Professional Documents

Culture Documents

Methods of Installation & Inspection To en 1090 2-1412867019

Uploaded by

yatinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Methods of Installation & Inspection To en 1090 2-1412867019

Uploaded by

yatinCopyright:

Available Formats

Specified Methods of Installation for Preloaded Bolts to EN 1090-2

Torque method

Combined method

Direct tension indicator method

TCB method (HRC)

Before commencement of preloading the connected components shall be fitted together.

General

Tooling

First tightening

step

Second tightening

step

Each bolt assembly shall be brought at least to snug-tight condition with special care being given to avoid over-tightening. The tightening

process shall be carried out from bolt to bolt of the group starting from the most rigid part of the connection and moving progressively

towards the least rigid part. To achieve a uniform snug tight condition, more than one cycle of tightening may be necessary.

The bolts shall be tightened using For torque wrenches used in the

Bolts fitted to snug-tight using a

Shear wrenches do not require

a torque wrench offering a

first step of the combined

normal size spanner.

calibration.

suitable operating range. Impact installation method an accuracy

Bolts tightened using appropriate

wrenches may be used for the

of +/-10% is required with annual tooling to achieve compression of

first step of tightening only.

testing.

the DTI.

Torque wrenches used in all steps

shall be capable of +/-4%

accuracy and checked weekly.

For the first step the wrench shall be set to a torque value to achieve

The first step of tightening to

The first tightening step is

about 0.75 Mr,i with Mr,i = Mr,2 or Mr,test. This first step shall be

reach a uniform snug-tight

achieved using the shear wrench.

completed for all bolts in one connection prior to commencement of

condition of the fastener

When the outer socket stops

the second step

assembly shall be when initial

turning and the gearing

deformation of the DTI

backtracks, it allows the tool to

protrusions begins.

be taken off the bolt.

For the second step , a torque

The second tightening step

The second step of tightening

The second tightening step is

wrench shall be set to a torque

involves a specified part turn to

bolts shall be as EN 14399-9 and

achieved when the spline end of

value of 1.1Mr,i with Mr,i = Mr,2 or

be applied to the bolt assembly.

annex J of EN 1090-2;

the bolt shears off.

Mr,test

The position of the nut relative to Indicators are usually applied

The torque reference values Mr,i

the bolt thread shall be marked

under the bolt head and the bolt

to be used for a nominal

after the first step using a

is usually tightened by rotation of

minimum preloading force Fp,C

marking crayon or paint so that

the nut.

are determined for each type of

the final rotation of the nut

A feeler gauge (as specified in

bolt and nut combination used by relative to the bolt thread can be table J.1 of EN 1090-2) shall be

one of the following options:

easily determined.

used to determine whether the

1) values based on k-class

The additional rotation during

DTI has compressed in

declared by the fastener

the second step shall be in

accordance with the

manufacturer

accordance with values given in

requirements.

2) values determined by Annex H table 21 of EN 1090-2:2008

No more than 10% of the

of EN 1090-2 (test to determine

indicators in a connection bolt

torque values for preloaded bolts

group shall exhibit full

under site conditions)

compression of the indicator.

Specified Methods of Inspection for Preloaded Bolts to EN 1090-2

Torque method

Inspection tooling

Inspection of bolts

during and after

tightening

General

Inspection at first

step

Specific

Inspection at

second step

Specific

Note

Combined method

Direct tension indicator method

TCB method (HRC)

Torque wrenches used for inspections shall be calibrated and have a

Feeler gauge used as a no-go

NA

+/-4% accuracy.

inspection tool

All connections with preloaded fasteners shall be visually checked after they are initially bolted up and before commencement of preloading.

The number of bolts inspected at random depends on the Execution Class specified EXC1 to EXC4

If the inspection leads to rejection, all of the bolting assemblies in the group shall be checked.

Overall number of bolts to be checked in a class EXC2 structure 5% for the second step

The inspection shall be carried

out on 100% of the bolting

assemblies by visual inspection.

EXC3 and EXC4 - 10% for the

EXC3 and EXC4 - 5% for the first

EXC3 and EXC4 - 10% for the

second step

step and 10% for the second step second step

Inspection shall be carried out using a sequential sampling plan according to annex M of EN 1090-2. If the

result of inspection to sequential type A is negative, the inspection may be enlarged to sequential type B.

If fasteners are not applied in accordance with the defined method, the removal and re-installation of the

whole bolt group shall be witnessed.

Identification of bolt assembly lot For EXC3 and EXC4 the first step

Connections shall be inspected to

locations

shall be controlled before

ensure they are properly packed

Checking the bolt tightening

marking using the same torque

as per specification.

procedure for each bolt group.

conditions as used to reach the

75% condition.

The inspection of a bolt assembly After the second step the marks

After final tightening, assemblies

shall be carried out by the

shall be inspected with the

selected for inspection shall be

application of a torque to the nut following requirements:

checked to establish that the final

using a calibrated torque wrench. 1) If the rotation angle is less

indicator settings are in

The objective is to check that the than 15 below specified value,

accordance with the

torque value necessary to initiate the angle shall be corrected

requirements specified in

rotation is at least equal to the

2) If the rotation is more than 30 EN 14399-9 and Annex J of

torque value 1.1Mr,i with Mr,i =

over specified angle or the bolt

EN 1090-2

Mr,2 or Mr,test.

has failed, the assembly shall be

replaced.

Inspections shall be carried out

between 12 and 72 hours after

final completion of tightening of

the bolts concerned.

Fully tightened assemblies are

identified as those with the spline

sheared off.

You might also like

- Indian Standard: Carbon Steel Castings For General Engineering Purposes - SpecificationDocument8 pagesIndian Standard: Carbon Steel Castings For General Engineering Purposes - SpecificationchepurthiNo ratings yet

- Manifold Burst Pressure TestDocument3 pagesManifold Burst Pressure TestrajeshNo ratings yet

- Estimation of Overhead TankDocument8 pagesEstimation of Overhead TankTeja AmereNo ratings yet

- Raw Material Cutting Request Form: Raw Size SR # Date Job No Material Plate No Length Width Thickness Heat NumberDocument1 pageRaw Material Cutting Request Form: Raw Size SR # Date Job No Material Plate No Length Width Thickness Heat NumberAMIT SHAHNo ratings yet

- NDT ReportDocument14 pagesNDT ReportEric Doctore KrageNo ratings yet

- Manual For RX-Multi (en-ES) - VFebmanual RXDocument4 pagesManual For RX-Multi (en-ES) - VFebmanual RXricardoNo ratings yet

- Bolting Program Info PDFDocument2 pagesBolting Program Info PDFIrshad AhmadNo ratings yet

- Inspection and Monitoring of Lead Acid Batteries inDocument17 pagesInspection and Monitoring of Lead Acid Batteries inBenNo ratings yet

- Description: Tags: 03session7Document63 pagesDescription: Tags: 03session7anon-157775No ratings yet

- Course in Non-Destructive Testing of WoodDocument3 pagesCourse in Non-Destructive Testing of Woodأحمد دعبسNo ratings yet

- Human Reliability 07Document4 pagesHuman Reliability 07Fernando RomeroNo ratings yet

- Isa-5 3Document22 pagesIsa-5 3Sanghamitra Bhattacharya100% (1)

- Bolt Torquing SpecialistDocument2 pagesBolt Torquing SpecialistMarkus Landington100% (1)

- FMS Training M02Document12 pagesFMS Training M02donyemjoroNo ratings yet

- FMS Training M01Document14 pagesFMS Training M01donyemjoroNo ratings yet

- NG-018-XX-PNL-430926 - Rev04 Weld Numbering System and Procedure UnsignedDocument20 pagesNG-018-XX-PNL-430926 - Rev04 Weld Numbering System and Procedure UnsignedFolarin Ayodeji100% (1)

- Class Test 4 & 5 Cams - Gears - Assignment Questions KomDocument10 pagesClass Test 4 & 5 Cams - Gears - Assignment Questions KomVenkateswar Reddy MallepallyNo ratings yet

- NG-018-XX-PNL-431203 - Rev07 NDT MatricesDocument20 pagesNG-018-XX-PNL-431203 - Rev07 NDT MatricesFolarin Ayodeji100% (1)

- Problems Reliability PDFDocument2 pagesProblems Reliability PDFmanasaavvaruNo ratings yet

- USUA Reports October. 2012Document16 pagesUSUA Reports October. 2012ikehdNo ratings yet

- SI No. Sample TestsDocument5 pagesSI No. Sample TestsMohamed AfsalNo ratings yet

- The Role of Control Room Operators: Andrew Brazier Principal Consultant Entec UK LTDDocument17 pagesThe Role of Control Room Operators: Andrew Brazier Principal Consultant Entec UK LTDMatthewNo ratings yet

- Maintenance and User Manual: Borehole TV Camera Inspection System Setting Up InstructionsDocument21 pagesMaintenance and User Manual: Borehole TV Camera Inspection System Setting Up InstructionsFranklin L SilvaNo ratings yet

- Leak Test PipingDocument1 pageLeak Test PipinguknowNo ratings yet

- Bristle Blaster BrochureDocument6 pagesBristle Blaster BrochureDom BergeronNo ratings yet

- ISO Index Welding Standards - 1Document1 pageISO Index Welding Standards - 1Waqas WaqasNo ratings yet

- OSPRAG Final Report 2011Document48 pagesOSPRAG Final Report 2011jiuzhiyeNo ratings yet

- IRIS Min WTDocument2 pagesIRIS Min WTphanthanhhungNo ratings yet

- Water TreatmentDocument16 pagesWater TreatmentReinaldo Steven100% (1)

- Pheonwj I PRC 0005 0Document54 pagesPheonwj I PRC 0005 0Iksan Adityo Mulyo100% (1)

- Control Valve Common Interview QuestionsDocument10 pagesControl Valve Common Interview QuestionsMustafa MehdiNo ratings yet

- New SSIV InstallationDocument12 pagesNew SSIV InstallationDidiNo ratings yet

- STD 188 PDFDocument36 pagesSTD 188 PDFsashikant31No ratings yet

- Screen SandDocument2 pagesScreen SandIng Jose BelisarioNo ratings yet

- Erection ProcedureDocument4 pagesErection ProcedureRanjit BanerjeeNo ratings yet

- (En) SHC107-84 PART B (Ver.7.3)Document8 pages(En) SHC107-84 PART B (Ver.7.3)Minh BảoNo ratings yet

- BS 5345-4 1977 PDFDocument18 pagesBS 5345-4 1977 PDFArt JamesNo ratings yet

- Assignment - 4Document7 pagesAssignment - 4paridhisahni0% (2)

- Spatter Reduction ChecklistDocument6 pagesSpatter Reduction ChecklistJorge perezNo ratings yet

- Narrow Gap FcawDocument33 pagesNarrow Gap FcawNitin Bajpai100% (1)

- Kareem Ebraheem Abdelaziz: Welding QC EngineerDocument2 pagesKareem Ebraheem Abdelaziz: Welding QC EngineerKareem AbdelazizNo ratings yet

- Hydrostatic Test ProcedureDocument7 pagesHydrostatic Test Procedurelaleye_olumideNo ratings yet

- QC Inspector (Offshore Pipeline Installation) Jobs in Propel Consult in UAE - United Arab Emirates - NaukrigulfDocument7 pagesQC Inspector (Offshore Pipeline Installation) Jobs in Propel Consult in UAE - United Arab Emirates - NaukrigulfAshif IqubalNo ratings yet

- BemeDocument1 pageBemeAbdulyekini AhmaduNo ratings yet

- Liquefied Natural Gas Terminals: Services and SolutionsDocument7 pagesLiquefied Natural Gas Terminals: Services and SolutionsJohnNo ratings yet

- Wrapping MethodDocument5 pagesWrapping Methodnnuek67% (3)

- Vessel Module Sans RH GoodDocument24 pagesVessel Module Sans RH GoodThaksenNo ratings yet

- Risk Assessment Form - Part A: Hazard ListDocument2 pagesRisk Assessment Form - Part A: Hazard Listapi-297561383No ratings yet

- QC Surveillance Report: As Per P.OrderDocument3 pagesQC Surveillance Report: As Per P.OrderRahul MoottolikandyNo ratings yet

- NG-018-XX-PNL-430808 - Rev04 ITP Cable Tray UnsignedDocument16 pagesNG-018-XX-PNL-430808 - Rev04 ITP Cable Tray UnsignedFolarin AyodejiNo ratings yet

- Zinc Rich Anticorrosive Primer PDFDocument53 pagesZinc Rich Anticorrosive Primer PDFDhruv SevakNo ratings yet

- MOTS-08 Squirrel Cage Induction Motors - Rev 4.0Document17 pagesMOTS-08 Squirrel Cage Induction Motors - Rev 4.0Kingston RivingtonNo ratings yet

- TorcUP AP 1000 Manual 2013 04Document26 pagesTorcUP AP 1000 Manual 2013 04ZulferiNo ratings yet

- TCW Tube CleaningDocument56 pagesTCW Tube CleaningMarcela Vargas GomezNo ratings yet

- Tank Inspectiom ChecksheetDocument3 pagesTank Inspectiom Checksheetyskushwah16100% (1)

- Usha MartinDocument33 pagesUsha MartinmontymilkyNo ratings yet

- NDT Training Syllabus PDFDocument8 pagesNDT Training Syllabus PDFNkwor AndersonNo ratings yet

- Design and Construction of Palm Fruits Digester For Palm Oil Production Industries in Osun StateDocument41 pagesDesign and Construction of Palm Fruits Digester For Palm Oil Production Industries in Osun StatejuanNo ratings yet

- Filmbadge and TLD ManualDocument2 pagesFilmbadge and TLD ManualAldrin Cabrera100% (1)

- TCB Installation Booklet HRCDocument11 pagesTCB Installation Booklet HRCAlexandre FonsecaNo ratings yet

- Is 1239 Pipe Dimensions JindalDocument1 pageIs 1239 Pipe Dimensions JindalyatinNo ratings yet

- Integration Formulas: 1. Common IntegralsDocument5 pagesIntegration Formulas: 1. Common IntegralssiegherrNo ratings yet

- Niphad DemographicsDocument3 pagesNiphad DemographicsyatinNo ratings yet

- FEA Through Critical Path MethodDocument5 pagesFEA Through Critical Path MethodyatinNo ratings yet

- UV UltraFEA SpectrosDocument6 pagesUV UltraFEA SpectrosyatinNo ratings yet

- HP Deskjet Simulation ExpressDocument29 pagesHP Deskjet Simulation Expressyatin0% (1)

- RPN Synthesis Using FEADocument8 pagesRPN Synthesis Using FEAyatinNo ratings yet

- Integration Formulas: 1. Common IntegralsDocument5 pagesIntegration Formulas: 1. Common IntegralssiegherrNo ratings yet

- FTMT Motor CatalogueDocument18 pagesFTMT Motor CatalogueyatinNo ratings yet

- BE Mechanical Syllabus SPPUDocument54 pagesBE Mechanical Syllabus SPPUshrikantwadekarNo ratings yet

- Introduction To CFD BasicsDocument21 pagesIntroduction To CFD BasicsVijay KrishnanNo ratings yet

- FQHD SynthesisDocument1 pageFQHD SynthesisyatinNo ratings yet

- CE MarkingDocument3 pagesCE MarkingyatinNo ratings yet

- Introduction To CFD BasicsDocument21 pagesIntroduction To CFD BasicsVijay KrishnanNo ratings yet

- Roto DynamicsDocument18 pagesRoto DynamicsyatinNo ratings yet

- Basic of Steel Structure-Architectures GuideDocument3 pagesBasic of Steel Structure-Architectures GuideyatinNo ratings yet

- Roto DynamicsDocument18 pagesRoto DynamicsyatinNo ratings yet

- Fracto Non-Linear MechanicsDocument11 pagesFracto Non-Linear MechanicsyatinNo ratings yet

- Roto DynamicsDocument18 pagesRoto DynamicsyatinNo ratings yet

- Steel StructuresDocument56 pagesSteel StructuresAwais Safder Malik0% (1)

- Design of Steel StructureDocument2 pagesDesign of Steel StructureyatinNo ratings yet

- SN26 062008 Preloadable BoltsDocument2 pagesSN26 062008 Preloadable Boltsraman123456No ratings yet

- Design of Steel StructureDocument2 pagesDesign of Steel StructureyatinNo ratings yet

- Tresca ElementDocument1 pageTresca ElementyatinNo ratings yet

- Mechanic ADocument1 pageMechanic AyatinNo ratings yet

- Design of Steel StructureDocument2 pagesDesign of Steel StructureyatinNo ratings yet

- Fracture Mechanics EvidenceDocument1 pageFracture Mechanics EvidenceyatinNo ratings yet

- Clinimetrics Single Assessment Numeric EvaluationDocument1 pageClinimetrics Single Assessment Numeric EvaluationNicol SandovalNo ratings yet

- DUN Bukit Lanjan CNY Sponsorship Form2Document1 pageDUN Bukit Lanjan CNY Sponsorship Form2alamsekitarselangorNo ratings yet

- Rectification or Correction of Sale DeedDocument4 pagesRectification or Correction of Sale Deedsumanth_0678No ratings yet

- OrthoDocument22 pagesOrthosivaleela gNo ratings yet

- Rape and Challenging Contemporary ThinkingDocument17 pagesRape and Challenging Contemporary ThinkingKirthna MadhavanNo ratings yet

- Inside Out or Outside inDocument6 pagesInside Out or Outside inΧΡΗΣΤΟΣ ΠΑΠΑΔΟΠΟΥΛΟΣNo ratings yet

- Confidential Recommendation Letter SampleDocument1 pageConfidential Recommendation Letter SamplearcanerkNo ratings yet

- Grade 5 Forces Acting On Structures and Mechanisms CirriculumDocument3 pagesGrade 5 Forces Acting On Structures and Mechanisms Cirriculumapi-2072021750% (1)

- MTAP Math ChallengeDocument5 pagesMTAP Math ChallengeHaron Abedin100% (1)

- Mitochondrial Mechanisms of PhotobiomodulationDocument4 pagesMitochondrial Mechanisms of PhotobiomodulationGabrielNo ratings yet

- Nurse-Patient Trust RelationshipDocument12 pagesNurse-Patient Trust RelationshipMarina Costa100% (1)

- Introduction To E-Business SystemsDocument19 pagesIntroduction To E-Business SystemsArtur97% (79)

- Aruego, Jr. v. Court of Appeals, G.R. No. 112193, March 13, 1996Document5 pagesAruego, Jr. v. Court of Appeals, G.R. No. 112193, March 13, 1996hello kitty black and whiteNo ratings yet

- Ogayon Vs PeopleDocument7 pagesOgayon Vs PeopleKate CalansinginNo ratings yet

- Endocrine System Unit ExamDocument3 pagesEndocrine System Unit ExamCHRISTINE JULIANENo ratings yet

- Sales OrganizationsDocument12 pagesSales OrganizationsmohitmaheshwariNo ratings yet

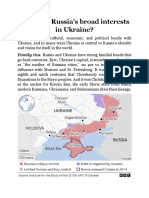

- What Are RussiaDocument3 pagesWhat Are RussiaMuhammad SufyanNo ratings yet

- Southeast Asian Fabrics and AttireDocument5 pagesSoutheast Asian Fabrics and AttireShmaira Ghulam RejanoNo ratings yet

- Public Administration 2000 - CSS ForumsDocument3 pagesPublic Administration 2000 - CSS ForumsMansoor Ali KhanNo ratings yet

- Brain and LanguageDocument3 pagesBrain and LanguageJasper AngelesNo ratings yet

- ATLS Note Ed 10Document51 pagesATLS Note Ed 10Nikko Caesario Mauldy Susilo100% (10)

- Sample Internship PPTDocument19 pagesSample Internship PPTSangeeta JamadarNo ratings yet

- Fortune 2010Document14 pagesFortune 2010Stefan JenkinsNo ratings yet

- 38 Page 2046 2159 PDFDocument114 pages38 Page 2046 2159 PDFAkansha SharmaNo ratings yet

- RPT Form 2 2023Document7 pagesRPT Form 2 2023NOREEN BINTI DOASA KPM-GuruNo ratings yet

- Articles 62 & 63: Presented By: Muhammad Saad Umar FROM: BS (ACF) - B 2K20Document10 pagesArticles 62 & 63: Presented By: Muhammad Saad Umar FROM: BS (ACF) - B 2K20Muhammad Saad UmarNo ratings yet

- Friedman LawsuitDocument12 pagesFriedman LawsuitChris GothnerNo ratings yet

- Role of Courts in Granting Bails and Bail Reforms: TH THDocument1 pageRole of Courts in Granting Bails and Bail Reforms: TH THSamarth VikramNo ratings yet

- Reaction PaperDocument3 pagesReaction PaperCecille Robles San JoseNo ratings yet

- Impact of Micro FinanceDocument61 pagesImpact of Micro FinancePerry Arcilla SerapioNo ratings yet