Professional Documents

Culture Documents

2223 SM PDF

Uploaded by

minoltaep40500 ratings0% found this document useful (0 votes)

11 views214 pagesOriginal Title

2223 SM.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views214 pages2223 SM PDF

Uploaded by

minoltaep4050Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 214

SERVICE MANUAL

CSM-2223 Mm JULY 1997

Important Notice

In response to a great number of requests from branch and dealer field technicians, Konica's

Corporate publishing Services Department has configured this manual so that a quick reference

guide (QRG) can be pulled directy from this book

Configuring the manual in this way eliminates the need to duplicate the same information in

both the service manual and a seperate QRG. Once the QRG has been removed, the size of the

‘manual willbe signifigantly reduced allowing it tobe stored ina smaller binder. An added benefit

is that only one book must be updated when revisions are issued.

‘The table below outlines the procedure for pulling the QRG.

Section _ Remove pages 7

| Remove tho cover located at the rear of

Front matter] Sieur Rovies Hitt onthe

Sections have been stapled to the cover |

Tae

2 | oa-pa2 |

ees

«fal

6 fam -

fan

Po ue

le 13-15

2223

SERVICE MANUAL

JUNE 1997

IMPORTANT NOTICE

Because of the possible hazards to an inexperienced

pperson servicing this equipment, as well as the risk of

damage to the equipment, Konica Business Machines

U.S.A, Inc., strongly recommends that all servicing be

perfermed by Konica-trained service technicians only.

Changes may have been made to this equipment to

improve its performance alter this service manual was

Printed. Accordingly, Konica Business Machines

U.S.A, Inc., makes no representations or warranties,

cither expressed or implied, that the information con:

tained in this service manual is complete or accurate. It

is understood that the userof this manual must assume

all risks or personal injury and/or damage to the equip-

‘ment while servicing the equipment for which this serv-

ice manual is intended

Corporate Pubieatione Deparment

(© 1997, KONICA BUSINESS MACHINES U.S.A, INC.

Allright reserve,

Prntedin USA,

CONTENTS

REVISION HISTORY.

SAFETY PRECAUTIONS.

SAFETY CIRCUTTS,

DIFFERENCES BETWEEN 1120 ANO 2223,

MAIN BODY

SYSTEM OUTUNE

PRODUCT CONFIGURATOR

PRODUCT SPECIFICATIONS:

“ype

Functions

‘Cony Paper

Options

Pareulars a chine

Msitanance

‘Copy Matorale

Machine Operating Emironment

CENTER CROSS SECTION.

FIVE SYSTEM DRAWINGS

‘Maiyrum Dive

Coptes ine

ons Un Ove

EXTERNAL SECTION,

Conetrcton,

Disassomeiy and Assombly

DRIVE SECTION

Construction,

Mechanim,

Dicasomby and Assombly

ain) Cont!

rum Drive) Cone.

optics secriON

‘Conatction,

Mechanism

Dlssembly and Ascoby

‘Optics Dive (Ma) Contat

Lens Drive (M3) Contre

Exposure Lamp Conta

RES Contos

PS Conta

Radiation solenoid (608) contra

[OFUM CARRIAGE UNIT

‘Conercton

Mechanism

Disassombl and Assembly

EL Control

POL Cont

Separation Caw Conta

(CORONA UNTT

‘Consrton

Daassombly and Assembly

(charging, TansorSe

DEVELOPING SECTION,

‘Constiton

Mochanim.

Disassembly and Base

Deveioping Bias Cont

Tonor Daety ont

TONER SUPPLY UNIT

‘Constructo,

Mechanism

ona Lee! Detection Cont

(CLEANING UNIT/TONER COLLECTING UNIT

Contraction

chan

Diaseomsy and Assembly

PAPER FEED SECTION

‘constuction.

chan.

Disassembly and Ascot

Paper Feed Contot

Paper Sie Dstecton Gant

ABER CONVEYANCE SECTION

‘Consnitio,

Mechanism

‘Disassembly and Assomely

FUSING UNIT

Consrston.

Disessambiy and Assombly

sing Tomporatue Conte

OTHER CONTROL,

149

+50

Pare hat Remain ON when th Man Sitch Is Trad

OFF.

Pans nat Operate

hon th Main Sieh fe Turned ON

‘operat Panel Cont

‘Courter Conta

{Goong Fan Conve

Option Cont

DIAGRAMS.

ELECTRICAL PARTS LAYOUT DRAWING

‘CONNECTOR LAYOUT DRAWING

‘OVERALL WARING DIAGRAM

2223 OPTION WIRING DIAGRAW

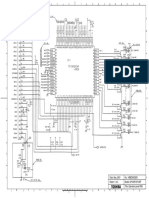

‘CONTROL BOARD CIRCUIT DIAGRAM (7).

‘CONTROL BOARD CIRCUIT DIAGRAM (2/7),

CONTROL BOARD CIRGUTT DIAGRAM (7),

‘CONTROL BOAAD CIRCUIT DIAGRAM (47),

‘CONTROL BOARD CIRCUTT DIAGRAM (57),

‘CONTROL BOARD CIRCUIT DIAGRAM (87),

‘CONTROL BOARD CIRCUIT DIAGRAM (7)

POWER SUPPLY BOARD CIRCUIT DIAGRAM (12)

POWER SUPPLY BOARD CIRCUIT DIAGRAM (22)

LEFT OPERATION BOARD CIRCUIT DIAGRAM,

FIGHT OPERATION BOARD CIRCUTT DIAGRAM

(CHARGE ELIMINATION LED CIRCUIT DIAGRAM

(CHARGE CORRECTION CIRCUIT DIAGRAM,

POL CIRCUIT DIAGRAM

“7

178

+81

2a

27

22

21

246

27

218

220

221

22

22

2.26

225

[AES SENSOR CIRCUIT DIAGRAM.

TONER DENSITY SENSOR CIRCUIT DIAGRAM

TIMING CHART

TIMING CHART (85x11, 1,2 shoots)

JAM LISTS

AM USTs

Paper Jam

ions

Main Body Abnocmaly

ADJUSTMENT

HOWTO USE THIS SECTION

ADWUSTMENTS WHEN REPLACING PRATS

/ADWUSTMENTS WITH THE P BUTTON.

P Function Uist

P Functon Operating Procesures

{checking and Rossing the PM Counter

Cheek and Reseting the Oeroping as Shit

Chock and Raseting tne Orum Courter.

Checking the Copy CounterToal Courtor

CChockng the ROM Veron

OTHER ADJUSTMENT.

Light Oiteuton Adjustment

(Conor Acusiment

Distortion Adjustment

Focus Adjustment -

Lor Size Selecton

Acjusing ADU goa ting

‘Aaj nip roller elrating cam ming

Aajusing ne ADU changeover gate poston

Acjosting pape shew.

various USTS. =

1

‘Standard Value for Each Pt.

DIAGNosTiCs

25 MODE,

Seting procedures

‘Auto sat original Salacon|

‘Countor Selection “

Message Language Selection

Prolerentil Paper Sie Saacton

Criginal tum back slacion

[Auto Low pomer made Tene Seng

‘to shut OFF rade eeacton

‘Auto Start oiase Tene Salacon

[ADF Frame Erase Selocbon

PM Cyele Speciation

"Minimum Orginal Size atecton Selon.

Sort nal Mode Seting

Closing Fusing Fale.

‘Auto Reset Seting

CGtoaing Curent Leskage Main Relay Fire

Douse Count Speciation for x17 Copies

2.26

Init Tay Seting for APS Canceling ea

‘Ado Ty Seacon 4

‘ie Start Buton Function Selection. eal

Erg Star nits rode election ea

‘to ton Funston Ato Funan Seting when an

‘Original piaoed inthe ADF and ADF

opened, es

‘Key Counter Operation Scitcaion 6s

inl Mode Sting os.

[AMS Mode Pty Seting es

sore Bine Shit Selacion 66

‘Mea Original Functon Slacton os.

‘uta Shut OFF Tier Seting re

(td Number of Original Count Mode Ssocion 6

Poet of Original Taser Sheet Slecon 6-7

‘Whole image selection or bypase and universal

ay 67

Master kay code sang 67

Intra! Heatr ating 67

LCT Paper Size Selection. e7

‘Switching he Sle SeictoniCansete Seoction 6-8

Inmate Stop Mode Seting ee

(Copy uarity Soting Lint Seacion 68

25 Meds Acdese Map, 69

a7 MODE oz

Seting te 47 Noe ee

(Checking Speraon Claw Clearance e12

AdjstingLDatacon (Tes Dena) eis

AES Aausimont cia

InpuOuput Check Lit e14

6 MODE ea7

Seting Procedires ear

Fung Test Mose 617

ght intent Aausiment. oe.

Lead Ege Timing Acta 6-18

orc! Magatizaton Adusmont e109

Horizontal Magitcaton Adjustment 6:10

Lead Ege Erasure With Adjustment 520

‘Waling Edge Erasure Wish Aqustmont eat

Ho to Original Lead Edge Distance Adpsiment 6:21

SERVICE

SERVICE SCHEDULE m

Service Seneduie "4

Mantenance tome 72

Pere Check Service 1

(COPY MATERIALS. rt

Toror Kt mt

Pu Parte mH

Maistenance Kit 72

SERVICE MATERIALS re

‘SPECIAL TOOLS, ma

INSTALLATION,

INSTALLATION yes et

Instatton requroment. a

Installation space

Wirt

‘Accessory parts

Inctataton recede

How to eat ne PM counter

Toner donsty adjustment (L detection

‘agjuaman

How to set tha paper a

INDEX

INDEX

BULLETINS

Tis pagel ak intertonaly.

REVISION HISTORY

MODEL 2223

ne 1997

AN the ime of release of this service manual, no TECHNICAL BULLETINS have beun issued fortis model

‘The following SAFETY BULLETINS have beon issued which ether apply specifically to this model or address

‘general safety. In addiion to the safety bulletins, review tha Safety Procalions section ofthis manual,

BULLETIN € me Date,

" Isopropyl Alcohol Incorporated 1st edtton

“4 ‘Sharp Edges (All Models) Incorporated ts edtion

170 Policy on Unauthorized Modifications (All Models) Incorporated tt etion

6 Installation Envicrmant (Al Models) Incorporated tt etion

‘This pagoftbank introns

SAFETY PRECAUTIONS

Installation Environment

Safety considerations usually are rected toward me

chine design and the possibly of human enor. In

‘adtion, tne environment in which a machines ofe

fated must not ba overlooked as a potential say

hazard,

Most electrical equipment is eafo when installed in a

‘normal environmant. However, ithe envitanmant is

siferent rom what most people consideriobenoreal,

itis conceivable that the combinaton ofthe machine

land the room air coud presenta hazardous combina

tion Tis is because Neat (suchas from fusing unts)

land elecral ares (wien can ooour inside rtohas)

have the ably to ignite flammable substances, n-

‘lung a.

‘When instaling a machine, check to see if there ls

anything nearby which suggests that a potential

hhazard might exist. For example, alaoratory might

se organic compounds which, when they evaporate,

‘make the ream air volatile, Potential dangerous con”

‘ions might be seen or smelled. The presence of

substances suchas cleaners, paint thinners, gasoin,

alcoho, solvents, explosives, or silar lems shouts

because for concern.

1 conditions such as these exist, take appropriate

action, such as one ofthe folowing suggestions.

+ Dotormine that the environment is controll

(such as through the use ofan exhaust hood) 0

that an offending substance or its umes cannat

reach the machine.

‘+ Remove the offending substance,

‘+ Install the machi

‘The specific remady wll vary rom site ost, but he

principles remain the same, To avoid the isk of nny

fr damaga, be alot for changes In the environment

‘ben peronming subsequentservce on any machine,

and take appropiate action,

Ina diferent location,

Unauthorized Modifications

Konica has gained a reputation for manufacturing

reliable products Thishas been stained by the com

bination of austanding design and knowledgeable

seni forces,

‘The design of the equipment is extremely important.

Itsthe design procoss that determines tolerances and

safety margins for mechanical, electcal, and elec-

tronic aspects. tis nat reasonable to expect nd

ais not Involved in predct engineering to know what

‘tect may be caused by alloring any aspect ofthe

machine's design. Such changes havsthe potential of

degrading product performance and reducing safely

margins

For these reasons, instalation of any modfcation not

‘speoifaly authorized by Konica Business Machines

USA, In. i sicty prohibited.

‘The following lst of prohibited actions isnot alin

sive, but demonstrate the intent ofthis paoy.

+ Using an extension cord or any unauthorized

ower cord adapter.

‘+ Instling any fuse whose rating and physical

size difers from that viginally insalie.

+ Using wir, paper cis, solder, et, to replace

for eliminate ary fuse (inciuding temperature

‘se.

+ Removing (except or replacement) any atte.

‘+ Defeating the operation of relays by any means

(uch as wedging paper between contacts),

‘Causing the machine to operate in a fashion

‘other than as twas designed.

‘+ Making any change which might have a ehanes

‘of defeating built-in salty features,

+ Using any unspectied replacement part

General Safety Guidelines

This machine has been examined in accordance with

the laws pereainng to various product safety regula

tions prior to leaving the manufacturing faci fo pro-

tect the operators and service personnel fom injury.

However, as wih any operating davies, components

willbreak down through thewearand-tear of everyaay

use, as wil adiional safety discrepancies be discov

‘ered, For this reason, itis important thatthe technician

perioscaly performs safely checks on the machine a

maistain optimum reliably and safety

‘The folowing checks, not alkincusive, shoulé be

‘ade during each seni cal

CAUTION: Avoid injury. Ensure thatthe machine is

disconnected romits power sourca before continuing,

+ Look for sharp edges, burs, and damage on al

extemal covers and the machine tame.

‘+ Inepect all cover hinges for wear (oase or bro-

ker,

‘+ Inspect cables for wear, ays, or pinched areas.

‘+ Ensure thet the power cord insulation is not

damaged (no exposed electrical conductors).

‘+ Ensure thatthe power cord Is propery mounted

to the frame by cor clamps.

“+ Chock the continuity from the round lug (GND)

ofthe power cord tothe ame el the machine —

ensure continuity. An improperly grounded ms

chine can cause an electcally-charged ma:

chine tame,

‘Safeguards During Service Calls

Confirm that all serows, pats, and witing which are

removed during maintenance are installed in their

tginal positions.

‘+ When disconnecting connectors, donot pl the

wing, pariculary on AC line wiring and high

voltage pats,

‘+ Do not route the power cord where it is hely to

be stopped on or crushed.

+ Carefully remove all toner and dit adhering to

any electrical units or electrodes.

+ Atter part replacement or rpsir work, route the

wig in such a way that does not contact any

burs or sharp edges.

+ Do not make any adjustments ouside of the

spectied range

Applying Isopropyl Alcohol

Care shouldbe exercised whan using isopropyl alco-

hol due to its flammability. When using alcoho to

‘lean parts, obsorve the folowing precautions

‘+ Remove power from the equipment

‘+ Use alcohol in small quanties to avoid spillage

+ pudding. Any spilage should be cleaned up

‘with rags and cisposed of propery.

‘+ Be sure tha there is adequate venation,

‘+ Alow a surface which has been in contact with

slconal to dy fora tow minutes to ensure that

‘he alcohol has evaporated completely betore

applying power or instaling covers.

‘Summary

Itis the responsibity of every technician to use pro

‘essionalskils when servicing Konica preduts. There

are no short custo high-aualty service. Each mar

chine must be thoroughly inspected wih respect to

salely considerations as part of every routine service

‘al The operably of tha machine, and more impor

‘anil, the safely of those who operate or service the

machine, are directly dependent upon the conscien-

tous efor of each and every tectne'an,

FRemember..when performing service calls, use good

Judgement (hava a watchful eye) to identity safety

hazards or potential sally hazards that may be pre

Sent, and correct these problem areas as they are

identi ~the caety af those who operate the copier

as well as those who sence the copier depend oni

SAFETY CIRCUITS

‘Tho olestcal ccut of hie machine contain the oloning

saltyceuitstoprevertan acientrom acuring nthe oven

‘ofan abnormal,

11) Overal safety cicut protector

12} Exposure lamp (L)cverheatng protectin cout

15} Fusing heater lamp (L2} overhetng protectin circu:

“Te fotoning expanaions are provide fo prevent serve

enginaots em wnetontonnly esbng the saley eres

Overall Safety Circuit Protector

SAFETY ciRCUTS

Exposure Lamp (L1) Overheating Protec-

tion Circuit

9

| [we

& | 6

| Lem

polls

canned ~~

aa |

JT

__}

1. Protection function provided by ercuit breaker

(car)

This function broaks the AC ne isartaneously inthe

overt tht thre is exces caren ow due to short

bine tha AC Ines

"Note:The titson of CBR mustnetbedescvated ude any

2, Protection function provided by current leakage

dotecting circuit (LR)

“This tunein turns tha main relays (RL1 and RL2) OFF and

beaks the AC ine neantaneast the ever tha ke

age cuent we de 6 aground short none ede of he

Note: The uncbon of LAR must nate desetaled undo any

1. Protection function provided by software

Wen te L1 CONT signal ouput from the protectin

fencton by satware on the contol board (C8) becomes

[UL tights. Siutanecusy, the LY ACK sgn, whic

Indeates hatte ep romthe CVR onthe power

apply board (PSB) othe CB.

“he CB montors bth he Lt CONT andLt ACK signa

lee aifrtom eachother hemain clay (RL and.)

vill tuned OFF en power to Lt wil bs cut OFF

[Note:The furcton of RL1 and RL2 most net be desebtas

under any crcunstances,

2, Protection function using hardware timer circuit

om

IL Tomansitfocmorethan approximately 1645 seconde

‘bsauso of some abnarmay the hardware meron he

COVR in he PSB wl operate, ob euting of RL and

A.

Note: Tho fucon of RL and L2 must not be deactivated

under any creursaneas,

2. Protection{unetion using optics temperaturetuse

a)

Ne tomperatre in the init of ess sbove 36°F, 1

sil blow, ating of te ow of erento L

loco of wie In place of funder any

Fusing Heater Lamp (L2) Overheating

Protestion Circuit

1. Protection function provided by softwa

‘This uncon tums OF Fusing heater amp (2, the main

relays (FLY, and FL2) int overt hat th opt voeage

trom tusinglmperature sensor (TH), teadbytecontat

board (0), le abnocal

Note: Periodically chock ne suracas of THt and TH that

contacter andreplace thom hoy are abnormal

under any cecurstaness.

2. Protection function provided by hardware

“This function uses a comparator cut which compares

‘he ouput votiage of THT andueng temperature sensor?

{TH} wth the abnormal judgment relerence value

‘hat tho output votaga of THI of THE exosde the rete

‘Note! Check the surfaces of TH and TH2 that contact he

‘olor pedal and replace ham i hey are abnor

‘The tune of FLY an RL2 must not be desetsted

ser any cumstances.

3. Protection function using thermostat TS1)

tthe erace temperature ofthe upper fusing roles ox

‘neds epecied value, TSH wit blow, deol cating of

the How of eurent oL2

Note: De not use apiece of wir in place of TS1 under any

DIFFERENCES BETWEEN 1120 AND 2229

DIFFERENCES BETWEEN 1120 AND 2223

‘This machine has been desgned based on the Konica 1120machine, The main iferance between the Konica 1120 andthe Konica

2223 a ltod beso

Product Specifications

Type Ta Ba Reasons]

Speceatons | 1. Copy apeed

20 shoots Bett 23 hosts 85x11

1 shoots 11817 12eheots 1x17 eM change

2. Fist copy tne

| "es soconds ast __|__siseconde sett (oP change |

5 Photograph mode

Net used | uses Toinpove function

“4 Energy corsonaon

Preheat nade Power save mace Torespondto Energy Stae_|

5 Bhnaing margin ot

| Lesion Lez and reaction Toimprove tncton

1 Patan auto so

Netused se Toimerove hancton

Options

ed

F208 F204, DF-208

sone

‘sT-102, $F:210 st10s.st04,sr-216 | Tostlupoptons

(9) raworbaso unt

‘DB-205A (io PFU)

(08-2088 mee Pru) 08-907 LeTsPFUYADU)

18.607 LCTsPFU)

8-107(ADU)

(4) ana Stand |

Maintenance:

vor 30,000 cope Ever 45.0 copes “To improve servosaby

‘che enange

.Gepy atoals -

‘rum: Common with 1015 common with 1015, 1120 | CMPehange

Developer: Excusol for 1120 | Exclusively for 2229,

“Toner Excel for 1120 Erosive for2z2a

Mechanism

Te i120 ma essere

“Gperaton secten | 1 Operation pant |

| ED eaten Lcd panet Toimorove cporatonabity |

‘Biv secon | 1B mathe - |

| ‘Whale man metor ive Separated dning ito main | Adoption of rum dive mote

rotor and deen ctor \oimprove natal dab

- snd abit

‘Opies socten | 1 Opies minors (eto th miro)

‘ren by uppor sing rer

Independent ven clarng eer

‘Senitaaton riot hyporenstition minor

2 inside cooing

aust cooing by osing fen | Exhaust oolngbyedaten | To¥mprov unetion

nator and cooing fn

‘Drmunieecion | Aula separation Toimgrove soparaton

- ‘Soparaton claws: 3 Separation clan: 5 pofmarce

Fusing seston | 1 Clesnng ce

To improve claaing peor.

2, Sansor caring bide

Nato Heatreasing nner | Moral? ren “Toreepondte market teh

ety _

Electrical Control

iim 2 Faasane

| 1 Baan aie

‘Conon de papsrtea’ | Nowy aed excsbeum — | To mproe deve and

_ eveopngtsng detpng dive nett dium dy

‘piseedon | 1. Opie mio Toimprove megs guy

| JN oc bratiose ett ops mot Tosi conta creat

| 2 Opts brake Petes overin P|

Used tases pee mt sapton

Tan yc tan 1

excne Toimpove petomarce

| Need Newt tod ‘Topreventnactine nae

- - tempera om feng

‘pertain | 1. Operation boar

exci Toresponato nena

(Fight core boars) __|exparsion

Faporlrd scion | 1 eit een

_ Exch “Toimeroe sefomanoe

Gromcoriogs unt | FOL boo

Exchsie “Torespondohighr CPM

2 Charge crests

Beckie Torescond to photoaph

Fushgeedon | 1 Fiahgsewort

xcuive oinprove potomance

Electrical Control (continued)

DIFFERENCES BETWEEN 1120 AND 2009,

Omer 1. High wotage power up

Seve Toresena to higher CPM

2 Power sup boa

Seve “Toreepondt higher CPM

nd tnetnal xparion|

Z ‘a0u).

3 Gonwatboara

Excise ‘Toreependt high CPM

Teroponatonnetens |

+ ROMITRONE

xchsve Torespond highor CPm

Torependo tetera

evpesion

‘Ths page lof be internal.

Replace this page with the

tab divider printed:

MAIN BODY

SYSTEM OUTLINE

AF: OF 208

Konica

Machine and Accessories

er Description Tem Number

supplies

im Description Them Number

| PM Kit

tem Number 947-434

edi

Opt Fee

Type | Recepiacle | Holder Hem No

onde] Pan No [30%

wan 800"

PRODUCT SPECIFICATIONS

Type

ype: Desk op tps

Copying method: Ire! tate maths

Original able

system: xed ype

Photo sensitivity

mater ore:

‘Senslive method Direct ieaton method

Paper fooding|

method “Two stacked taj (250 shoei. 208)

uso fod (0 chet 20)

10807 (1000 shoes CToasoshoet!

FU, 2015)

(Option

1DBE07 (7000 shetsh.cT+250 sheet!

Pru.20b)

(Option)

Functions.

Kinds of erginals: Shoots, books, sats

Ns17 maximo

tint7-55085

Magniteation|

Fixed magnifction:x00,90.71,x0.82,x086,x.15,x1.22,

al

‘Special aio

‘magnification: mode

Zoom magnitomion: 180% to x200% (1% sap)

Warmup time: Approx. 65 eo. (68°F, aod votago)

Fist copy time: ieee

[see asi]

ManuaiAES rede 68

continuous copy

‘speed: Unt: copyminae a sae

Si andi] 1

Senna 12

Continuous copes: 11099

‘Special unetions: Auto roel

‘Auto ah oft

Book cony

Image si duction st

COMP itresve

Photogragh mode

Preneat uncon

Copy Paper

‘rainary pa

f+ High quatty paper (16,1 2416)

‘Special paper: Transparendes (epee),

Labels

Ble print mastor tobe deleted

High quality paper (13.1616)

High aualty bape (24 16 35)

cautions:

When using specs papers

+ Do nt use weed cong

+ Asays eed thm using herd bypass feed ty

{The teed, conveyance, and copy image partormance of

special papers may sometines be inti to thal oer

navy paper (161.924),

Options

a0: F206, OF 208

Some: ‘87-109, S7-104, ST.216

Stapler unt 25a 288

Stand

Drawer aso untt DB-S07 (ADUSLCTSPFU)

16-07 (ADU

6-07 (LcT¥PFU)

1015712072008 papor conveyance kt (for ncessary sonar)

DF Adapt (oe necessary DF-208 and F208)

Fourth miror neater

Pedestal heatr

Specifications

Power requiremente:120VAC+- 10%, 208, 6oHes!-2.H2

Power consumption: 13 kit

Weight ‘oproximatty 1101

Machine dimensions

Maintenance

Maintenance: Every 4,000 copie

Copy Materials

rm: (OFC um (160)

Comanon hs Korea 015,120

Developer Exetaive fr 2223

Toner! xchsive for 2223

‘Machine Operating Environment

Temperature: SOF 91°F

Humid 10% to 80% RH

Note: These specications are subject 16 change without

Man 200"

CENTER-CROSS SECTION

Cleaning unt Ccherging arena unit

toner eating unt a cel

Optics section

Developing unt

Ccoalng tan

\

bum

Trane corona

sepataingcoxora eit

Paper ted secon

DRIVE SYSTEM DRAWINGS

an g0Dy

Optics Drive

Esposure unt Optics sive motor (M2)

Lens Unit Drive

Magricaton arm Lone dott

Tension spe Lens eve metor M3)

EXTERNAL SECTION

Construction

‘ ‘Main body separating lever

Fina ever per main body

Let oper

deer

ass aa ap hanes Mut bypass ay |

reaveance soot |

Disassembly and Assembly Procedure

Replacing the ozone fiter (1) Press th ft and ght front door reloae butions to

Caution: Reistl the ozone fer, securely wth eto open tha ent dot

ow, (2) Remove me eran, then remove te le hed.

(2) Pulthe ozone titer toward you

| Lens older zone titer

—_]

(4) Reinstall ho pare by reversing the precede do

sorbed above

DRIVE SECTION

Construction

Aatating ral ive goat

Bypass pape food rot

Stee gee

Fst paper toed ve rte.

‘velgear (Upper paper tesa)

Fst pape ood dive rll dive

(20 (Lawer paper ised)

Paper tod lr dive gear

‘rom ve moor MB)

Fusing tive goat

Main cor 41)

{Seer pops tes) (Upper eaport

Mechanism Disassembly and Assembly

nea iiaioi——]_Removingteinstaling the main motorérum drive

motor

a tor raheas OC mot, or

—_ ior {0 Tum tho potrsouce OFF when wing on te

‘Dan ve mar Brushless OC motor, oer cng sectors “

tor ype

+ ) Mak sure tt al comector reser onthe conta

Developing ave Gear tain eee

Tera coleton dive | Gear ain

[ing and paper xt ve | Geri Proceduree

Paper ood ve [[Geartan |") Dicennet he connectors for ADF sot, LCT, ADU,

(2) Remove the rear cover ater romoving the 7 sro.

(3) Romovetho crew, then eomavo te ni roar cover by

ling its wor and toward you

(3) Oleconnee a connector om he cont boars (CE).

(6) Remove te wie from th wie clamping ples (11

te serous, then remove the CB,

core, telase the tbo thet roar cover

from tho tame, than remove the rer cover ow

a

(6) Disconeet all eannectrs omthe power supp board

38).

(0) Romovethewies connectedtothePSBomtneseven

wie eames,

(10)Remove tho sik ot screws, thn rmavethe PSB.

‘ire imps

PSE\Power Suply Board)

(1)Dicconnect th connecter tom

Main mater board

Connector

an BODY

(17) Fines ho parts inte revere ord of removal,

Drive secon

Main (M1) Control

oo

wich] ©

Nain is corral bythe conte boars (C8) the power

supply board (5),

Operation

Misa bushess OC motor ute rotor ps, cen by

24VD6.isusedtocietepaperteedsocton, and paper

anveyance eystom,

Mt i PLL-contold by a buitin speed sensor, which

oops the sped of Mt constant

Signals

Output signat

Mt DRIVE (08 > P88 mt)

“This ith de contol signal or Ms

[ys mion

[Hy M1 OFF

M1 ROY (08 + PSB +41)

“This tha otaing codon signal or Mt

IL) = tis under apectiod speed

[HI ts nt spectodspons

Drum Drive (M6) Contro!

23-1

vs in 53

ve rerio

‘280 135

ro 18

«3 |

rum ev (46) contled the convo boars (C8,

Operation

6

Mo isa brushes, outer flor ype OC motor, driven by

DDC2Av. ie use to ve the developing un dum it

‘ing unt, and ext oer.

Mi is PLLcontoled by a builtin speed sensor, which

oops the epoed of MS constant

Drum ne speed: 145 Semseconde

Signals

Output signat

MB DRIVE (C8 + Me)

“This the ve control gal or Me

[Uy MBON

IW: Me OFF

M6 READY (CB -> m6)

“This isthe rotating contion signal for Mi

IL) £6 under spactod speed,

TH] : M6 not epi speed.

8

OPTICS SECTION

Construction

APSseReOPSI2)- Fiat riror

‘APS soncor (P81) ‘ Coptie ave shat

AE onsen, Fourth minor

Optics rive —

motor ta}

optics rive wre —

tis Vir

Ration sates —

‘Coong tan M8) —

oe

josef ewe mecer

ecraniem lige cee Sapam Raa

ies id ee ee

‘Light source | ‘Halogen lamp (280), “These plates are driven by the light distribution regulator

‘Expose ‘Moving Eiht source with off |everthat moves along the light distribution regulator que

om oes

“Scanning First, second, third mirror aa) "

camera — nas saat uae

a

Fosusing Sovedion whan | Fouth mir sit |

adjusting mageations _

gt intensity conpen- | Uh dibaon pao

faton for reduction copies

‘Opie and machine side | Exhaust cooing by fan and

cooling radaton shter

Magnification

‘Tha lens unt changes the magiicton by moving along

‘hemagnicaton dive sha. This movements preducnd Lt strewn utr patos

byte lana unt eve mcr (3) and eve Bet srangy. — L__-Onosvetonrogditerplaie

1 the same time, the fouth minor also changes the

‘magnieton by moving along the magnteaten dive

‘haf This movoment is produced by the lane Unt a

‘mages armloeatedunderthe un andongaged wh

113

3 Opti and machine Inside coating

‘radiation shuter provided at ho outs or iniaks

Redaton

shuter

MAIN BODY

bly and Assembly

at must not be removed.

forthe lane unit

‘crows that must note removed

+ 2 stems ana one austing sere forthe fourth ior

‘Screws that must pet be removes

+ One ange austin scr forthe fourth mor unit

‘Screw tat must nat ba moved

Removing/einstaling the exposure unit

‘Cautions:

the poner cor

(1) When movg the exposute unt, be sure to Na the

pes dive hat sid o move &

(2) Wan instaling the exposure unt. shay patra

capyimage check (Reertote adjustment secon ot

setae)

Removal procedure

(1) emave the origina ever or ADF

(2) Opon tron dor.

{@) Remove the 2 screws, thn ove th ssl pl,

(6) Laosen te sere orth las pressure pao,

remove the ogi ass

| eae

(6) Remove the 9 cen, then remove the ont over and

pper rar cover.

‘Serow Upper ear cover

455 fed ay, remove he 5 screws, and

Year over and rant sie caver

"Note: The igh tear cove i secured by the claw, Theretre,

when removing height ear cover, tenould be tstod

toad you so that maybe esengaged rem the cl

ft) of oar cover

ser rmoving the sre (om

Saws

ign cte cover

Fight ear cover

(@) Move ne oxpccur unitto e cteut ot heron rar,

(8) Remove he 2 screws socutng the exposure unt

Exposure unit

Chto

Note: The wie and doesnot nad o be cl,

Main BODY

(10)move te exposure unto tho paper eedldo, nna

uly canbe ean,

(11 Removethe ope wire fromthe uy, andvemove tie

exposure unt upward

Exposyro unit

(12) Remove te seow, anton remove the wie clamping

an

(19)Remove the wie tom the wire stay, caconnect CNS,

{and emove te expoaute unt

Conneeto“{Onss)

Wire camping band

Instalation procedure

(3) Connect CN6to the oxposure unt nahang the opes

io on the wie oer

the opis eat holder 2 tha

aligned.

(6) Remove me damper nts rom the paper fod side

frame, ton mv th exposure Unt the way tothe

paper eed side

Esposue unit

Damper ubber |

(6) Proseingthe exposure unto the ameby hand, hon

the 2c

natal ato)

dammparubberiete the ctotot he ae

(9) Secure he wir withthe wire banding he set se.

(a) insta tne exposure unttmpocaly using the 2 serous

(@) Peinsta he removed parts by reversing the procedure

bed above,

7

|

‘Scrons (soured)

ain B00

Replacing the exposure lamp

Cautions:

(3) Unpig the power ors

(2) Vinenasconnectng to lamp tominal, be curt hold

‘he teminal,

Never pul the cord

(9) Derot touche glass a ne exposure amp with bare

(@) Se au0 mat connectors are connected ny core

rot caught and a stews are tightened

‘cautions:

(1) When instating the exposure lamp, ens thatthe

‘manufacture label onthe lam is facing the ont of

{he main body

‘Wen instaling the exposure lamp, ensur that tho

ripples facing the paper ext side

a

(9) When intaling the exposure unt, aye perform a

cepyimage check (lero thedustment section foe

‘ete

(4) Wen moving he expoeure unit, lstonth sideofthe

‘opts ve shat

{1} Remove the orignal cover or ADF, sal plat, ihn

‘lass, ont cover an rer cover.

(2) Move ne exposure writ tthe cutut of ont rane,

Expocur unt

(9) Remove th 2 crews, han remove therefor cover

Retiestor over

(4) Rosse the tee hooks, then remove the teminal

over fom the exposure lamp tamil secte,

Caution: Do not aamage the hooks.

Fests

Lame terminal

(6) Using 2 paper to hold he exposure amp, move t

pars

Mantacturermarkaces|

Exposurelamp

(7) Roistall he parts by reversing the procedue de

bed above,

Fomovingleinstalling the optics V-mirror

‘Caution: Unplug the power cons

{Cauion: When mov the optes Viorel on the

side athe opti ve shat.

Procedure

(1) Remove the orignal cover or ADF, ss

conginal glass

{2} Movothooptes V-mizorto he etoutctthe entrar

(6) Romove to 2 ser, then remove the eis Vitor

upwara

cuout

Optic Vmirarunt

(4) Reinstall ho parts by raversing the roceaure de

149

MAIN B00¥

Removinglteinstalling the fourth mi

‘Caution: Unplg the power cord

Procedure

(1) Femove th scale plat and ho original lass.

[2) Movetheexposure tale way tothe papa entside,

(3) Remove tna 2 rows, thon remove the fourth ror

coverto the upper slant ection whe releasing he

(4) Reinstall he removed party reversing the procedure

deserted above

‘+ Puttwotabe ofthe fourh miner over inthe grove of

tne ame corti

Fret, tighten he sre orcover atthe rot ofthe main

‘ay (screw ti he gue) while pressing the cover

‘agnnet th ame the paper taeda. The, hen

the sre al the rear seo ho main body (er 2 in

te igre.

Removingreinstalling the lens cover

“auton: Unplug te power cord

Procedure

(1) Remove the sale pla and rg glo.

rh mitor cover

3 crwth remove he los cover

Lons ever

(4) Reineta hepa by rversing he procedure described

"Noe: Install he shading plate propel into the grooves othe

(1) When ceplacing or rewinding the optics wr, always

perorma copy mage check. (lar to the adjustment

‘Section forces)

(2) When wining wie onthe pully, be sue town it

Lightly along he groove witout eroesing tho wi,

(9) When moving tho lane unt, hls on the si of re

magnification dive shat

Removal procedure

(1) Fomave th orginal cover or ADF, Sal lt, ogra

(ase, tont cover, upporrearcoves eee cover ht

‘io cover, and tea aver (Re tothe dive socten

for toa cover removal)

(2) Remove the exposure unit and opts Vix

(3) Remove the fourth nor cover

(6) Mack poeson of he gle stopper pl

nthe wppsr

sustrent

‘Seat plate

Adjustment washers

Maring

(Gass stopper plate

1a

(=

ons unit

opts postoning pat (1) Vamitor guide

(8) Using the 2 serous shown below, Ista the ploy

lanai (special tot) one Ham onthe rar sid ot

‘thomambody and hp, tenet pon the

man boy.

Main s00¥

then remove the optics dive shat

tho paper fod ade

sloppertotheframe, ghien

the et screw wha pressing he stopper rear

Paley olin ia

Stenger

(0) Remove tho 2 sews tough the secest helos as

shown

(10)Remove the serow securing the ops ir

(12}Firt ps the ops dive shat tothe pape feed side,

‘han famove the sal up

Note: Ds notin removathe V-murar guide rom the ope

shalt remove, intalto 2 fats eorect ah

fos set between the gue and shat hoe

italing th dre shat ts grooved edge shouldbe

{acing te paper food se.

(pts ave shat

venir guide|

(16) Temporary lesen the sero ofthe whe se plate.

(171Using ne working hol, asthe wie setae cothat

San cenar of he eat pat hale i aigned wth eee of

frame hole. Eneure that pin (3) can bo pasced

though snooty

(18) Tgton the ere of he wie sa pat

(13)Romovethe2 crews, than emeve he sensor backe.

Setplate hole |

at

(Remove the 5 sere, ten remove he opti pulley

(15)Femove the 3 gears, hen remove he optics wire

(19)teat te edge with stance between he end of wee

‘re back gar.

Longe eae

wed achat

(20)Atach he cn ot wit tothe hook on the wt ot pte

and throod the wire by follwing the numba bow,

"Note: instal the shorter hook oo ta tnsion ping othe

nt of

0 tel he hook facing vowara

Upper

Main BODY

(21)Roatl he pars by reversing the procedure.

(2) Pass trough tnerear (1) Hangtewireantotie (6) Pass tough the ont

‘yoo, ie gt00%0 a hook the

oaeciein grg {Brain apong osteo

tho wie end sna wie

Noto oe te (3) above:

on he paper ent de,

+ Wind the wir iy.

+ Wind the wits onthe centr seson of th ply to prevent it om touching he edges

“Tis prevents the wre em isng on he pulley sage when the sxpaeure unt may Oven

(9) Pass trcugh te tont (3) WindSmaciociea, (4) Pass trough the

gem (going ram the rar front groove.

thatont

Procedure

(3) Remove the origin! cover scale ste, orignal la,

‘ont cover upper cove, ght ie

over andrearcover(Reortothocia secon fore

over reomoval)

(2) Movethe exposure utah way oth paper en side

(3) Remove the tur muror cover

(@) Discennoct ON 7 forth lans civ matortom he CBto

prevent dynamictrake ganeratby rotating the mote

_

(@) Move foun mir unit atthe way tothe pape feed

‘do.

(7) Loosen tne screwotth tension gerplateleatedst the

teed ee

paver

(8) Preset ting pully patho way othe paper oxt

tighten the sere "

Seren

MAIN B00¥

(10) Wie pressing ne magnification arm he paper ex Note: Loosen the ger late screw toad onion othe ln

2, remove he ls unt uptart rom he magni ‘ve Bt, ten tighten he screw agai,

tan eve sat

Lene uit

So -

ray 3

“|

pT

Femovinglreinstalting the cooling fan motor

Caution: Unplug te power cord.

‘Caution: When isang te an caso n he uppe boa,

_aignine bose ofthe case wth he les oe

‘pper body

Procedure

(1) Remove tho scale plato, egal gas, tort cover,

upper rearcoverletide cover andrear over, (Reet

tothe dive easton or sar cover erov).

(2) Fomove the 8 scrows, press the main switch, and

remove the main ewtch cover

an aston

aan std cover Sehcrews

(9) Whon ADF has boon installed, pross the DF locking

nob cotattne manbodysopaatinglovercanbe used

‘o.open the upper Bay.

DF loging kn |

Main body separating lover

(4) Remowethe paprtaythen remove he 2screws. pan

‘a rom cover and vemove thee cover of he wer

boa

Left over ffm ay

(©) Looten the sore forthe lower pvt ofthe igh gas

‘sping unl he ower pot can be removed.

(6) Remove the 2g. then remove he ge spring

‘nen ADF has been instal, th 2 gaa Spenge are

Installed, They must be removed

Eng

Seve or vot

ver

Main Bo0Y

(7) Disconnect CHAS forthe main sich tom the PSO.

(ower svply board

(6) Femove th wre for CN rom the wire clamps

(1190icconnsct CNS! forthe mln swt,

(1a}Removetho2 screws, thn emevetecooing ton case

Connector (CNA)

‘Cangas ONS

Coding an case

(9) Disconnect ON7S and CN7S or the colin an motor

‘nd radon sland located on height i tthe

optics met.

(10)Remove the screw, then emove te ground wire lth

cooing fan motor.

ComeseCN78) Sew Grou

connect (CN7)

(13}Remove tho serowsscungtho wie clamp oration

(14)Remove the 2 sens, hen remove he fan cover rom

the fan cae,

(15}Remove the screw securing the lamp forthe fan motor

(15)Remove he seen, hensemoverecoolngtan rom

tha fan ca,

‘cooing Wire

fan clamps:

(7)Feinetal ho parts by reversing the prosodue de-

serbea above!

Man B00Y

Optics Drive (M2) Control ‘AES ccanning

——— Wihen pressing the copy button withthe AES made se

acta the exposure unt perfoms RES scanning bolo

normal copy sean

8 menses .

soe) 3 ree

| A scanning

see Noma py

scones i sanang!

Somes a

|

= —— Optics ome

‘The ope sean perormod by ops ve (M2) whic s ed

sivonby 28 VDC. MB's dventy sep sqal rom he cont!

(CB), The home poston ofthe expasue un ie aeectd by

S« nome poston ‘Scanning speed

— "AES scanning Forward scan | 250 nmis0e |

MO a 2-phaee sopping rotor. The searing distance is Return “450 mse

otarminet bythe number oft stop sna mm the C3 jomma apy aa mand oan a

= Normal copy scanning | Fe 5 meisee

Exposure unit home postion search (when tte se

‘en the main ewtch sured ON and th exposure unk z= 450 mmfane

Isat athe home positon, the home pein the

exposure unt wll be automaticaly searched,

‘Stopped poston of

xpos unt

Psa

Opies home

poston senaor

ook copy mode

When 8511 or 8.55.5 paper size Is soected

"Te est page ofthe books coped contruousy inthe

se copy quanity wits he paper edn ordinary ing,

“hen, second page i copied according tte fll

log sequence. Tho exposure arp ist atthe home

raion eo thatthe ft and escond pages wil be

Scanned, (Wf the 85x11 size paper is socted, the

19517 se copy is pelomed. tho 85155 so is

selocted ha 85x14 20 copy ispeformed}) Howeves,

_Spiporis fed at he moment he exposure lap comes

‘ona secondpageso that only secondpago's copied,

Tha Busta below tha scanning example using ts

{85x11 siz paparin3 copies

oss a

Bypass food unit used

When the contrious copes is slete, the onal ie

copied using afllongh sean or hes gape. PS2 (pe

Shute Senco) detects heist paper siz otal he ral

per length canbe scanned rom the second paper st

ter

Universal tray used

Regardless ofthe siz, tho rg copied using af

langth cca for al papas.

‘When paper other than 0.511 or 8.5x5.5 size selected

“Te rst page of he book fcoped continual ne

‘ot copy quantity wth th paper fd in arcnary ting.

‘Ath time the teleted pape length copied

Than, second page is copiod according the folow

ing soqunce. The exposure lamp It at he home

pallon to sat seaming, bt smultsneaust the CEL

Ieitteracethe charge m 85x55 paper lonth. tor

the CEL hasbeen tuned OFF. the seaning conn:

od un the selected paper length Is coped. ne

‘x7 eae papers ealaced tha copy of 856 S plus

11217 size length fs planed, however, the return

seperation complee when the exposure unit eect

the maximum seaming poston,

The station below the scanning example using

tho 11x17 ezod paper in 3 copies.

Man B00

St (P54 CB)

This the exposure unit home postion detection

signa.

[The expocure unt inthe PS fore pion,

IH: The exposoreuntisnetintnaPhomepostion

‘Output signa

‘Me DRIVE (CB -» ma}

This stop signal hich uns each phage of M2 ON

and OFF. ® number of Mo retain proportional to 3

ume’ pulses i detemines

weower LS 1S”

woomes F LS LS”

woowes LS LIL |

Lo

Lens Drive (M3) Control

Tholons unis movedby lone aro (MG), Mi civ by tp

signa rom the contel (3). The en 11 pion a detected

by PS7 Jens home positon.

operation

2-phace sopping moter. The dctance moved by

switehed ON

Lena unt

mages Less ome poston sensor

‘Rodin

\When the lon uni eon the alaigement side

ane unit

ven

Per

tha lan unt inte 1:1 positon

eduction

(Operation when @ maghifistion is selected

“ho difrence baween the spectiod magntaton and

present magnitieaton road, and a numberof pases (

‘orerpending exact i dilerence fs ouput fom he

8, causing MS ott

‘Wham the lon units onthe right the selected postion

Selected potion

Snape, acute

hon the ans unison thee of the sect pstion

Lene unt

Selected postion

Fae uct

se

MAIN 800¥

‘Signal

Input signal

PS7(PS7 ~» cB)

Tiss the ans unt home postion detocton signal

[Us The lens unt i the ernrgerent poston,

[1 Th fen nt nthe 11 or eduction poston

outpu signa

MS DRIVE (CB -+ Ma)

‘Thi easep signal whieh ums ach phase of M8 Ot

and OFF. Tho moving stance ofthe len unit ropor:

tent a rumbor of pulses i detrmined,

wowes LT LS L

Exposure Lamp (L1) Control

aoe

‘The exposure amp (L) supplied wth powerby the constant

veltage regulator (VR) nade ne power suey board (PSB)

hic is conte by th conto (C8).

Operation

Light intensty control

The ight iorsy of Lt varies aocong to te ouput

volage tom te CVR cect in PSB (poner euppy boa)

‘The CVR cecut cupuls 8 vollage proportional tothe

votago of he L1 PWM signal rom tho CB.

LUght intensity correction

During eaemalexpoice, the ouput voltage rom the CVR

cteuklsconectedarcorangto the setectedragrtcton,

temperature inside he machine, slacton of photograph

made, endcopy cout The temperatre is detected he

tomporatur sensor en the CEL.

[ier WR oan [PWM oa

Normal | (valu varies according o

frposure | the temperature nid the] 01010 V

‘machine, copy count

‘Setecton of pharaoh

‘ose, and selected

‘magnieaton)

ght intensity austment

Changngthe ouput voage tthe CVRcan aust tlight

Intensity: Using the 9 mae, code 90, he ott valage

of OVR cane changes wihn he range of 80 Vio #55

Yims

Flor othe lagnstos section tor ats

Fault protection

= Hardware timer cect

IL remain ON coninuoualyforatless 1815 seconds

‘orsoma reasoner other, tears timer of he CUR

in PSB wifuncton witching main rely and2 (RL

land Fz} OFF. Coneequenty, power fo the AC loads

ineuding Lt wa be cut OF.

+ Temperature tues

IhetomporturoofLt ess toacontainvalue, tt (Optics

temperature use) wil om, eutng of he power tL.

1 meting temperature: 396°F

Signals

Input signals

LACK (P58 CB)

“Ths signal ls sede inom tha C8 a he ON or OFF

state of Lt

TY :t1 OFF

(iy-u1 on

‘TEMP SENSOR (CEL 08)

‘This analog signal used fe lforn the C8 of the

{enpersur nse the machine datctd by the ter

portize sansor onthe CEL,

output signale

Li cONT (cB - P58)

“hi contol signal ¢ ueodto ta LI ON oF OFF,

Ty:t10N

[H:LiOFe

Li pwn (cB -+ P58)

‘This anaiog signal © use Yo determine the etput

voago (CVF output votage: Lt DRIVE} tL

‘The iluteaton below inceats the rlatonip be-

LL PW signal and C¥R output wooo.

8

(OVR ouput vatage (9)

Pa ty 8) |

FL CONT (CB > P88)

‘This gnalie used to contol main slays tan 2(RLA

and FL2} inthe PB,

itbecomes (Hin he event that an abnormality oss

Inthomactin, causing RL! andRL2tobe rnedOFF,

MAN BODY

AES Control mona

yh oat grt rea

[ Darke Z Lighter

ee ee ee

Pee om eS

BBP 2 =a

vert [efi ter te

oa ieee a

wel wep —fee LS [Sa [ones

* . vow Fafa fea Ea

Ast net amet

| “Smet nae om va sty cn

| miei

‘AES contl i performed when the conta board (CB) po

‘oesosthe signal road byte AES cancor when he AE acane

pesormed

Operation

[AE tection operation

When the AES mode a elected andthe copy baton

rested tha optes unt sans the AES sean. Al th ne,

Tho AES consorreastholghtrofectodffte orginal and

acorreponding analog votage foutputo he CB. Tho CB

Jusgosthe onal deny om he ouput votge, sects

‘ooptimum ae vag, and sends ths bis gral othe

igh volage unt (4). This signa ao he HV fo ouput

the bias votage 1 the developing unt

“This AES soneormeasureshe denety ofthe orignal inthe

Jozation seated inte hatraton bow

| —

a ]

; ov,"

ica

[AES scanning speed) Fonward sean 280 mmisec

tum: 450 mee

Signals

Input signat

"AES (AESB > C8)

‘Analog votage signal changing depending ona ight

amount of reficted bgt ecoved

APS Control

‘The olaon botwoon each sensor and the papor sizes as

sar

| [eso | psa | esit

sa) my pap sia i -

veson| rab ——[ para ‘on ow on

soxt7 OFF ON. ON.

OFF ON. orr |

‘Bade ON OFF ON.

| ‘5d ON ‘ON. OFF

‘3565 | on | ofr | oFF

‘aaxiih | ofr | OFF | on

= 8555 [OFF | —orF | or

[APS ie ear out when the signa 888 by the APS sonsor

\whon tha angal cove is panes or ose ar processed by

onl boar (C8).

Felted sgl ncludes PS12 (APS tein)

Operation

[APS detection operation

“The pape sz is detected by ONOFF combination of PSS

{APS (win wit), PSTO (APS (outside wiah). PSI

(APS (wai eng) anc P52 (olsen in APS

‘election, The APS sensor Ie camposes of LED and 2

photosenar, Detecton ofthe paper size Ie cared cut

Shon ight emited Fem each LED Is rllected on tho

tnigralandinretectodightierecovedty tne patneneae

1 Pt

re

opie eg

PS10 @: Photosensor

O:Leo

* Selac ther #20 wth DIP suteh on 25 made

[APS detection timing

‘Wen tho exiginal cover (ltowADF is closed PS1S is

tured ON andthe sae ofthe original ets detected by

Ps9- P5t2

Note

(1) Establed dts are stored in the Backep memory

(von-olsle memory). Theor, the orginal se

omaton btore power supply OFF can bo retained

deepo ONOFF of power supply on the machine,

provided hat the fing Yermeraturs i nt lower han

fear

When the orginal cover not apened o los at

sierthepowerauppiy lerihemachneic med ON, ho

fignal 2 udgod a the maximum origina ize.

a

Signals

Input signal

PS (P39 + CB)

Paper size (win wth) detecton signal

[U; Paporis dtectes

IW: Papa i ot detected

P10 (Psi0— ca)

Papar size (outsi with) dotoctin signal

[Uf Paper is detecte,

[Hi: Papers not detected

psi1estt cB)

Peper sie (ongtudna doteston signal

[U: Paporis detected

IH: Paper i ot detected

Poizirsi2» ca)

{UE Paporis detected.

IM) Paperie not detected

Ps13 PS13 CB)

Detection signal for openingltosing of original cover

[ON (APS exzouton)

IHi-OFF (APS cancoina)

Main BODY

Radiation Solenoid (SD6) Control

cocttve| 1311 a soe

‘The asation shut i¢ apenas and ceeodby the SDS (radi

tion sland). SDS f contd by the ive sina om

control board (C8).

Operation

During iting

Dut ing, SOB ic OFF and the radiation shuter ©

opaned,

uring Mt (main moter 18 ON

‘When M1 isturned ON, 808s energlzedbythedive sil

trom te CB 0 close the raciaton etn

Signal

Output signal

'SOBDFIVE (CB ~ SD6)

‘Thi the ONOFF signa fr 8.

(us sos oN

(Hi S08 OFF

197

DRUM CARRIAGE UNIT

Construction

Charging covena unt

(Charing corona unt CEL Ooveloping unt

Ctearingtner

foiecing seston POL

——Metiod Separation ei

7 Fixed ra solenls(805)

ro

1D

+3 aan separation Separation i

‘on te dan unt, the rum is eureunded by the flowing

tar charging corona/CEUPCL na, developing unt ea

ing un, toner colton unl, and seconded paper fed

von oer unt

‘The ve separation claws prevent paper jms by sepaat-

ng the paper rom the dum ter te wane process.

‘Thecis represcedcrreloaseaiomtna ramen ho

parting law sano (SDB) tums ON or OFF, respec:

v0

‘No, chum seraiches are prevanted by changing the

Separation caw postion with tho separation claw shit

Tove at every PM

(Claw dperation aver

ain BoD

Disassembly and Assembly

Removingleinstalling the drum tnt

caution

1. Always cover the drum wih rum cover andteroina

Gar place whenever removing the dum caro.

2, When instalig the rum unt, enaure at he charge

ie leaning kn e pushes thoroughly ino the un

{Instat of rmove by holding bth eages ofthe pedetal

to proven outing the rum,

Procedure

{() Oponthe rentdoo, thn gil us tha mainbody sepa:

Inglever to open tre upper body

(2) Open te toner supply cover of th toner box

{@) Romave te dum unt st sere, then soy pu the

chm unto

(4) Reinet

ats by reversing the procedure de

Removingheinstalling the PCL

aut

‘ihe rating the PCL board, allow he notes below.

1. Leck he Bora using the honk.

2 Reto te wie though he we hook of he PCL. over.

{8 Algn the tabs of he cover wit he hls af he und

Procedure

(1) Opentho uppermain bod, hen remove the dum unt

(2) Dscannect ON9S em tha PCL boar

(9) Remove the wre tom the wiehcok one PCL cove.

{@) Remove the sce then remove the PCL cover in an

Upward decton

CL bara

PCL Boat

(©) Peinsta ne removed pans by reversing ne procedure

sescrbed above

Removingleinstalling the CEL, emovingleinstalling the drum

Procedure Cnstion:

(0) Open uppermainbody thenremovethe drum unt, When temoving he dram ante laaning blade, ont |

(2 Disconnect N02 tye ham wth bara hands or src them,

{G) Remove he wies Hom the hook ofthe CEL. over 2, When he dram 8 ouside ofthe drut nt, always cover

{@) Remove the CEL cover see, then remove he CELn itt ace cover and tore ina rk pace

S. When istaing a new dram, always rset the um

‘counter using mode 47-1, Also parton scopy image

chesk torte adustment section for cea),

corona unt cleaning biae, ana

developing unt. (Rel To each init eon for

removal nsuctena)

(5) Rema te pats by teversing the procedure do

‘sebod above, nating the flowing,

‘lg ho fcatin groove cf ho CEL cover and tho

ensign corona unt

Lecaten groove

10

MAN 800"

(4) Pulte crum sat ou ofthe unit

(6) Hekabotn ends of he um wth your ger ips ana it

upward

Tako care notte srateh ha ra,

(6) Finca mo pars by reversing the procedure do

_setbed above ating he feng

1. Asply cong ponder tothe drum le suace hon

replacing, one when resting) and eae tithe

opposta ection

‘Then, cate inthe normal deecton ad nse tha

-soting ponder ofthe surlaco i as shown bow.

‘Sating waar ‘Seting powder |

so0d No'geod

2, When ntalng he cum hat ensure hat he grove

sid saci the oppate side of te toner box.

{Aer the cram has been reinstall, vary that both

fg ofthe rocoling PET ofthe sparaton ene

holdgpece are contacted wih he um srace. nl,

tenor leakage may occu.

‘Shows bp oontated

uy

Feceiing PET

gyn

“Separation caw holding piece

‘Removing/einstalting the separation claws

cat:

1. hon removing the seperation claws the dum mast be

removed ts For exaone when handing the er

‘olr othe dam remeual secon

2, Make sur restathe seperation claw nthe proper

Sirection,

3, Do mot touch he clearing blade with bare hands

Procedure

(3) Open uppermain body then remove the cum unt

{2} Remove tho dram om tne dram unt,

@

caw holding poo,

raion ls

‘Separation claws

Holding pisce

©

Fersal the parte by reversing the procadure de

erbed above,

1

Changing the separation claw installation position

"Note Pert tis eperton every PM,

Procedure

(1) Opentte ronterthonullupthe mainbody separa

Ing lave to open the upper ba.

(2) Remavete serow thenmove te separation it shit

‘overtone oppose sido and secure wth he sre.

[rosomone

Separation law shitiever

{Curentpostion) after changing)

(9) Close he upper main body and rot doo

CEL Control

ceutn ew Fes

|

wwolew | Jee

i

@

‘The CEL (charge alminatn ame) consists a 52 LEDS. Each

lthese LED i tehed ON oF OFF according tthe seal

ata eutpu rom tho conel Roar (8), nora oraa he

charge ous the effective mage rea

1. Operation

a CELONIOFF pater

“The CEL has vo ONOFF pater a lows:

(CEL ONOFF pate

LEDs ifr charge erasure ate

climage:

(Chagos are eased to form aark mar

sna te lead ogo ofthe image.

‘LEDS

“Tha charges ar tne image has been

scanned are eras to prevent excess

toner rom adhering to he um during @

apy process.

The charges outdo the area hat are

dete y te caret Sze and |

magneton 6 es

eae

LEDS

LEDS itor

hare oacire

Innarenage |

12

Man BoD

Number of LEDs ut

(1) ATLEDs ie

‘AILEDS are

(2) LEDs itfor charge erasure in non-mage oes

“he number of LEDS It doponds onthe paper clze and

magnate,

Number of LEDs depending onthe paper size

oe Number of ee

‘asthe o

Bas no

a 3

5 ie

a5 ia

Fe 7

Thai? ‘

waa i

eee tt ‘

Bie i

Sim 812 18

‘SPECIAL oe]

Number of LED epening on he magneton

["Wepnicaion | mbar oftizbeie—]

08010052 25

05310056 ——a

05710081 EA |

06210085 | 20

09510080 “8

07010073 16

078.908 2

0219085 7

08510089 3

09019098 6

09810 0.99 2

100 - °

When using he enargerent mode the numberof LEDs that

tat varies accorang to he paper se

inthe :Torreducton medes, he ighingpalto orth paper

‘20 or magnification lbs elected accrdng whichever

16 grate

Signals

‘Output signals

(CEL CLOCK (C8 CEL)

“Thi dock nal uted to ransor CEL DATA.

(CEL DATA (C8 = CEL)

“hiss tho LED ON datas input seray in synetno-

rem wth CEL CLOCK

(EL LATOH (08 - CEL)

“This signa fe used 10 oupia CEL DATA,

‘nis 9palcausostneLED, specited bythe CELDATA

gna to Hgh

PCL Control ‘Separation Claw Control

_— -

cm | 646 2 pay asaneles | —sfo2 soe

o @

14 LEDs ar used for he precharge lamp (PCL) which are The separation claws are diven by SDS (separation came)

conrle by the cont! boar (C8).

Operation

‘The PCL itumed ON or OFF nsynctrerem with homain

smotrt),

Signals

Output signal

() PCLCONT (CB PCL)

‘Thi contl signals used to tun PCL ON oe OFF.

(Pot on

[W): POL OFF

which ae contaled by the contel board (C3),

Operation

‘Wen the separation discharge occurs, SDS tumad ON,

causing te separation cas touch he dram anole

tho paper to separa mare aaa.

“Timing

'SDS is tuned on ater the fed period tom when S05

(sit olen) has ben tuned ON.

‘Then S04 tarnod OFF ator 150 m5

Signal

Ouiput signal

'5D5 DRIVE (o8 > SDS)

“nis control signals used to ve the SDS.

[y=s05 oN

IH: S05 OFF

CORONA UNIT

Construction

‘Transfer/separation corona unit

Plunging proventon pte

+1] Charging | Seoraver(DGnagabvecoronacechags)

Discharge wie: tungston 0.06 mm

‘Gr reels 0.1 mm

ity wire oaring leat,

TTreraer

Separation | AC cote discharge iogater wih sepa

| rating cas

Diechargo wie tungsten £008 rm

“1 Charge wie cleaning

‘The charge corna Wire is equipped wit a. Searin Sharae wie

irechann ae ene tnce

‘Dien th wite canbe removed by moving acharge we

tearing knob back and tort

‘Caution: Always push th knb thoroughly into the uni ater

cleaning,

Disassembly and Assembly

Femovingteinstaling the charging corona unit

Caatons

"Alva coverthe an wth a hum eve and ttt

‘dt place whennier rain the um argo

2 hon taling te aun nt ener tht he cage

te cleaning tno pices acu he ot

Procedure

(1) Openthe upper main body, then remove te drum unit

(Peter he drum eariage Unt section for removal

Inetuctene)

(2) Remove the stopper, thon remove the loaning nob

(9) Disconnect he 2 conectors(ON9R and CN).

() Romave the 2 sews, then remove the PCLICEL

chargngeorenauni san ascembly om the drum unt

‘Connector (CN)

(6) Reinstalth removed pansy reversing the procedure

oscrbed above, noting the folowing.

+ Insta postion er stopper

‘Stopper

Main a0D¥

Removinghoinstal

wnt

Note: After instalation, press the rear sie of he ante!

separation corona unt downto lok ecu,

Procedure

(0) Opentho rot der, hen pau the mainboay separa

Ingvar 6 open he upper boy.

(2) Pull me unt stopper toward he font of he un, hen

‘emove the trasferSeparaton corona unt an up

ware decton

iathetransfer/separationcorona

“TrarserSeparaon corona unt

(9) Finca tho pans by reversing the procedure de

fered above,

Removing/einstaling the plunging prevention plate

Procedure

(1) Remove the tranfereeparaton corena unt

(©) Rebntal he pars by rversing the procedure de-

seroed above,

Charging, Transfer/Separation Control

=

ey,

mh

[om

ae

ev

ca

|

|

‘The operation ofthe igh votage (A) unt which petonms

‘charging, transfer, and soparaon, i conoled by contol

Signals em the conraboard Routes ah volge to ach

le. gid votage forte charging ot is contoled by the

Zener ode,

Operation

Charging

"A scotoron charging mod is used In this method,

24VDC iput rom he CB is oosteate a neg igh OS

vice decnaged

Charging contol using the gid voltage

“The gid vetage is controled by te high vot

iodo.

‘The anor procees use

Separation

Tha Separation recess uses a high AC vllage,

Zener

negate high 0.

Signals

Input signs

HIV (HV + 65)

line V detects a spark ouput a sinatothe C8,

17

‘Outpt signal

‘CHARGE CONT (C8 -+ HY)

‘Thi contol signal iuseato tu ON oe OFF he cupit

forthe charge corona unt

{U:Chargng ON.

(Hi:Chargng OFF

TRNSEP CONT (CB —+ HV)

“Thi contol inal ius otummON or OFF the outoat

{or the transterisepsration corona un.

(U: Transtovseparaton ON

[i Transtovseparaton OFF

TcoNT(ca Hv)

“Thi the anetrcuret eft sgnal

[U:tow outa

[H):tigh out

D.coNT (68 HV)

“This th separaton curent shit signal

[LF Low oupue

IM: High output

DEVELOPING SECTION

Construction

‘Mechanism

Develoning cover

Developing sleeve

Developerragultor pate

Deveoning sleeve

iad

Developing | Two eamponantdevelemant

1 [Developing Bias | OC bis

+21 Developing Main agisioragtatng vey

agtaton | Aurtayeatatorantting screws)

“1 Developing bias

Developing ia is upp rom he la ping ofthe HY

nt

‘The pushing pressure spring onthe drum casing receives

‘hebiastemhobiasspngendpasses longo the bis

ato ofthe developing unt where fal reaches he

‘eveoping saove

149

‘atatng oer

Pushing pressure spring

main Bony

Aatatng screws

Developing ection

2: Flow route of developer

‘The agitating roller inside the developing unt supple

oveoper othe dovaopng sleeve wher the eveaper

regular pats convo so the toner tre

‘so, developer on he develop sloove at devel:

oping tums to the agiating roll acon fo eu

eat

PHT Developing reat plate

/

Develsing sloove

Agtating ter

‘Aalating soon

Developing nit dive

‘The developing unt is von bythe drum dive motor

(16) Power am the motoris anid the deve

pig input gearto rotate tho agtsing olor. In tun the

developing sleeve and againg screw ae olated by

forthe developing operation.

‘atating serene

Develosing input gear

Disassembly and Assembly

Screws that must not be removed

(1) 2 sores or he aoveape emuntor plate,

(2) Tho stew forthe adusting ob for magnet angi’

developing bias plate,

Serene hat must rete removes |

|

|

Removing/reinstalling the developing unit

Note: hen nstaling he develpingunt ensure tatiishots

ecu with he topes

Procedure

{3} Open tho upper main bed, thon remove the dram un

(eer tothe drum eariage it section for remo

lestuctions)

(2) Disconnect CNS forthe toner dnsty sensor

(3) Pree the 2stoppor of ho dovelping unt tomar the

rum and item vo. Plthe developing uitout fhe

Connector (N95)

‘Stoppers

(4) Rencall the parts by reversing the procedure de

seed above!

0

Main a00¥

Replacing the developer

Caution

1. When pacing the developer, postion he develo

sleeve upward Aso do not slow foreign parties te

feo" the veloping une

2, De natu the developing

Doveleping

2. After replacing the developer, always ptr the toner

denalyadusiment (Referte he dagnostes sation or

‘ete

Note: tr eplacing the develope, do ot supply ener tothe

tonerboruntlthe L detection aqustrentis compte,

Procedure

(9) Open ne upper main ody, then remove te dru uit

(Fer fo the ium cariage unt sect fr removal

Ineructons)

(2) Ossconnect CNS forthe toner densty sensor

(3) Remove the doveloping unt rom the dam uni

(4) Unnook the developing coverin2 lacs, then rove

itn the upward ecton,

Deveenra cover

Hook

(6) tnvente developing unitandromove the developer ou

oft

(6) itt developing unt and tum the developing sleeve

gearintnedracionathe tom, shownntha tration

‘oto, o remove all races ot developer in the unt

‘especialy onthe love aa in tho toner supply pot

Note: Avo gting one on the gears,

———

Toner surly pat

(7) Sprinkle now developer evenly on the aging tle,

(8) Retatethe deveepingsleovegearinthe decon ofthe

‘row ae shown blo e0 tat ne developer enters the

evelping unt

(0) Repeat step (7) and () un al of the dovelopsr hae

cnteredne developing unt

Developer

((0)Rotate he developing sleove gear afew Hes the

‘rectonothearrow sndenauretattnonew sevlopet

‘ome a consistent bests height over he developing

(1ipnstal me aeveieping cover onto the developing unt

‘hen ntl the developing unit ont the drum unt

(12)Cennect CN orn toner dens senser,

(Gaps te dum tint the uppee main body

Developing Bias Control

w) 7

‘Ta doveopng bis ie conte by thoconto! beard ia he

igh votage une (0),

‘The bas output aves corected according tan used peed

of davaioper (copy courts).

Operation

Blas output control

“Toro are two kinds of developing bias outputs a follows:

ten Bias op

os Indeston

Signal

Output signal

‘BIAS (CB HV)

‘Thi signal is used to contol he bias ouput ove

IAS ouput range =o to -220V (64 steps 6 Viste)

‘Tha lsaton Below teal the relationship be

nth BIAS signa ans bias cubutvotage.

‘IAS OUTPUT VOLTAGE

é

‘Speciied | Spodiisdbias soda dveepeirage

‘hen ees the manual mode's elected

forthe densi 6 selected automatically

tring the AES funtion

Bias output afar then whan Speaiied

bias is use. (150)

Neamage a]

Biss output votage

“TeQVDC = a standard bas,

(is shit: aL)

[[Seeced bias | AE apectiod |Manual specod

bas) | bias 1

E =a

=120

=150

=280

Dak =

Nema 50

ght 180

ght) B50

Ug =280

182

Basi

sain BoD

Toner Density Control

“onor donate controled bythe one density sensor (DS),

toner supply (MS) and cnet Board (8).

Operation

‘Toner density detection

“The TOS deacs toner dnsiyasaresu of measure

Inductance) ofthe cabin the TS, endout.astotre

(3 an analog signal (TDS. ANG) eoresponding to the

tensity.

‘The CB detrmines ho toner supely pid by comparieg

‘a votage detected bythe TDS fo the ference vokage

onespendng te he ita density of devloper,

‘Tone: supply operation

tte detection vetage ofthe TOSislessthantheretrencn

‘volage, conte sign wl be ouput rom he Co rie

5, ths supiying one.

“The fable below inscsts the elationship between te

voige (Ve) detected by the TDS and te toner supp

otod

—Tneryesecnasel —]

~Poversize | 505,06, | at | 3.08

| Posteantaze | asxtt |esxts

vem *

for 8600

“00 900

(500 m0

0 | 800

soa]

oo]

VTS detection vag

* Yen tonersupyLEDontheperatenpanalist wen

‘he spp prods require,

Signs

Input sla

"Tos ANG (TDS ->c8)

This isan analog signal which corresponds to tne

dena

‘Output signals

TDS CONT (cB Tos)

“This inal isan analog votoge fr reference wd io

cont! the TOS,

(MS CONT (C8 + m5)

“This control sgnl used to ve MS

{When taming IS ON, te one i sped.

u:m5 ON

Hes OFF

TONER SUPPLY UNIT

Construction

‘shuter

Mechanism

S "2: Toner supply shuttor

Pisani ined “The shut ofthe one supply units designed to eose

Tener sup ‘Seren conveyance Stem ‘vers epening when the developing unt is removed

a Pero a prox \ihen the ust netaleg onthe drum un. the enter

Toner agiaton ‘Main agttor pte toner to be supped to te developing

“Toner supp amount —| 280

39° prevenion|Toner supply shut

Toner sippy contol | OC bush mole

“ts Toner supply

The

los the mod tonor oho develeping un

Note: Tnorcanwoyanco screw oflescounorlockwisowhen

viewed trom he fag nt

ain Boor

‘Toner Level Detection Control

mw

Pete kf —Ad FM agg

‘or lve detection conte porormed by tho tone ost

etetr (TLD) an cont boat (C8).

Operation

‘Toner level detection

‘piezo dove is used asthe TLD.

"nen the lve ofthe ener the toner box becomes ow

(ossthan approx. 60g) te toner suppl signals output o

‘CB. Censoguont the toner suppy LED on ho epera-

ten bord (08)

Detection ting

“Tha toner leve edetcted continously whl the man

“smth (SW) is ON.

Signals

Input signal

"1.0 LD -»c3)

“This pulse signals usd dotetth evel ofthe toner

{U: Low toner tovet

[6]: High toner evel

Output signals |

‘Os CLOCK (08 +08)

“ThissgnlisuredtoresdL.ED DATA (OBDATAsgna)

tothe onthe OB, The data are ean menroniem

vith te sora

‘0B DATA (CB ~ 08)

‘This contel signals used to tum the LED ON or OFF.

8 LATCH (cB =» 08)

“This elgnalisueedt len OBOATA oe shtegeter

‘ontioO8, Whon his gal becomes[L} ho data read

Inthe register ie dapayed on the LED

CLEANING UNIT/TONER COLLECTING UNIT

Constr

| ose 7 :

(loaning blade —_

Toner ealecting

Receting PET

Disassembly and Assembly

aa Removing/einstalling the cleaning blade

Senge 1. han roving the clearing bade, do not ouch the

pring pressured) _| ‘ado wah bare hands in any way.

[Tener colecion [Screw conveyancesyaiomieading |p. Donut toseatth he dan

process stoner colton bx oer 3. When he drum ouside che rum unt.

. . oe) Itwih a drum cove and lore a dark pl

[aera tag PET 4. Beto istaing to cloning lade, apply

[sotecton | —_ ‘orto the des, (Side on the drum suace te ntl

cn

‘5, Aorta earing bade has ben ental erty that

both edgos of he blade are contacted withthe drum

uae. no, toner leakage may occ.

Releto"removingtinstting tne ru forth vorying

recto,

Procedure

(0) penne upper main body then remove the dum unit

(Gsfrto rum unit eecton fx rmovalnstractone

(2) Remove the charging caning knob forthe charging

corona un rm te drum unt

Main a00¥

(3) Disconnect ONS? nd CNB for POL and CEL

(6) Remove the 2 eres, then remove the charge corona

(6) Remove he2 serous, hen rove the upper ening

‘Seren

Upoe caning cover

(6) Remove te earng blade by ting the hands,

Henges

‘tearing fade

(7) Pensa tho pats by reversing the procedure ce

serbod above

PAPER FEED SECTION

Construction

Pperlesdler bypass)

(eras)

Preshtor sensor (P88)

“Thidpaperteed

Gruen ee

Trcpapereed

Giveraior =

A .

oral P|

oy

Secon panes

feodanvensoter

Bypass paper teed rote

a oom tem

Mechaniom

ae aaa |

rata" — | Treen aa

soe eee

a

anni |poaee

ee

ee

anced

“Bnd paper feed Feed rol, rest laa Peieion ala

‘Resistant solenoid ‘Rotation with & feo Paes)

fmapemeer eae] [STs

eee. leas

"1: Torque inter

Wher using he bypas feed ue cierto the

paper feed role sends a pape othe 2nd paper fod

rol, Simstaneousy, the double fees preven rotee

and torque tnter engaged wih # are rlated counter

‘Slockwie,

I two sheets ot papers are sot tho retumn spring a the

torque mir alons the torque kriter to automatically

rote dockvse, This ation aco tu the double fed

Proventonrllerockse causing any sheet that ren

‘oct contact wih tho prventio lero be pushed bic

to he bypass feed uit

Deutle fees

Toque ier

“2: Bypass food

‘One solenoid (S04) ana wo tension springs provi the

bypass feed as flows:

(1 Wen the bypaes fd elena (S04) i tuned ON,