Professional Documents

Culture Documents

Design and Analysis of Ball Bearing

Uploaded by

Gamini SureshCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design and Analysis of Ball Bearing

Uploaded by

Gamini SureshCopyright:

Available Formats

International Journal of Advanced Science and Engineering Research

Volume: 1, Issue: 1, June 2016

www.ijaser.in

ISSN: 2455-9288

DESIGN AND ANALYSIS OF BALL BEARING

Author: 1. M.DEVENDRAN PG Scholar, Department of Mechanical Engineering, Al Ameen Engineering College. Erode,

Tamilnadu.

ABSTRACT:The main objective of our project is to explore the analysis of a ball bearing. This has entailed performing a detailed

thermal analysis. The study deals with dynamic, modal and transient thermal analysis. A proper Finite Element Model is developed

using Cad software Pro/E Wildfire 4.0. Here we are doing the material optimization of balls used in bearing. We are designed the 3D

model of the axle by using pro-e software and the analysis are made by different combination of materials for the bearing and the

analysis carried out using ansys software. In this project we are analyzing the rotational velocity and moment acting on the bearing

by the two materials. Presently the bearing is made by the stainless steel material. we are testing the same load for ceramic material.

Then the thermal analysis is done to determine the total heat flux in the existing ball bearing for the given temperature conditions.

The temperature acting on the inner surface of the bearing is applied and the results were also used to determine the total heat flux

for a particular material.

1. INTRODUCTION

1.1 Materials Already Used:

There are essentially two choices for the material used in ball bearings - chrome steel or stainless steel.

Since the material plays a major part in the performance of a bearing in any given application, it is very important that

the correct material is used. Note that the specified material applies to the load bearing components only - the rings and

the balls. The retainer and the shields (if used) are usually made from a different material and are subject to separate

specification.

1.2 Chrome Steel:

This is the standard material used for ball bearing applications where load capacity is the main

consideration. The machinability of this steel is excellent, giving smooth, low noise raceway finishes, together with

superior life. Chrome steel material is recommended in applications where corrosion is not a factor.

1.3 Stainless Steel:

400 series martensitic stainless steel is the standard material for miniature and instrument ball bearings where corrosion

resistance is more important than load capacity. There are 3 types of 400 series stainless steel used in the bearings

described in this handbook. These materials have evolved in response to different manufacturing and application needs.

It is important to note that the actual material used is generally determined by the manufacturer, and cannot be specified

by the user. The bearing part numbering system gives the appropriate codes for each material type.

2. CERAMIC BEARING AND CERAMIC BALL BEARINGS CLASSIFICATION

Press materials: ceramic bearings can be divided into zirconia ceramic bearings, silicon nitride ceramic bearings,

ceramic bearing compound.By the structure: ceramic bearings can be divided into: zirconia ceramic bearings with cage, silicon

nitride ceramic bearings with cage, composite ceramic bearing with retainer. General ceramic bearing retainer materials to

Copyright 2016 by the Authors.

This is an open access article distributed under the Creative Commons Attribution License, which permits

unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

413

International Journal of Advanced Science and Engineering Research

Volume: 1, Issue: 1, June 2016

www.ijaser.in

ISSN: 2455-9288

polytetrafluoroethylene (PTFE) as a standard configuration, you can also use glass fiber reinforced nylon 66 (GRPA66-25), special

engineering plastics (PEEK, PI), stainless steel (SUS316, SUS304), Brass (Cu) and so on. Ceramic materials because of pocket-hole

cage processing, molding technology and other problems, still less use; as retainer material restrictions for special occasions and

developed using a non-retainer all-ceramic zirconia full ball bearings and silicon nitride balls full Full ceramic ball bearings and full

ceramic bearings composite.

Divided by the integrity of the material: ceramic bearings to the above mentioned major components inside and

outside the ring and rolling elements are mostly ceramic material, it is defined as the ceramic bearings; if the bearing outer rings and

rolling elements are part of the ceramic material is not used when we it is defined as the hybrid ceramic bearings. The use of hybrid

bearings is more extensive use of ceramic materials known as ceramic ball bearings, can be divided into zirconia ceramic ball

bearings, silicon nitride ceramic ball bearings.

Different materials and different structure of the ceramic bearing and ceramic ball bearings in use need attention

vary, please check the specific details of the ceramic bearing and ceramic ball bearings professional manufacturer for more help.

3. LOOKING CERAMIC BEARING AND CERAMIC BALL BEARINGS WITH PROSPECTS

Ceramic bearing and ceramic ball bearings have many excellent properties such as: self-lubricating, high

temperature, corrosion resistant, magnetic, electrical insulation, etc., yet in the wider field of development and utilization of potential

applications is enormous. The first high-quality high-speed ceramic ball bearings: excellent service to the domestic machine tool

industry, high-speed, high precision spindle, spindle bearing a large amount of the estimated annual demand picked up in a few

million units or more. But the high-precision spindle bearings precision bearings requires relatively high quality and more stringent

requirements as the G5 P4-bearing ceramic ball above the level of precision is currently able to produce very few manufacturers,

product stability is poor. Second: the medium-quality ceramic bearings in oil exploration, oil refining, in particular, fine chemicals,

chemical fiber, new energy, printing and dyeing, electroplating, water treatment, marine development, deep-water pumps, acid

pumps, high temperature, vacuum, magnetic resonance, electrical insulation, medical, X-ray tube and the food industry and many

other areas can be extensive and well used. Many only require the general accuracy level; medium and low speed and load;

requirements bearing resistant to a certain concentration of acid, alkali and salt corrosion; resistant to 300 400 high temperature;

non-magnetic, electric, non-toxic; can be used without oil or lubrication of the working medium itself; in seawater can also be used.

Bearing applications in these areas account for a very large proportion of special bearings and ceramic bearings and ceramic ball

bearings are fully capable to replace, and can barely reach the metal bearing the work of competent and incompetent, engineering

ceramics has its irreplaceable position. Have such a huge market for the premise, our product development and manufacturing can

create a new way to broaden the application areas of ceramic bearing greater. The new materials, new processes, new technologies to

better serve the production.

Copyright 2016 by the Authors.

This is an open access article distributed under the Creative Commons Attribution License, which permits

unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

414

International Journal of Advanced Science and Engineering Research

Volume: 1, Issue: 1, June 2016

www.ijaser.in

ISSN: 2455-9288

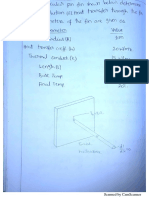

4. BEARING DESIGN

5. MATERIAL PROPERTIES

Structural

Si3N4

Stainless Steel

Youngs Modulus

3.17 e+005 MPa

1.93 e+005 MPa

Poissons Ratio

0.27

0.31

Density

3.29 e-006 kg/mm3

7.75 e-006 kg/mm3

Thermal Expansion

3.3 e-006 1/C

1.7 e-005 1/C

Thermal

Si3N4

Stainless Steel

Thermal Conductivity

2.4 e-002 W/mm C

1.51 e-002 W/mm C

Specific Heat

0.17 J/kg C

480 J/kg C

6. INPUTS & RESULTS OF STAINLESS STEEL AND CERAMIC

6.1 Stainless steel

6.1.1DYNAMIC

6.1.2 Total Deformation

Copyright 2016 by the Authors.

This is an open access article distributed under the Creative Commons Attribution License, which permits

unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

415

International Journal of Advanced Science and Engineering Research

Volume: 1, Issue: 1, June 2016

www.ijaser.in

ISSN: 2455-9288

STAINLESS STEEL

MINIMUM

MAXIMUM

Si3N4

MINIMUM

MAXIMUM

6.2 Si3N4 CERAMIC

6.2.1 DYNAMIC

6.2.1 Total Deformation

7. COMPARISON OF STAINLESS STEEL AND Si3N4

Copyright 2016 by the Authors.

This is an open access article distributed under the Creative Commons Attribution License, which permits

unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

416

International Journal of Advanced Science and Engineering Research

Volume: 1, Issue: 1, June 2016

Total deformation ( mm)

www.ijaser.in

ISSN: 2455-9288

0.011039

0.01133

Equivalent elastic strain( mm/mm)

4.1274e-6

0.00047875

3.1357e-6

0.00048118

Equivalent stress ( Mpa)

0.79659

92.398

0.99401

92.868

Total deformation 1( mm)

33.013

33.015

34.489

34.49

Total deformation 2( mm)

33.014

33.014

34.489

34.49

Total deformation 3( mm)

33.013

33.014

34.489

34.49

Total deformation 4( mm)

0.062856

65.129

0.10357

68.363

Total deformation 5( mm)

8.4466

47.254

9.0095

49.59

Total deformation 6( mm)

0.12992

65.19

0.12754

68.44

TEMPERATURE( C)

21.768

158.15

21.768

156.31

TOTAL HEAT FLUX( W/mm2)

4.0199e-6

1.1178

4.0589e-6

1.4045

DIRECTIONAL HEAT FLUX

-0.92726

0.89011

-1.1771

1.1264

( W/mm2)

CONCLUSION

Experimental results are obtained from testing the conventional ball bearing and optimized bearing under total

deformation, equivalent strain and stress, temperature are listed in the Table. Analysis has been carried out by dynamic, nodal and

thermal. The stainless steel material is used as a conventional. The results for dynamic, nodal and transient thermal such as total

deformation (0.01133mm), equivalent elastic strain (0.00048118mm/mm), and equivalent stress (92.868Mpa), temperature

(156.31C), total heat flux (1.4045W/mm2) and directional heat flux(1.1264W/mm2) in each direction are determined. Comparing

the optimized ball bearing and the conventional ball bearing, optimized ball bearing posses the high withstand temperature. Hence

we concluded optimized ball bearing is suitable.

REFERENCES

1. Design data book

-P.S.G.Tech.

2. Machine tool design handbook Central machine tool Institute, Bangalore.

3. Strength of Materials

- R.S.Kurmi

4. Manufacturing Technology - M.Haslehurst.

5. Design of machine elements - R.S.Kurmi

Copyright 2016 by the Authors.

This is an open access article distributed under the Creative Commons Attribution License, which permits

unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

417

You might also like

- Crankshaft fatigue analysis review focuses on life estimation methodsDocument7 pagesCrankshaft fatigue analysis review focuses on life estimation methodsGamini SureshNo ratings yet

- Crankshaft fatigue analysis review focuses on life estimation methodsDocument7 pagesCrankshaft fatigue analysis review focuses on life estimation methodsGamini SureshNo ratings yet

- Finite Element Simulation of Shear Wave PropagatioDocument6 pagesFinite Element Simulation of Shear Wave PropagatioGamini SureshNo ratings yet

- FEM Record PDFDocument43 pagesFEM Record PDFGamini SureshNo ratings yet

- Someka Templates InfoDocument12 pagesSomeka Templates Infosunildubey02No ratings yet

- Lopez Etal CFD Study of Jet Impingement Test Erosion Using Ansys Fluent and OpenFoamDocument21 pagesLopez Etal CFD Study of Jet Impingement Test Erosion Using Ansys Fluent and OpenFoamGamini SureshNo ratings yet

- Experimental and Numerical Study of Angu PDFDocument9 pagesExperimental and Numerical Study of Angu PDFGamini SureshNo ratings yet

- 4213 11136 1 SM PDFDocument4 pages4213 11136 1 SM PDFGamini SureshNo ratings yet

- ME - R16 Book PDFDocument200 pagesME - R16 Book PDFGamini SureshNo ratings yet

- Fins ProblemDocument4 pagesFins ProblemGamini SureshNo ratings yet

- 2 D ElementsDocument18 pages2 D ElementsBennet KuriakoseNo ratings yet

- Study On Mechanical Performance and Wear Resistance of Halloysite Nanotubes/PTFE Nanocomposites Employing Solution Mixing MethodDocument9 pagesStudy On Mechanical Performance and Wear Resistance of Halloysite Nanotubes/PTFE Nanocomposites Employing Solution Mixing MethodGamini SureshNo ratings yet

- Exoskeleton Design For LegDocument8 pagesExoskeleton Design For LegGamini SureshNo ratings yet

- Isoparametric FormulationDocument42 pagesIsoparametric FormulationLarryNo ratings yet

- Surogate ModelingDocument11 pagesSurogate ModelingGamini SureshNo ratings yet

- Fatigue Design of Automotive Suspension Coil SpringDocument7 pagesFatigue Design of Automotive Suspension Coil SpringGamini SureshNo ratings yet

- Surrogate Based OptimizationDocument18 pagesSurrogate Based OptimizationGamini SureshNo ratings yet

- ADMET Materials Testing Guide July 2013Document17 pagesADMET Materials Testing Guide July 2013Gamini SureshNo ratings yet

- Secants Tangents Arcs AngleDocument7 pagesSecants Tangents Arcs AngleGamini SureshNo ratings yet

- FEM Method in 2D Heat Conduction PDFDocument52 pagesFEM Method in 2D Heat Conduction PDFAhmadreza AminianNo ratings yet

- FEA101 CourseNotesDocument149 pagesFEA101 CourseNotesRadhikaNo ratings yet

- b7 Force Analysis PDFDocument25 pagesb7 Force Analysis PDFGamini SureshNo ratings yet

- Surogate ModelingDocument11 pagesSurogate ModelingGamini SureshNo ratings yet

- Ch1 Trib IntroDocument58 pagesCh1 Trib IntroJaime BerryNo ratings yet

- TgaDocument1 pageTgaGamini SureshNo ratings yet

- WWW Manaresults Co inDocument2 pagesWWW Manaresults Co inGamini SureshNo ratings yet

- Tribology BasicsDocument70 pagesTribology Basicsfeni4kaNo ratings yet

- MEL 417 Lubrication Lec 030211Document37 pagesMEL 417 Lubrication Lec 030211Gamini SureshNo ratings yet

- VISCOSITYDocument17 pagesVISCOSITYAnonymous MxVWU4No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- LAC-Documentation-Tool Session 2Document4 pagesLAC-Documentation-Tool Session 2DenMark Tuazon-RañolaNo ratings yet

- City of Brescia - Map - WWW - Bresciatourism.itDocument1 pageCity of Brescia - Map - WWW - Bresciatourism.itBrescia TourismNo ratings yet

- IE399 Summer Training ReportDocument17 pagesIE399 Summer Training ReportgokanayazNo ratings yet

- 99 181471 - Sailor System 6000b 150w Gmdss MFHF - Ec Type Examination Module B - Uk TuvsudDocument6 pages99 181471 - Sailor System 6000b 150w Gmdss MFHF - Ec Type Examination Module B - Uk TuvsudPavankumar PuvvalaNo ratings yet

- Indian Institute OF Management, BangaloreDocument20 pagesIndian Institute OF Management, BangaloreGagandeep SinghNo ratings yet

- A Systematic Scoping Review of Sustainable Tourism Indicators in Relation To The Sustainable Development GoalsDocument22 pagesA Systematic Scoping Review of Sustainable Tourism Indicators in Relation To The Sustainable Development GoalsNathy Slq AstudilloNo ratings yet

- Strain Gauge Sensor PDFDocument12 pagesStrain Gauge Sensor PDFMario Eduardo Santos MartinsNo ratings yet

- HP OpenVMS Alpha Version 8.3 and HP OpenVMS Version 8.3-1H1 For IntegrityDocument65 pagesHP OpenVMS Alpha Version 8.3 and HP OpenVMS Version 8.3-1H1 For IntegrityAlexandru BotnariNo ratings yet

- Global 6000 SystemsDocument157 pagesGlobal 6000 SystemsJosé Rezende100% (1)

- Practical LPM-122Document31 pagesPractical LPM-122anon_251667476No ratings yet

- Addition and Subtraction of PolynomialsDocument8 pagesAddition and Subtraction of PolynomialsPearl AdamosNo ratings yet

- Class 9th Chemistry Unit#4 Structure of MoleculesDocument8 pagesClass 9th Chemistry Unit#4 Structure of MoleculesIrfanullahNo ratings yet

- Mark Dean GR6211 Fall 2018 Columbia University: - Choice Theory'Document5 pagesMark Dean GR6211 Fall 2018 Columbia University: - Choice Theory'bhaskkarNo ratings yet

- Fundamental Managerial Accounting Concepts 9th Edition Edmonds Solutions ManualDocument35 pagesFundamental Managerial Accounting Concepts 9th Edition Edmonds Solutions ManualDrMichelleHutchinsonegniq100% (15)

- Understanding Culture, Society and PoliticsDocument62 pagesUnderstanding Culture, Society and PoliticsTeds TV89% (84)

- CH - 3Document3 pagesCH - 3Phantom GamingNo ratings yet

- Shimano Brakes ManualDocument36 pagesShimano Brakes ManualKon Arva100% (1)

- Critique On A Film Director's Approach To Managing CreativityDocument2 pagesCritique On A Film Director's Approach To Managing CreativityDax GaffudNo ratings yet

- Medical filter performance specificationsDocument1 pageMedical filter performance specificationsPT.Intidaya Dinamika SejatiNo ratings yet

- The Life and Works of Jose RizalDocument20 pagesThe Life and Works of Jose RizalBemtot Blanquig100% (1)

- The Invisible Hero Final TNDocument8 pagesThe Invisible Hero Final TNKatherine ShenNo ratings yet

- Lesson 5 CMADocument10 pagesLesson 5 CMAAssma SabriNo ratings yet

- Chapter 08Document18 pagesChapter 08soobraNo ratings yet

- Guidelines 2.0Document4 pagesGuidelines 2.0Hansel TayongNo ratings yet

- Aquafine Optivenn Series Data SheetDocument8 pagesAquafine Optivenn Series Data SheetKenz ZhouNo ratings yet

- STEM Spring 2023 SyllabusDocument5 pagesSTEM Spring 2023 SyllabusRollins MAKUWANo ratings yet

- BMXNRPDocument60 pagesBMXNRPSivaprasad KcNo ratings yet

- Seminar #22 Vocabury For Speaking PracticeDocument7 pagesSeminar #22 Vocabury For Speaking PracticeOyun-erdene ErdenebilegNo ratings yet

- English Skills BookDocument49 pagesEnglish Skills BookAngela SpadeNo ratings yet

- Electronic Harassment Strahlenfolter - A Short History of Sound Weapons Pt2 - InfrasoundDocument10 pagesElectronic Harassment Strahlenfolter - A Short History of Sound Weapons Pt2 - InfrasoundFrank-BoenischNo ratings yet