Professional Documents

Culture Documents

RCC Deck X-Girder Design

Uploaded by

Suman NakarmiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RCC Deck X-Girder Design

Uploaded by

Suman NakarmiCopyright:

Available Formats

20m_IL_RCC_TBeam_Bridge

DesignofCrossGirder

DesignData:

WidthofMaingirder=

Depthofcrossgirder=

Widthofcrossgirder=

Widthofrailingpost=

Spacingofmaingirders,B=

SpacingofCrossgirders,L=

Impactfactor,IF=

0.4

1.3

0.25

150

2.4

5

1.2

m

m

m

mm

m

m

UnitweightofRCC=

UnitweithtofW.Coat=

Sizeoffillets=

Thicknessofdeckslab,ds=

ThicknessofSlabatedge,de=

Avgthicknessofw.coat,dw=

24

22

300x100

215

150

75

kN/m

3

kN/m

mm

mm

mm

mm

5

0.215

2.4

1.09

0.25

CLofCrossGrider

A)DeadLoadMoment

i)Selfweightofcrossgirder=

ii)Deckslabandwearingcourseloadonxgirder=

Wightofdeckandwearingcourse=

TotalDeadload=

Crossgirderassumedasrigid,So

15.98kN/m

2.4

25.57

25.57

4.8

7.8

8.17

6.81

15.98

2.4

Reactiononeaschgirder=

25.57 kN

MaximumBendingMomentatMidSpan,B.M.max=

MaximumBendingMomentatMidSpanincludingimpact,B.M.max=

MaximumShearforceduetodeadloadatsupport,S.F.max=

MaximumShearforceduetodeadloadatsupportincludingimpact,S.Fmax=

kN/m

kN/m

2

kN/m

kN/m

25.57

19.18

23.02

25.57

30.68

B)LiveloadMoment:

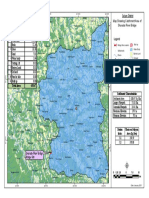

MaximumBMandSFoccurduetoclassAA70RTrackedvechicle.Vechiclepositionedasshowninfig.

ClassAA70RTracked

Axleloadof70RTrackedVechicle=

700 kN

LengthofTrckedwheel,l1=

4.57 m

WidthofTrckedwheel,b1=

0.84 m

SpacingofWheelatlongitudinaldirection,

m

SpacingofWheelattransversedirection,

2.06 m

Xgirder

kNm

kNm

kN

kN

20m_IL_RCC_TBeam_Bridge

5

270.03

270.03

1.37

2.4

180.02

2.4

2.06

2.4

2.4

180.02

Loadonthecrossgirder=

Reactiononeachlongitudinalgirder=

Max.LiveloadBM=

Max.LiveloadBMincludingimpact=

Max.ShearForceatSupport=

ClassAA70RWheeled

Axleloadof70RTrackedVechicle=

Lengthofwheel,l1=

Widthofwheel,b1=

SpacingofWheelatlongitudinaldirection,

SpacingofWheelattransversedirection,

5

270.03

180.02

246.62

295.95

180.02

180.02

kN

kN

kNm

kNm

kN

170

0.61

0.86

1.375

1.93

kN

m

m

m

m

5

146.63

146.63

2.4

1.93

1.63

2.4

2.4

2.4

97.75

Loadonthecrossgirder=

Reactiononeachlongitudinalgirder=

Max.LiveloadBM=

Max.LiveloadBMincludingimpact=

Max.ShearForceatSupport=

ClassA

Axleloadof70RTrackedVechicle=

Lengthofwheel,l1=

Widthofwheel,b1=

SpacingofWheelatlongitudinaldirection,

SpacingofWheelattransversedirection,

146.63

97.75

159.33

191.20

97.75

97.75

kN

kN

kNm

kNm

kN

114

0.5

0.25

1.2

1.8

Xgirder

kN

m

m

m

m

20m_IL_RCC_TBeam_Bridge

5

100.32

100.32

2.4

1.8

1.325

2.4

2.4

2.4

66.88

Loadonthecrossgirder=

Reactiononeachlongitudinalgirder=

Max.LiveloadBM=

Max.LiveloadBMincludingimpact=

Max.ShearForceatSupport=

SummaryofB.M.andS.F.

100.32

66.88

88.62

106.34

66.88

66.88

kN

kN

kNm

kNm

kN

70RWheelVechicle

Tracked

Wheeled

106.34

295.95

191.20

66.88

180.02

97.75

ClassA

BendingMoment,kNm

Shearforce,kN

DesignofSection

MaterialPropertiesBasedonFromIRC21:2000;Table9&10

Permissibleflexuralcompressivestress,cbc=

Permissibleflexuraltensilestress,st=

DesignMomentand

Shear

318.96

210.70

8.33

200

ModularRatio,m=280/(3xcbc)=

11.20

RatioofN.A.toeffectivedepth=K=m.cbc /(mcbc+st)

Leverarmfactor,j=1K/3

Neutralaxisconstant,n=(1/(1+st/m*cbc)=

Theresistingmomentcoefficient,R=1/2xcbcxnxj

SlabCover,S

Effectivedepth,d=

Mainreinforcement

M

Requiredtensionsteel,Ast=

=

st j d

0.32

0.89

0.32

1.18

25 mm

1269 m

Usetensilesteelof

25

mmdia. No.ofbarrequired=

Providedtensilereinforcement,Ast=

ShearReinforcement:

Designshearforceatsupport,V=

Percentageoftensilesteel=(100Ast)/(bd)=

ActualShearstress,=V/bd

=

1405.85703 mm2

3 Nos.

1472.62 mm2

210.70 kN

0.20 %

0.86

FromIRC21:2000Clause304.7.1.3.3Table12B,permissibleshearstress,cis

Now,Permissibleshearstressc=

0.20

NotSafeinShearStress

DesignshearstrengthofShearr/t,Vs=ShearforcePerm.Shearstress=

178.80 kN

Centretocentrespacingofthestirrup,Vs=(sv*Asv*d)/Vs

Provide

10 mmdia.

2 Leggedstirrups

10 mmdia.

So,Provideshearr/t

Xgirder

190.636 mm

157.08

150 Spacing

20m_IL_RCC_TBeam_Bridge

EndCrossBeam:

TotalSuperstructuredeadload=

DistributedtoMaingirder=

Hydrullicjackareplacedat

1800 kN

300.00 kN

450 mmfromthecentreofexternallongitudinalgirders.

300.00

4.8

300.00

300.00

2.4

2.4

0.45

0.45

450.00 =RB

RA= 450

MaximumBendingMoment,BMmax=

157.50 kNm

MaximumShearForce,SFmax=

450.00 kN

Mainreinforcement

M

j d

Requiredtensionsteel,Ast=

=

Usetensilesteelof

20

mmdia. No.ofbarrequired=

Providedtensilereinforcement,Ast=

Provisionalreinforcement:

Areaofsteelrequiredatbottom=

Usetensilesteelof

25

mmdia. No.ofbarrequired=

Providedtensilereinforcement,Ast=

ProvideMainbar(bottomr/t)forCrossgirder

4.00

Numbersof

Areaofsteelrequiredattop=

Usetensilesteelof

20

mmdia. No.ofbarrequired=

Providedtopreinforcement,Asc=

ShearReinforcement:

Designshearforceatsupport,V=

Percentageoftensilesteel=(100Ast)/(bd)=

st

ActualShearstress,=V/bd

694.19 mm2

3.00

942.48 mm2

1625

4

1963.50

25.00

812.50

3.00

942.48

mm2

mm2

mmdiameter

mm2

450.00 kN

0.20 %

1.84

FromIRC21:2000Clause304.7.1.3.3Table12B,permissibleshearstress,cis

Now,Permissibleshearstressc=

0.20

NotSafeinShearStress

DesignshearstrengthofShearr/t,Vs=ShearforcePerm.Shearstress=

444.69 kN

Centretocentrespacingofthestirrup,Vs=(sv*Asv*d)/Vs

76.652 mm

Provide

10 mmdia.

2 Leggedstirrups

So,Provideshearr/t

10 mmdia.

150 Spacing

ProvisionalShearReinforcementforcrossgirder:

Min.2leggedstirrupsof10mmdia@150mmC/Cspacing.

157.08

SidefaceReinforcement

Providesidereinforcement10%ofsectionalareaofbeamaspercode.

2

Areaofsteel,Ast=

162.5 mm

Provide

10 mmdiameterbar

4 Numbereachsideofweb.

Xgirder

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- B-701 Boysen Permacoat Flat Latex2Document7 pagesB-701 Boysen Permacoat Flat Latex2ircvpandoNo ratings yet

- Nursing Practice Skills: Adult Intensive Care Unit PatientsDocument10 pagesNursing Practice Skills: Adult Intensive Care Unit PatientsMona Doria67% (3)

- SeimicDocument1 pageSeimicSuman NakarmiNo ratings yet

- New Text DocumentDocument1 pageNew Text DocumentSuman NakarmiNo ratings yet

- LiquefactDocument1 pageLiquefactSuman NakarmiNo ratings yet

- 15 CV 741Document48 pages15 CV 741Suman NakarmiNo ratings yet

- ScourDocument2 pagesScourSuman NakarmiNo ratings yet

- DCPDocument1 pageDCPSuman NakarmiNo ratings yet

- DCPDocument1 pageDCPSuman NakarmiNo ratings yet

- Summary of Land Use Type in Catchment AreaDocument1 pageSummary of Land Use Type in Catchment AreaSuman NakarmiNo ratings yet

- At Support: IRC 70R Wheel Vechicle Main Girder Response (ILD)Document2 pagesAt Support: IRC 70R Wheel Vechicle Main Girder Response (ILD)Suman NakarmiNo ratings yet

- DCPDocument1 pageDCPSuman NakarmiNo ratings yet

- Compression Member LSMDocument1 pageCompression Member LSMSuman NakarmiNo ratings yet

- RateDocument1 pageRateSuman NakarmiNo ratings yet

- StaadDocument3 pagesStaadSuman NakarmiNo ratings yet

- 3 SummaryDocument1 page3 SummarySuman NakarmiNo ratings yet

- Defelction IRC Class ADocument1 pageDefelction IRC Class ASuman NakarmiNo ratings yet

- Nor Rubber-Elastomeric Bearing PadsDocument13 pagesNor Rubber-Elastomeric Bearing PadsWILLWAYS CONSULTANCY INDIA PVT LTDNo ratings yet

- Connection Design:: SB NB Ub Yb Mo MB MFDocument1 pageConnection Design:: SB NB Ub Yb Mo MB MFSuman NakarmiNo ratings yet

- Nepal Road Standard 2070Document55 pagesNepal Road Standard 2070surendra_pangaNo ratings yet

- ConnectionDocument1 pageConnectionSuman NakarmiNo ratings yet

- Deflection and Rotation Due To Dead Load: Mid Span SupportDocument3 pagesDeflection and Rotation Due To Dead Load: Mid Span SupportSuman NakarmiNo ratings yet

- Ir 98 01Document200 pagesIr 98 01Suman NakarmiNo ratings yet

- TestDocument1 pageTestSuman NakarmiNo ratings yet

- Assessment of A Railway Concrete Arch Bridge by Numerical Modelling and MeasurementsDocument10 pagesAssessment of A Railway Concrete Arch Bridge by Numerical Modelling and MeasurementsSuman NakarmiNo ratings yet

- Pre Stress Section Design RevisedDocument2 pagesPre Stress Section Design RevisedSuman NakarmiNo ratings yet

- NewDocument1 pageNewSuman NakarmiNo ratings yet

- ReactDocument2 pagesReactSuman NakarmiNo ratings yet

- PileDocument5 pagesPileSuman NakarmiNo ratings yet

- Ir 98 01Document200 pagesIr 98 01Suman NakarmiNo ratings yet

- Nepal Road Standard 2070Document55 pagesNepal Road Standard 2070surendra_pangaNo ratings yet

- 6 Chapter 6 9781786393814Document41 pages6 Chapter 6 9781786393814yunicenjeNo ratings yet

- Manual de Servico Samsung Sgh-I677-Eplis-11Document10 pagesManual de Servico Samsung Sgh-I677-Eplis-11Anselmo Antunes0% (1)

- Pathoftherosesyllabus2015 1 PDFDocument12 pagesPathoftherosesyllabus2015 1 PDFsperm100% (7)

- Smart City Scheme GuidelinesDocument48 pagesSmart City Scheme GuidelinesKarishma Juttun100% (1)

- Effect of Chloride Ions On The Corrosion of Galvanized Steel Embedded in Concrete Prepared With Cements of Different CompositionDocument13 pagesEffect of Chloride Ions On The Corrosion of Galvanized Steel Embedded in Concrete Prepared With Cements of Different CompositionAbubakar Yakubu YakubuNo ratings yet

- Igcse ReadingDocument4 pagesIgcse ReadingIvonne PuspakencanaNo ratings yet

- Comparative Superlative With Key PDFDocument1 pageComparative Superlative With Key PDFAnonymous 8AHCMsPuNo ratings yet

- Nasa ThesisDocument8 pagesNasa Thesisdnr3krf8100% (2)

- 10 de Thi Tieng Anh Hướng Dẫn Giải Chi TiếtDocument145 pages10 de Thi Tieng Anh Hướng Dẫn Giải Chi TiếtVuong DiepNo ratings yet

- Excess Fluid VolumeDocument27 pagesExcess Fluid VolumeAdrian Ardamil100% (1)

- p14.6 - D.C. Motor - Igcse AidDocument2 pagesp14.6 - D.C. Motor - Igcse Aidrandom channelNo ratings yet

- Author Name Title Paper/Submission ID Submission Date Total Pages Document TypeDocument32 pagesAuthor Name Title Paper/Submission ID Submission Date Total Pages Document TypeArka ChakrabortyNo ratings yet

- Content (SG)Document88 pagesContent (SG)Kusuma Cakra WardayaNo ratings yet

- Unit 21Document22 pagesUnit 21Yuni IndahNo ratings yet

- Middle East ManufacturerDocument6 pagesMiddle East Manufacturerhsco rdNo ratings yet

- Role of Packaging in Sales of FMCG Products and Its TrendsDocument57 pagesRole of Packaging in Sales of FMCG Products and Its TrendsSaurabh0% (1)

- Taiwan API Manufacturer ListDocument4 pagesTaiwan API Manufacturer Listkalyani dynamicsNo ratings yet

- StringTokenizer in JavaDocument11 pagesStringTokenizer in JavaNeha saxena Neha saxenaNo ratings yet

- Global Projects Organisation: Material Specification For 316/316L and 6mo Austenitic Stainless SteelDocument33 pagesGlobal Projects Organisation: Material Specification For 316/316L and 6mo Austenitic Stainless SteelThiyagarajan JayaramenNo ratings yet

- 3 RVDocument8 pages3 RVDivaruzNo ratings yet

- Sediments and Sedimentary Rock-Week 4Document61 pagesSediments and Sedimentary Rock-Week 4qomaruzzaman5740No ratings yet

- Chemistry Lab ReportDocument9 pagesChemistry Lab Reportapi-327824087No ratings yet

- A Study On Risk Assessment in The Construction of High-Rise BuildingsDocument5 pagesA Study On Risk Assessment in The Construction of High-Rise BuildingsMohamedSaidNo ratings yet

- CHEM333 Syllabus 2020 2021Document4 pagesCHEM333 Syllabus 2020 2021lina kwikNo ratings yet

- Approved Reading List Editions 2019ff As of 01 19 2023 2Document9 pagesApproved Reading List Editions 2019ff As of 01 19 2023 2nikolNo ratings yet

- Therelek - Heat Treatment ServicesDocument8 pagesTherelek - Heat Treatment ServicesTherelek EngineersNo ratings yet

- The Poet of NatureDocument31 pagesThe Poet of NaturejulyNo ratings yet

- Ap Art and Design Drawing Sustained Investigation Samples 2019 2020 PDFDocument102 pagesAp Art and Design Drawing Sustained Investigation Samples 2019 2020 PDFDominic SandersNo ratings yet