Professional Documents

Culture Documents

Solid State Contactor: DRC Series

Uploaded by

loritocomOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Solid State Contactor: DRC Series

Uploaded by

loritocomCopyright:

Available Formats

Solid State Contactor

DataSheet

DRC Series

7.6 Amp Motor Controller rated Solid State Contactor

Load voltage range up to 530VAC

Fits standard 35mm DIN-RAIL

LED input status indicator

AC or DC control

Zero-crossing (resistive loads) or instantaneous turn-on (inductive loads) output

C-UL-US Listed, IEC Rated, CE & RoHS Compliant, Horsepower Rated

Built in Overvoltage Protection

Ultra-efficient thermal management design (Patented)

Start / Stop

Reversing

Solicon DRC3 Series are Solid State Contactors intended for

frequently switching on and off three phase loads up to 5 HP, 480

VAC 7.6 Amps. They are available in both contactor versions

DRC3P and reversing contactor versions DRC3R.

The Solicon Contactor DRC3P is available in either instantaneous

turn-on (for Motor Control) or zero voltage turn-on (for Resistive

Loads). It is available in either 2 or 3 controlled leg versions. The

2 legs control version is particularly suitable for motor control

circuits where the neutral conductor is not utilized.

The Solicon Reversing Contactor DRC3R includes an interlock

control that allows only off, forward and reverse operation in a

safe mode while providing high space saving; it switches

instantaneously upon application of the control voltage unless an

instantaneous change of direction is commanded, then it will

delay the direction change by 100msec in order to prevent

simultaneous forward and reverse operations.

All the models of Solicon DRC3 Series combine the benefits and

advantages of a solid state contactor with the functionality and

simplicity of use of an electromechanical contactor thanks to the

proprietary thermal management technology (Patented) and

complete electrical insulation (no grounding required); the

embedded auxiliary contacts, normally open and/or normally

closed are intended to be used at 18-280Vac. Three different

control voltages are available in order to cover most the

applications. All models include overvoltage protection.

PRODUCT SELECTION

Control Voltage

Without Auxiliary Contact

230 VAC

120 VAC

24 VAC/DC

1 NO+NC Auxiliary Conctat

DRC3P48A400, DRC3R48A400

DRC3P48B400, DRC3R48B400

DRC3P48D400, DRC3R48D400

DRC3P48A411

DRC3P48B411

DRC3P48D411

2 NO Auxiliary Contact

DRC3P48A420, DRC3R48A420

DRC3P48B420, DRC3R48B420

DRC3P48D420, DRC3R48D420

AVAILABLE OPTIONS

Operating Voltage

40: 400 VAC

(3R function only)

48: 480 VAC

Series

DRC

3P

48

Function

3P: Contactor

3R: Reversing Contactor

Load Current per Phase

4: 7.6 Amp FLA

(x2 Controlled Legs

& 3R function);

4.8 Amp FLA

(x3 Controlled Legs only)

Control Voltage

A: 230 VAC

B: 120 VAC

D: 24 VAC/DC

Required for valid part number

For options only and not required for valid part number

Do not forget to visit us at: www.crydom.com

00

Switching Mode

(3P function only)

Blank: Zero Voltage Turn-On

R: Instantaneous Turn-On

Controlled Legs

Auxiliary Contacts,

(3P function only)

N.O. - N.C.

Blank: 3 Controlled Legs

00: Not included

2: 2 Controlled Legs

11: 1 Solid State Auxiliary

Contact, Normally Open;

1 Solid State Auxiliary

Contact, Normally Closed

(3P function only)

20: 2 Solid State Auxiliary

Contacts, Normally Open

Copyright 2014 Custom Sensors & Technologies. Specifications subject to change without notice.

Solid State Contactor

DataSheet

OUTPUT SPECIFICATIONS (1)

Description

DRC3Pxxxx

DRC3Pxxxx-2

DRC3R40xxx

DRC3R48xxx

Operating Voltage (47-63Hz) [Vrms]

Transient Overvoltage [Vpk] (2)

Maximum Off-State Leakage Current @ Rated Voltage [mArms]

Maximum Off-State dv/dt @ Maximum Rated Voltage [V/sec]

Load Current, Resistive UL508/AC51 @ 40C [Arms] (3)

Load Current, Motor Controller UL508/AC53 @ 480VAC [Arms] (3)

Minimum Load Current [Arms]

Maximum Surge Current [Apk] 1 Cycle 60Hz

Maximum Surge Current [Apk] 1 Cycle 50Hz

Maximum I2t for Fusing (8.33msec)[A2sec]

Maximum I2t for Fusing (10msec)[A2sec]

Maximum On-State Voltage Drop @ Rated Current [Vrms]

Minimum Power Factor (with Maximum Load)

Ratings according to UL 508/IEC60947-4-2 [HP/KW]: 240 VAC

Ratings according to UL 508/IEC60947-4-2 [HP/KW]: 400 VAC

Ratings according to UL 508/IEC60947-4-2 [HP/KW]: 480 VAC

48-530

1200

3.0

500

5

4.8

0.15

750

716

2330

2560

1.15 per channel

0.5

1/.75

2/1.5

3/2.2

48-530

1200

3.0

500

7.6

7.6

0.15

750

716

2330

2560

1.15 per channel

0.5

2/1.5

3/2.2

5/3.7

48-415

1200

3.5

500

7.6

7.6

0.15

750

716

2330

2560

1.15 per channel

0.5

2/1.5

3/2.2

-

48-510

1600

3.5

500

7.6

7.6

0.15

625

597

1621

1779

1.5 per channel

0.5

2/1.5

3/2.2

5/3.7

INPUT SPECIFICATIONS (1)

Description

Control Voltage Range

Minimum Turn-On Voltage (5)

Must Turn-Off Voltage

Minimum Input Current (for on-state) [mA]

Maximum Input Current [mA]

Nominal Input Impedance

Maximum Delay to Turn-On [msec] (8)

Maximum Turn-Off Time [msec] (9)

Option A

Option B

Option D

208-265 (VAC)

208 (VAC)

60 (VAC)

5.5

7.7

36 K

20

30

90-140 (VAC)

90 (VAC)

20 (VAC)

5

8

16.4 K

20

30

18-30 (VAC / VDC)

18 (VAC / VDC)

7 (VAC / VDC)

10

22

1.3 K

20

30

SOLID STATE AUXILIARY CONTACTS (1)

Description

Operating Voltage Range (47-63Hz) [Vrms] (11)

Transient Overvoltage [Vpk]

Maximum Load Current [Arms]

Minimum Load Current [mA]

Maximum Surge Current [Apk] 1 Cycle 60Hz

Maximum Surge Current [Apk] 1 Cycle 50Hz

Maximum I2t for Fusing (8.33msec)[A2sec]

Maximum I2t for Fusing (10msec)[A2sec]

Maximum Off-State Leakage Current @ Rated Voltage [mArms]

Minimum Off-State dv/dt @ Maximum Rated Voltage [V/sec]

Maximum Delay to Turn-On [msec] (8)

Maximum Turn-Off Time [msec] (9)

Normally Open Suffix 2x,1x

Normally Closed Suffix x1

18-280

600

1

5

40

38

6.7

7.2

0.1

500

20

30

18-280

600

1

5

40

38

6.7

7.2

5 mA

500

20

30

GENERAL SPECIFICATIONS (1)

Description

Dielectric Strength, Input/Output/Base (50/60Hz) (4)

Minimum Insulation Resistance (@ 500 V DC)

Maximum Capacitance, Input/Output

Ambient Operating Temperature Range

Ambient Storage Temperature Range

Weight (typical)

Housing Material

Housing Color

LED Status Indicator (color) (7)

Short Circuit Current Rating (10)

Pollution Degree

Protection Degree

Humidity

Control and Auxiliary Contact Terminal Screw Torque Range (in-lbs/Nm)

Load Terminal Screw Torque Range (in-lbs/Nm)

Input Terminal Wire Capacity

Output Terminal Wire Capacity

Do not forget to visit us at: www.crydom.com

Parameters

3750 Vrms

109 Ohm

20 pF

-30 to 80 C

-40 to 100 C

2 Controlled Legs (6.940 oz [196.7 g]) / 3 Controlled Legs (8.050 oz [228 g])

UL94 V-0

Black and Light Gray

Forward (Green) / Reverse (Amber)

100KA

2

IP20

85% non-condensing

12 / 1.36

15 / 1.7

18-12 AWG (IEC 1-4 mm2) (standed /solid)

18-10 AWG (IEC 1-6 mm2 (standed /solid)

Copyright 2014 Custom Sernsors & Technologies. Specifications subject to change without notice.

Solid State Contactor

DataSheet

MECHANICAL SPECIFICATIONS (1)

Tolerances: 0.02 in / 0.5 mm

All dimensions are in: inches [millimeters]

3.51

[89.16]

2.92

[74.17]

0.23

[5.84]

A3

23

A1

DRC3

2.58

[65.53]

2.29

[58.26]

1.23

[31.19]

3.41

[86.71]

13

1.68

[42.67]

IND. CONT. EQ.

INPUT

STATUS

XXXX

14

24

A2

3.78

[96.02]

1.78

[45.31]

Fig. 1

TERMINAL SCREW TYPE

Top/Bottom view (Fig. 1)

THERMAL DERATE INFORMATION (12)

DRC3Pxx (3 legs controlled)

Single unit (6)

Multiple units

DRC3Pxx-2 (2 legs controlled)

Single unit (6)

Multiple units

3

2

1

Load Current (Amps)

Load Current (Amps)

5

4

3

2

1

0

10

20

30

40

50

60

70

80

6

5

4

3

2

1

0

0

Multiple units

Load Current (Amps)

DRC3R

Single unit (6)

10

Ambient Temperature (C)

20

30

40

50

60

70

80

Ambient Temperature (C)

GENERAL NOTES

(1) All parameters at 25C unless otherwise specified.

(2) For DRC3P relay will self trigger between 900-1200V, Not suitable for capacitive loads

(3) Mounted in the Vertical position.

(4) For input to auxiliary output the dielectric strength is 2.5KV.

(5) For low temperature operation consider nominal control voltage.

(6) Minimum spacing to obtain max. current is 22mm between adjacent units.

(7) Reverse Amber Indicator is for DRC3R models only.

(8) For DRC3R the turn-on time is 100ms 30ms. For DRC3P Instantaneous Turn-on, Option D, turn-on time is 1 msec.

(9) For DRC3R the turn-off time is 20ms.

(10) When protected with J Class fuses rated 600 VAC, 20 A or equivalent

(11) Operating voltage range 18-30 VDC is also valid when used to latch the DRC contactor control input.

(12) Derate information is valid when DCR contactors are used with or without accessories, installed on top and/or bottom.

(13) For DRC3P models external loads can be connected in parallel to the control input.

Do not forget to visit us at: www.crydom.com

Copyright 2014 Custom Sensors & Technologies. Specifications subject to change without notice.

0

0

10

20

30

40

50

Ambient Temperature (C)

60

70

80

Solid State Contactor

DataSheet

SWITCHING FREQUENCY/LOAD CHARACTERISTIC FOR ALL DEVICES

IL : Load Operating Current

IR : Rated Full Load Current [FLA]

ID : Direct-On-Line Inrush Current

tL : Load Operating Current Time

tD : Direct-On-Line Inrush Current Time

tC : Cycle Time

tOn : On Time

tOff : Off Time

ID

IR

IL

tD

tL

tOn

tOff

tC

MAXIMUM ALLOWABLE NUMBER OF STARTS PER HOUR DEPENDING ON THE STARTING

TIME tD AND THE ON PERIOD tOn (as for standard IEC 60947-4-2) FOR ALL DEVICES

Without overload relay (limit given by the contactor itself)

Table 2

Table 1

High inrush current (ID/IR = 4 to 7.2)

Full load (IL/IR= 1)

Table 3

High inrush current (ID/IR = 4 to 7.2)

60% load (IL/IR= 0.6)

tOn (sec)

tOn (sec)

Low inrush current (ID/IR < 4 )

60% load (IL/IR= 0.6)

tOn (sec)

0.1

10

100

0.1

10

100

0.1

10

100

0.1

10

0.05

5000

2700

350

35

0.05

6000

3550

350

35

0.05

7450

3200

350

35

0.05

9000

3550

350

35

0.1

3200

1950

350

35

0.1

4100

3000

350

35

0.1

4050

2100

350

35

0.1

5400

3550

350

35

0.2

950

320

35

0.2

1300

350

35

0.2

1200

350

35

0.2

1700

350

35

0.4

500

280

35

0.4

700

320

35

0.4

650

320

35

0.4

850

350

35

0.8

290

160

35

0.8

400

320

35

0.8

350

280

35

0.8

560

350

35

1.6

110

30

1.6

125

35

1.6

180

35

1.6

240

35

3.2

3.2

3.2

3.2

180

35

25

90

35

tD (sec)

tOn (sec)

tD (sec)

75

tD (sec)

Table 4

Low inrush current (ID/IR < 4 )

Full load (IL/IR= 1)

90

35

tD (sec)

100

With overload relay (limit given by the overload relay itself)

Table 5

Table 6

High inrush current (ID/IR = 4 to 7.2)

Full load (IL/IR= 1)

Table 7

High inrush current (ID/IR = 4 to 7.2)

60% load (IL/IR= 0.6)

tOn (sec)

Table 8

Low inrush current (ID/IR < 4 )

Full load (IL/IR= 1)

tOn (sec)

Low inrush current (ID/IR < 4 )

60% load (IL/IR= 0.6)

tOn (sec)

tOn (sec)

tD (sec)

0.1

10

100

tD (sec)

0.1

10

100

tD (sec)

0.1

10

100

tD (sec)

0.1

10

100

0.05

2200

1650

330

30

0.05

2800

1800

320

35

0.05

5150

2800

260

35

0.05

5600

3200

350

35

0.1

1500

1000

280

28

0.1

1700

1300

310

32

0.1

2850

1920

250

34

0.1

3200

2700

350

35

0.2

550

255

26

0.2

650

290

30

0.2

1100

250

33

0.2

1400

350

35

0.4

250

150

24

0.4

300

200

26

0.4

600

200

32

0.4

700

350

35

0.8

80

60

20

0.8

200

90

25

0.8

320

200

30

0.8

350

280

35

1.6

40

16

1.6

65

25

1.6

120

25

1.6

170

35

3.2

3.2

3.2

75

20

3.2

80

25

Do not forget to visit us at: www.crydom.com

Copyright 2014 Custom Sensors & Technologies. Specifications subject to change without notice.

Solid State Contactor

DataSheet

SHORT CIRCUIT AND OVERLOAD PROTECTION FOR ALL DEVICES

(Conforming to the IEC60947-4-2 and UL508)

IEC standard 60947-4-1 make a distinction between two different types of protection, (called coordination), which are designated types 1 and "2".

Any short-circuit that occurs is cleared safely by either type of coordination.

The only difference between the 2 categories concerns the extent of the SSR damage caused by the short-circuit.

Type "1" coordination requires that in the event of a short-circuit, the Solid State Contactor does not endanger personnel or installations,

but permanent damage to the SSC is permissible. In this case the SSC may need to be replaced. For this type of co-ordination,

the use of fusing or circuit breakers adequate to protect the system and wiring from short circuits, (but not specifically considering SSC protection), can be used.

Type "2" coordination requires that under a short-circuit condition, the circuit is interrupted, the SSC does not endanger persons or installations,

and in addition the SSR will be able to operate after the fault condition is repaired.

Type of coordination 1

Protection by Thermal Magnetic Circuit Breaker

Nominal Motor

Current

Thermal Magnetic Circuit Breaker

(Schneider Electric)

Solid State Contactor

2 controlled legs

Solid State Contactor

3 controlled legs

Solid State Contactor

Reversing

0.40-0.63 A

GV2ME04 / GV2P04

DRC3Pxxx4xxx2

DRC3Pxxx4xxx

DRC3Rxxx4xx

0.63-1 A

GV2ME05 / GV2P05

DRC3Pxxx4xxx2

DRC3Pxxx4xxx

DRC3Rxxx4xx

1-1.6 A

GV2ME06 / GV2P06

DRC3Pxxx4xxx2

DRC3Pxxx4xxx

DRC3Rxxx4xx

1.6-2.5 A

GV2ME07 / GV2P07

DRC3Pxxx4xxx2

DRC3Pxxx4xxx

DRC3Rxxx4xx

2.5-4 A

GV2ME08 / GV2P08

DRC3Pxxx4xxx2

DRC3Pxxx4xxx

DRC3Rxxx4xx

4-6.3 A

GV2ME10 / GV2P10

DRC3Pxxx4xxx2

DRC3Pxxx4xxx (up to 4.8A)

DRC3Rxxx4xx

6.3-10 A

GV2ME14 / GV2P14

DRC3Pxxx4xxx2 (up to 7.6A)

DRC3Rxxx4xx (up to 7.6A)

Protection by overload relays and fuses

Nominal Motor

Current

Overload Relay

(Schneider Electric)

Class gG fuses

(example from Littlefuse)

Solid State Contactor

2 controlled legs

Solid State Contactor

3 controlled legs

Solid State Contactor

Reversing

0.40-0.63 A

LRD04

CY14X51G16

DRC3Pxxx4xxx2

DRC3Pxxx4xxx

DRC3Rxxx4xx

0.63-1 A

LRD05

CY14X51G16

DRC3Pxxx4xxx2

DRC3Pxxx4xxx

DRC3Rxxx4xx

1-1.6 A

LRD06

CY14X51G25

DRC3Pxxx4xxx2

DRC3Pxxx4xxx

DRC3Rxxx4xx

1.6-2.5 A

LRD07

CY14X51G25

DRC3Pxxx4xxx2

DRC3Pxxx4xxx

DRC3Rxxx4xx

2.5-4 A

LRD08

CY14X51G25

DRC3Pxxx4xxx2

DRC3Pxxx4xxx

DRC3Rxxx4xx

4-6.3 A

LRD10

CY14X51G40

DRC3Pxxx4xxx2

DRC3Pxxx4xxx (up to 4.8A)

DRC3Rxxx4xx

6.3-10 A

LRD14

CY14X51G40

DRC3Pxxx4xxx2 (up to 7.6A)

DRC3Rxxx4xx (up to 7.6A)

Type of coordination 2

Protection by overload relays and fuses

Nominal Motor

Current

Overload Relay

(Schneider Electric)

Semiconductor fuses with less than 1621A2S Solid State Contactor

(example from Littlefuse)

2 controlled legs

Solid State Contactor

3 controlled legs

Solid State Contactor

Reversing

0.40-0.63 A

LRD04

LA50QS40-4

DRC3Pxxx4xxx2

DRC3Pxxx4xxx

DRC3Rxxx4xx

0.63-1 A

LRD05

LA50QS40-4

DRC3Pxxx4xxx2

DRC3Pxxx4xxx

DRC3Rxxx4xx

1-1.6 A

LRD06

LA50QS40-4

DRC3Pxxx4xxx2

DRC3Pxxx4xxx

DRC3Rxxx4xx

1.6-2.5 A

LRD07

LA50QS40-4

DRC3Pxxx4xxx2

DRC3Pxxx4xxx

DRC3Rxxx4xx

2.5-4 A

LRD08

LA50QS40-4

DRC3Pxxx4xxx2

DRC3Pxxx4xxx

DRC3Rxxx4xx

4-6.3 A

LRD10

LA50QS40-4

DRC3Pxxx4xxx2

DRC3Pxxx4xxx (up to 4.8A) DRC3Rxxx4xx

6.3-10 A

LRD14

LA50QS40-4

DRC3Pxxx4xxx2 (up to 7.6A)

DRC3Rxxx4xx (up to 7.6A)

Note: All the Schneider Electric Thermal magnetic circuit breakers GV2 family (GV2ME and GV2P) is fully mechanical compatible with the DRC contactor using the GV2AF3 connection block.

All the Schneider Electric Overload relay LRD family is fully mechanical compatible with the DRC contactor without the need of any adapter.

The DRC Series can accept the LAD7C1 module (pre-wiring kit allowing direct connection of the NC contact of relay LRD to the contactor)

When the LAD7C1 module is used, the common terminal for the control input is not anymore the A2 terminal of DRC but it is the 96 terminal of the overload relay.

Do not forget to visit us at: www.crydom.com

Copyright 2014 Custom Sensors & Technologies. Specifications subject to change without notice.

Solid State Contactor

DataSheet

WIRING AND BLOCK DIAGRAM (13)

DRC3P CONTACTOR

DRC3Pxxx400xx

DRC3Pxxx411xx

DRC3Pxxx420xx

48-530 VAC, 50 - 60 Hz

L1

L2

L3

L1

L2

L3

Short circuit and overload

current protection (see page 5)

L3

A1

DRC3PXXX400XX

IND. CONT. EQ.

CONTROL

INPUT

INPUT

STATUS

XXXX

A2

T1

T2

T1

T3

T2

T3

L1

T2

/>

L2

13

/>

L3

21

A1

DRC3PXXX411XX

IND. CONT. EQ.

CONTROL

INPUT

INPUT

STATUS

XXXX

14

T1

Motor Controller /

AC-53 Application

T1

/>

22

A2

T2

T1

T3

T2

T3

2nd Auxiliary Contact (18 - 280 VAC) Normally Open

L2

/>

1st Auxiliary Contact (18 - 280 VAC) Normally Open

/>

2nd Auxiliary Contact (18 - 280 VAC) Normally Closed

L1

/>

1st Auxiliary Contact (18 - 280 VAC) Normally Open

/>

General Use /

AC-51 Application

T1

T3

T2

L1

13

L2

L3

A1

L1

L2

L3

A1

T1

T2

T3

A2

T1

T2

T3

A2

DRC3Pxxx400x

DRC3Pxxx420x

(2 Normally Open)

Auxiliary Contacts

13 23

14

T1

DRC3Pxxx411x

(1 Normally Open - 1 Normally Closed)

Auxiliary Contacts

13 21

14

Do not forget to visit us at: www.crydom.com

24

14

Copyright 2014 Custom Sensors & Technologies. Specifications subject to change without notice.

22

CONTROL

INPUT

24

T2

T1

Without Auxiliary Contacts

A1

INPUT

STATUS

XXXX

DRC3P

L1

23

IND. CONT. EQ.

(2 controlled legs model)

Main Circuit

L3

DRC3PXXX420XX

DRC3P

/>

L2

T3

(3 controlled legs model)

Main Circuit

/>

A2

T3

T2

T3

Solid State Contactor

DataSheet

DRC3R REVERSING CONTACTOR

DRC3Rxxx400xx

DRC3Rxxx420xx

48-510 VAC, 50 - 60 Hz

L1

L2

L3

L1

L2

L3

Short circuit and overload current

protection (see page 5)

L1

/>

L2

/>

L3

A3

A1

CONTROL

INPUT

(Forward)

DRC3RXXX400XX

IND. CONT. EQ.

CONTROL

INPUT

(Backward)

INPUT

STATUS

XXXX

A2

T1

T2

T1

COMMON

FOR CONTROL

INPUT

T3

T2

2nd Auxiliary Contact (18 - 280 VAC) Normally Open

/>

1st Auxiliary Contact (18 - 280 VAC) Normally Open

/>

L1

T1

T2

/>

L2

A3

L3

13

23

A1

CONTROL

INPUT

(Forward)

DRC3RXXX420XX

IND. CONT. EQ.

CONTROL

INPUT

(Backward)

INPUT

STATUS

XXXX

14

T1

Motor Controller /

AC-53 Application

T3

/>

24

A2

T2

T1

COMMON

FOR CONTROL

INPUT

T3

T2

T3

T3

Overload current

protection needs to

be considered

DRC3R

Forward

L1

L2

L3

A1

T1

T2

T3

A2

Forward

13

14

Reverse

23

Reverse

L1

L2

T1

T2

L3

24

T3

DRC3Rxxx420

models only

Do not forget to visit us at: www.crydom.com

A3

Copyright 2014 Custom Sensors & Technologies. Specifications subject to change without notice.

A2

Solid State Contactor

DataSheet

TIMING DIAGRAM FOR DRC3R

Input/Output

TIME DIAGRAM

4

5

10

Input A2

Input A3

FWD Direction

100 msec

100 msec

REV Direction

100 msec

STEP

interlock

DESCRIPTION

1, 4, 10

Initial Condition A2 & A3 open

A2 is activated, FWD Output wait for 100ms

3, 9

FWD direction is activated

A2 change to off. FWD Output is desable at the same time

A3 is activated REV Output wait for 100ms

REV direction is On

Interlock fuction is activated. REV is desable due to A2 & A3 are both activated

A3 is open, A2 close, begin 100ms delay

Input A2

Input A3

FWD

REV

Open

Open

Off

Off

Close

Open

On

Off

Open

Close

Off

On

Close

Close

Off

Off

AGENCY APPROVALS

Certification in accordance with:

United States Standard for Industrial Control Equipment - UL 508 and

Canadian Standard Association for Industrial Control Equipment C22.2 No. 14.

DRC3 series conforms to the harmonized EN standard EN/IEC 60947-4-2

Electromagnetic Compatibility:

IEC 61000-4-2 : Electrostatic Discharge Level 3

IEC 61000-4-4 : Electrically Fast Transients Level 3

IEC 61000-4-5 : Electrical Surges Level 3

Vibration Resistance:

IEC 60068-2-6 : Amplitude Range 10-55 Hz, Displacement 0.75mm

Shock Resistance:

IEC 60068-2-27 : Peak Acceleration 15g, Duration11ms.

E116949

Do not forget to visit us at: www.crydom.com

Copyright 2014 Custom Sensors & Technologies. Specifications subject to change without notice.

Rev. 020614

Solid State Contactor

DataSheet

ACCESSORIES FOR ALL DEVICES

Recommended Accessories

Motor Nominal

Current

Bimetal

Overload Relay

Electronic

Overload Relay

Thermal Magnetic Circuit

Breaker (Push Button)

Thermal Magnetic Circuit

Breaker (Selector)

0.40 - 0.63 A

LRD04

LR97 D015xx

GV2ME04

GV2P04

0.63 - 1 A

LRD05

LR97 D015xx

GV2ME05

GV2P05

1 - 1.6 A

LRD06

LR97 D07xx

GV2ME06

GV2P06

1.6 - 2.5 A

LRD07

LR97 D07xx

GV2ME07

GV2P07

2.5 - 4 A

LRD08

LR97 D07xx

GV2ME08

GV2P08

4 - 6.3 A

LRD10

LR97 D25xx

GV2ME10

GV2P10

6.3 - 10 A

LRD14

LR97 D25xx

GV2ME14

GV2P14

Fully compatible with

Schneider Electric

thermal overload

relays &

thermal magnetic

circuit breakers

Note: All the Schneider Electric Thermal magnetic circuit breakers GV2 family (GV2ME and GV2P) is fully mechanical compatible with the DRC contactor using the GV2AF3 connection block.

All the Schneider Electric Overload relay LRD family is fully mechanical compatible with the DRC contactor without the need of any adapter.

The DRC Series can accept the LAD7C1 module (pre-wiring kit allowing direct connection of the NC contact of relay LRD to the contactor)

When the LAD7C1 module is used, the common terminal for the control input is not anymore the A2 terminal of DRC but it is the 96 terminal of the overload relay.

ID Marker Strips

CNLB, CNLN, CNL2

Packages of 10 plastic strips comprising 10

individual markers which can be placed for easy

identifications during the use of multiple units.

Numbered 1 to 10 Strips

Part no.: CNLN

Do not forget to visit us at: www.crydom.com

Copyright 2014 Custom Sensors & Technologies. Specifications subject to change without notice.

Blank Strips

Part no.: CNLB

Numbered 11 to 20 Strips

Part no.: CNL2

Solid State Contactor

DataSheet

DANGER / PELIGRO / DANGER /GEFAHR / PERICOLO /

HAZARD OF

ELECTRIC

SHOCK,

EXPLOSION,

OR ARC FLASH.

Disconnect all

power before

installing or

working with

this equipment.

Verify all

connections

and replace all

covers before

turning on

power.

Failure to follow

these

instructions will

result in death

or serious injury.

RIESGO DE

DESCARGA

ELECTRICA O

EXPLOSION.

Desconectar

todos los

suministros de

energia a este

equipo antes

de trabajar

con este equipo.

Verificar todas

las conexiones

y colocar todas

las tapas antes

de energizer

el equipo.

El

incumplimiento

de estas

instrucciones

puede provocar

la muerte o

lesiones serias.

RISQUE DE

DESCHARGE

ELECTRIQUE

OU EXPLOSION

Eteindre

toutes les

sources

d'nergie de

cet appareil

avant de

travailler

dessus de cet

appareil

Vrifier tous

connections, et

remettre tous

couverts en

olace avant de

mettre sous

De non-suivi de

ces instructions

provoquera la

mort ou des

lsions srieuses

srieuses.

GEFAHR EINES

ELEKTRISCHE

N SCHLAGES

ODER EINER

EXPLOSION.

Stellen Sie

jeglichen

Strom ab, der

dieses Gert

versorgt, bevor

Sie an dem

Gert Arbeiten

durchfhren

Vor dem

Drehen auf

Energie alle

Anschlsse

berprfen

und alle

Abdeckungen

ersetzen.

Unterlassung

dieser

Anweisungen

knnen zum

Tode oder zu

schweren

Verletzungen

fhren.

RISCHIO DI

SCOSSA

ELETTRICA O

DELLESPLOSI

ONE.

Spenga tutta

l'alimentazion

e che fornisce

questa

apparecchiatu

ra prima del

lavorare a questa

apparecchiatu ra

Verificare tutti

i collegamenti

e sostituire

tutte le coperture

prima della

rotazione

sull'alimentazi one

L'omissione di

seguire queste

istruz ioni

provocher la

morte o di

lesioni serie

WARNING / AVERTISSEMENT / WARNUNG /ADVERTENCIA / AVVERTENZA /

RISK OF MATERIAL DAMAGE AND HOT

ENCLOSURE

RISQUE DE DOMMAGE MATERIEL ET DE

SURCHAUFFE DU BOITIER

GEFAHR VON MATERIALSCHDEN UND

GEHUSEERHITZUNG

The product's side panels may be hot, allow

the product to cool before touching.

Follow proper mounting instructions including

torque values.

Do not allow liquids or foreign objects to enter

this product.

Les panneaux latraux du produit peuvent tre

chauds. Laisser le produit refroidir avant de le

toucher.

Respecter les consignes de montage, et

notamment les couples de serrage.

Ne pas laisser pntrer de liquide ni de corps

trangers l'intrieur du produit.

Die Seitenwnde knnen hei sein. Lassen Sie

das Produkt abkhlen, bevor Sie es berhren.

Beachten Sie die Montageanweisungen,

Fhren Sie keine Flssigkeiten oder

Fremdkrper in das Produkt ein.

Le non-respect de cette directive peut entraner,

Failure to follow these instructions can result in des lsions corporelles graves ou des

serious injury, or equipment damage.

dommages matriels.

Die Nichtbeachtung dieser Anweisung kann

Krperverletzung oder Materialschden

zur Folge haben.

RIESGO DE DAOS MATERIALES Y DE

SOBRECALENTAMIENTO DE LA UNIDAD

RISCHIO DI DANNI MATERIALI E D'INVOLUCRO

CALDO

Los paneles laterales del producto pueden

estar calientes. Esperar que el producto se

enfre antes de tocarlo.

Respetar las instrucciones de montaje, y en

particular los pares de apretado.

No dejar que penetren lquidos o cuerpos

extraos en el producto.

I pannelli laterali dell'apparecchio possono

scottare; lasciar quindi raffreddare il prodotto

prima di toccarlo.

Seguire le istruzioni di montaggio corrette.

Non far entrare liquidi o oggetti estranei in questo

apparecchio.

Si no se respetan estas precauciones pueden

producirse graves lesiones, daos materiales.

La mancata osservanza di questa precauzione pu

causare gravi rischi per l'incolumit personale o

danni alle apparecchiature.

Do not forget to visit us at: www.crydom.com

Copyright 2014 Custom Sensors & Technologies. Specifications subject to change without notice.

Solid State Contactor

DataSheet

ANNEX - ENVIROMENTAL INFORMATION

The environmental information disclosed in this annex including the EIP Pollution logo are in compliance with Peoples Republic of China

Electronic Industry Standard SJ/T11364 2006, Marking for Control of Pollution Caused by Electronic Information Products.

Part

Name

Toxic or hazardous Substance and Elements

Lead

(Pb)

Mercury

(Hg)

Cadmium

(Cd)

Hexavalent

Chromium

(Cr (VI))

Polybrominated

biphenyls

(PBB)

Polybrominated

diphenyl ethers

(PBDE)

Semiconductor die

Solder

-

SJ/T11364 - 2006,

(Pb)

(Hg)

(Cd)

(Cr (VI))

(PBB)

50

Do not forget to visit us at: www.crydom.com

Copyright 2014 Custom Sensors & Technologies. Specifications subject to change without notice.

(PBDE)

You might also like

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Description Power Range: Analog Servo DriveDocument7 pagesDescription Power Range: Analog Servo DriveElectromateNo ratings yet

- Description Power Range: Analog Servo DriveDocument7 pagesDescription Power Range: Analog Servo DriveElectromateNo ratings yet

- Description Power Range: Analog Servo DriveDocument7 pagesDescription Power Range: Analog Servo DriveElectromateNo ratings yet

- Description Power Range: Analog Servo DriveDocument7 pagesDescription Power Range: Analog Servo DriveElectromateNo ratings yet

- Data SheetDocument7 pagesData SheetOvi PanteaNo ratings yet

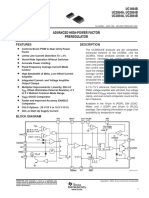

- Advanced High-Power Factor Preregulator: Features DescriptionDocument18 pagesAdvanced High-Power Factor Preregulator: Features DescriptionAlejandro Navarro CrespinNo ratings yet

- Description Power Range: Analog Servo DriveDocument8 pagesDescription Power Range: Analog Servo DriveElectromateNo ratings yet

- DRC-24V30W1A Technical DatasheetDocument11 pagesDRC-24V30W1A Technical Datasheetzivko13No ratings yet

- ULTRA-700 0 - 1040 0-1400 0-EN-New DC Recombiner PDFDocument4 pagesULTRA-700 0 - 1040 0-1400 0-EN-New DC Recombiner PDFAdrian Ioan POPNo ratings yet

- 12 Volt Smps Circuit DiagramDocument7 pages12 Volt Smps Circuit DiagramAnura MaddumageNo ratings yet

- Description Power Range: Analog Servo DriveDocument8 pagesDescription Power Range: Analog Servo DriveElectromateNo ratings yet

- Fuse Contactor Selection - 6.6kVDocument10 pagesFuse Contactor Selection - 6.6kVapmanungadeNo ratings yet

- TRN Spec SheetDocument2 pagesTRN Spec Sheetapi-170472102No ratings yet

- GS 01f06a00-01e - 013Document36 pagesGS 01f06a00-01e - 013Gilang RomadhonNo ratings yet

- Single Phase Recloser CatalogDocument8 pagesSingle Phase Recloser CatalogCesar VenturoNo ratings yet

- 250T Frequency TransmitterDocument13 pages250T Frequency Transmitterreality88No ratings yet

- Catalog: General Purpose Plug-In RelaysDocument12 pagesCatalog: General Purpose Plug-In Relaysmicaziv4786No ratings yet

- Relay PDFDocument6 pagesRelay PDFankursharma17No ratings yet

- STR A6151 STR A6159 DatasheetDocument7 pagesSTR A6151 STR A6159 DatasheetVidal VelasquezNo ratings yet

- Features Description: D D D D D D D D D D D DDocument16 pagesFeatures Description: D D D D D D D D D D D D1eugen1No ratings yet

- Description Power Range: Analog Servo DriveDocument9 pagesDescription Power Range: Analog Servo DriveElectromateNo ratings yet

- CA3059, CA3079: Description FeaturesDocument12 pagesCA3059, CA3079: Description FeaturesMiltongrimi GrimilNo ratings yet

- Timers, Time, Switches, Hour Meters & Supply MonitorsDocument24 pagesTimers, Time, Switches, Hour Meters & Supply MonitorsnogeshwarNo ratings yet

- A6251 6252Document7 pagesA6251 6252Giovanni Carrillo VillegasNo ratings yet

- 5101 Motor DriverDocument11 pages5101 Motor DriverMoise CristinaNo ratings yet

- Ca3140, Ca3140A: 4.5Mhz, Bimos Operational Amplifier With Mosfet Input/Bipolar Output FeaturesDocument22 pagesCa3140, Ca3140A: 4.5Mhz, Bimos Operational Amplifier With Mosfet Input/Bipolar Output FeaturesfcabreraibanezNo ratings yet

- STR-A6151 Al 6159 PDFDocument7 pagesSTR-A6151 Al 6159 PDFJosé BenavidesNo ratings yet

- EearDocument14 pagesEearOswald NgNo ratings yet

- M/V™ Series Servo Drive: Description Power RangeDocument11 pagesM/V™ Series Servo Drive: Description Power RangeElectromateNo ratings yet

- Air Circuit Breaker: Catalogue 2012Document20 pagesAir Circuit Breaker: Catalogue 2012Addin Galih PrakosoNo ratings yet

- Description Power Range: Analog Servo DriveDocument9 pagesDescription Power Range: Analog Servo DriveElectromateNo ratings yet

- Circuito Integrado TA8207KDocument11 pagesCircuito Integrado TA8207KIberê CamposNo ratings yet

- Danfoss MCD3000 BrosuraDocument2 pagesDanfoss MCD3000 BrosurazvekoslavNo ratings yet

- CA3140Document20 pagesCA3140Brzata PticaNo ratings yet

- Unisonic Technologies Co., LTD: Reverse Blocking Triode ThyristorsDocument3 pagesUnisonic Technologies Co., LTD: Reverse Blocking Triode ThyristorsroozbehxoxNo ratings yet

- PWM Module Drv101Document20 pagesPWM Module Drv101DTPHawkNo ratings yet

- Relay XRU PDFDocument3 pagesRelay XRU PDFdanielliram993100% (1)

- ATV32HD15N4Document12 pagesATV32HD15N4gasm22No ratings yet

- Technical Data Sheet 3RW33 Soft Starter For Carrier NGC IV: DangerDocument6 pagesTechnical Data Sheet 3RW33 Soft Starter For Carrier NGC IV: DangervickersNo ratings yet

- ACB - AH TypeDocument4 pagesACB - AH Type4usangeet50% (2)

- Low Frequency Power Amplifier: FeaturesDocument10 pagesLow Frequency Power Amplifier: FeaturesgusguicorNo ratings yet

- Op MFM384 MFM384-C Op347-V05Document4 pagesOp MFM384 MFM384-C Op347-V05Lyle ThompsonNo ratings yet

- Description Power Range: Analog Servo DriveDocument7 pagesDescription Power Range: Analog Servo DriveElectromateNo ratings yet

- 9-1 Inverter Specifications 9-2 Specifications of Accessories 9-3 Option SpecificationsDocument26 pages9-1 Inverter Specifications 9-2 Specifications of Accessories 9-3 Option SpecificationsAlejandro HernandezNo ratings yet

- E Tended Environment: Analog Servo DriveDocument8 pagesE Tended Environment: Analog Servo DriveElectromateNo ratings yet

- Analog Servo Drive: Description Power RangeDocument9 pagesAnalog Servo Drive: Description Power RangeElectromateNo ratings yet

- RECLOSER-FARADAY-33KV Auto Recloser BrochureDocument9 pagesRECLOSER-FARADAY-33KV Auto Recloser BrochureJoel Alevxandr OsorttoNo ratings yet

- Analog Servo Drive: Description Power RangeDocument9 pagesAnalog Servo Drive: Description Power RangeElectromateNo ratings yet

- C 011 AredDocument21 pagesC 011 AredreidashmanNo ratings yet

- Amc 12a8 SpecsheetDocument9 pagesAmc 12a8 SpecsheetElectromateNo ratings yet

- STK433-890-E: 4-Channel Class AB Audio Power IC, 80WDocument10 pagesSTK433-890-E: 4-Channel Class AB Audio Power IC, 80WSelvacellsNo ratings yet

- Relay P14X DatasheetDocument24 pagesRelay P14X Datasheetaeqv12No ratings yet

- Tma Bias TeeDocument3 pagesTma Bias TeeLeandro Bernal MohrNo ratings yet

- M/V™ Series Servo Drive: Description Power RangeDocument11 pagesM/V™ Series Servo Drive: Description Power RangeElectromateNo ratings yet

- tps54240 q1Document52 pagestps54240 q1Em GomezNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsFrom EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsRating: 3.5 out of 5 stars3.5/5 (6)

- Termometro Bimetalico FichaDocument6 pagesTermometro Bimetalico FichaloritocomNo ratings yet

- Hydrolysis Kinetics in Anaerobic Degradation of Particulate Organic Material: An OverviewDocument13 pagesHydrolysis Kinetics in Anaerobic Degradation of Particulate Organic Material: An OverviewloritocomNo ratings yet

- Direct Dimethyl Ether SynthesisDocument9 pagesDirect Dimethyl Ether SynthesissltnrmnNo ratings yet

- Case Study 104Document9 pagesCase Study 104loritocomNo ratings yet

- Track SizingDocument1 pageTrack SizingloritocomNo ratings yet

- E-Line KX EngDocument58 pagesE-Line KX EngIppiNo ratings yet

- Pulsation Systems: Setting The Standard For Durable and Consistent PulsationDocument8 pagesPulsation Systems: Setting The Standard For Durable and Consistent PulsationbanerjeeamlanNo ratings yet

- NT00243 en 04Document97 pagesNT00243 en 04Pedro OcantoNo ratings yet

- Dilution Tank Heater Temp. ControlDocument152 pagesDilution Tank Heater Temp. ControlBayu Dwi AsmaraNo ratings yet

- Bi CMOSDocument1 pageBi CMOSJunaid IkramNo ratings yet

- So KZ Re MN SMP Series en GL 231130Document36 pagesSo KZ Re MN SMP Series en GL 231130beriloNo ratings yet

- WG CIRED - Smart Secondary Substations - Final ReportDocument58 pagesWG CIRED - Smart Secondary Substations - Final ReportqxzyNo ratings yet

- Practical Electronics 1978 01Document84 pagesPractical Electronics 1978 01Marcelo KraiserNo ratings yet

- Error Messages 4.1 Brief DescriptionDocument10 pagesError Messages 4.1 Brief DescriptionRuben DuranNo ratings yet

- EDC Lab I ManualsDocument101 pagesEDC Lab I ManualskattaswamyNo ratings yet

- Analysis of The Interaction of Laser-Induced Solid-State Plasma With Electromagnetic Waves in Silicon Waveguides at 67-220 GHZDocument4 pagesAnalysis of The Interaction of Laser-Induced Solid-State Plasma With Electromagnetic Waves in Silicon Waveguides at 67-220 GHZalimadan1992No ratings yet

- Sdwu SX0 o QP 2 H 9 XW NSew 3Document4 pagesSdwu SX0 o QP 2 H 9 XW NSew 3Lorena OrtizNo ratings yet

- Current Mode Slope CompensationDocument11 pagesCurrent Mode Slope CompensationDaniel BiasiNo ratings yet

- Cathodic ProtectionDocument10 pagesCathodic Protectionmayank dhokeNo ratings yet

- 6 in 1 RF Remote Control SystemDocument56 pages6 in 1 RF Remote Control SystemCynthia LezamaNo ratings yet

- Power and Distribution Transformers Catalog 2015Document17 pagesPower and Distribution Transformers Catalog 2015Pook ElvinNo ratings yet

- Sanyo Ce14at3cDocument3 pagesSanyo Ce14at3cpheromail2001No ratings yet

- For ELECTRICAL TESTING LABORATORIES - The NABL (PDFDrive)Document122 pagesFor ELECTRICAL TESTING LABORATORIES - The NABL (PDFDrive)Mani Dhamodharan100% (1)

- 2 Marks With Answers Collection 1Document19 pages2 Marks With Answers Collection 1Guna PriyaNo ratings yet

- Cathodic Protection Manual-QUIZDocument66 pagesCathodic Protection Manual-QUIZrobythoppil100% (12)

- Medium Voltage UPS - Fuji Electric GlobalDocument3 pagesMedium Voltage UPS - Fuji Electric GlobalRaymart MateoNo ratings yet

- Electrical Safety Tester User Manual Electrical Safety Tester User ManualDocument12 pagesElectrical Safety Tester User Manual Electrical Safety Tester User ManualJorge Cardona GilNo ratings yet

- Lft-Tet, Transformer Trainer Exp Manual, 9082b, ImtacDocument102 pagesLft-Tet, Transformer Trainer Exp Manual, 9082b, ImtacRanciesHambreyMagatRodriguezNo ratings yet

- Clinox Pro Energy - Service Manual (Eng) r1.3Document52 pagesClinox Pro Energy - Service Manual (Eng) r1.3Mohamed AbdalhakamNo ratings yet

- Bipolar Transistor: 30V, 1.5A, Low VCE (Sat), NPN Single PCPDocument8 pagesBipolar Transistor: 30V, 1.5A, Low VCE (Sat), NPN Single PCProlandseNo ratings yet

- Ingaas/Gaassb Heterojunction Tfet: January 2015Document6 pagesIngaas/Gaassb Heterojunction Tfet: January 2015Anonymous jxm0WNS7QaNo ratings yet

- TDT 172718DEI 65Fv05Document1 pageTDT 172718DEI 65Fv05Дмитрий100% (1)

- Crumar Mojo Classic SuitcaseDocument20 pagesCrumar Mojo Classic SuitcaseLouis LukenNo ratings yet

- Semiconductor MaterialsDocument13 pagesSemiconductor MaterialsRizza Mae SorianoNo ratings yet

- SMAW BasicsDocument28 pagesSMAW BasicssanjibkrjanaNo ratings yet