Professional Documents

Culture Documents

V3i4 Ijertv3is040786 PDF

Uploaded by

sarikagOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

V3i4 Ijertv3is040786 PDF

Uploaded by

sarikagCopyright:

Available Formats

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 4, April - 2014

Design of Sewage Treatment Plant for a Gated

Community

Bharathi Bhattu1, Prof. Murthy Polasa (P.E.) 2

1, 2

Department of Civil Engineering,

Sree Dattha Institute of Engineering & Science, Hyderabad,

Andhra Pradesh, India.

I.

INTRODUCTION

The tertiary treatment is an additional treatment beyond

Secondary. Tertiary Treatment can remove more than 99%

of all the impurities from Sewage, producing an effluent of

almost drinking water quality. .Disinfection, typically with

chlorine can be the final step before discharge of effluent

[1, 2].

II. TYPES OF TREATING UNIT OPERATIONS

The different types of Unit operations involved in this

study are show in table 1, table 2 and table 3.

Table 1. Physical unit operations

Screen Chamber

A liquid waste of domestic or Industrial Origin which is

Foul in nature and consists of 99.9% water is called

sewage. A Sewage Treatment Plant treats the sewage

coming from various sources and brings it to the acceptable

levels of impurity and then it is disposed. Sometimes the

results meet the characteristics of normal drinking water

and their mineral value. The Treatment process has a series

of treating units which are categorized under primary

(mechanical) treatment, secondary (biological) treatment

and tertiary (disinfection) treatment.

The primary treatment removes gross, suspended

& floating solids from raw sewage. It includes Screening to

trap solid objects and Sedimentation by gravity to remove

Suspended Solids. This level is sometimes referred to as

Mechanical Treatment although chemicals are often used

to accelerate the Sedimentation process. Primary Treatment

can reduce the BOD of the incoming Wastewater by 2030% and the Total Suspended Solids by some 50-60%.

Primary Treatment is usually the first stage of Wastewater

Treatment.

The secondary treatment removes the dissolved

organic matter that escapes Primary Treatment. This is

achieved by microbes consuming the organic matter as

food & converting it to Carbon Dioxide, water & energy

for their own growth & reproduction. This Biological

process is then followed by additional Settling tanks i.e.,

IJERTV3IS040786

Secondary Sedimentation Tank, to remove more of the

Suspended Solids.

IJE

RT

Abstract-The main objective of this study is to carry out

design of a Sewage Treatment Plant for a Gated

Community. The sewage released from each source (63

lots + 1 shopping mall) located in the Gated Community

is grouped together and the total discharge is

calculated. For the calculated discharge the Sewage

Treatment Plant is designed by adopting biological

treatment method. It includes physical, chemical, and

biological processes to remove floating material,

suspended solids and dissolved organic matter. The

designs are drawn using AUTOCAD 2010 software. By

this design it can be said that the minimal changes in

Detention time can give better results in treating sewage

designed for small scaled purposes.

Keywords -Discharge, floating material, suspended solids,

dissolved organic matter, Detention Time.

Grit Chamber

Removal of coarse and readily settle

able solids from the waste water by

screens.

To separate out the grit, gravel, sand

etc. from the sewage of size 2mm or

large with flow velocity

(0.2-0.3) m/sec.

Table 2. Chemical unit operations

Sedimentation

Tank

To remove impurities by the action of the

natural forces i.e., by gravitational force or

with the addition of chemicals called as

coagulants.

Table 3. Biological Unit Operation

Activated

Sludge process

Removal of digested Organic matter in the

presence of oxygen and is known as

Aerobic Process.

A. Count of Treating Units

The number of treatment units used in this design in order

to achieve the maximum efficiency are listed below in table

4.

www.ijert.org

498

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 4, April - 2014

= 52002 l/day

= 52 cumecs

From the calculated Water Demand, only

(75-80)% gets converted into sewage.

Total Sewage Discharge (Q):80% of 52 cumecs

Therefore, (Q) = 41.6 cumecs

Table 4. Count of treating units.

Sr No.

ITEM

No. OF UNITS

Screen Chamber

Grit Chamber

Collection Tank

Intermediate sump

Aeration Tank

Chlorine contact Tank

Intermediate Sump

III. DESIGN OF SEWAGE TREATMENT PLANT

The design of Sewage Treatment Plant is categorized into

three (3) Stages:

B. Basic Data

The basic data considered for designing the sewage

treatment plant is wastewater quantity which has a Design

flow rate inm3 /day and the characteristics of the raw

sewage considered for designing the STP are as given

below in table 5.

A. DESIGN I (Primary Treatment Units)

The series of treating units in the Primary Treatment are

screen chamber, grit chamber and Primary Sedimentation

Tank. From the calculated discharge volumes of each

treating unit is found by the help of Detention time.

General detention times of Treating Units are shown in

table 7.

Table 7. Detention times of treating units

Sr. No.

Treating Tank

Detention

Time

Grit Chamber

<1 min

Primary Sedimentation Tank

2-4 hrs

Aeration Tank

4-8 hrs

Secondary Sedimentation Tank

2-4 hrs

Chlorine Tank

10-20 mins

Table 5.Characteristics of raw sewage

1

Parameter

Concentration

pH

6.5-8.5

TSS

150-200

BOD (5 day at

250 300

20 0 C)

4

COD

400-450

*All parameters except pH expressed as mg/l

IJE

RT

Sr. No.

1

2

3

The expected characteristics of the treated wastewater on

adopting the scheme of treatment given under item 1.1 are

as given below in table 6 [3].

Table 6. Characteristics of treated wastewater

Sr.No.

Parameter

Concentration

1

2

3

pH

TSS

BOD(3 days at

0

27 C)

6.5-8.0

< 80

< 30

6.5 - 8.0

< 10

< 15

COD

< 175

< 150

For better results, detention time is multiplied by 2.5 and

the volumes are manipulated. The formula used for

calculation: D = (V/Q)

Where, D = Detention Time; V = Volume;

Q

= Discharge

After manipulations the cross sectional dimensions of

different treating units are given in AUTOCAD drawings.

*All parameters except pH expressed as mg/ltr

C. Calculations

The Gated community consists of 63 lots and 1 groceries

shopping mall. A rough estimation of 5 persons per lot and

6 persons operating the shopping mall is made. If the gated

community is GHMC (Greater Hyderabad Municipal

Corporation) approved then it receives 162 lpcd [4, 5].

Total Population: (63x5) + (1x6) = 321 (approximately

330)

Total Water Demand: (162 lpcd) x (330)

IJERTV3IS040786

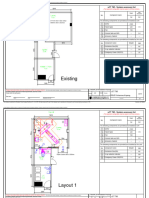

Figure 1. Top view of screen chamber and Grit chamber (all dimensions

www.ijert.org

are in mm)

499

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 4, April - 2014

The top view of Screen chamber & Grit Chamber

is shown in figure 1. The sewage is initially passed through

the Screen Chamber which consists of two Screens, fine

screen and the coarse screen. The effluent of Screen

chamber enters into the Grit chamber which has a detention

time generally less than 1 min. But, as the design of sewage

treatment plant is for a gated community with very less

sewage discharge the detention time is multiplied by

multiplication factor 2.5 for getting optimum dimensions of

grit chamber. However the detention time of screen

chamber is negligible. The design of screen chamber is

done by taking the standard dimensions of screen bars (MS

flats 25 X 3 mm). Spacing of 3mm is adopted between two

adjacent bars. The angle to which the screen bars are

inclines is 450.The side view of screen and grit chamber is

shown in figure 2

Figure 3: The dimensions of Aeration Tank

IJE

RT

The detention time of aeration tank is 4-8 hrs. This is an

aerobic process as we supply oxygen which serves as

energy for the growth of microbes reproduction. After the

aeration process the effluent of Aeration tank enters into

Secondary Sedimentation tank which fallows the same

principle of settlement by natural forces. The efficiency is

calculated and found to be 85%. The effluent of Secondary

Sedimentation Tank then enters the Sludge Digester which

takes place in the absence of oxygen and known to be as

anaerobic process. Adopted Parameters are F/M Ratio: 0.40.3, Sludge Age: 5 to 15 days and efficiency: 85-95 %.

Figure 2.The side view of the Screen & Grit Chamber

The effluent from Grit Chambers enters into Primary

sedimentation tank with Detention time of 2-4 hrs. Here,

the efficiency in removal of settle able impurities is 6065%.

B. Design II (Secondary Treatment Unit)

The secondary treatment unit is the biological activity that

takes place in order to reduce the digested organic matter.

The methodology adopted for this treatment plant is

Activated Sludge Process. The Activated Sludge Process

consists of Aeration Rank (Aerobic), Secondary

Sedimentation Tank and Sludge Digester (Anaerobic) [6].

For proper seeding and start-up of aerobic

treatment process fresh cow dung up to 10% of volume of

aeration tank is mixed with 80% fresh water and the

balance 10% volume of aeration tank is filled with clarified

wastewater. The contents are aerated for 20hrs. After that

continues aeration for 20hrs it is stopped for 3hrs and the

mixture is allowed to settle and decant 10% of supernatant.

About 10% of volume of aeration tank id made up and

filled with fresh clarified wastewater. The process of

aeration is repeated for 20 hrs and again kept idle for 3 hrs

after continues process of aeration. This method is repeated

till a constant percent of reduction in BOD is noticed. On

reaching 80% BOD removal, the wastewater flow into

aeration tank is increased by 20% of volume of tank.

Process of aeration is repeated and again at the stage of

removal of 80% of BOD 40% by volume of tank is filled

with wastewater. This process is repeated continuously and

after the wastewater increased by 60% of volume of tank

over flow from aeration tank is allowed from which the

effluent enters in to the Secondary clarifier.

The entire sludge collected in the secondary

clarifier should be recycled to aeration tank and this is a

cyclic process till the desired concentration of MLSS is

build up in the aeration tank. When MLSS concentration in

aeration tank reaches the desired value, full load of

wastewater is fed to the aeration tank.

C.Design III: Tertiary Treatment Unit

As the study is related to Gated community we can either

adopt the process of Chlorination or UV rays for

IJERTV3IS040786

www.ijert.org

500

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 4, April - 2014

disinfection. As Ultraviolet rays method is very costly and

chlorination being well known disinfection treatment

method which gives good results instantaneously and also

provides residual effect for future contamination,

chlorination is preferred over Ultraviolet rays method. The

chlorine dosage is generally kept between 1-2 ppm with a

contact time of about (10-20) min. The efficiency is about

99.9%.

*MOC: Material of Choice

V. REMOVAL EFFICIENCY DATA

The removal efficiency of SS, BOD, COD, pH after each

treatment are shown in table 9

Table 9. Removal efficiency data

Item

After

Primary

After

Secondary

After

Tertiary

SS

70%

80%

95%

BOD

15%

90%

95%

COD

20%

61%

95%

pH

6.5-8%

6.5-8

95%

VI. SCHEDULE OF PARAMETERS TO BE TESTED

IJE

RT

It is necessary to have the observation reports of

parameters like Flow, pH, SS, COD, BOD for the efficient

functioning of a treatment plant. The details of the

parameters to be tested are given in Table 10.

Figure 4: chlorine tank

IV. DETAILS OF OTHER WORKS

The various units mainly include mechanical works in

sewage treatment plant. Details of Mechanical works

are shown in Table 8

Table 10. Details of the Parameters to be tested.

S.No

PARAMETERS TO BE

TESTED

FREQUENCY OF

TESTING

Flow

Hourly

pH

Hourly

SS

3 Hours

COD

Twice a Day

BOD

Once a week

Table 8. Details of Mechanical works

UNIT

No.OF

TYPE

MOC

UNITS

SCREENS

MS flats 25 X 3

2

GATES

MSEP

mm

Rising spindle type

MSEP

Piping

PVC

AERATION

GRID

FOR

SUMP

with

network

header

laterals

PUMPS

HEAD: (10-25) m

PVC

BLOWERS

Twin lobe rotary

MOC

type.

FEED PUMPS

Head:

VII. CONCLUSION

and

PVC

The Removal Efficiency data from Table (9) satisfies the

efficiency required by each treating unit in order to treat the

Sewage coming from sources in Gated Community and

meet the acceptable quality of Sewage for the disposal after

treating. By increasing the detention time of sewage in

each treating unit increases the efficiency of removal of

unwanted impurities and this type of design suits well for

small scaled purposes like Gated community, Educational

Institutions, Hospitals etc.

(35 -100) m

IJERTV3IS040786

www.ijert.org

501

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 4, April - 2014

ACKNOWLEDGEMENT

The Authors are thankful to Md.Sameeruddin Khan,

Director; Dr. V.V.V.Satyanarayana Murthy, Professor &

Principal Department of Civil Engineering; Sree Dattha

Institute of Engineering and Science, for their cooperation

and encouragement throughout the work.

REFERENCES

IJE

RT

[1] B.C.Punmia, Arun Kumar Jain & Ashok Kumar Jain,

Environmental Engineering Volume-II

(Wastewater),Laxmi Publications Pvt Ltd, 1998

edition, pp 256-259.

[2] G.S.Birdie&J.S.Birdie, Water Supply and Sanitary

Engineering, Jain book depot, 9thedition.

[3] Metcalf & Eddy, Wastewater Engineering

Fourth Edition, McGraw Hill Inc., 1972.

[4] Ashton, John; Ubido, Janet

The Healthy City and the Ecological Idea

Journal of the Society for the Social History of

Medicine, pp 173181, 2013.

[5]

David Hill, Sewage Plant Undergoes Dramatic

Society of Transformation, Journal byAmerican

Society of Civil Engineers, 2013.

[6] Tilley, David F. (2011), Aerobic Wastewater

Treatment Processes; IWA Publications, 2013.

IJERTV3IS040786

www.ijert.org

502

You might also like

- HR Calculation-HotelDocument6 pagesHR Calculation-Hotelmunim87No ratings yet

- Vehicle Air ConditioningDocument32 pagesVehicle Air ConditioningAkshay Chandel100% (2)

- Manual On The Causes and Contril of Activated SludgeDocument21 pagesManual On The Causes and Contril of Activated SludgeRiianti WidiiNo ratings yet

- TIA Workshop ITBDocument48 pagesTIA Workshop ITBFirman Suhendra100% (1)

- User Guide To Nzs 4230:2004Document83 pagesUser Guide To Nzs 4230:2004Siva KumarNo ratings yet

- ENIRAM - Guide To Dynamic Trim Optimization 280611 PDFDocument14 pagesENIRAM - Guide To Dynamic Trim Optimization 280611 PDFPhineas MagellanNo ratings yet

- Operation & Maintenance Manual (O&M) OF Package Water Treatment Plant (PWTP)Document16 pagesOperation & Maintenance Manual (O&M) OF Package Water Treatment Plant (PWTP)Ashish Nair100% (1)

- Project Report On Extended Aeration and Step AerationDocument38 pagesProject Report On Extended Aeration and Step AerationHakim Asif Haider100% (2)

- Water Treatment Plant Performance Evaluations and OperationsFrom EverandWater Treatment Plant Performance Evaluations and OperationsNo ratings yet

- Capacity 5,0 m3 (1) New CraneDocument64 pagesCapacity 5,0 m3 (1) New CraneAnonymous iI88LtNo ratings yet

- Microsoft Word - Festo Rain Water Harvesting Flow ChartDocument5 pagesMicrosoft Word - Festo Rain Water Harvesting Flow Chartjeykumar.BalannairNo ratings yet

- Service Product Training - EWAD-EWYD-BZ - Chapter 1 - General Info - Presentations - EnglishDocument23 pagesService Product Training - EWAD-EWYD-BZ - Chapter 1 - General Info - Presentations - Englishjmdc100% (1)

- Simple Sewage: Treatment SolutionsDocument10 pagesSimple Sewage: Treatment SolutionsAnonymous oUoJ4A8xNo ratings yet

- CPCB Effluent Discharge StandardsDocument9 pagesCPCB Effluent Discharge StandardsPavan Tamiri100% (1)

- Project Semester ReportDocument60 pagesProject Semester ReportPrabhjot Singh TinnaNo ratings yet

- Handover Document - Yaden KatunayakeDocument39 pagesHandover Document - Yaden KatunayakeUTY ENGNo ratings yet

- Atc Ama202Document1 pageAtc Ama202Mahmoud BdourNo ratings yet

- Revotech Sewage Treatment Opt PDFDocument5 pagesRevotech Sewage Treatment Opt PDFPrashant Singh ChauhanNo ratings yet

- Iare Ce Iwwt Lecture Notes 2Document101 pagesIare Ce Iwwt Lecture Notes 2SHEKHARNo ratings yet

- SE WA GE TR EA TM EN T: Intro. Waste Water (Sewage) TreatmentDocument49 pagesSE WA GE TR EA TM EN T: Intro. Waste Water (Sewage) TreatmentRefisa JiruNo ratings yet

- Introduction To Domestic Wastewater Treatment, and Physical Treatment ProcessesDocument209 pagesIntroduction To Domestic Wastewater Treatment, and Physical Treatment ProcessesNitesh KumarNo ratings yet

- ETP Plant ProposalDocument12 pagesETP Plant ProposalRoshan KaluarachchiNo ratings yet

- Trehan STPDocument2 pagesTrehan STPsoma_sharadNo ratings yet

- Yamaha XJ6 2009 - Service Manual (Inglês)Document554 pagesYamaha XJ6 2009 - Service Manual (Inglês)fabiokruse70% (10)

- Tertiary TreatmentDocument45 pagesTertiary TreatmentsunitaudayNo ratings yet

- Sewage Treatment Plant: By: Abhishek Jat Aditi Singh Parihar Aishwarya & Akshay ShahDocument27 pagesSewage Treatment Plant: By: Abhishek Jat Aditi Singh Parihar Aishwarya & Akshay Shahbhobho100% (1)

- CPE675 - Chapter1Document170 pagesCPE675 - Chapter1Azizrin Azali100% (1)

- Efficiency Comparison of Various Sewage Treatment Plants in BangaloreDocument36 pagesEfficiency Comparison of Various Sewage Treatment Plants in BangalorePRETTY MARY100% (1)

- Design of Arraba Waste Water Treatment Plant: Prepared By: Waleed Rahhal Hamed Daghles Saleh Abdel-RhmanDocument47 pagesDesign of Arraba Waste Water Treatment Plant: Prepared By: Waleed Rahhal Hamed Daghles Saleh Abdel-RhmanMOHAMMED ABBAS NAJI MAALANo ratings yet

- Aerobic and Anaerobic Wastewater TreatmentDocument15 pagesAerobic and Anaerobic Wastewater TreatmentVictor100% (1)

- Lesson Plan: How Do We Clean Polluted Water?Document15 pagesLesson Plan: How Do We Clean Polluted Water?Tarun MattaparthyNo ratings yet

- CH 4 Sewage TreatmentDocument134 pagesCH 4 Sewage TreatmentGetu BogaleNo ratings yet

- Ate Huber-1Document47 pagesAte Huber-1Ravena RemaditaNo ratings yet

- Textile Environmental PresentationDocument52 pagesTextile Environmental PresentationNayeem RahmanNo ratings yet

- Concept of Zero DischargeDocument4 pagesConcept of Zero DischargeShesharam Chouhan67% (3)

- O&M Offer For STP - 75KLD & WTP - 100 KLDDocument11 pagesO&M Offer For STP - 75KLD & WTP - 100 KLDbioengsolutionschnNo ratings yet

- Chapter 18 FiltrationDocument18 pagesChapter 18 FiltrationGMDGMD11No ratings yet

- Rotating Biological ContactorsDocument18 pagesRotating Biological Contactorsjjiménez_142046No ratings yet

- Toyota Corporate BrochureDocument18 pagesToyota Corporate BrochureToyota Malaysi69% (36)

- Boq 196423Document87 pagesBoq 196423sanjaygkpNo ratings yet

- EE-2 Mini Project ReportDocument7 pagesEE-2 Mini Project Report63GANESH SINGHCIVILNo ratings yet

- M13 - L17 Grit ChamberDocument6 pagesM13 - L17 Grit ChamberBerliana Cahya Ningtias0% (1)

- Lesson 17 - Activated SludgeDocument8 pagesLesson 17 - Activated SludgeShane RodriguezNo ratings yet

- DNIT Vol 2 Part 1Document196 pagesDNIT Vol 2 Part 1JitendraHatwarNo ratings yet

- Treatment of Seafood Processing Wastewater Using A Moving Bed Biofilm Reactor (MBBR)Document4 pagesTreatment of Seafood Processing Wastewater Using A Moving Bed Biofilm Reactor (MBBR)Dương Ánh100% (1)

- ENVI Trickling FiltersDocument23 pagesENVI Trickling FiltersbaBy daBy AnNetTeNo ratings yet

- Visit ReportDocument9 pagesVisit Reportrohit Sharma100% (1)

- Equalization Lec 7 Week 7 MSC 2021Document21 pagesEqualization Lec 7 Week 7 MSC 2021haseeb tahirNo ratings yet

- Pulsator - P ER 003 EN 1603 - v2 PDFDocument2 pagesPulsator - P ER 003 EN 1603 - v2 PDFpjrapanutNo ratings yet

- TC Owtu 502 PDFDocument288 pagesTC Owtu 502 PDFRon100% (1)

- Mini Project ReportDocument5 pagesMini Project ReportSaj BhaiNo ratings yet

- Anaerobic Baffled Reactor (ABR) - SSWM PDFDocument9 pagesAnaerobic Baffled Reactor (ABR) - SSWM PDFAnonymous gqtnY7iRk1No ratings yet

- Bar ScreenDocument16 pagesBar ScreenamaranthussativaNo ratings yet

- Package Type STPDocument4 pagesPackage Type STPjeykumar.BalannairNo ratings yet

- Lift Station Calculation - REV2Document13 pagesLift Station Calculation - REV2Rawan Alwan ZarifNo ratings yet

- Sewage Treatment Plant (STP) - Module 2Document21 pagesSewage Treatment Plant (STP) - Module 2diana bunaganNo ratings yet

- CH 9 - Attached Growth ProcessDocument30 pagesCH 9 - Attached Growth Processxuantra92100% (1)

- Wastewater Treatment Methods Physical Unit Operations Chemical Unit Operations Biological Unit OperationsDocument34 pagesWastewater Treatment Methods Physical Unit Operations Chemical Unit Operations Biological Unit OperationsNumanNo ratings yet

- Project Report On STPDocument24 pagesProject Report On STPRinku SinghNo ratings yet

- SITE VISIT TO Waste WATER TREATMENT PLANTDocument12 pagesSITE VISIT TO Waste WATER TREATMENT PLANTNajum U Saqib BhatNo ratings yet

- Sewage Treatment PlantDocument3 pagesSewage Treatment PlantPranshu Singh BirthalNo ratings yet

- Waste Water TreatmentDocument4 pagesWaste Water TreatmentIbrar ZahidNo ratings yet

- Water Supply and Sanitary EngineeringDocument3 pagesWater Supply and Sanitary EngineeringVinod KumarNo ratings yet

- Design Manual For Small Wastewater Works 2009-2Document52 pagesDesign Manual For Small Wastewater Works 2009-2VichekaNo ratings yet

- 30mldstp 190419131720 PDFDocument26 pages30mldstp 190419131720 PDFNikhil SachdevaNo ratings yet

- ACO Passavant - Technical Handbook and Product CatalogueDocument24 pagesACO Passavant - Technical Handbook and Product CatalogueACO PassavantNo ratings yet

- Experiment 3 Arvia Water TreatmentDocument24 pagesExperiment 3 Arvia Water TreatmentBrendaNo ratings yet

- Handling Dairy Milk House WastewaterDocument31 pagesHandling Dairy Milk House WastewaterAndreea CalcanNo ratings yet

- Textile WastewaterDocument43 pagesTextile Wastewatersujal jhaNo ratings yet

- ESE 568: Mixed Signal Design and Modeling Lecture Outline: Simplified For Hand AnalysisDocument13 pagesESE 568: Mixed Signal Design and Modeling Lecture Outline: Simplified For Hand AnalysisVarun SinghalNo ratings yet

- Kelantan - Welcome Kit YSEALI Bootcamp 2022Document25 pagesKelantan - Welcome Kit YSEALI Bootcamp 2022Farhan HafizNo ratings yet

- Optimize WMSDocument54 pagesOptimize WMSMohammed_Abbas_7507No ratings yet

- An Experimental and Theoretical Study of Planing Surfaces With Trim FlapsDocument63 pagesAn Experimental and Theoretical Study of Planing Surfaces With Trim Flapsمرتضی عزیزیNo ratings yet

- The Joy of Computing Using Python: Assignment 1Document6 pagesThe Joy of Computing Using Python: Assignment 1Farheen BanoNo ratings yet

- Shindengen: Stepping Motor Driver IcsDocument2 pagesShindengen: Stepping Motor Driver IcsEngin UzunNo ratings yet

- MBA Final MIS ProjectDocument11 pagesMBA Final MIS ProjectNurul HasnainNo ratings yet

- FRA5310 TechDocument2 pagesFRA5310 TechBash MatNo ratings yet

- Brosur All New Innova MUVs 16393Document7 pagesBrosur All New Innova MUVs 16393Roni SetyawanNo ratings yet

- Van Der WallsDocument24 pagesVan Der WallsAnonymous oVRvsdWzfBNo ratings yet

- Cisco LetterDocument1 pageCisco LetterAlexandru DrăganNo ratings yet

- Roslyn Riley ResumeDocument2 pagesRoslyn Riley Resumeapi-78443823No ratings yet

- Why 50 OhmDocument2 pagesWhy 50 Ohmwrite2arshad_mNo ratings yet

- Coca ColaDocument12 pagesCoca ColaNishtha JainNo ratings yet

- Manjula Kumari.Document5 pagesManjula Kumari.Sanjay KaithwasNo ratings yet

- Desain Ruangan CT-ScanDocument3 pagesDesain Ruangan CT-ScannewmanonmarsNo ratings yet

- IOCL-EKC-STATIONARY CASCADE-DIA 559 X 06 CYLINDER X 3000 LTR-SHEET 5 OF 5-REV.01Document1 pageIOCL-EKC-STATIONARY CASCADE-DIA 559 X 06 CYLINDER X 3000 LTR-SHEET 5 OF 5-REV.01subudhiprasannaNo ratings yet

- 1PX12PSCNARMDDocument1 page1PX12PSCNARMDJainam ShahNo ratings yet

- RETS Developer Start GuideDocument10 pagesRETS Developer Start GuideKlemNo ratings yet

- Card Authentication Kit (B) Operation Guide: ECOSYS P2040dn ECOSYS P2040dwDocument5 pagesCard Authentication Kit (B) Operation Guide: ECOSYS P2040dn ECOSYS P2040dwClic CsiNo ratings yet

- Practice ZAcademy Excel NewiesModeDocument9 pagesPractice ZAcademy Excel NewiesModedadang hermawanNo ratings yet