Professional Documents

Culture Documents

Energy Conservation Through VFDs (Proposal)

Uploaded by

Shareef ChampOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Energy Conservation Through VFDs (Proposal)

Uploaded by

Shareef ChampCopyright:

Available Formats

ENERGYCONSERVATIONUSINGVARIABLESPEEDDRIVES

PreparedBy:HassaanRauf;ReviewedBy:FaisalNaeem

Variable Speed Drive (or Variable Frequency Drive) is an electronic controller for speed

adjustment of an electric motor. It varies the speed of the motor by varying the supply

frequencybeingfedtothemotor.

Traditionalmethodsofenergyconservationusedinthepastatprocessplantsmostlyinvolved

somesortofprocessoptimization.Butoverthelastcoupleofyears,amajorparadigmshifthas

beenobservedintheprocessindustryfromenergyconservationviewpointasthepotentialof

energyconservationthroughtheuseofVariableSpeedDriveshasbeenrecognized.

Tocontroltheprocessvariablesinaprocessindustry,threeavailableoptionsare:

1. ThrottlingControl(Bythrottlingavalveplacedatthedischargeofthedrivenmachine)

2. ON/OFFControl(ByturningthedrivenmachineON/OFFrepeatedlyasperrequirement)

3. VariableSpeedControl(Byvaryingthespeedofthedriverdrivingthemachine)

Firsttwomethodsarethetraditionalmethodsbeingusedatalmostalltheprocessplants(first

methodbeingthemostpopularone),bothinefficientfromtheenergyviewpoint.MethodNo.3

based on VFD (Variable Frequency Drive) based control is the latest and the most energy

efficientmethodwherethespeedofthemotor(driver)isvariedpreciselytocontrolthespeed

ofthedrivenmachineandthuscontroltheprocessvariablesinvolved.

Anexamplecanbequotedtocomparetheabovethreemethods.Tostoporslowdownafast

moving car, car driver first needs to release the accelerator followed by the application of

brakes. But with the throttling control, the method is analogous to pressing the brake pedal

withtheacceleratorfullpressed(i.e.throttlingthevalvetoachievethedesiredpressureand

flowwhereasthedrivenmachineisoperatingatfullspeed).Anenergyefficientalternativeon

the other hand would be to reduce the speed of the driven equipment to reduce the

pressure/flow(VFDbasedcontrol).

ThisconceptofENERCONthroughVFDshasbecomeverypopularworldwideinthelastcouple

ofyearsduetopersistingenergycrisisandindustriesareswitchingmoreandmoretowardsthis

VFDbasedprocesscontrol.

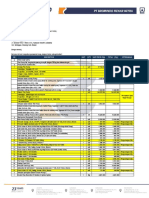

Recently Engro Chemicals Pakistan Limited (ECPL) has retrofitted its urea plant with this VFD

basedprocessvariablecontrolfortheenergysavingspurpose(ReportAttached).Thedetailsof

thisprojectareasfollows.

TotalProjectCost:PKR74.64Million

GuaranteedSavings:PKR17.39Million/year

PaybackPeriod:4.29years

AVANCEON (a strategic partner and distributor of ROCKWELL AUTOMATION) has completed

thisprojectatECPL.Themostimportantpointinthisprojectisthattherehasbeennocapital

investmentandECPLwillpaythroughtheenergysavingsinaperiodof4.29years.

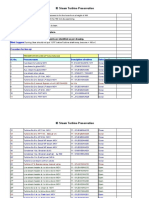

To show the potential of energy saving available through the use of this VFD based process

controlatFFC,astudyhasbeencarriedoutforthepumpmotorsetMP4302BatAmmoniaII

using a tool provided by ABB for Energy Savings Calculations. The results of this study are as

follows.

AnnualEnergySaving=34MWh

SavingPercentage=7.2%

AnnualSaving=295,116PKR

PaybackPeriod=3.0years

Followingistobenotedabouttheaboveresults.

1. Theaboveresultsarejustaroughestimationandareforelaborativepurposeonly.The

exactcalculationswouldneedadetailedstudyandextensivecollaborationfromallthe

departmentsincludingProcess,ProductionandMachinery.

2. The tool used for the above results calculates the payback period based just on the

energy savings. The fact that we can use this reduction in Natural Gas consumption

(achieved through the use of VFD based control) for increase in our UREA production

canreducethepaybackperiodevenfurther.

Recommendation:

BasedonthecurrentNGcurtailmentandforeseeingthefuture,FFCmustgoforthisVFDbased

ENERCONsolution.AVANCEONhasvisitedFFCandiswillingtocarryoutthesimilarprojectwith

FFConsametermsofpaybackperiodaswithECPL.Sothefeasibilitystudyfortheprojectneeds

tobestartedASAP.

You might also like

- Closed Loop Speed Control of 3-Phase Induction MotorDocument27 pagesClosed Loop Speed Control of 3-Phase Induction MotorRajesh kumar yadavNo ratings yet

- VF Constant Speed Control Single Phase Ac Induction MotorDocument3 pagesVF Constant Speed Control Single Phase Ac Induction MotorUddy ArdiaxaNo ratings yet

- VFD Ac-1Document16 pagesVFD Ac-1Sameer ZareNo ratings yet

- Energy Saving With Variable Speed Drives in Industry ApplicationsDocument7 pagesEnergy Saving With Variable Speed Drives in Industry ApplicationsHitesh PanigrahiNo ratings yet

- VFD Ac ReportDocument20 pagesVFD Ac ReportSameer ZareNo ratings yet

- UNIT - 3 Electrical DrivesDocument6 pagesUNIT - 3 Electrical DrivesMohit L.E. 008No ratings yet

- VFD Ac-3Document21 pagesVFD Ac-3Sameer ZareNo ratings yet

- Speed Control of Three Phase Induction Motor Using Arduino and V/F TechniqueDocument10 pagesSpeed Control of Three Phase Induction Motor Using Arduino and V/F TechniqueAnonymous oyUAtpKNo ratings yet

- Theory and Implementation of A Simple Digital Control Strategy For Brushless DC GeneratorsDocument12 pagesTheory and Implementation of A Simple Digital Control Strategy For Brushless DC GeneratorsYvv ReddyNo ratings yet

- Load Frequency Control For Hydropower Plants Using PID ControllerDocument4 pagesLoad Frequency Control For Hydropower Plants Using PID ControllersanthoshNo ratings yet

- Indirect Field Oriented Speed Control of An Induction Motor Drive by Using Pso AlgorithmDocument5 pagesIndirect Field Oriented Speed Control of An Induction Motor Drive by Using Pso AlgorithmĦana RababȜhNo ratings yet

- VFD Energy Efficiency GuideDocument100 pagesVFD Energy Efficiency Guidevijayk1968No ratings yet

- 528 Ici PC I Free Governor ModeDocument6 pages528 Ici PC I Free Governor ModeNguyễn Hữu LượngNo ratings yet

- Backstepping Adaptive Control of Dfig-Generators For Wind Turbines Variable-SpeedDocument11 pagesBackstepping Adaptive Control of Dfig-Generators For Wind Turbines Variable-Speedhamza gaNo ratings yet

- Speed Control of Single and Three Phase Induction Motor Using Full Bridge CycloconverterDocument10 pagesSpeed Control of Single and Three Phase Induction Motor Using Full Bridge Cycloconverter2019-EE-35 Hafiz NoumanNo ratings yet

- Variable Frequency Drive-VfdDocument6 pagesVariable Frequency Drive-VfdKumaraswamyNo ratings yet

- Variable Frequency Drive BasicsDocument8 pagesVariable Frequency Drive Basicssrithu1008100% (2)

- Abstract ToumiDocument16 pagesAbstract ToumiJean MartinNo ratings yet

- Induction Motors - Applications, Control and Fault Diagnostics (PDFDrive)Document383 pagesInduction Motors - Applications, Control and Fault Diagnostics (PDFDrive)Mohamed AmineNo ratings yet

- Speed Control of Ac Motor Using IgbtDocument23 pagesSpeed Control of Ac Motor Using IgbtARVIND0% (1)

- Final ReportDocument59 pagesFinal ReportAzeez SharieffNo ratings yet

- Shymgen System - Optimizing The Performance of Shaft Generator and Drive Train On Fishing VesselsDocument6 pagesShymgen System - Optimizing The Performance of Shaft Generator and Drive Train On Fishing VesselsADRIANSF1No ratings yet

- Speed Control of Induction MotorDocument23 pagesSpeed Control of Induction MotorRamuEdukullaNo ratings yet

- 2005 8Document18 pages2005 8Mehmed BrkicNo ratings yet

- What Is A Variable Speed DriveDocument6 pagesWhat Is A Variable Speed DriveTerdy MNNo ratings yet

- Speed Control of Three Phase Induction Motor Using PLC Under Open and Closed Loop ConditionDocument6 pagesSpeed Control of Three Phase Induction Motor Using PLC Under Open and Closed Loop ConditionTana AzeezNo ratings yet

- Control of Variable Frequency Drives With PLC: A ReviewDocument7 pagesControl of Variable Frequency Drives With PLC: A ReviewIAEME PublicationNo ratings yet

- Introduction About VFDDocument3 pagesIntroduction About VFDHuzaifa WasimNo ratings yet

- PareshDocument11 pagesPareshabhishekray6370No ratings yet

- Ieee TVT 2007 BenbouzidDocument10 pagesIeee TVT 2007 Benbouzidbellali badreNo ratings yet

- Control Systems For PMSG Based Small Wind Turbines: MotivationDocument1 pageControl Systems For PMSG Based Small Wind Turbines: Motivationteju2812No ratings yet

- Integrated Variable Speed DrivesDocument14 pagesIntegrated Variable Speed DrivesulatbookNo ratings yet

- 19 Speed PDFDocument8 pages19 Speed PDFNur Muhammad DzikriNo ratings yet

- 1 - Part - One - LecturesDocument74 pages1 - Part - One - Lecturesrida.hamza.muhammadNo ratings yet

- An Introduction To Rotor Flux ControlDocument14 pagesAn Introduction To Rotor Flux Controlgarethgriffiths1984No ratings yet

- Ahmed Chapter 1 PDFDocument11 pagesAhmed Chapter 1 PDFيوسف سامي عبد هاديNo ratings yet

- Electrical Power and Energy Systems: A. Khodabakhshian, R. HooshmandDocument8 pagesElectrical Power and Energy Systems: A. Khodabakhshian, R. HooshmandNabin AdhikariNo ratings yet

- New, Simple Blade-Pitch Control Mechanism For Small-Size, Horizontal-Axis Wind TurbinesDocument12 pagesNew, Simple Blade-Pitch Control Mechanism For Small-Size, Horizontal-Axis Wind TurbinesAmlan DasNo ratings yet

- Variable Frequency DriveDocument2 pagesVariable Frequency DriveDrazan GalusicNo ratings yet

- Fluid CouplingsDocument3 pagesFluid CouplingsSwaraj BiswasNo ratings yet

- Fuzzy Logic Speed ControlDocument12 pagesFuzzy Logic Speed ControlRasheed AhamedNo ratings yet

- Key Words:: Motion Control Is Required in Large No of Industrial and Domestic Applications LikeDocument11 pagesKey Words:: Motion Control Is Required in Large No of Industrial and Domestic Applications LikeVijay BhaskarNo ratings yet

- VFD Speed ControlDocument7 pagesVFD Speed ControlLICHEN YUNo ratings yet

- Design and Implementation of Gain Scheduling Linear Quadratic Regulator (LQR) in Speed Control of Three Phase Induction MotorDocument2 pagesDesign and Implementation of Gain Scheduling Linear Quadratic Regulator (LQR) in Speed Control of Three Phase Induction Motorfadli wardanaNo ratings yet

- Pump Control With Variable Frequency Drives - Case Study: Hitachi America, Ltd.Document4 pagesPump Control With Variable Frequency Drives - Case Study: Hitachi America, Ltd.Hitachi America, Ltd., Industrial Components and Equipment DivisionNo ratings yet

- Variable Frequency Drives IntroductionDocument11 pagesVariable Frequency Drives Introductionvigneshwaranj87No ratings yet

- Governor ResponseDocument3 pagesGovernor ResponseLim VinNo ratings yet

- Narrow Band in A Power System Operation. Frequency in A Power SystemDocument3 pagesNarrow Band in A Power System Operation. Frequency in A Power SystemSenthil NathanNo ratings yet

- Eee-Vii-Industrial Drives and Applications (10ee74) - NotesDocument90 pagesEee-Vii-Industrial Drives and Applications (10ee74) - NotesMohammed AlhakeemiNo ratings yet

- Dynamic Performance Application of A Variable Speed Centrifugal PumpDocument10 pagesDynamic Performance Application of A Variable Speed Centrifugal PumpTon PhichitNo ratings yet

- My ThesisDocument28 pagesMy ThesisDillip kumar mishraNo ratings yet

- VFD SDocument25 pagesVFD Svasanth11kvNo ratings yet

- Wind Turbine System: P= ρ C A V ρ C A VDocument4 pagesWind Turbine System: P= ρ C A V ρ C A Vbantyrock9671No ratings yet

- Regenerativ BrakingDocument5 pagesRegenerativ BrakingAnkit SinghNo ratings yet

- Electric Drives - EPM 451 - Module1modifiedDocument68 pagesElectric Drives - EPM 451 - Module1modifiedasmrsamir5No ratings yet

- National Institute of Technology, Rourkela: Department of Electrical EngineeringDocument11 pagesNational Institute of Technology, Rourkela: Department of Electrical Engineeringvineeth kumarNo ratings yet

- I Dont KnowDocument4 pagesI Dont KnowDarksky PaulNo ratings yet

- Electric Motor Control: DC, AC, and BLDC MotorsFrom EverandElectric Motor Control: DC, AC, and BLDC MotorsRating: 4.5 out of 5 stars4.5/5 (19)

- Electrical Motor Products: International Energy-Efficiency Standards and Testing MethodsFrom EverandElectrical Motor Products: International Energy-Efficiency Standards and Testing MethodsNo ratings yet

- Diesel GeneratorDocument54 pagesDiesel GeneratorShareef ChampNo ratings yet

- TG-701A Breaker ResultsDocument1 pageTG-701A Breaker ResultsShareef ChampNo ratings yet

- Assignment 1Document2 pagesAssignment 1Shareef ChampNo ratings yet

- Travelling Waves 1Document12 pagesTravelling Waves 1Shareef ChampNo ratings yet

- C-1 MV BreakerDocument1 pageC-1 MV BreakerShareef ChampNo ratings yet

- Busines Plan-Juice StopDocument41 pagesBusines Plan-Juice StopShareef ChampNo ratings yet

- E S B M: Ntrepreneurship and Mall Usiness AnagementDocument1 pageE S B M: Ntrepreneurship and Mall Usiness AnagementShareef ChampNo ratings yet

- MV Breaker MeggeringDocument1 pageMV Breaker MeggeringShareef ChampNo ratings yet

- Title:: Multi-Sensor Based Detection, Identification and Notification of Abnormal Driving BehaviorDocument2 pagesTitle:: Multi-Sensor Based Detection, Identification and Notification of Abnormal Driving BehaviorShareef ChampNo ratings yet

- SectionB GradesDocument2 pagesSectionB GradesShareef ChampNo ratings yet

- Simulation Report: Hassan Muzaffar Qureshi 2013-EE-67 Sec B' Exp # 10Document4 pagesSimulation Report: Hassan Muzaffar Qureshi 2013-EE-67 Sec B' Exp # 10Shareef ChampNo ratings yet

- DF250A 300A SuzukiDocument128 pagesDF250A 300A SuzukiWidhana FajarNo ratings yet

- Manual de Partes FC 350 Motor 2020 089352t enDocument24 pagesManual de Partes FC 350 Motor 2020 089352t enrutasuramericaNo ratings yet

- Caterpillar 793FDocument28 pagesCaterpillar 793FGonzalo Donoso RecasensNo ratings yet

- Clow PRVDocument10 pagesClow PRVjabh311No ratings yet

- Motor Diesel Iveco CamionDocument478 pagesMotor Diesel Iveco Camionjuanka_huaman100% (1)

- Fluidomat Coupling CatalogueDocument15 pagesFluidomat Coupling CatalogueAnonymous xrBCp9EjNo ratings yet

- Cryostar Machinery November 07Document38 pagesCryostar Machinery November 07Tino KhamphasithNo ratings yet

- Asbuilt Drawing Km2-ModelDocument2 pagesAsbuilt Drawing Km2-ModelHanif HalimNo ratings yet

- Electrical Tools and MaterialsDocument36 pagesElectrical Tools and MaterialsRonaldo Paloma100% (2)

- SPACE TURN LB2000 EX2-E-11a-300Feb2014 PDFDocument15 pagesSPACE TURN LB2000 EX2-E-11a-300Feb2014 PDFigorNo ratings yet

- Microsoft PowerPoint - OPERATING PRINCIPLE OF AIRCRAFT PISTON ENGINEDocument28 pagesMicrosoft PowerPoint - OPERATING PRINCIPLE OF AIRCRAFT PISTON ENGINEMoses DevaprasannaNo ratings yet

- Honda-1997 Cr125Document226 pagesHonda-1997 Cr125Eat At100% (1)

- Automation Lab ManualDocument99 pagesAutomation Lab Manualmanikandan_murugaiahNo ratings yet

- Electrical Tools Supplies and MaterialsDocument32 pagesElectrical Tools Supplies and MaterialsJoy Cabug Lemosnero100% (1)

- 250 XC-W USA 2007: Spare Parts Manual: EngineDocument24 pages250 XC-W USA 2007: Spare Parts Manual: EnginecharlesNo ratings yet

- IB Steam Turbine PreservationDocument6 pagesIB Steam Turbine PreservationUdhayakumar VenkataramanNo ratings yet

- Amreya Petroleum Refinery Company (Aprc) : Atlas Copco CrepelleDocument9 pagesAmreya Petroleum Refinery Company (Aprc) : Atlas Copco Crepelleالبريمه المصريهNo ratings yet

- Argapura, PT - Rvs.04ENG (Viking) - 044 - 1209Document4 pagesArgapura, PT - Rvs.04ENG (Viking) - 044 - 1209Tristan100% (1)

- NEMA Motor Shaft Diameters PDFDocument3 pagesNEMA Motor Shaft Diameters PDFluiscontentoNo ratings yet

- Nissan Livina L11 - Engine Control SystemDocument629 pagesNissan Livina L11 - Engine Control SystemH. Yusmira (Kang Otto)No ratings yet

- Manual Industrial Overlock JackDocument54 pagesManual Industrial Overlock JackMario DM67% (3)

- Golf SupliersDocument1 pageGolf SupliersFrederico Rad FernandezNo ratings yet

- Electrical Interview Questions With Answers DC Machines 1: Electicalquestion 1: What Is Electrical Machine?Document4 pagesElectrical Interview Questions With Answers DC Machines 1: Electicalquestion 1: What Is Electrical Machine?Priyesh GuptaNo ratings yet

- A Study On Vehicle Differential SystemDocument4 pagesA Study On Vehicle Differential SystemNguyễn Thị Minh ThuNo ratings yet

- Omex 600 Wiring 600 055Document54 pagesOmex 600 Wiring 600 055bertiemurphyNo ratings yet

- Lab Sheet CNC TurningDocument4 pagesLab Sheet CNC TurningSeiichi HaruhiNo ratings yet

- Mechanical Power TransmissionDocument15 pagesMechanical Power Transmissionabdullah 3mar abou reashaNo ratings yet

- MSD Axially Split Multistage Pump E00577Document6 pagesMSD Axially Split Multistage Pump E00577chijioke ekekeNo ratings yet

- Altis WiringDocument80 pagesAltis Wiringjaesz80% (10)

- G Drive Engines Weichai Oman MuscatDocument14 pagesG Drive Engines Weichai Oman MuscatmustafaNo ratings yet