Professional Documents

Culture Documents

Engine Water Treatments

Uploaded by

Mullah FassudinCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Engine Water Treatments

Uploaded by

Mullah FassudinCopyright:

Available Formats

4

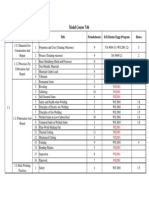

Corrosion Controller CWT

Liquid Engine cooling water corrosion and scale inhibitor

Description

Aquamarine Corrosion Controller is an easy to use liquid that inhibits electrolytic

corrosion, cavitational corrosion and controls scale and sludge. It is also compatible

with a wide range of hoses, gaskets and seals.

Water Treatments

Water Treatments

Aquamarine Corrosion Controller passivates metal surfaces and combines with

sludges, scale and rust deposits to allow their gradual removal.

Uses:

Internal combustion engine and compressor cooling systems.

Heat pump water systems.

Recirculating cooling water systems.

Hot water heating systems.

Suitable for jacket water used in evaporator feed heaters.

Chilled water systems.

Hot chilled water systems.

Ice melting water systems.

Compatible with Ethylene Glycol used as antifreeze.

Aquamarine Corrosion Controller should be fed directly by the bypass pot feeder

to the main circulating line or into the cooling water expansion tank.

(For systems using totally de-ionised water raise nitrite levels to 1700 p.p.m. as

corrosion is more likely.)

Control is based on nitrite concentration and additions should be made after

representative sampling. Aquamarine test kit is available for accurate checking.

Target = 1500 p.p.m.

Nitrite p.p.m.

Ltrs/1000 Ltrs make up

Target Parameters

pH

Nitrite

Chloride

Total Hardness CaCO3

0

12.5

500

8.3

1000

4.2

1500

0

Between 8.3 and 10

1500 p.p.m.

Less than 50 p.p.m.

Less than 100 p.p.m.

Note: Log sheets should be returned to Aquamarine by fax e.mail or post on a

monthly basis for analysis address details at front of brochure. Log sheets are

supplied free of charge. A full report will be forwarded back by return with any

comments or recommendations.

Visit: www.aquamarinechemicals.com for log sheet downloads.

Email your log sheets to us monthly at: logs@bayer-wood.co.uk

13

Water Treatments

4b

Corrosion Controller 30 Concentrate

Liquid Engine cooling water corrosion and scale inhibitor

Aquamarine Corrosion Controller is an easy to use concentrated liquid that inhibits electrolytic

corrosion, navigational corrosion and controls scale and sludge. It is also compatible with a

wide range of hoses, gaskets and seals.

Aquamarine Corrosion Controller passivates metal surfaces and combines with sledges,

scale and rust deposits to allow their gradual removal. It is suitable for low, medium and high

speed engines.

To clean out a cooling water system which has been treated previously with another chemical

or has oil or scale contamination use the Diesel engine cooling water Inline Cleaner (Product

No 14).

For oil only contamination use the Aquawash in circulation at a dilution of 0.5 and 7 litres per

tonne of cooling water dependant on degree of contamination. Circulate for 1-2 hours, empty

and then flush with clean water.

Uses

Internal combustion engine and compressor cooling systems

Heat pump water systems

Re-circulating cooling water systems

Hot water heating systems

Suitable for jacket water used in evaporator feed heaters

Chilled water systems

Hot chilled water systems

Ice melting water systems

Compatible with Ethylene Glycol used as antifreeze.

Aquamarine Corrosion Controller should be fed directly by the bypass pot feeder to the main

circulating line or into the cooling water expansion tank.

(For systems using totally de-ionised water raise nitrite levels to 1700 p.p.m. as corrosion is

more likely.)

Control is based on nitrite concentration and additions should be made after

representative sampling. Aquamarine test kit is supplied for accurate checking.

Nitrite Target = 1500 p.p.m

Nitrite p.p.m

500 1000 1500

Chlorides should be less than 50 p.p.m

PH should be between 8.3 and 10

Litres / 1000 litres make up / Dose

3.3 2.2 1.1

Try to keep Nitrites within the parameters described.

Low Nitrite levels will give rise to an unprotected system and ultimately corrosion problems.

Log sheets should be returned to Aquamarine on a monthly basis for analysis by email or fax.

A report will be sent back to you

25 Litre Pack Size

Ref. No. J100 6850-99-239-2381

Visit: www.aquamarinechemicals.com for log sheet downloads.

Email your log sheets to us monthly at: logs@bayer-wood.co.uk

14

Aluminium Corrosion Controller

Description

A biostable, fully synthetic fluid that gives significantly high levels of corrosion protection to

water systems even at low concentrations and possesses extremely good scale inbibition.

Due to its unique formulation which uses a combination of nitrate free properties with low

foaming tendencies and the ability to protect a variety of metals in cleaning and recirculatory

systems such as hot water radiators and cooling pipes.

Water Treatments

Suitable for large enclosed systems

Low foaming

Compatible with a full range of metals

Biostable

Effective in hard and soft waters

Low odour

Widely used and accepted

Does not produce sticky residues

Application

Suitable for a wide range of ferrous and non-ferrous materials including copper and

aluminium based alloys. Also outperforms nitrate-based fluids when in contact with mild

steel and cast iron.

Recommended dilution rate: 2.0% - 5.0%

Suitable for enclosed systems and testing equipment at 0.5% - 1.0% dilution

IP 287 Corrosion Test: 2.5%BP

Available in 5, 25, 205 and 1000 litre containers

Ref. No. J100 6850-99-666-5296

Visit: www.aquamarinechemicals.com for log sheet downloads.

Email your log sheets to us monthly at: logs@bayer-wood.co.uk

15

Water Treatments

Antifreeze

AQUAMARINE UNIVERSAL ANTIFREEZE

Description

Aquamarine Universal Anti-freeze is an Ethylene Glycol based anti-freeze, which

contains inhibitors to protect radiators and engines, including aluminium engines,

against rust and corrosion.

The anti-freeze should be left in cooling systems throughout the year and will thus

give all year round corrosion protection.

Aquamarine Universal Anti-freeze contains no methanol and has a low flammability.

It is biodegradable and does not present an environmental problem.

Note: Whilst ethylene glycol is biodegradable it is TOXIC to animal and human

metabolisms.

Uses

Ethylene Glycol based anti-freeze

Conforms to requirements of British Standard BS 6580: 1992

Contains no methanol

Contains effective inhibitor to give all year round protection against rust and corrosion

Suitable for all commonly available commercial engine cooling systems including

aluminium engines.

Application

A 25% solution (1 part anti-freeze to 3 parts water) will remain fluid down to 14C.

In severe winter conditions, increase to a 33% solution (1 part anti-freeze to 2 parts water)

to give protection down to 17C.

NB: Antifreeze used in engine & most applications should be changed annually to give

optimum protection

Pack Size 25 litres

Ref. No. J100 6850-99-797-2246

16

Evaporator Scale Controller

Uses

This product is used for scale and foaming control in marine all temperature range

evaporators and heat exchangers, and for scale and sludge control in boiler

water systems

Removes existing scale by in-service cleaning

Prevents scale formation

Low foam properties reduce evaporator foaming

Low toxicity

Water Treatments

Typical Uses

To prevent scale and foam formation in marine evaporators

To control the formation of scale deposits in heat exchangers and boilers

For scale removal use Aquamarine Descaling Liquid

Dose

When used for treating marine evaporators, the product should be dosed continuously

into the sea water feed line where all of the treatment will enter the evaporator. Since

Evaporator Scale Controller is highly concentrated it should be pre-mixed with cool

distillate in a separate dosing tank and dosed via a flow meter or metering pump.

The recommended daily dose rate is dependent on brine density (S.G.) which should

be checked daily with a hydrometer and is normally as indicated below.

Dosage

The standard dosage, applicable to most systems, is 0.01 litres of Evaporator Scale

Controller per tonne of distillate produced. This is based on the production capacity of the

evaporator. In a standard 25 metric tonne/day evaporator use 25 x 0.010 = 0.25ltrs

Evaporator Scale Controller/day.

Setting the Flow Rate

The treatment is added to the dosage tank and mixed with water.

For example: With the 0.25 litres of Evaporator Scale Controller add sufficient water to

make up 50 litres of liquid.

Flow rate calculation:

Flow rate = 50 litres = 35ml/min setting

24 x 60

This will then last 24 hours.

N.B.

The brine density should not exceed a density of 1.038. The scaling potential increases

rapidly over this level. An increase in the amount of Evaporator Scale Controller used will

assist in retaining potential scale forming salts in suspension.

For example: If the density rises to 1.050 the dosage should be 0.06 litres/tonne of water

produced.

Pack Size 25 Litres

Ref. No. J150 6850-99-149-8932

17

Water Treatments

Biological Growth Controller cooling water treatment biocide enclosed cooling water systems

Description

Aquamarine Biological Growth Controller includes a safe biocide for preventing and

controlling marine growth in fresh or seawater cooling systems. It also protects against

electrolytic and acid corrosion by film formation. Fully biodegradable and non-oil based

it is safe to discharge.

Aquamarine Biological Growth Controller is also effective against bacteria and algae in oil

and contaminated water.

Uses

Ballast tank cleaning

Mollusc control in seawater intakes and cooling systems

Algae, shellfish and micro-organism controller

Trim tank cleaning

Closed circuit cooling system cleaning

Suitable in systems operating up to 130oC

Fuel and lube oil decontamination

Application

In water systems dosage should be varied between 1 litre/tonne of water in a closed

circuit system up to 10 litres/tonne for Static Ballast Tanks or Trim tanks.

In sea water intakes and cooling systems a concentration of 6 p.p.m. over a period of one

hour is sought. This period is sufficient to remove the foulants before adult development,

after which they are difficult to control. In the absence of the availability of Aquabac 80 this

product may be used at 6 p.p.m. in the water phase of fuel oil before separation.

Pack Size 25 litres

For specific Fuel Oil Treatment use Aquabac 80 MBC treatment.(see fuel treatments)

Summary

A very strong broad-spectrum product with biocide characteristics for fuel, water or lube

oil microbiological contamination.

25 litre Drum

Ref. No. J150 6840-99-433-2417

18

Aquamarine CW25B Chilled Water Plant Treatment

Description

Aquamarine CW25B contains sodium nitrite and a copper corrosion inhibitor. It is a

very effective corrosion inhibitor for modern air conditioning chilled water systems,

and hot water heating boilers. It is compatible with alcohol and glycol anti-freezes.

Aquamarine CW25B is a complete, easily applied, single solution treatment which

provides economical waterside protection for mixed metal systems containing copper,

brass and ferrous based metals.

Water Treatments

36

A biocide is incorporated in the formulation to prevent bacterial contamination.

Specification

Physical State

Pale Yellow Liquid

SG

1.190

Dosing

5 litre Aquamarine CW25B per cubic metre water in system.

Feeding

AQUAMARINE CW25B is usually added to closed systems by utilising a pot feeder,

or by a manually operated chemical injection pump.

Testing and Control

A simple test procedure is available for control of AQUAMARINE CW25B recommended

normal concentration level is 800 1200 p.p.m of Nitrite.

Handling

Aquamarine CW25B is alkaline and contact with skin, eyes and clothing should be avoided.

In case of contact flush with water.

Please refer to material safety data sheet for detailed handling/storage instructions.

Packaging

Aquamarine CW25B treatments are shipped in 25 litre and 205 litre non returnable drums.

Ref. No. J150 6850-99-724-4377

19

Water Treatments

37

Marisol CW

Approved Cooling Water Scale and Corrosion Inhibitor

MARISIOL CW is a liquid compound, based on nitrite/borate products, improved with

active agents, which together protect iron and metal against corrosion, scale and deposits.

MARISOL CW contains no chromates. It can be mixed with ordinary anti-freeze (glycol)

or water containing similar cooling water additives. It is not sensitive to moderate

over-dosing. Recommended limits should be considered along with engine manufacturers

instructions.

MARISIOL CW is developed for use in diesel engines and main and auxiliary cooling

water systems, not containing aluminium; MARISOL CW should preferably be used

together with evaporated or deionised water with hardness as close to zero as possible.

This type of water is chemically clean and forms less deposits. However, it is also more

corrosive and contains more oxygen and needs careful chemical treatment. Ordinary tap

water would be avoided but could possibly be accepted if no other water is available.

The hardness must not exceed 10ppm and the pH shall be such that treated water does

not exceed pH 10. MARISOL CW has been approved according to the international, and

by engine manufacturers commonly accepted FW method, (Forschungs Vereinigung

Verbrennungskraftmashine), Frankfurt. Individual approval is given by New Sulzer Diesel,

MAN/B&W, Wrzil Diesel, etc.

Dose Rate

Initial Dose

Dose an untreated system with 6 litres MARISOL CW per m of cooling water to reach a minimum level of 1000 p.p.m and 9 litres for a medium level of 1500ppm.

If tests show too low concentration , an additional dosage of (q) litre/m3 should be made

to reach the medium level of 1500 p.p.m: q = 9 (0.006 x C)

Example

Test figure show 800 p.p.m Nitrite in a 15m3 cooling water system.

q = 9 (0.006 x 800) = 4.2 litres/m3 = 4.2 x 15 = 63 litres to be added.

Dosage should be performed by a dosing pump or manually in the header tank for 20-30

minutes, providing that at least part of the water is circulating through.

Pack Size: 25 litres

Ref. No. J150 6850-99-192-5292

Visit: www.aquamarinechemicals.com for log sheet downloads.

Email your log sheets to us monthly at: logs@bayer-wood.co.uk

20

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Remote Citrix Access For Students v2.0Document3 pagesRemote Citrix Access For Students v2.0Mullah FassudinNo ratings yet

- HNC Shipbuilding Award GuideDocument27 pagesHNC Shipbuilding Award GuideMullah FassudinNo ratings yet

- Chief Engineer (Yacht)Document1 pageChief Engineer (Yacht)Mullah FassudinNo ratings yet

- 1121 - Associate Dean Nautical ScienceDocument8 pages1121 - Associate Dean Nautical ScienceMullah FassudinNo ratings yet

- Higher Waiting ListDocument3 pagesHigher Waiting ListMullah FassudinNo ratings yet

- DN3X 35 Electrical GU2 Project MilestonesDocument5 pagesDN3X 35 Electrical GU2 Project MilestonesMullah FassudinNo ratings yet

- Recruitment and Admissions ModuleDocument76 pagesRecruitment and Admissions ModuleMullah FassudinNo ratings yet

- Ddr2f34 Sqa Unit SpecDocument9 pagesDdr2f34 Sqa Unit SpecMullah FassudinNo ratings yet

- CoG - Presentation-Women in EngineeringDocument15 pagesCoG - Presentation-Women in EngineeringMullah FassudinNo ratings yet

- Min - 565 McaDocument6 pagesMin - 565 McaMullah FassudinNo ratings yet

- Watchkeeping GuidanceDocument73 pagesWatchkeeping GuidanceMullah FassudinNo ratings yet

- Document CoGCDocument20 pagesDocument CoGCMullah FassudinNo ratings yet

- DG2V 35 Electronics Graded Unit 2Document75 pagesDG2V 35 Electronics Graded Unit 2Mullah FassudinNo ratings yet

- Bursting of Starting Air Compressor: No. 1/99 Edited by DTP-245 Ship Type: Size (GRT) : Built YearDocument1 pageBursting of Starting Air Compressor: No. 1/99 Edited by DTP-245 Ship Type: Size (GRT) : Built YearMullah FassudinNo ratings yet

- Brief Overview Generator Free Ebook Part1 FinalDocument44 pagesBrief Overview Generator Free Ebook Part1 FinalSushant SinghNo ratings yet

- CALM PowerPoint Template 2015Document8 pagesCALM PowerPoint Template 2015Mullah FassudinNo ratings yet

- Mitigating Circumstances Application Form 2016Document3 pagesMitigating Circumstances Application Form 2016Mullah FassudinNo ratings yet

- Progress Report 4Document10 pagesProgress Report 4Mullah FassudinNo ratings yet

- Hydraulic Fluid Purpose & PropertiesDocument36 pagesHydraulic Fluid Purpose & PropertiesMullah FassudinNo ratings yet

- Brief Overview Generator Free Ebook Part1 FinalDocument44 pagesBrief Overview Generator Free Ebook Part1 FinalSushant SinghNo ratings yet

- Brochure LNG Shipping Solutions DNVGLDocument8 pagesBrochure LNG Shipping Solutions DNVGLMullah Fassudin100% (1)

- Hydraulic Fluid 3 DocumentsDocument45 pagesHydraulic Fluid 3 DocumentsMullah FassudinNo ratings yet

- Autocad NotesDocument53 pagesAutocad Notesadnan100% (7)

- Brief Overview Generator Free Ebook Part1 FinalDocument44 pagesBrief Overview Generator Free Ebook Part1 FinalSushant SinghNo ratings yet

- Workshop Guide To The Various MachinesDocument27 pagesWorkshop Guide To The Various MachinesMullah FassudinNo ratings yet

- F914 34 Marine Engineering Graded Unit 1Document10 pagesF914 34 Marine Engineering Graded Unit 1Mullah FassudinNo ratings yet

- DG2V 35 Electronics Graded Unit 2Document75 pagesDG2V 35 Electronics Graded Unit 2Mullah FassudinNo ratings yet

- Course Work1Document6 pagesCourse Work1Mullah FassudinNo ratings yet

- EFQM 16march16 Final After CorrectionDocument66 pagesEFQM 16march16 Final After CorrectionMullah FassudinNo ratings yet

- Manual Fuel Pump ControlDocument1 pageManual Fuel Pump ControlMullah FassudinNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- NTPC PresentationDocument222 pagesNTPC PresentationReaderRRGHT100% (2)

- Feedwater System 2Document45 pagesFeedwater System 2ika yuliyani murtiharjonoNo ratings yet

- Marine Boiler Fundamentals GuideDocument73 pagesMarine Boiler Fundamentals GuideMithunNo ratings yet

- JWP-26-C100 92&92 DrawingDocument82 pagesJWP-26-C100 92&92 DrawingSANDEEPNo ratings yet

- Data Sheet Turbodisc Drier PDFDocument2 pagesData Sheet Turbodisc Drier PDFDaniel SouzaNo ratings yet

- 7.VA1-YEA-00100-I-I1-DCD-0110 - Rev DDocument10 pages7.VA1-YEA-00100-I-I1-DCD-0110 - Rev DKevin NgoNo ratings yet

- Fat Splitting: Fatty Acid Isolation and Glycerine RecoveryDocument41 pagesFat Splitting: Fatty Acid Isolation and Glycerine RecoveryAzhan FikriNo ratings yet

- Shipboard Water Treatment Manual 4th EditionDocument72 pagesShipboard Water Treatment Manual 4th Editionusna1970No ratings yet

- Repeat Situations in Cycle Chemistry ControlDocument22 pagesRepeat Situations in Cycle Chemistry ControlAnonymous lHiaDxlpkxNo ratings yet

- MECS - SyllabusDocument3 pagesMECS - SyllabusRagunath PalanichamyNo ratings yet

- Coast Guard Exam 2Document32 pagesCoast Guard Exam 2MustafaNo ratings yet

- N-015235 v00 DPU-2-36-C125 OPDocument124 pagesN-015235 v00 DPU-2-36-C125 OPkimurapedrosNo ratings yet

- Mep Multi Effect Plate Evaporator DatasheetDocument4 pagesMep Multi Effect Plate Evaporator DatasheetKarim Sowley DelgadoNo ratings yet

- Waste Heat Recovery System (WHRS)Document32 pagesWaste Heat Recovery System (WHRS)Дмитрий ЗинченкоNo ratings yet

- Imo (7 04Document21 pagesImo (7 04drthuhan100% (1)

- 2658 Dometic Digital Operations Manual 20090312 5321Document24 pages2658 Dometic Digital Operations Manual 20090312 5321Anonymous M0OEZEKoGi100% (1)

- Unitest - CBT - Part3 - ManualDocument127 pagesUnitest - CBT - Part3 - ManualAkejelu GeorgeNo ratings yet

- ELISABETH Maersk - Machinery PDFDocument274 pagesELISABETH Maersk - Machinery PDFpNo ratings yet

- High Pressure BoilersDocument3 pagesHigh Pressure BoilersRajendrakumar B VariaNo ratings yet

- Abstracts 01 2023 PDFDocument2 pagesAbstracts 01 2023 PDFVikram KumarNo ratings yet

- Soot Deposits and Fires in Exhaust Gas BoilerDocument21 pagesSoot Deposits and Fires in Exhaust Gas BoilerJose G. CastilloNo ratings yet

- FWG and Heat Recovery System PDFDocument7 pagesFWG and Heat Recovery System PDFgkmkgmNo ratings yet

- Nuradi Maintain A Safe Engineering Watch - pdf-1Document74 pagesNuradi Maintain A Safe Engineering Watch - pdf-1Dimas wangsit indraprasti0% (5)

- q511 1st Assist 2018 GeneralsDocument31 pagesq511 1st Assist 2018 Generalsedgar munizNo ratings yet

- Fresh Water Generator: Shipboard Distillation SystemDocument11 pagesFresh Water Generator: Shipboard Distillation SystemGuruNo ratings yet

- Boiler - Operation and Maintenance of BoilersDocument57 pagesBoiler - Operation and Maintenance of Boilersdumitrescu viorel80% (5)

- Final Drawing With Instruction Manual For Fresh Water Genera PDFDocument79 pagesFinal Drawing With Instruction Manual For Fresh Water Genera PDFPhay Thwin Htun83% (6)

- Alfa Laval Manaul 26 C 100 PDFDocument131 pagesAlfa Laval Manaul 26 C 100 PDFMARCO VERAMENDINo ratings yet

- Sondex SFD6Document160 pagesSondex SFD6a.amangazinov1995No ratings yet

- HRSGDocument36 pagesHRSGDumitrescuNo ratings yet