Professional Documents

Culture Documents

Din 6930

Uploaded by

Eduardo Perez0 ratings0% found this document useful (0 votes)

755 views9 pagesnormas de tolerancias iso-din

Original Title

DIN-6930

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentnormas de tolerancias iso-din

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

755 views9 pagesDin 6930

Uploaded by

Eduardo Pereznormas de tolerancias iso-din

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 9

UDC 669.14-411-13:621.96:621,753.1__ DEUTSCHE NORM April 1989

Steel stampings

ition.

‘Stanztelle aus Stahl; Allgemeintoleranzen ‘Supersedes Jenusry 1983 «

‘In keeping with current practice in standard published by the International Organization for Standerdiation (ISO),

‘@ comma has been used throughout as the decimal marker.

Dimensions tn mm

is intanded to simplify drawings. It specifics general tolerances on linear and angular dimensions and on

‘coaxiality and symmetry in four accuracy grades comprising f fine}, (medium, 9 (coarse) and sa (very coarse). Whar

selecting a defined accuracy grade, the respective workshop accuracy isto be taken into account.

{smaller tolerances ae required or if arger tolerances are parmitted and more economical, these shal be indicated

adjacent to tha relevant basic size.

2 Field of application

General tolerances as specified in this standard intended for use cold and hot stampings made from steel fst products.

‘They shal apply whenever reference is made to this standard on drawings of relevant documents (e.g. in delivery

conditions)

General tolerances for parts made by fine blanking (ne VDI 3348) are not covered inthis standard.

i, by way of exception, it's intanded to apply this standard ato to components made from semiinished products

other than flat products, or from materials other than steel, this shall be particularly agreed,

Iti recommended that tis standard be applied in conjunction with the speciicstions given in DIN 6932.

‘The technical delivery conditions for stampings are coverd by DIN 6930 Part 1.

Guidelines relating to general tolerances indicated on existing drawings are given in clause 6.

3. General tolerances

j 3 Gone

“The general tolersnces specified inthis standard oke account ofthe particular conditions of stampingprectice ineluding

allowance tor de woar.

In the case of blanked stampings the tolerances apply to the cut band (se figure 1.

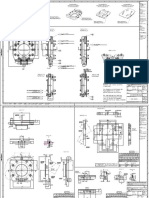

Figure 1. Determination of actual siza

Note. Where the postion and sizeof the draw-in band, break band ane burr may affect the functioning ofthe stamping,

‘corresponding agreement shall be reached botween manufacturer and purchater, details of which are tobe

‘ontored in the drawing.

{Inthe case of stampings produced by eibbling (of. DIN BBBB), the actual size the dhmension measured over the

Deaks of the undulating sheare face (see figure 2)

Figure 2. Determination of sotval sizeof stampingt

Produced by nibbling

Actual slag

‘The actual sie ofa stamping may posibly be influenced by the tolerance on thickness of se fat product used, tn this

‘connection, it isto be considered thatthe thickness of the fat product may ater when subjected to bending or deep

‘drawing

Continuad on pages 2 t0.9

zum arg bl Beri ha TANT ae ATTN SOaNEE Ra DIN 6830 Part? Eng Price group?

Copyright by the DIN Deutsches institut Fur Normung EV

‘Tue Jan 24 14:53:19 2003,

Page 2_ DIN 6590 Pare 2

3.2. General tolerances for flat stampings

are to be made exelusvny from Fist products by cutting (using shear or blanking toll. Cf, DIN 8588

imenaions Including the olemeters of fiat stampings

pubeause 3.2.2.

com Limit deviations for thicknesses

eee ee eee

t zoos | 008 | +01 oz #04

From 1 m for fos | £02 £08 Or

a * ° 02 £08 04 08 208

2 05 E08 £08 x7) 218

t ‘tops | #01 £015, #02 =04

Or 6 = kots | £02 £025 | t04 7

eee 9 £08 04 £05 £08 208

0 £08 at #t #18 215

t ‘ot 08 £015 £02 #04

over 10, a E02 tos | £08 04 £08

aerate Ere 04 os £08 08 et

0 #1 at E18 215 #2

1 or zor | £02 £08 oA

over 25 m ‘025 | £08 04 #05 as

teteHtee a £05 208 98 at 212

a at = 21s #2 8

1 zors | sors | 202 £08 £04

Over 63 m £08 =04 £08 £06 E08

fe et 3 £08 208 at £12 218

a £15 =18 az Fx) =

1 on zon 08 zo4 £05

Over 160 = 05 Eas £06 E08. #10

een 2 a E12 212 218 £2

8 £18 22 £25 #8 #8

t 204 3 £08 £05 £08

‘Over 400 ™ ‘08 08 #t a1 £18

een 8 aw | #18 #2 #2 #s

0 £25 £25 £8 ee Fz

t ‘£05 £08 08 #1 et

‘Over 1000 = 212 ENS 215 #2 2

pte 6200 ° 225 £28 Fx) 4 za

0 ae 4 24 4 =e

Copyright by the DIN Deutsches Institut Fur Normung EV

Tuo Jan 24 14:54:30 2003

DING930Part2 Page 3

3.2.2 Genera tolerances for radi of curvature of fat stampings

Seo table.

‘Table 2. Limit deviations for rail of curvature

[ren na as init devietions for leks

2 eee from 0,1 to 1 |over 1 up to 3lover 3 up to Blover6 upto 10] over 10.

Foon 4 tm, soz] tos | sos - =

2 6

a9 zoe | sos | 210 - -

eee sos | so | sos | x08 =

fee £06 +08 219 212 -

Sete soa | os | aos | os | x10

wpe 3

299 sos | so | a12 | ais | 220

ote: tm sos | see | 208 | aso | 12

we

ssa ai | +2 | as | a20 | 220

te tm sop | sto | at2 | ata | 210

eee 8.80 218 220 24 £28 £32

Ray tm aw | st | a | aie | #20

eee 089 #29 £24 #90 296 £40

om, ais | 20 | 222 [| 228 | xa0

over 400

829 saz [| sso | saa | x50 | 250

Toble Limit deviations for angular dimension of fat stamings

init deviations fora nominal de ofthe shorter, in angular unite

Aecurscy

‘vase | From1 | Over € | Over 10 | Over 25 | Over 62 Over 160 | Over 400] Over 1000

to 6 | vpto10 | upi025 | uptoas | upto 160 | uptod00 | up to 1000] up to 2600)

7 ze [| av | so | sw | aw | ao | ae | as

m sra [ara | ao | sw | aa | aw | aw | sw

eo | se | ae | ez | ar | av | aw | sw | cr

3.24. Gonoral tolerances on coaxiality and symmeby of latstampings

See 180 1101 for the definitions of ‘coaxiality tolerance’ and ‘symmetry to

drawings.

324.1 Comialiy

The nominal sz ofthe Iarget ofthe related form elements isthe sito be conde forthe caaxaty tolerance, On

vominl size, the coaxilty tolerance results from the cfferance between the upper and lower deviations

{for the accuracy grade concerned and the given thickness of the fat proctuct.

‘anc the corresponding indications on

DIN Deutsches Institut Fur Normung & V

30 2003,

Page DIN 6930 Part 2

Example:

CConcontie arrangement of outer and inner contours ofa pierced dise (se figure 3).

08mm.

32.42 Sym

‘The nomi: largest ofthe related form elements Is the size to be considered for the symmetry tolerance. On

the basis of this. n the uppar and lower deviations

speoified In table 1 for the accuracy grace concerned and the glven thickness product.

Example:

‘Symmetrical arrangement of two notches and of a hole relative to the sides ofa rectangular strip (ae figure 4).

4 4 i

&

3

=) \—" — ae

i

§

ee eae 3

PESeeneAeanAe neva ESR Eg

Temi to br anid

Fipre4 Nain zt be cone for he syrmeey se

‘Asming tchne ofr be at rt od ensconced om

oon

3.3 Ganeral tolerances for stampings made by forming

‘Stampings manufactured by forming are those which have undergone at least one forming

bbencing or deep drawing) and thus are not flat. As ale, stampings manufactured by fr

produced by cutting

‘Note. Stampings manufactured by formin

Copyright by the DIN Doutsches Institut Fur Normung EV

DIN 6930 Part 2 Page S

3.3.1. Gonoral tolerances for linear dimensions of stampings manufactured by forming

‘Table 4. Limit deviations For linear dimensions of stampings manufactured by forming, excluding rail of curvature

Nomina! size ange | Accuracy grade eee eee:

om0.11tfovert upto dfowr Supe Sevrs upto oer 10

7 zor | sare | soa | sae | sen

pea ™ | #02 £038 ‘04 £06 £08

* . o 204 £06 208 £12 £18

= FS Se)

t oo £02 208 £04 £08

ote = zos [see [=0s | 00 | 0s

eee a £06 £08 12 218 218

= ze [ ase [ae [ee [ee

7 za | sea | sea | son | son

Sallis 5 zoe] sas | soe | sae | aia

badeubutiad a £08 £10 ai 218 £18

a sao [ze [oss | se | ee

1 sea [aaa | zea [20s | 200

cues = zos [aa | sce [ss | as

ee 9 £10 £12 £16 +2 £24

" zi [am [es [ae [ae

7 x03 | #08 | se [s00 | 200

Owe = zoe | 0s [ sw | aa] ae

a Oe, a 212 £16 £2 £24 £32

= a0 [ao [ ee | ae [ee

qi za [ #08] soe [sea | 200

Pani m zw [aia | ave | are | a2

ema, 9 2 £24 £24. £392 +4

«a =e pes pee

i zoo | sas [at [at | ase

pane . zu [lew [se [en es

upto 1000 o £32 £32 +4 ak £6

ry = [fe pp ae]

t zie [se [ ee | sa ea

er ™ za | za] seo | ae | ee

wp to 2500 a £5 £5 £6 £8 £8

= ze | ss | se] =e [| =

DIN Deutsches Institut Fur Normung EV

2003

Poga 6 DIN 6930 Part 2

382 Gear tienes to feu ssi etry foming

evitions specified In table 5 sh ‘of curvature produced by cutting or by @ forming operation,

ote In subelause 3.3,

‘Table 6. Limit deviations for radi of curvature (produced by utting, bending or deep drawing) of stampings manutac-

by Forming

Nemcalszenne | Asem sate |rgm atte ijourt opto dforr3 pt gjow upto) one 10

t oz | soa | + 06 = -

From 4 n aos | +08 - - :

o 6 ; aan : a 7 c

ing > Z 7 z z

1 £ OM #08 | -

see ® £08 zu | = =

eee ° £12 £28 - =

0 ais | 22 £25 - 7

' tos | sop | a7 fi | 205

patictap m =1 ti | £18 | #2 £25

een 8 x2 was | £4 - -

a a2 | #4 £4 - -

f toe | #4 ei | tas [ #2

art eae " aw [ets [| #2 #25 | 24

eee 3 x28 | #4 #6 = =

°0 Pz #6 #6 = =

t #4 si | 21s [ #2 £25

foarte m tis [ +2 eas | =4 6

eae ° #4 #6 #10 25 £25

9 6 £10 210 #15 £35

' za [| et | £2 £26 | £8

lance m #2 os | #4 #6 £10

eee ° a6 10 #15 £25 £40

8 =10 218 218 £25 40

t aw | #2 sa | #3 eZ

ourtcane. m #25 | #4 #6 £10 #18

ee eee a #10 a8 #35 40 £60

9 £15 £25 ZS 40 £0.

Copyright by

Tuo Jan 24

DIN Deutsches Institut Fur Normung EV

2003

DIN 6930 Part 2 Pogo 7

Note, Since the present standard also covers hot formed stampings, the angular

iations specified in DIN 6936 apply to

‘these products as well.

33.4 General tolerances on cosxility and symmetry of strapings manufactured by forming

‘Syrnmetscal arrangement of a hole in 2 bent channel (ee figure 6).

ferent planes of the stamping.

4 Indication on drawings

FI e590 Pare 2 4h sop

Copyrig

Tuo Jan

1e DIN Deutsches Institut Fur Normung EV

192 2003,

Page 8 DIN 6830 Part 2

© Special cases,

‘The specifications made in this claus shall epply to all accuracy grades.

ot exceed the values specified

thickness of 26:1. For

‘of the ection.

‘Table 8. Straightnoss tolerance n, for stip cut by shears

seattle

‘pinginor

Berar 7 songhtn tran.

Toe 7

Or 2000 vv 3000 a

Orr 300 up to 000 7

Orr Cw 105000 ta

rr 5000 up 00 °

Figure 6, Sveightness of trip | |_________f)_ ____. Ss

62 Warping of strip and sections

rip cut by shears and of sections bent from strip shall not exceed 0.5° per 1000 mm of length (see

st being based on a minimum ratio of strip width, b to fat product thickness s, of 25:1.

Figure 7. Warping of strip

Copyright by the DIN Deutsches Institut Fur Normung EV

IN 6030 Part? Page

‘Standards and other documents referred to

IN 6890 Part Steel suumpings; technical delivery conditions

IN 6032 Rules for designing stel stampings

DIN 6895

DIN seas

180 1101

ing; tolerances of form, orientation, location and run-out

and ingications on drawings

Amendments

‘The following amendments have bwen made tothe January 1885 edition.

4} Some ofthe values specitied In tablet 4 and B have besn amended,

1b) The standard has been editorially revised.

Explanatory notes

For converting the angular dimensions spucfid in table 8 to linear dimensions for measurement purposes, table 7 bslow

ves tangent values

‘Table 7. Angles and asoctated tangante

‘Ange | Tangent] | Angle | Tangent | | Angle | Tangent |

s [ooo || 25° | coors || war | onze

w [ona [| 37 | aoe || > | ono

1 | ocoee || sr | coms ||» | cvsae

20 | 09088 | aos |

International Patent Classification

8210 28/00

3 Breria8

Copyright by the DIN Deutsches Institut Fur Normung EV

You might also like

- Diseño Industrial Mecánico Con CATIA V5-6 R2015Document11 pagesDiseño Industrial Mecánico Con CATIA V5-6 R2015Eduardo Perez0% (1)

- VW 01088 EsDocument17 pagesVW 01088 EsEduardo Perez100% (2)

- Solicitud BajaDocument1 pageSolicitud BajaEduardo PerezNo ratings yet

- LT - 03 - Lineamiento para Maquinado de Piezas - Chicas R2016 (Autosaved1)Document28 pagesLT - 03 - Lineamiento para Maquinado de Piezas - Chicas R2016 (Autosaved1)Eduardo PerezNo ratings yet

- 11-59D 323327Document3 pages11-59D 323327Eduardo Perez0% (1)

- Plan de Mantenimiento Preventivo TornoDocument51 pagesPlan de Mantenimiento Preventivo TornoEduardo Perez50% (2)

- Reporte 11002883-02Document3 pagesReporte 11002883-02Eduardo Perez100% (1)

- Pirateria y ContrabandoDocument4 pagesPirateria y ContrabandoEduardo PerezNo ratings yet

- Reporte DimencionalDocument13 pagesReporte DimencionalEduardo PerezNo ratings yet