsulated

are proper so as to not rupture the microcapsules. The

natural sweetener may be added at this time. After 55 droplets being present in an amount of 35-45% by

about 10 minutes mixing the breath freshener slurry was

transferred to suitable drums for storage and cooling to

ambient temperature. The material was. then formed

into round wafers, each " to " in diameter and approx

60

imately, l/32" to g" in thickness.

In use, the wafer applied to the upper or lower gums

adjacent to the cheek, was found to provide effective

protection against bad breath for periods of time in the

order of 4-6 hours.

It was also found that the wafer composition had a 65

cooling effect in the mouth of the user, akin to the feel

ing of having just brushed the teeth. It was also found

that the cooling effect and the sustained release of the

weight and consisting essentially of liquid ?avoring

material in an amount of 85-95%, and an encapsulating

wall material of cross-linked gelatin in an amount of

5-15% by weight, said base or carrier consisting essen

tially of an adhesive.

2. A method as claimed in claim 1 wherein said mi

croencapsulated droplets consist of the following in

percent by weight:

Liquid ?avoring material

Gelatin

Gum Arabic

Glutaraldhyde

85%

7.25%

7.25%

.25%

4,597,959

-continued

-continued

Sodium Silicate

gum arabic

.25%,

40%

propylparaben

ethyl aminobenzoate

3. A method as claimed in claim 2 wherein said mi

croencapsulates are added to said base or carrier to

form a slurry from which wafers are formed.

0.3%

0.3%.

7. A method as claimed in claim 3 wherein said base

or carrier to which the microcapsulates are added con

sists essentially of in percent by weight:

4. A method as claimed in claim 3 wherein said base

or carrier includes an anti-fungicide, or an analgesic or

combinations thereof.

microcapsulates

69.7%

Carrageenan or Klucel

fungicide is an alkylparaben and said analgesic is

ethylaminobenzoate.

20%

water

5. A method as claimed in claim 4 wherein said anti

10%

propylparaben

0.3%.

15

6. A method as claimed in claim 3 wherein said base

8. A method as claimed in claim 1 wherein the ?avor

ing material is a mint material.

9. A method as claimed in claim 1 wherein said ?a

or carrier to which the microcapsulates are added con

sists essentially of in percent by weight:

voring material comprises a germacide.

20

microcapsulates

water

10. A method as claimed in claim 1 wherein said

?avoring material comprises stannous ?uoride.

20%

39.4%

II!

25

30

35

45

50

55

60

65

1'

You might also like

- Project Final 2023 PratikDocument24 pagesProject Final 2023 PratikPratik sableNo ratings yet

- US3630925Document2 pagesUS3630925Pallav SaikiaNo ratings yet

- Intraoral Fluoride-Releasing Devices: A Literature ReviewDocument0 pagesIntraoral Fluoride-Releasing Devices: A Literature ReviewmanikantatssNo ratings yet

- Harrys Cosmetology Chapter 31 35Document67 pagesHarrys Cosmetology Chapter 31 35NidhiNo ratings yet

- Field Isolation and Moisture ControlDocument39 pagesField Isolation and Moisture ControlDr. Nikhil saran100% (1)

- DijonDocument43 pagesDijonNaren KarthikNo ratings yet

- Stable Solid Deodorant Product Grape Fruit1Document15 pagesStable Solid Deodorant Product Grape Fruit1sabunbeningNo ratings yet

- Gargle and Mouthwash ResearchDocument13 pagesGargle and Mouthwash ResearchArifah SabriNo ratings yet

- The Effect of Mouth Rinses On Composite ResinDocument54 pagesThe Effect of Mouth Rinses On Composite ResinvishalbalpandeNo ratings yet

- Ijpi 3 2 63 67Document5 pagesIjpi 3 2 63 67Rabiatul AdawiyahNo ratings yet

- Mynenivenkatasatya (2020), Effectiveness of A Novel Dentifrice Containing Stabilized Chlorine Dioxide, Sarkosyl, and Sodium FluorideDocument11 pagesMynenivenkatasatya (2020), Effectiveness of A Novel Dentifrice Containing Stabilized Chlorine Dioxide, Sarkosyl, and Sodium FluoridePhuong ThaoNo ratings yet

- Question From PracticeDocument8 pagesQuestion From PracticeBella Anisa PutriNo ratings yet

- Research Paper 1Document7 pagesResearch Paper 1reyankasab1.25No ratings yet

- Chitosan Nanoparticles For Loading of Toothpaste Actives and Adhesion On Tooth AnalogsDocument9 pagesChitosan Nanoparticles For Loading of Toothpaste Actives and Adhesion On Tooth AnalogsFatma MaharaniNo ratings yet

- Reminerlization in DentistryDocument29 pagesReminerlization in DentistrykeerthanaNo ratings yet

- TIEDocument4 pagesTIEIrwandi MuslimNo ratings yet

- Chemistry Investigatory ReportDocument16 pagesChemistry Investigatory ReportYash SaxenaNo ratings yet

- Mouthwashes and Their Use in Different Oral ConditionsDocument6 pagesMouthwashes and Their Use in Different Oral ConditionsBagus RahmawanNo ratings yet

- SJDS 22B186 191 PDFDocument6 pagesSJDS 22B186 191 PDFyudhistira pradiptyaNo ratings yet

- Mouthwashes and Their Use in Different Oral ConditionsDocument6 pagesMouthwashes and Their Use in Different Oral ConditionsReemALMousawiNo ratings yet

- Amalgam / Orthodontic Courses by Indian Dental AcademyDocument6 pagesAmalgam / Orthodontic Courses by Indian Dental Academyindian dental academyNo ratings yet

- Topical FluorideDocument55 pagesTopical Fluoridedisha 146jandial100% (1)

- Effect of Toothpaste Rinses Compared With Chlorhexidine On Plaque Formation During ADocument12 pagesEffect of Toothpaste Rinses Compared With Chlorhexidine On Plaque Formation During Avidyadhar kaipaNo ratings yet

- Endodontic SealersDocument138 pagesEndodontic SealersGayathri100% (2)

- 1 s2.0 S000281771730822X MainDocument3 pages1 s2.0 S000281771730822X MainHoàng Gia Bảo NguyễnNo ratings yet

- Effervescent Tablet of AlbendazoleDocument29 pagesEffervescent Tablet of Albendazolemails4virk100% (1)

- Keywords: Disintegration, Lyophilization, Orodispersible Tablets, SuperdisintegrantsDocument17 pagesKeywords: Disintegration, Lyophilization, Orodispersible Tablets, SuperdisintegrantsAsvina_Rikasih_1107No ratings yet

- Pit and Fissure Sealants FinalDocument54 pagesPit and Fissure Sealants FinalAj VishwadheebNo ratings yet

- Chemistry Project On Study of Effect of Potassium Bisulphite As Food Pre Servative Under Various ConditionsDocument24 pagesChemistry Project On Study of Effect of Potassium Bisulphite As Food Pre Servative Under Various ConditionsMahi SrivastavaNo ratings yet

- Difference Between Pulpotomy and PulpectomyDocument4 pagesDifference Between Pulpotomy and PulpectomyAnonymous Sb7suHTWNo ratings yet

- Review Literature On Toothpaste: AbstractDocument5 pagesReview Literature On Toothpaste: Abstractpiyush jainNo ratings yet

- ECC Prevention Requires Dental Home by Age 1Document4 pagesECC Prevention Requires Dental Home by Age 1CristinaNo ratings yet

- Denture AdheivesDocument77 pagesDenture Adheivesسینا ایرانیNo ratings yet

- Fluoride Toothpastes and Fluoride Mouthrinses For Home UseDocument11 pagesFluoride Toothpastes and Fluoride Mouthrinses For Home UsePînzariu GeorgeNo ratings yet

- Pediatric Dentistry Dental Caries: Dr. Mukhaled Louay Alfalluji B.D.S. M.SCDocument64 pagesPediatric Dentistry Dental Caries: Dr. Mukhaled Louay Alfalluji B.D.S. M.SCDr-Kinan Khalil ShraifyNo ratings yet

- Racecadotril Tablet FormulationDocument14 pagesRacecadotril Tablet FormulationRezaul RazibNo ratings yet

- ATROMATIC RESTORATIVE TRETMENT KKKKKKKKKKKKKDocument34 pagesATROMATIC RESTORATIVE TRETMENT KKKKKKKKKKKKKAbhishek ChourhaNo ratings yet

- Formulation and In-Vitro Evaluation of Fast Dissolving Oral Film of Furosemide Using A Combination of Natural and Synthetic DisintegrantDocument9 pagesFormulation and In-Vitro Evaluation of Fast Dissolving Oral Film of Furosemide Using A Combination of Natural and Synthetic DisintegrantVidyavardhini UshirNo ratings yet

- Us20060037158a1 PDFDocument10 pagesUs20060037158a1 PDFSchuster StephanNo ratings yet

- Calcium HydroxideDocument12 pagesCalcium HydroxideKarina KariadiNo ratings yet

- An Introduction To Toothpaste - Its Purpose, History and IngredientsDocument14 pagesAn Introduction To Toothpaste - Its Purpose, History and IngredientsInge Yuni LestaryNo ratings yet

- Group 2 Student List and Dental Sealant InformationDocument33 pagesGroup 2 Student List and Dental Sealant InformationFarhan AhmedNo ratings yet

- Chemistry ProjectDocument6 pagesChemistry ProjectshrutiNo ratings yet

- Jurnal ObturatorDocument4 pagesJurnal ObturatorEuginia YosephineNo ratings yet

- Formulation and Evaluation of Mouth Dissolving Film Containing RofecoxibDocument7 pagesFormulation and Evaluation of Mouth Dissolving Film Containing RofecoxibSathish SizzyNo ratings yet

- Eye care formulations guideDocument3 pagesEye care formulations guideMulayam Singh YadavNo ratings yet

- kp3 PDFDocument13 pageskp3 PDFdrvivek reddyNo ratings yet

- Advanced Drug Delivery Systems For Local Treatment of The Oral CavityDocument24 pagesAdvanced Drug Delivery Systems For Local Treatment of The Oral CavityanjaNo ratings yet

- Lecture 4 Pit and FissureDocument7 pagesLecture 4 Pit and FissureKhaled Al-haddadNo ratings yet

- The Effect of Oral Processing On The Viscosity of Thickened Drinks For Patients With DysphagiaDocument6 pagesThe Effect of Oral Processing On The Viscosity of Thickened Drinks For Patients With DysphagiaAmi R. VirueteNo ratings yet

- Cariology FellowshipDocument70 pagesCariology Fellowshipraghh roooNo ratings yet

- Pit and Fissure SealantsDocument5 pagesPit and Fissure SealantsAkram HatamNo ratings yet

- Orally Dissolving Strips: A New Approach To Oral Drug Delivery SystemDocument19 pagesOrally Dissolving Strips: A New Approach To Oral Drug Delivery SystemDuong NguyenNo ratings yet

- Print and SpiralDocument13 pagesPrint and Spiralsreelakshmi sreelakshmi.KKNo ratings yet

- DR Taylor JournalDocument9 pagesDR Taylor JournalDannii Lee WallaceNo ratings yet

- Hydrogen Peroxide: Benefits and Cures of Hydrogen Peroxide For Cleaning and HealthFrom EverandHydrogen Peroxide: Benefits and Cures of Hydrogen Peroxide For Cleaning and HealthNo ratings yet

- Oral Wound Healing: Cell Biology and Clinical ManagementFrom EverandOral Wound Healing: Cell Biology and Clinical ManagementHannu LarjavaNo ratings yet

- Hydrogen Peroxide Elixir: Top Extraordinary Uses of Hydrogen Peroxide for Beauty, Health, Wellness, Glowing Hair and Total Body HealingFrom EverandHydrogen Peroxide Elixir: Top Extraordinary Uses of Hydrogen Peroxide for Beauty, Health, Wellness, Glowing Hair and Total Body HealingRating: 3 out of 5 stars3/5 (2)

- Confectionery Gum and Jelly Products PectinsDocument31 pagesConfectionery Gum and Jelly Products PectinsercanefeogluNo ratings yet

- BSE 4514: UV Stability of Cellulose DerivativesDocument12 pagesBSE 4514: UV Stability of Cellulose Derivativesbalaji19745No ratings yet

- Sweet and CandiesDocument8 pagesSweet and Candiesbalaji19745No ratings yet

- Hyfoama VersawhipDocument16 pagesHyfoama Versawhipbalaji19745100% (2)

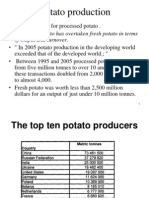

- Potato Production, Processing and Trade TrendsDocument125 pagesPotato Production, Processing and Trade Trendsbalaji19745No ratings yet

- VWR UserGuideDocument50 pagesVWR UserGuidebalaji19745No ratings yet

- Enzymes at WorkDocument64 pagesEnzymes at Workbalaji19745No ratings yet

- VWR UserGuideDocument50 pagesVWR UserGuidebalaji19745No ratings yet

- How To Choose StarchDocument20 pagesHow To Choose Starchbalaji197450% (1)

- GE JENBACHER t1000-1109Document16 pagesGE JENBACHER t1000-1109nemesis8835No ratings yet

- Hybrid Additive Manufacturing TechnologiesDocument11 pagesHybrid Additive Manufacturing TechnologiesmaheshboobalanNo ratings yet

- 4CH0 2C Que 20170118Document20 pages4CH0 2C Que 20170118Rajib KhanNo ratings yet

- Scale Formation in Reheating FurnaceDocument7 pagesScale Formation in Reheating FurnaceDeepti ShakyaNo ratings yet

- TEMPLATE - Fuel Voucher - ExternalDocument2 pagesTEMPLATE - Fuel Voucher - Externalmodarib26100% (1)

- 18 Ni (250) MaragingDocument68 pages18 Ni (250) MaragingsunsirNo ratings yet

- IChO32 Prep ProbDocument68 pagesIChO32 Prep ProbMuhammad GhifariNo ratings yet

- CHM 3301 Lab Report Structure SolidsDocument7 pagesCHM 3301 Lab Report Structure SolidsAida NordinNo ratings yet

- PDS Fucogel1.5P 0707 PDFDocument2 pagesPDS Fucogel1.5P 0707 PDFRafael Saldanha LopesNo ratings yet

- Hydrogenator DesignDocument9 pagesHydrogenator DesignA MNo ratings yet

- ASTM G112 - 92 (Reapproved 2009)Document7 pagesASTM G112 - 92 (Reapproved 2009)Mohamad ZandiNo ratings yet

- 9-04-03 Contaminated Land IGNDocument6 pages9-04-03 Contaminated Land IGNChris KyriacouNo ratings yet

- SDS University, UttarakhandDocument9 pagesSDS University, UttarakhandHemanginee DasNo ratings yet

- Quantifying Casein in Milk SamplesDocument10 pagesQuantifying Casein in Milk SamplesAshish YadavNo ratings yet

- Peroxyacetyl Nitrate (Pan) : Historical PerspectiveDocument8 pagesPeroxyacetyl Nitrate (Pan) : Historical PerspectivehjbhhbjNo ratings yet

- Kendriya Vidyalaya Sangathan: Chennai RegionDocument281 pagesKendriya Vidyalaya Sangathan: Chennai RegionAshray EapurNo ratings yet

- Aerosol 1Document44 pagesAerosol 1monoj5859No ratings yet

- Early1974 - Investigation of The Landslide at Walton's Wood, StaffordshireDocument2 pagesEarly1974 - Investigation of The Landslide at Walton's Wood, StaffordshireSantiago OsorioNo ratings yet

- Polymerization Reactions ExplainedDocument111 pagesPolymerization Reactions ExplainedHamsiah Sayah100% (1)

- Unit 11Document3 pagesUnit 11Bharath GowdaNo ratings yet

- Msds Light SpiritDocument9 pagesMsds Light SpiritrifkaNo ratings yet

- 1st Activity-Quiz ANSWERDocument6 pages1st Activity-Quiz ANSWERKate MendozaNo ratings yet

- Hess's Law WorksheetDocument2 pagesHess's Law WorksheetsaadixNo ratings yet

- Balanced Equations & Associated Calc's 05 QPDocument8 pagesBalanced Equations & Associated Calc's 05 QPlmao lmaoNo ratings yet

- Tests For Categorizing Carboxylic Acids and Their DerivativesDocument7 pagesTests For Categorizing Carboxylic Acids and Their DerivativesFaye ConstantinoNo ratings yet

- Chemical Bonds WorksheetDocument2 pagesChemical Bonds WorksheetJewel Mae MercadoNo ratings yet

- Jee-Main - Numeric Value Questions - ChemistryyyyyyyyyyyyyyyyyyyyDocument111 pagesJee-Main - Numeric Value Questions - ChemistryyyyyyyyyyyyyyyyyyyySai GokulNo ratings yet

- Calculating Entropy, Enthalpy Change and Solubilty Product of The Dissolution of Potassium BitartrateDocument14 pagesCalculating Entropy, Enthalpy Change and Solubilty Product of The Dissolution of Potassium BitartrateSam BarnesNo ratings yet

- QuestionDocument4 pagesQuestionPaula AquinoNo ratings yet

- Nutrition of Blueberry 10-7-11 MO StrikDocument60 pagesNutrition of Blueberry 10-7-11 MO StrikJesús Miguel Maguiña EspinozaNo ratings yet